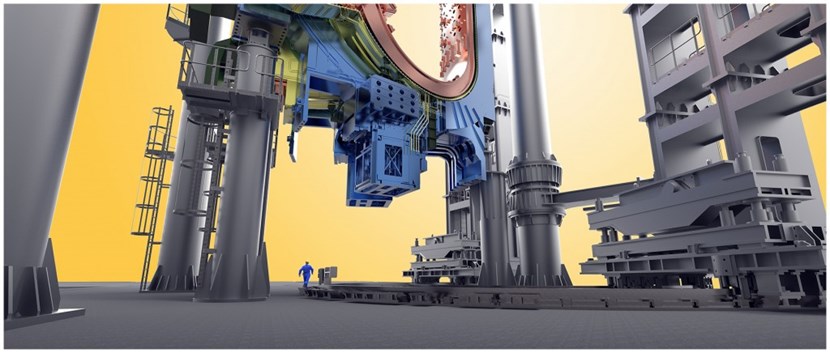

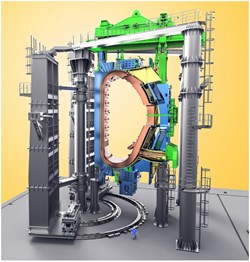

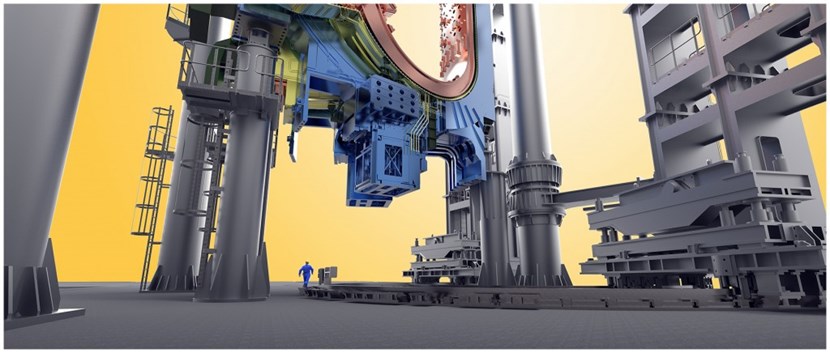

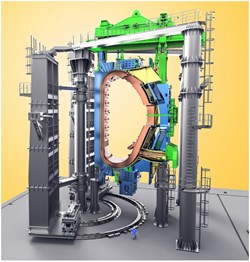

Six storyes high, made of 800 tons of steel, the Sector Sub-Assembly tools will work in concert to equip the nine sectors of the vacuum vessel before their transfer to the Tokamak Pit.

"It's far from a simple operation," says Emma Watson, an engineer who works within the Machine Assembly & Installation Section at ITER. "For each of the nine sectors, the complete sub-assembly operation will take five to six months." To optimize the overall schedule for the nine sectors, two identical tools are planned, each one capable of holding a sector on its end while positioning—and aligning—the associated components.

Standing shoulder to shoulder, two Sector Sub-Assembly tools will suspend the vacuum vessel sectors from the top while carefully positioning and installing—via the rotary motion of the ''wings''—the vacuum vessel thermal shielding and two toroidal field coils.

Made from 800 tons of steel, the 22-metre-tall tools will be capable of supporting, aligning, and stabilizing the vacuum vessel sectors and the toroidal field coils independently through a sophisticated array of precision actuators and sensors. "The assembly of the first sector will take the longest time, as assembly procedures based on the results of tests (involving partial component mockups) are honed via the experience gained as the sequences are performed for the first time on real components," says Emma. At different stages in the sub-assembly process, metrology surveys will be used to verify the components' positions. The final sub-assemblies, weighing a maximum of 1,200 tons, will be transferred by two overhead cranes operating in tandem to the Tokamak Pit.