you're currently reading the news digest published from 17 Sep 2018 to 24 Sep 2018

featured6

of-interest1

press7

featured

Thermal shield | First 23 panels fit like clockwork

During fitting trials in Korea, 23 stainless steel panels have been successfully pre-assembled into the first sector of vacuum vessel thermal shield. In a major achievement for the thermal shield procurement program, the pre-assembly test on the vacuum vessel thermal shield sector #6 has been successfully completed at SFA Engineering Corp in Changwon, Korea. Technical responsible officers and engineers from the ITER Organization, the Korean Domestic Agency (ITER Korea) and SFA were there to witness the milestone, which took place in early August. The purpose of the pre-assembly test was to demonstrate the feasibility of assembling the same sector of thermal shield at ITER. The test jig and fixture design (inboard frame, outboard frame) and the clamping conditions were identical to those that will be called into action as part of vacuum vessel sector sub-assembly activities in the ITER Assembly Hall beginning next year on the sector sub-assembly tool. The vacuum vessel thermal shield is a 10- to 20-millimetre-thick barrier interposed between the vacuum vessel and the superconducting magnets. It will be actively cooled with gaseous helium at 80 K (minus 193 °C) to minimize the radiation heat load that is transferred by thermal radiation and conduction from warm components (vessel) to the components operating at 4.5 K (minus 269 °C) such as the magnets. Each of the nine 40° sectors of vacuum vessel thermal shielding consists of 23 stainless steel panels, each with its own welded cooling tube. The pre-assembly test for sector #6 took place in four steps: Jig assembly of the outboard 10° segment, with dimensional inspection Jig assembly of the outboard 20° segment Jig assembly of inboard 40° segment, with dimensional inspection Jig assembly of inboard 40° segment and two outboard 20° segments, with dimensional inspection Dimensional inspection of the shell was performed for the sub-assembled segments by 3D laser scanning. Observers were also able to verify the tight tolerances (2 mm) that are required for the 1,800 bolt holes of the sector. 'Nine hundred bolts and corresponding holes were verified and all the flanges were assembled well without gaps,' says Dongkwon Kang, ITER technical responsible officer for the thermal shield. 'This gives us confidence that there will be no critical interface issues for the assembly and the operation of the vacuum vessel thermal shield at the ITER site.' Vacuum vessel thermal shield sector #6 will now be dismantled for silver coating before being re-assembled into inboard and outboard segments for shipment to ITER. All is on schedule to meet the ITER Council milestone for delivery of the thermal shield sector by April 2019.

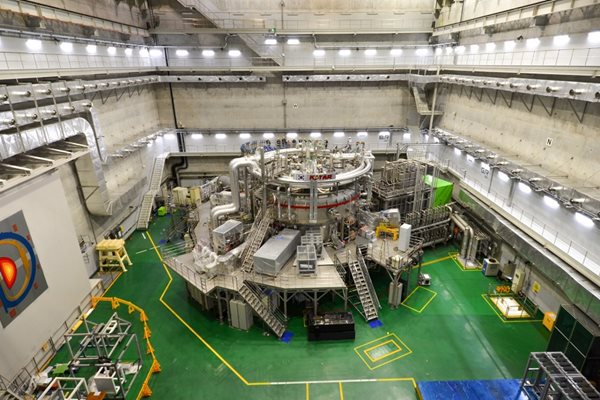

Promising research | Taming "ill-behaving" fusion plasmas

Certain types of magnetic distortions have proved beneficial in suppressing ELM-type instabilities at the edge of fusion plasmas—periodic bursts of energy that can lead to an accelerated erosion of the divertor and first-wall components. Up to now, though, the ideal 3D topology of the distortion field—among innumerable potential combinations—was unknown. As reported this month in Nature Physics, physicists from Korea and the United States have developed a key predictive capability of how to configure 3D magnetic fields optimally for ELM control, and successfully tested their predictions on the KSTAR tokamak in Korea. One of the critical challenges in nuclear fusion has been how to tame 'ill-behaving' fusion plasmas that tend to intermittently outburst tremendous amounts of heat and particles from plasma edge. These so-called edge-localized-modes (ELMs) have the potential of eroding material from the plasma-facing components—material which can then penetrate and contaminate the plasma. The physics understanding of ELMs and the development of a methodology to control ELM crashes have thus been a major focus of research in the fusion community for two decades. Among various ELM control means, the most promising method is to apply resonant magnetic perturbation (RMP) to the plasma edge—small magnetic fields that 'perturb' the plasma edge, releasing the pressure in a measured way. The RMP technique has proved effective in influencing the unruly high-pressure ELM crashes, but identifying the correct 3D magnetic field configuration—among endless possibilities—has remained a challenge. Now, a 14-person team led by physicist Jong-Kyu Park of the Princeton Plasma Physics Laboratory (PPPL), has identified a way to move forward. The research team—comprised of physicists from PPPL (US), the National Fusion Research Institute (NFRI) of Korea, and Oak Ridge National Laboratory (US)—has been able to map out an optimal 3D topology that suppresses ELM crashes at the plasma edge without destabilizing the plasma core. 'We demonstrate the phase-space visualization of the full 3D field-operating windows of a tokamak,' explain the authors in their abstract, 'which allows us to predict which configurations will maintain high confinement without magnetohydrodynamic instabilities in an entire region of plasmas.' The predictions were tested on the KSTAR tokamak at NFRI with excellent results. Equipped with ITER-like RMP systems, including unique in-vessel mid-row RMP capabilities, and state-of-the-art imaging diagnostics, KSTAR is one of the leading devices in the world for studying ELM-taming using precisely controlled 3D magnetic fields, and clarifying the physics mechanisms during critical transitions. The researchers' work will allow plasma physicists to not only establish the modus operandi of 3D magnetic fields in order to suppress ELM crashes among innumerous combinations of 3D configurations, but also to contribute to designing the ideal position of 3D field coils in future reactors. The results are important to ITER, which will operate with a 3D coil system that is similarly configured to that of KSTAR. More information: Jong-Kyu Park et al, 3D field phase-space control in tokamak plasmas, Nature Physics (2018) Please also see the reports published on the NFRI (in Korean) and PPPL websites.

