you're currently reading the news digest published from 08 Oct 2018 to 15 Oct 2018

featured7

press13

featured

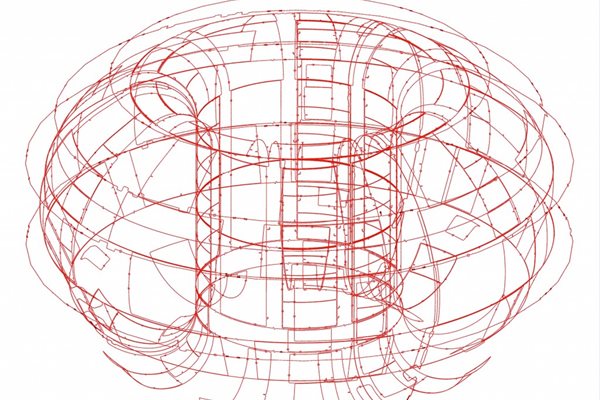

Media Days 2018 | ITER, from the inside out

As concrete and steel structures rise on site and major strides are being made in the fabrication of machine components, interest in the project is growing worldwide. ITER is tangible; it is happening for real. Visitors on site—13,000 last year alone—can bear witness to the progress that is made every day. But the pace of work on site and finite resources for on-site tours place a limit on the number of individuals ITER can receive. This is why—in addition to its weekly program of visits—the ITER Communication team organizes targeted events such as Open Doors Days for members of the public and annual media events for journalists. In the latest Media Days event on 10-11 October approximately 30 reporters/camera teams were on site for a full two-day program of events—complete site tour with access to every major building, interviews with the ITER Director-General, and a slate of lectures on ITER's science, technology, international make-up, and status.  All ITER Members were represented at this year's event. Teams came from Agence France Presse (AFP), Al Jazeera (see video), China News Service, Chosun Biz, Corriere della Sera, The Engineer, the Indo-Asian News Service, Nature, Nature Research, RAI News 24, Sky News and Xinhua News Agency to name but a few. Stories have already been trickling through; please see the links below. The full list will be kept current on this page (scroll down to "In the Press"). Al Jazeera Chosun Biz Chosun Biz (interview) Economic Times of India RAI News Connaissance des Energies Sakal Times Europe Daily QQ News Sky News Sky News video Xinhua News Agency

All ITER Members were represented at this year's event. Teams came from Agence France Presse (AFP), Al Jazeera (see video), China News Service, Chosun Biz, Corriere della Sera, The Engineer, the Indo-Asian News Service, Nature, Nature Research, RAI News 24, Sky News and Xinhua News Agency to name but a few. Stories have already been trickling through; please see the links below. The full list will be kept current on this page (scroll down to "In the Press"). Al Jazeera Chosun Biz Chosun Biz (interview) Economic Times of India RAI News Connaissance des Energies Sakal Times Europe Daily QQ News Sky News Sky News video Xinhua News Agency

Magnets | CEA delivers ITER cryogenic instrumentation

The ITER Organization has relied on the French CEA institute and its expertise in cryogenics and large superconducting magnets for the specialized instrumentation needed to control and protect the ITER magnets during the cooling operation. This past summer the full scope of the procurement—more than 3,000 devices—was completed on time, and to cost, quality and performance specifications. Cryogenic temperature chains and flowmeters are small devices that will convey accurate measurements of magnet temperature and helium flowrate from their positions inside the magnet structures, terminals and supply lines (feeders). This data is critical to ensuring that the magnets are operating under well controlled and reliable conditions, and that helium flow distribution to the magnets is correct. The measurement solutions are based on proven technologies, augmented by specific development to meet ITER's challenging performance and environmental constraints. Two separate contracts were placed in 2014 with the French Alternative Energies and Atomic Energy Commission (CEA Grenoble) for this work, carried out under the supervision of ITER Magnet Instrumentation and In-Vessel Coil Section. The first order was for 2,200 cryogenic temperature chains—three-part instruments (a sensor, signal interfaces and a signal conditioner) that can measure temperature over a wide range (3K to 300K), relay low-level signals out 350 metres to the electronics with high accuracy, and operate in challenging radiation and power dissipation conditions. The second order comprised 277 cryogenic flowmeters that will be installed in the feeder coil termination boxes to measure the helium volumetric flow. In addition, 860 pressure measurement devices are required that will operate in normal (and not cryogenic) conditions. Both components went through extensive design and qualification phases before series production could begin. This past summer the full scope of the procurement—more than 3,000 devices—was successfully completed on time, and to cost, quality and performance specifications. After inspection at the neighbouring Magnet Infrastructure Facilities for ITER (MIFI, hosted by CEA Cadarache) this equipment will be shipped by the ITER Organization to the Domestic Agencies procuring magnet structures, terminals and feeders.

Sector sub-assembly | Twin meets twin

Although they were born one full year apart, they are identical twins: when the second vacuum vessel sector sub-assembly tool (SSAT-2) is complete, nothing will distinguish it from its sibling. In the vast and resounding Assembly Hall, the first sub-assembly tool is a towering presence: the mechanical structures have all been assembled and work on electrical and hydraulic connexions will soon proceed. SSAT-2, by contrast, is just hatching—four batches of components, out of a total of six, have been delivered by Korea to the ITER site. Specialists from the French contractor CNIM are busy installing and precisely aligning the toroidal rail tracks upon which the wings of the giant tool will travel, and the first leg segment has been brought in for installation. Full assembly of the second vacuum vessel sub-assembly tool should be complete by the end of January 2019. For more pictures and details, check the gallery below.

