you're currently reading the news digest published from 13 May 2019 to 20 May 2019

featured4

of-interest3

press6

featured

Open Doors Day | An intense and unforgettable experience

Saturday was Jacques's birthday. At age 90, the long-retired engineer from Aix-en-Provence had only one item on his wish list: to visit ITER for a third time and 'see the progress of the Tokamak.' Jacques was lucky: his birthday this year coincided with the 14th edition of the ITER Open Doors Day—a twice-a-year opportunity for the public to take the full measure of the ongoing works on the ITER construction site in Saint-Paul-lez-Durance, southern France. The Open Doors Day has come a long way since the event's inception in October 2011. The first edition had little to show: a 'near-finished' Poloidal Field Coils Winding Facility, a 'forest of pylons' in the electrical switchyard, and a 17-metre-deep excavation where installation work had just begun on the anti-seismic system of the Tokamak Complex. Eight-and-a-half years later, the ITER installation is a massive presence. More than 70 percent of civil work to First Plasma has been completed, spectacular assembly tools are in place, and giant components are taking shape on site. For the 800 visitors who passed through the worksite gates on Saturday, the experience was intense and unforgettable. As they walked from the Cryostat Workshop, where the base section of the cryostat is in the last stages of fabrication ... past the lower cylinder (now cocooned on site) ... through the lofty Assembly Hall ... and finally into the depths of the Tokamak Complex, they were able to take the full measure of ITER in both its scientific and industrial dimensions. The success of an Open Doors Day rests on faultless organization¹, the dedication of dozens of volunteers, and a collective enthusiasm for explaining and sharing what ITER is about. All these pre-requisites and more were fulfilled by the participants in the 14th edition on 18 May. Scientists traded the complex equations of plasma physics they are familiar with for simple and concrete explanations and examples accessible to the lay public; engineers discarded their technical jargon to convey the challenges of ITER construction. For everyone involved the reward was in the eyes of the children exploring a 3D rendition of the ITER machine, or in the eyes of their parents gasping at the sheer size of the sub-assembly tools and the unique strangeness of the Tokamak Pit. ¹Open Doors Day is organized by the ITER Organization in close collaboration with the European Domestic Agency, Fusion for Energy, and its contractors Engage, Apave, Energhia, etc. Close to 50 volunteers participated in the 14th edition. Representatives of 'Les petits débrouillards,' a national network that promotes scientific and technical education, were also present to provide hands-on experiments on magnetism and electricity.

Power conversion | A potent illustration of the "One ITER" spirit

Europe made the buildings; the piping came from India; China and Korea provided the transformers; Russia manufactured the massive 'busbar' network. The ITER Organization, along with the Korean Domestic Agency for its own procurement, has begun assembling all these different components into the plant system that will convert electrical current into power that can be distributed to the ITER magnets. Located between the 400 kV electrical switchyard and the Tokamak Complex, the Magnet Power Conversion buildings are one of the most potent illustrations of the international collaboration that forms the core of the ITER Project. 'They are among the strongest symbols of the ONE ITER spirit that unites us all,' said ITER Director-General Bernard Bigot on 29 March as the ITER Organization officially took ownership of the buildings from the European Domestic Agency, Fusion for Energy. The equipment that lies in rows inside of the twin 150-metre-long structures (and also outside, in exterior bays) forms the lifeline of the ITER magnets. In order to generate a stable, non-oscillating magnetic field, the superconducting electromagnets in the ITER machine—all 10,000 tonnes of them—need to be electrically powered by DC current, which is obtained by converting the AC power that comes from the French national grid. In the twin Magnet Power Conversion buildings, no fewer than 32 AC/DC converter units—comprising a transformer, a converter, a filter and a busbar section—are tasked to bring down the AC voltage from 66kV or 22 kV to approximately 1kV, convert it into DC current, and distribute it to the different clients in the magnetic system—central solenoid, poloidal and toroidal field coils, correction coils, etc. Procurement responsibility for these electrical components is shared by Korea (18 converter units plus one master control system) and China (14 converter units). All units but two, one from Korea, one from China, have been delivered to the ITER site. Connecting the converter units to the magnets, first through the conversion buildings, then by way of two 50-metre-long bridges to the Tokamak, requires approximately 5 kilometres of massive steel-jacketed actively cooled aluminium 'busbars.' (A busbar is to ITER what a power cable is to an ordinary appliance: a device that connects an electrical component to a power source). The Russian Domestic Agency is procuring the busbars—some 900 tonnes of material in all—from the Efremov Institute in Saint Petersburg. A constant flow of pressurized water will be needed in the Magnet Power Conversion buildings to cool all of these densely packed components carrying high DC current. Manufactured in India, an impressive network of pipes runs between the cooling tower basins and the buildings, circulating approximately 80 cubic metres of cooling water through the electrical equipment in each building. Both buildings should be ready for commissioning in 2020. See gallery below for more technical information.