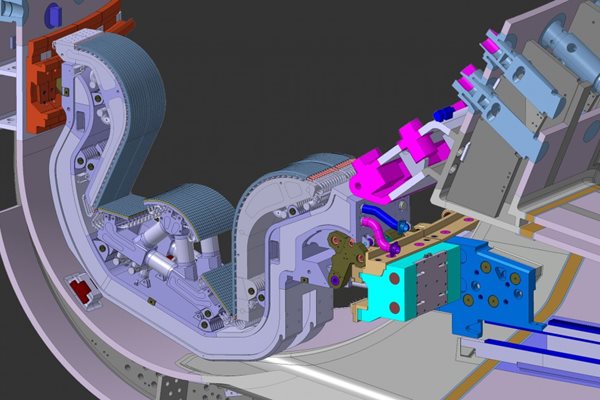

Divertor rails | A chicken and egg situation

In the ideal world of 3D drawings, a component's dimensions are by definition nominal and parts fit together like cogs and gears in a pricey wristwatch. The real world—even the high-precision world of ITER—is different: minute variances during the manufacturing process are inevitable, especially when components are as tall as a six-storey building ... In ITER, the pieces of the machine will not only have to fit together within extremely tight tolerances; they will also need to be aligned with utmost precision against fixed reference points, such as the matrix of metrology targets disseminated throughout the Tokamak Complex. An added difficulty arises when a reference can only be established once a set of components is completely assembled. The machine's magnetic axis for instance—a paramount reference for tokamak operation—will only be determined after the vacuum vessel is installed and an initial series of plasmas has been produced. The localization of the machine's magnetic axis, in turn, will determine the position of the 54 cassettes of the ITER divertor situated at the bottom of the vacuum vessel. 'The 54 elements of the divertor must be aligned with extreme precision—and I'm talking tenth of millimetres here,' says Divertor Section leader Frédéric Escourbiac. Divertor cassettes will be inserted by robotic handler into the vacuum vessel through the lower ports. Once inside the chamber, they will be moved along double concentric toroidal rails into their final position. Once positioned, the cassettes will be fastened on these inner and outer rails. A slight misalignment of the circular railing could result in the misalignment of one or more of the 54 divertor cassettes—hindering operational flexibility and threatening the integrity of the divertor targets which face intense heat and electromagnetic loads from the plasma. 3D drawings provide a theoretical magnetic axis based on a perfect vacuum vessel, perfectly machined and perfectly assembled. But the 'as built' reality, which will determine the precise dimensions and positioning of the rails, cannot reproduce this nominal perfection. Engineers are left with a 'chicken and egg' situation. How can the precise dimensions and positioning of the rail sections be determined when the 'as built' references are not available yet? The solution comes in the form of statistical models that compute the tolerances of all interfacing systems and take into consideration different scenarios for the localization of the magnetic axis. This is the basis upon which the rail sections can be manufactured—not completely finalized, but 'semi-finished' with extra thickness that will allow for adjustment later. Once everything is in place—the vacuum vessel has been fully assembled and welded, interfacing systems are in place, and magnetic axis has been determined—a geometrical 3D survey can render the as-built reality with absolute accuracy. 'With reverse engineering, we can then customize the rail sections and the interfacing pieces on site,' says Alain Durocher, the ITER Organization responsible officer for the divertor rails. The ITER divertor is designed to remain in place through the first decade of machine operation up to the end of the first phase of nuclear operations. The rails, however, are supposed to last for the whole duration of the ITER experiment. Their strategic importance was confirmed by a recent final design review, which recommended the realization of a mockup to mitigate risk and to practice assembly procedures.

