you're currently reading the news digest published from 25 Jun 2018 to 02 Jul 2018

featured5

of-interest2

press8

featured

Optic sensors | Testing the resistance to radiation

Inside the ITER machine, the divertor and the blanket will be equipped with more than 1,000 fibre optic sensors for recording temperature, strain, displacement and acceleration—important feedback to estimating the health and residual lifetime of these components that are located so near the plasma. Sensor prototypes designed by the ITER Organization have already been tested thermally, mechanically and optically; now—thanks to the first Implementing Agreement of the ITER Organization-Kazakhstan Cooperation Agreement—they will soon be tested for radiation resistance. A large number of sensors on the divertor and blanket will tell engineers how these internal machine components are doing under the stress of operation. Devices no larger than a postage stamp will be mounted on 3 of the 54 divertor cassettes and on 20 of the 440 blanket shield blocks installed inside the machine. These highly sensitive instruments—formed from steel-plate sensors embedded with neutron-resistant optical fibres—will be capable of measuring temperature, strain, displacement, or even the smallest vibration, and of transmitting the information to software for analysis. 'The optical operational instrumentation for the internal components is based on the analysis of transmission of light,' explains Sergey Bender, instrumentation engineer in the Divertor Section. 'As temperature or strain increases in the internal components of the machine, there is a corresponding shift in light wavelengths that can be measured and interpreted.' Optical fibre technology is attractive for fusion applications, in particular thanks to its immunity to the rapid and large variation of electromagnetic fields during plasma disruptions—exactly the moment when there is a major need for measurements. Neutrons can darken optical fibres over time, however, resulting in a reduction of their reflective index and hence their ability to transmit information. To overcome this drawback, ITER's instruments will use a special type of non-standard FBG optical fibre (for Fiber Bragg Grating) that is neutron-resistant. FBG measurements are based on wavelength shifts rather than on the amplitude of the optical wave, which is impaired by the reduction of reflective index. According to Bender, the neutron immunity of this particular type of fibre makes it an essential feature in monitoring the internal components. Under the first Implementing Agreement of the Cooperation Agreement that was signed between the ITER Organization and the National Nuclear Center of the Republic of Kazakhstan last year, samples of sensors and optical fibres for ITER operational instrumentation will be tested for neutron resistance in Kazakh research reactors to confirm all design assumptions and to clear the way for industrial manufacturing. Two test phases are planned: Several four-hour irradiation campaigns at the IVG -1M research reactor in Kurchatov to test how the operational instrumentation works under different temperatures and dose rates and to define the characteristics of the samples (fibre length, temperature) for the second campaign. A 23-day campaign at the WWR-K research reactor in Almaty, under fully ITER-relevant neutronic fluence (up to 1020 n/cm2, for an energy higher than 0.1 MeV). (Neutronic fluence is defined as the number of neutrons per unity of surface cumulated during a given time.) 'What we are looking for from these irradiation tests, is a final demonstration that the optical FBG sensors, as developed by the ITER Organization, are substantially immune to neutron damage in terms of accuracy and stability of measurements. The neutronic fluence attainable in the WWR-K reactor is similar to the one expected on the surface of ITER's internal components at the end of operations. This is the key capability proposed by our Kazakh colleagues, and it makes the tests highly interesting to us,' explains Frédéric Escourbiac who, as Divertor Section Leader, is in charge of the operational instrumentation for the internal components. Under the terms of the collaboration, the ITER team has ordered a small amount of radiation-resistant fibres from different manufacturers, had them 'marked' with lasers to print the FGB feature¹, and created the sensors. Kazakh colleagues will prepare a special canister called an 'ampoule' (see photo, left) with these sensors to be tested during the irradiation campaigns. The Kazakh team is also responsible for campaign implementation as well as the analysis of all results. The first radiation-resistance tests are planned in November this year after six months of preparation to manufacture and prepare the samples. ¹Fiber Bragg gratings are created by using a laser source to "inscribe" or "write" a systematic interference pattern along the optical fibre. The 'marks' reflect narrow bandwidths of light, which respond to changes in temperature or strain by shifting.

