ITER NEWSLINE

-

Fusion research benefits society (2/4)

Fusion research benefits society (2/4)

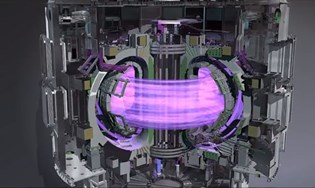

Developing fusion science, engineering and technology to a point where fusion energy can be supplied to the grid is one of the most exciting challenges of the 21st century, and potentially one of the most rewarding.

Since last week, Newsline has been featuring a series of videos that highlight the small and large advances that are being made daily. Improvements in industrial processes, new materials, innovative remote handling technologies, computer modelling techniques ... these products of fusion R&D at the cutting edge of science and technology are not only benefitting the fusion development effort, but also society at large through spinoff technologies.

This second video produced by the European Commission takes us to the Netherlands, where a company specialized in explosive metal forming techniques has expanded its horizons—and its client base—through work carried out for the European fusion program.

3D Metal Forming, which uses shock waves to press thin metal sheets into desired shapes, took on the challenging of using the same technique to form the thick, 6-cm steel plates used to manufacture the ITER vacuum vessel. Its success has led to applications in the aeronautics industry, the construction of a large new factory, and expectations of rapid growth.

Click here to view the video...

Many more videos are available on the ITER video page...

return to the latest published articles