Transformers | The switch can now be flipped

For close to four weeks they tested all the signals, confronting the figures that appeared on their screens to in-field observations and measurements. Transmitted by the CODAC system, more than a thousand pieces of information were checked: position of the switches and circuit breakers, oil temperature in the transformers, pressure, voltages, currents, alarms... 'We needed to be absolutely certain that there wasn't the slightest discrepancy between the information we were receiving and the actual status of the components and systems inside the switchyard and transformers,' explains Joël Hourtoule, who heads the ITER Electrical Power Distribution Section. What was at stake was the energization of the four transformers for the installation's steady-state electrical network (SSEN)—in lay terms, the connexion of ITER to the 400 kV French grid, a year-and-a half after the first test was performed in March 2017. Procured by the US and manufactured by Hyundai in Korea, the massive 160-tonne SSEN transformers decrease the 400 kV voltage fed by the grid to the industrial standard of 22 kV. The transformers will provide the necessary power to the installation's plant systems and buildings. (A second set of transformers, procured by China, will deliver power to the pulsed power electrical network needed for Tokamak operation.) However the full power of the SSEN transformers will not be needed before actual operations begin. In the meantime, an additional transformer will soon be installed to bring down the voltage from 22 kV to 15 kV, a level of voltage which responds to the needs of the construction worksite and buildings now1. Working in close coordination from both sides of the switchyard, operators from the French transmission system operator RTE (Réseau de transport d'électricité) and specialists from the ITER Organization as well as the European Domestic Agency (Fusion for Energy) and its contractors successfully completed the energization of the four SSEN transformers on Tuesday 18 September. 'From the point of view of RTE we are now an 'active installation,' comparable to a steel mill in terms of electricity consumption. This milestone represents the birth of a large industrial site,' says Gilles Consolo, ITER responsible officer for 400kV operations. Now that all procedures are validated ITER can plug into the grid at the turn of a switch. 1 — For the moment, ITER is connected on a 15 kV line coming from neighbouring CEA.

ITER at IAEA Conference | The spirit of "Atoms for peace"

The General Conference of the International Atomic Energy Agency is among the largest and most diverse annual gatherings—more than 2,500 participants from 153 countries—focused on nuclear science and technology. Last week, ITER was there as part of a collaborative focus on fusion energy. ITER Director-General Bernard Bigot was a featured speaker in the IAEA's Scientific Forum, entitled 'Nuclear Technology for Climate Change: Mitigation, Monitoring and Adaptation.' Speaking to the opening session on Tuesday, he highlighted the enormous potential of fusion energy, the challenges of constructing an industrial-scale fusion facility, and the progress and achievements of the ITER Project, including ground-breaking innovation by ITER Members and suppliers to keep the project on track for success. These themes resonated with the General Conference attendees. Hundreds of specialists and generalists, curious to learn more, spent time at the ITER exhibit: a small walk-in cinema where the latest drone videos showed overviews of the ITER worksite and the assembly and manufacturing ongoing inside major buildings. On Wednesday, the IAEA hosted an additional side event on 'Fusion Energy for Peace and Sustainable Development.' Meera Venkatesh, the Director of IAEA's Division of Physical and Chemical Sciences, hosted the event. In addition to Bernard Bigot, special guests included Sibylle Günter, the Scientific Director of the Max Planck Institute for Plasma Physics, and Mila Aung-Thwin, director of the award-winning documentary on the quest for fusion, Let There Be Light. Bigot offered a more detailed overview of ITER construction and manufacturing progress, and Günter presented the most recent results from Wendelstein 7-X and near-term operational plans. The event was heavily attended, with dozens of people standing throughout the presentations and Q&A session. Later in the morning, a sizable crowd stayed to watch the full documentary. The General Conference marked the end of a year-long celebration of the IAEA's 60th anniversary. As Director-General Bigot noted, in seeking to make ITER a model for international collaboration on complex science and technology challenges, the ITER Project is an embodiment of 'Atoms for Peace.'

Image of the week |A 4.7-tonne calling card

The most popular photo backdrop at the 30th Symposium on Fusion Technology (SOFT) in Giardini Naxos, Italy, sat just outside the conference building—the full-size prototype of a divertor cassette body. The divertor is located at the bottom of the vacuum vessel to extract ash and heat during full operation of the ITER machine. Each of the 54 divertor cassettes consists of a stainless steel support structure—as seen in the display—and three plasma-facing components: the inner and outer vertical targets and the dome. The divertor cassette body shown above was manufactured by the Italian company Walter Tosto for Fusion for Energy (F4E), the European Domestic Agency. The company was one of 35 companies to participate in this year's industry exhibition at SOFT, and the 4.7-tonne divertor cassette body was its calling card. According to Walter Tosto representative Massimiliano Tacconelli, the prototype could end up in the tokamak's vacuum vessel as it meets all ITER specifications and will be one of four spare cassette bodies.

of-interest

Carlos Alejaldre appointed Director General of CIEMAT

On 21 September, Carlos Alejaldre, who was an ITER Organization Deputy-Director-General from 2006 to 2015, was appointed Director-General of CIEMAT (Centro de Investigaciones Energéticas, Medioambientales y Tecnológicas), the Spanish public research agency focused on energy and the environment. A plasma physicist by training, Carlos has held several important positions in fusion research. Prior to joining ITER, he headed CIEMAT's national fusion laboratory (1992-2004)and was for two years (2004-2006) the director general of technological policy at the Spanish ministry of Education and Science. More on the CIEMAT website (in Spanish).