Fusion world | Upgrade completed on DIII-D tokamak

The DIII-D National Fusion Program (US) has completed a series of important enhancements to its fusion facility, providing researchers with several first-of-a-kind tools for controlling and understanding fusion plasmas. Operated by General Atomics in San Diego, California, DIII-D is a world-class fusion laboratory where 650 researchers from the US and across the globe explore a wide range of topics from fundamental plasma science to fusion power plant operations. The facility has been offline since May 2018 as a team of more than 100 engineers and technicians from General Atomics and collaborating institutions worked to install new capabilities for driving current in the machine. Controlling how this current is distributed is a key tool for optimizing performance in fusion plasmas. The largest upgrade project was the installation of a new steerable neutral beam system. Weighing more than 50 tonnes, it will allow researchers to vary the angle at which high-energy atoms are injected into the plasma for heating and control, enabling researchers to produce, study and exploit advanced physics important in making fusion reactors economical in the future. The team also installed an innovative system that researchers expect will significantly reduce the amount of power required to drive electrical current in the plasma. This system is predicted to double the current-drive efficiency by injecting microwaves from the top of the tokamak, rather than from the side. Significant progress was also made toward installing a new, advanced antenna to launch ultra-high frequency 'helicon' radio waves, which are more efficient and work over a wider range of plasma densities than earlier radio wave systems. Final installation of the helicon antenna is planned during the next opening of the tokamak this fall. In other work, the team used a new 3D laser scanning system to precisely align the upper divertor, which allows heat to dissipate prior to contacting the internal surfaces of the tokamak. This upgrade, in combination with newly installed measurement systems, will allow researchers to assess how the immense heat generated during plasma operation is best vented out of the tokamak. The DIII-D Program has been the recipient of numerous scientific awards for pioneering research. For the upcoming experimental campaign, the program received over 500 proposals for experimental time, with many researchers planning to exploit the recently-installed upgrades. "The new upgrades continue DIII-D's rich history of providing innovative solutions to key issues in fusion development,' said Mickey Wade, deputy director for Magnetic Fusion Energy at General Atomics. 'It is my expectation that these upgrades will place DIII-D experimental time in high demand in the coming years, as researchers seek to capitalize on these new capabilities.' See the DIII-D press release.

