14,000 m³ of concrete, 3,600 tons of rebar, 8 months of work—the ''floor'' of the Tokamak Complex was finalized on 27 August 2014.

Well before dawn on 27 August, the team was in place to prepare the worksite and position the concrete pumps. Ahead was a 12-hour continuous pour—some 865 m³ of concrete formulated to penetrate in and around the tight weave of rebar, particularly dense in this area of the basemat.

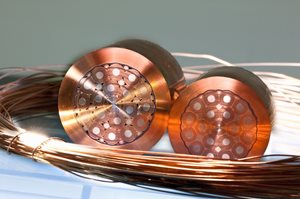

Shipped from New York on 5 August 2014, the 12 surge arrestors that were delivered to ITER on 4 September had a high symbolic value. As the first completed components to reach the site, they usher in a new phase on the road to building ITER.

Early September, another ITER milestone was celebrated as the very first completed components—12 high voltage surge arrestors shipped from the United States—were delivered to the site and stored. Destined for the installation's steady state electrical system, they'll take their place between the 400 kV switchyard and the transformers that will feed power to the ITER plant systems and components in order to provide protection from the type of major voltage surge that can be caused by lightning.