R&D in Europe | Working with industry on digital hydraulics

A contract signed with the European Domestic Agency is helping Finnish industry innovate in the domain of digital hydraulic valves. The result could interest ITER for use in its challenging remote maintenance environment. Once ITER is functioning in full power mode, it will be impossible to make changes, conduct inspections, or repair any of the Tokamak components in the activated areas other than by remote handling. Maintenance or repair activities on the 54 cassettes of the ITER divertor, for example, will be the responsibility of the divertor remote handling system under development now in Europe. This will be a hydraulics-based system with one particularity—it will rely on water and not oil due to the constraints of ITER's nuclear environment, where a leakage of oil in the vessel would be a showstopper. The European Domestic Agency has signed a contract with Finland's Tampere University of Technology (TUT) and Finnish companies Fluiconnecto and Tamlink to explore the development and testing of digital valves based on water hydraulics. The solution under examination relies on a set of 16 small, digital on/off valves connected in parallel and controlled by computer to achieve the required performance—a solution that offers the advantage of not being vulnerable to the failure of a single valve. Trials—including hundreds of hours with a test load simulating the weight of an ITER divertor cassette—have also pointed to superior tracking accuracy and better resilience. In the next phase of testing, the digital water hydraulic valves will be installed on the Divertor Test Platform (DTP2) environment in Tampere, Finland, where R&D on the installation/exchange of ITER's divertor cassettes was carried out for more than a decade. Read the complete story on the European Domestic Agency website.

Diagnostics | What is the plasma shape? Ask the flux loop

Inside the machine, the flux loop diagnostic will provide important information to operators on the boundary shape, energy and stability of the plasma. In ITER, arrays of magnetic diagnostics generate signals to control the position and geometry of the plasma, measure current in the plasma and machine structures, and determine the magnetic equilibrium. Measurements go directly to the control systems, making the proper functioning of these instruments essential for machine operation. Equilibrium information will also underpin all other measurements in the machine, linking their information to the correct region in the plasma. One array, the vacuum vessel flux loops, will be distributed over the surface of the vacuum vessel as 234 individual sensors. Formed from lengths of slim coaxial cable shaped into closed loops, each one senses variations of the magnetic flux expelled by the plasma. These variations create voltage in the closed loops, which can in turn be measured by electronics in the quiet zone of the Diagnostics Building. The flux variations are used to calculate evolution in the shape of the plasma. For more than four years, the ITER Organization has been collaborating with industry to develop these sensors made from a particular type of mineral-insulated coaxial cable. The cable can withstand the harsh electromagnetic fields, radiation and temperature conditions inside the machine. 'In the most recent pre-qualification tender phase, we worked with specialists to arrive at cables that fully satisfy ITER's specifications,' says Philippe Gitton, diagnostic engineer. 'The selected supplier Thermocoax (France) has successfully developed 1.9- and 3.0-millimetre-thick coaxial cables with a copper core, alumina insulant, stainless steel sheathing, and an added layer of copper coating to reflect the microwaves and hence avoid over-heating." ITER engineers will be in charge of overseeing the installation of the flux loops—work that will get off to a start as soon as the first vacuum vessel sector arrives at the Assembly Hall and continue as the individual sectors are assembled to form the final torus in the machine pit. The bulk of the coils are on the plasma side of the vessel, but four ex-vessel flux loops wrap around the full circumference of the vacuum vessel using special connections hidden between the thermal shield and the vessel. 'We will be forming the flux loops by hand on site from terminated cables provided by our supplier,' says Gitton. The loops hug the inner vacuum vessel wall, attached with novel fasteners that act as heatsinks in order to keep the temperature of the cables below 250 ˚C. A fastener is needed every six centimetres—so a total of 2.4 km of cable will require some 40,000 fasteners. Between clips, installers will use a specialized tool to add some curve to the cables, giving them the slight amount of play that will be needed as the vacuum vessel and loops expand and contract during different phases of operation and maintenance. The first batch of equipment arrived last month, in respect of an ITER Council schedule milestone.

Image of the week | Communicators of all countries, unite!

ITER is a fascinating story to tell—how it began and how it developed, the challenges it has never ceased to face, the awe its infrastructure and components inspire, the way it pushes technology to the limits of what is feasible ... Telling the ITER story, keeping stakeholders and the public informed of the project's progress, is the mission of the 'ITER Communicators.' At ITER Headquarters in France and in every Domestic Agency, one of the daily preoccupations is to turn hard science and complex technology into palatable items—news articles, videos, animations, exhibits, etc. Whether based in Asia, Europe or America, the ITER Communicators are in constant touch. However, once a year they feel the need to get together at ITER Headquarters to share experience, discuss strategy and seek a mutual understanding of respective challenges. The annual meeting on 8-9 October was particularly fruitful. 'Pecha Kucha' presentations (a slick and swift format based on a set of 20 slides, each shown for 20 seconds), informal discussions, and workshops contributed to reinforcing the 'One ITER' approach that is essential for communicating ITER.

Science Festival | My village in 2030

Can you imagine a village in 2030? The local "Fête de la Science" was the perfect place to do so this past weekend. Berre l'Etang, a village about 50 km from ITER, practiced the exercise by proposing to travel in time and discover what new technologies will be part of our lives in the future. ITER was there to represent fusion! 'The Village of the Future' hosted 150 organizations and 90 displays with hands-on experiments were proposed to students and the general public. The small ITER laboratory was a popular stop—visitors had the chance to see how a magnetic field is generated, to discover the principles of vacuum, and even to produce plasma into a microwave.