Vacuum lab | Ensuring leak test sensitivity

A helium leak test is one of several factory acceptance tests planned for the sectors of the ITER vacuum vessel before they are shipped to ITER. In a vacuum laboratory in the basement of ITER Headquarters, work is underway now to prepare and qualify the procedure and equipment. The nine sectors of the ITER vacuum vessel are in fabrication now in factories in Korea (four sectors) and Europe (five sectors). Each sector is welded together from four individual segments, which in turn are built from several smaller segments. A single vacuum vessel sector stands 13 metres tall, is 6.5 metres wide and 6.3 metres deep, and weighs approximately 400 tonnes. Sealed on either side by field joints, each sector is an independent double walled structure. A distance of 20 cm separates the sector's inner and outer walls, creating a 20-cubic-metre interspace that is filled with shield blocks and cooling water piping. Due to the number of welds in a vacuum vessel sector, the factory acceptance leak test is a crucial step in proving the absolute leak tightness of the component before shipment. Leakage of any material into the plasma volume could contaminate the plasma and potentially cause the fusion reaction to stop. The ITER Organization is developing and qualifying the test procedure and equipment that will be employed on the first vacuum vessel sector to be completed—sector #6 in Korea. The manufacturer—Hyundai Heavy Industries—is responsible for conducting the test, but there is close collaboration with the ITER Organization for its preparation, set-up and realization. During the acceptance leak test, powerful pumps will remove the air from the interspace to create a vacuum, while the entire sector sits in a giant enclosure or 'bag' filled with helium. A leak in the sectors shells would allow helium to seep into the interspace where it would be detected by a mass spectrometer leak detector. In the vacuum laboratory at ITER, vacuum design and construction officer Liam Worth and his colleagues are assessing the sensitivity of the mass spectrometer and the functionality of the procedure itself. 'If we don't achieve the required level of sensitivity we will not be able to establish whether or not the vacuum vessel sector is indeed leak tight,' says Worth. The team is testing the diagnostic using a small vacuum chamber (1 m³) that mimics the test vacuum in the sector interspace. One of the challenges is to ensure that the mass spectrometer can detect minute amounts of helium against the background 'noise' of outgassing—the release of gas particles from the surface of materials as a consequence of the manufacturing process. To gauge this effect, a gas with a similar composition as the one expected in the vacuum vessel interspace is injected into the test vacuum chamber. 'Simultaneously, we add helium to see whether the mass spectrometer leak detector is able to identify even small quantities of helium against the 'background' of the outgassing,' says vacuum design technician Sergei Nasluzov, who is responsible for the acceptance test qualification. 'We need to be certain that the level of sensitivity of our detection instruments meets the requirements for the acceptance test.' According to Worth, the likelihood of a leak in the vessel sector's shells is very small, as the sectors have been manufactured to rigorous technical specifications. In the unlikely event that operators do detect a leak during the acceptance test, they would need to scan the surface of the vessel—in particular the welds—with a hand-held helium spray gun to localize the leak and repair it. The team will finalize preparations before this summer when test equipment—two mass spectrometers, vacuum pumps, and vacuum instrumentation—will be shipped to Korea for the factory acceptance test.

of-interest

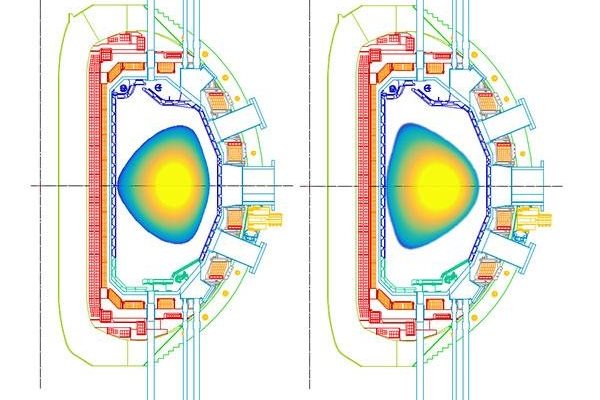

Reversing the plasma shape?

Researchers from the MIT Plasma Science and Fusion Center, PSFC, and the University of Texas at Austin have had promising results in terms of plasma stability in experiments with 'negative triangularity' on the DIII-D tokamak; that is, with reversing the conventional shape of the plasma in the tokamak chamber. In results published recently in Physical Review Letters and Physics of Plasmas, researchers Alessandro Marinoni (MIT) and Max Austin (UT Austin) discovered evidence that reversing the conventional shape of the plasma in the tokamak chamber can create a more stable environment for fusion to occur, even under high pressure. Marinoni and colleagues are planning future experiments to further demonstrate the potential of this approach in an even more fusion-power relevant magnetic topology, based on a 'diverted' tokamak concept. Read more on the subject on the PFSC website.