Icon | Microsoft co-founder visits ITER

He co-founded of one of the most iconic companies of the last half-century. His philanthropy and technology innovation has made him a champion in the fight against Ebola ... a primary funder of major brain science and artificial intelligence research ... and a leader of multiple deep-sea wreck discovery and recovery missions. He is the executive producer of several award-winning films. He owns three professional sports teams. And he is a passionate guitarist. So why would Paul Allen of Microsoft fame decide to carve out time from his very full life to visit ITER? In Allen's words, 'I was at the Cannes Film Festival, supporting the new Star Wars film. A visit to ITER was my chance to see preparations for the birth of a star on Earth.' A rapid review of Allen's diverse investment and philanthropic portfolios—from his 1975 co-founding of Microsoft with Bill Gates to his most recent ventures in bioscience, environmental conservation, and microgrids in Africa—reveals a fertile mind driven by curiosity and a remarkably broad range of interests. This includes fusion. Through his company, Vulcan, Inc., Allen has long been an investor in TAE Technologies, formerly Tri Alpha Energy, a 20-year-old privately funded effort to develop aneutronic¹ fusion power based on a field-reversed configuration. For ITER, it was an honour for Director-General Bernard Bigot and chief scientist Tim Luce to host Allen and his team. Global progress in ITER's manufacturing and construction activities was a central point of interest—as was the set of remaining engineering and science hurdles that must be addressed to bring tokamak fusion to commercial fruition. Several of those challenges, interestingly, lie in fields of Allen's expertise: big data, high performance computing, control software, artificial intelligence, and signal processing. Who knows? Perhaps our paths will cross again. ¹A field-reversed configuration differs from a tokamak in that the magnetic confinement of the plasma is controlled by eddy currents reversing the axial field, rather than by using a solenoid to generate an ambient field.

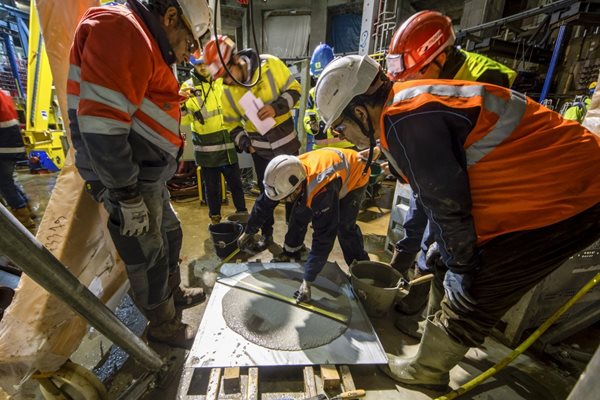

Concrete pouring | The "slump test" ritual

Like ancient priests bent over the entrails of a sacrificial bull, a group of men in hard hats are carefully examining a bucketful of semiliquid concrete as it slowly expands on a perfectly flat steel slab. A strategic operation, one for which no chance can be taken, is set to begin—the pouring of the tokamak 'crown,' the massive structure that will support the combined mass of the Tokamak and its encasing cryostat (23,000 tonnes) while transferring the forces and stresses generated during plasma operation to the ground. The 'slump test' will determine if pouring operations can begin. Up until that moment, the pumps had been fed with slurry, which acts as a lubricant for the interior surfaces of the pipes. Now, operators need to make sure that the concrete coming out of the pumps is slurry-free and consistent with the required formulation. On the steel slab, the concrete sample has stopped expanding—it is now perfectly circular and looks like an oversized grey pancake. This is the moment of truth: if the circle's diameter corresponds to a pre-established number, the concrete that comes out of the pumps matches the expected fluidity; if the diameter is larger, it means that slurry is still present and must be evacuated. Slump tests are systematically performed when the concrete-mixing trucks leave the batching plant to deliver their load to the pumps. When using special-formulation, self-compacting concrete—like in the crown's case—slumps tests are performed again on the very site of the pouring, minutes before actual operations begin. In the basement level of the bioshield, the ancient priests in hard hats are at last satisfied with what they see: the circle is perfect, its diameter precisely matching the right figure. Operations can begin—another long night of pouring for one of the most important structures of the whole Tokamak Complex.

Plasma-surface interactions | Where two worlds meet

Every other year for almost half a century, experts from two very different fields of research have been meeting to discuss one of the most critical issues facing the long-term success of fusion energy: the interaction between plasma and plasma-facing materials. The 23rd edition of the International Conference on Plasma Surface Interactions in Controlled Devices—PSI in short, which was hosted on 17-22 June hosted by the Princeton Plasma Physics Laboratory (PPPL)—is one of few places where experts in boundary plasma physics meet their counterparts in material science. 'The two fields require very different expertise and very few people, if any, have competence in both,' explains Richard Pitts, head of the ITER unit that focuses on divertor and plasma-wall interactions. 'Although communication between the two groups is constant and the relationship very osmotic, the conference provides a precious opportunity to be reunited in a very convivial atmosphere. It's a very tight community and most of us have known each other for many years.' At the PSI conference this year, ITER was strongly represented with three posters and two talks. As has been the case for the past 46 years, there was a lot to discuss during the conference—which took place over five days without parallel sessions—based on reports of two years of research at all the major fusion institutes on the planet in this key area. Since ITER now has a robust physics and technology foundation and, although many aspects remain to be refined, the focus worldwide is increasingly turning towards the plasma-wall interaction challenge faced by the many different incarnations of DEMO, the pre-industrial demonstrator for which conceptual studies are now well established in most of the ITER Member fusion programs. 'Not everything can be extrapolated to a DEMO based on the ITER concept,' says Pitts. 'A beryllium first wall for instance is not an option for a reactor, and a tungsten divertor like the one we are building for ITER will face a much sterner heat exhaust test in a device with higher thermal plasma power and neutron production.' 'Liquid-metal walls' using lithium or tin, innovative divertor magnetic geometries with exotic names like 'Snowflake,' 'Super X' or 'XD' designed to spread the exhaust power, and innovative new materials with good power-handling properties and more resistance to neutron irradiation are being actively studied experimentally and theoretically by the ITER partner research community. Materials play the key role as the ultimate boundary condition for the fusion plasma—as future reactors will not be commercially viable if plasma-facing surfaces have to be replaced too often—so it is a natural risk mitigation strategy to seek alternative solutions in parallel with the established science and technology base which ITER represents. Nevertheless, ITER will show us if the conventional route to tokamak fusion energy is viable and the PSI community remains strongly anchored to the ITER concept, continuing to refine the physics basis, to understand how materials will evolve through their lifetime of plasma exposure, and to develop operational scenarios and techniques for robust power exhaust.

Technical cooperation | Kazakhstan Agreement bears first fruit

The visit of a delegation from Kazakhstan on 29 June was the occasion to discuss opportunities for joint research activities made possible by an Agreement concluded last year between the ITER Organization and the Kazakh National Nuclear Center. One year ago, on 11 June 2017, an important event took place in in Astana, Kazakhstan. During the Ministerial Conference on Securing Sustainable Energy Development, held before a large gathering of delegates and media representatives at the EXPO-2017 Congress Center, the ITER Organization officially welcomed the National Nuclear Center of the Republic of Kazakhstan (NNC-RK) as a new technical collaborator and a Cooperation Agreement was signed. The Agreement opened the way to accessing Kazakhstan's IVG.1M and WWR-K fission reactors, the KTM tokamak for materials testing, the exchange of technical experts, and the development of diagnostics for ITER. On the occasion of the one year anniversary, Erlan Batyrbekov, Director General of NNC RK, and Alexandr Vurim, Deputy Director of the branch Institute of Atomic Energy (IAE) for reactor tests, visited the ITER Organization. The visit on 29 June also celebrated the signature of the first Implementing Agreement on 'Radiation resistance tests of fibres and fibre optic sensors under ITER-relevant nuclear irradiation,' which defined the details of the technical collaborative work in that area (see related article in this issue). Bernard Bigot, Director-General of the ITER Organization, welcomed the Kazakh delegation and presented the status of ITER, while Erlan Batyrbekov gave an overview of the activities carried out by NNC RK. 'The visit was an excellent opportunity to strengthen the relation with our Kazakh partners. Exchanges on their technical capabilities and ITER technical needs were instrumental to identifying areas of possible further collaboration,' said Mario Merola, Head of the Internal Components Division and ITER Lead Responsible Officer for the implementation of the Collaboration Agreement. 'The first technical collaboration has already started and we paved the ground for possible further future joint activities.'

of-interest

'Fusion in Europe' is out

Fusion in Europe's second edition this year is filled to the brim with interesting articles. Take the report about the latest experiment at the Dutch Institute for Fundamental Energy Research (DIFFER). Their linear plasma generator Magnum-PSI has set a new record for the longest exposure of any material to the harsh plasma conditions in a fusion device. A high vacuum is crucial for the fusion reaction to take place —Fusion in Europe spoke to German supplier Lybold about how they deliver custom-made vacuum solutions to Europe's fusion devices, including ITER. 'Now is the best time to be at JET,' says Eva Belonohy who contributes to preparations for the second deuterium-tritium campaign at JET in over 20 years, planned for 2019 and 2020. She organized a recent workshop for fusion scientists, to share JET's latest features such as its enhanced heating powers and diagnostics or its ITER-like wall made of beryllium and tungsten. The latest edition of Fusion in Europe also includes a report from the recent inauguration of SPIDER, the largest ion beam source in the word, in Padova, Italy; introduces award-winning young fusion expert Wei Zhang; and shows an example of how the enthusiasm for fusion can be passed on from one generation to the next within one family. To read the current edition of Fusion in Europe click here.

New supercomputer to boost fusion research

Summit, the world's fastest supercomputer recently launched at the Oak Ridge National Laboratory (ORNL) in the US, will be instrumental in accelerating fusion research. The new supercomputer takes computing powers to new heights. Summit can perform 200 petaflops per second: that is 200 quadrillion calculations, eight times more than the previous record-holder at ORNL, Titan. The massive machine—weighing more than a commercial aircraft—is also the world's largest computer equipped with artificial intelligence ... a machine whose software will write new software. Harnessing Summit's capabilities in machine learning and simulation as well as in artificial intelligence and deep learning will allow researchers to accelerate scientific discovery in many fields, including fusion. For more information on Summit read the ORNL news release here and the NVIDIA blog post here.