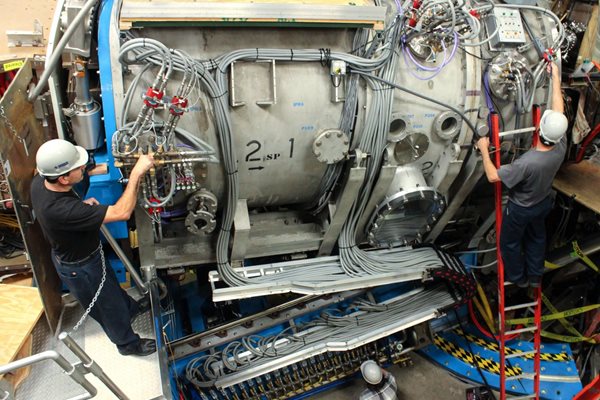

Assembling the second neutral beam testbed

At ITER's Neutral Beam Test Facility, one testbed has been launched and another is in the procurement/assembly phase. SPIDER—the ITER-scale negative ion source—turned on last year. Experiments on MITICA—a full-size prototype of ITER's 1 MV heating neutral beam injectors—are scheduled beginning 2022. Procurement is underway in Europe on the beam source and at Consorzio RFX in Padua, Italy, work is underway to install auxiliary components and systems. In May, the first part of the MITICA beam source vacuum vessel was installed (photo). This stainless steel component was procured by the European Domestic Agency, Fusion for Energy, as a voluntary contribution to the ITER neutral beam development program. See more about the manufacturing of the vessel here. See more about the Neutral Beam Test Facility at Consorzio RFX here.

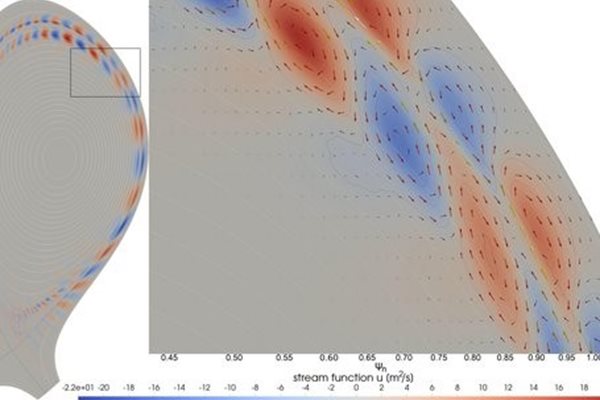

Modelling collaboration between ITER and TU/e

Physics of Plasmas (American Institute of Physics) has published a paper on research carried out under a collaboration between the Eindhoven Technical University (TU/e, Netherlands) and the ITER Organization. 'Kinetic modeling of ELM-induced tungsten transport in a tokamak plasma' (D. C. van Vugt, G. T. A. Huijsmans, M. Hoelzl, A. Loarte, et al) describes the role of edge-localized modes (ELMs) in exhausting tungsten impurities from the core plasma of tokamaks to ensure that their concentration remains low. The collaboration modelled tungsten impurity behaviour and power fluxes to plasma-facing components during controlled ELMs in ITER with advanced modelling by the JOREK code, which required specific upgrades to the code to include the necessary plasma-wall interaction and impurity transport processes. The authors write: 'This publication shows that the role of ELMs in cleaning up the plasma from tungsten eroded at the divertor in ITER can be opposite to that in present experiments, particularly when we approach the conditions required for high fusion energy production gain. This implies that the use of the ELM control coils, included in the ITER baseline design to modify ELM behaviour and eventually suppress ELMs, will be required not only for the control of power fluxes to the divertor but also to exhaust the eroded tungsten from the confined plasma to keep it clean.' Read the complete article on the TU/e website here.