you're currently reading the news digest published from 20 May 2019 to 27 May 2019

featured5

of-interest1

video1

press5

featured

10 years strong | A French school with an ITER flavour

The men and women who are building ITER come from all over the world, often with school-age children. They rightfully expect to be provided an adapted educational structure, one that would provide the benefits of an international curriculum while maintaining ties with their national system and language. Establishing an international school near ITER was part of the French commitment as host to the project. For the French Ministry of Education, the creation of an educational establishment catering to students aged 3 to 18 and hailing from more than 30 nations was a tremendous challenge, both technically and intellectually. On 24 January 2011, when the school was officially inaugurated, the head of the public education service in the Aix-Marseille region considered that the French authorities had gone 'as far as the Constitution would allow.' Although it was created to serve the needs of ITER, the International School of Provence-Alpes-Côte d'Azur (EIPACA) is part of the French public school system. As such, it is also open to 'non-ITER' children, which contributes to broadening the experience of all students. The objective from the beginning has been to provide a bilingual education—in French plus one of the ITER languages. Currently, six language sections are offered: Chinese, English, German, Italian, Japanese and Spanish. Furthermore, from junior high school on, English speakers can choose to join the European Section where the courses are taught 80 percent in English. From 130 students in 2007, the school has grown to 770 today (an average of 59 percent are from ITER families). After exponential growth in the early years, enrolment is now expanding at about 5 percent annually. The 'ITER school' was hosted at first by a high school in the city of Manosque, until a dedicated site could be built thanks to an investment of EUR 55 million from the Regional Council of Provence-Alpes-Côte d'Azur (PACA). From 20 to 24 May, five days of celebratory events took place to celebrate 10 years in the school's permanent location. 'We are proud to be a strong and nurturing school for children from thirty countries who study in seven different languages,' said Laure Béjannin, current director of the EIPACA International School. 'Our commitment to the future of the school is complete. With the support of ITER and of the French Ministry of Education, we will no doubt lead our 770 students today—and our students in the future—to great achievements.' Learn more about the EIPACA International School in this presentation, or by consulting the website.

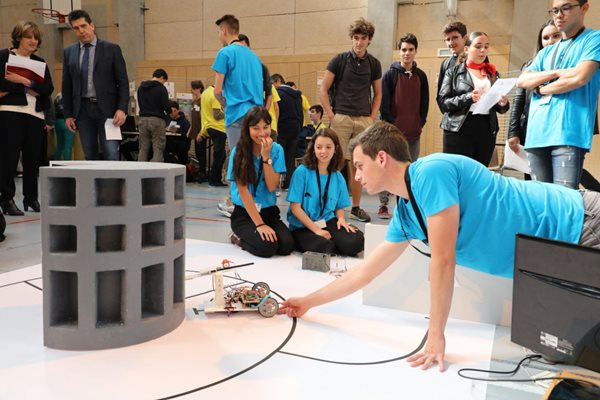

8th ITER Robots | 49 teams from 29 schools

Upon entering the gymnasium at the Lycée des Iscles, you can feel the energy. Seven hundred students, pulsating music, sounds of triumph (and disappointment). There is no doubt—ITER Robots are back in town. Each participating school can be identified by the colour of its T-shirt, and the gym seems lit with a vibrant rainbow of excitement. Lying on the floor, hunched over a robot made from LEGO Mindstorm components, a student tinkers with some final adjustments, listening intently to feedback from one of the facilitators in an orange cap. 'The lighting is different in the gym here than it was in our school,' he says with some trepidation. This is a common theme—that a last-minute surprise during the final competition derails months of hard work and practice. The student teams have each built a small robot to simulate a maintenance situation inside the future ITER Tokamak machine—namely the remote handling of components that need replacement or refurbishment. The process of creating them takes months of planning and execution, and of course, a dedicated teacher to oversee the process and keep the team spirit alive. The teachers clearly enjoy watching their pupils in action, and take the lead in helping them to prepare for their turn to display what they have learned. This is the eighth ITER Robots competition to be held at the Lycée des Iscles, and it boasts the highest-ever number of participants: 700 students (49 teams) from 29 schools. The contest was conceived originally by Agence Iter France, with the participation of engineers from the ITER Organization and the French Alternative Energies and Atomic Energy Commission (CEA). It is now supported by the French Ministry of Education, which has accredited the teaching modules of this competition and has made them available to all schools through its website. Each of the four challenges—Ways, Transport, Pick and Place, and Cooperate—focuses on tasks that the robotic systems at ITER will perform, ranging from following predefined trajectories ... to transporting components from within the Tokamak to refurbishment workshops ... to operating two robots simultaneously to perform a single task. In addition, the teams are evaluated on their communication skills and knowledge about fusion. It is hard work, but the pay-off is worth it. According to organizer Sylvie André from Agence Iter France, the objective is 'not about winning, but about participating, to enjoy working in a team and to succeed at making your own robot.' If this is the objective, clearly all of the teams are winners.

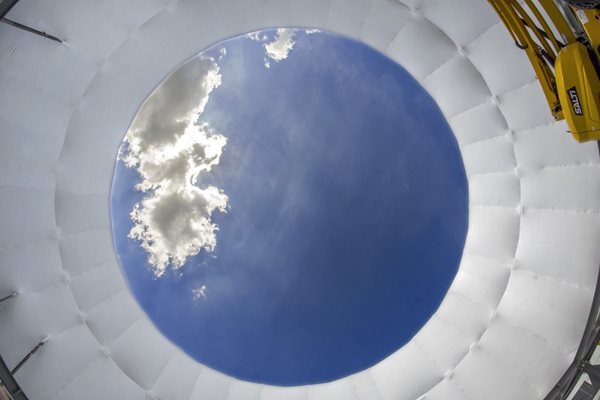

Image of the week | Comfy cocoon

The protective cocoon that encases the cryostat's lower cylinder briefly acquired some curves, last week, as air was pumped into it to test for potential leaks. Pressure inside the 2,300 m³ enclosure was raised to a few dozen pascals above atmospheric pressure, then lowered in the same proportion like in a breathing exercise. The cocoon's synthetic skin passed the test, which guarantees that no leak or uncontrolled air intake, however small, will alter the quality of the atmosphere inside the structure. In order to protect the lower cylinder from mould or corrosion, the air inside the cocoon will be kept circulating and maintained at a constant 38 percent humidity.

On site | New building, two purposes

Excavation has started for a concrete building designed for the distinct storage and handling requirements of ITER's beryllium components—in particular, the first-wall panels of the ITER blanket. But as these components are not expected on site before late 2024, the building will be used in the interim for Tokamak pre-assembly work. The first-wall panels of the ITER blanket—which will face heat fluxes of up to 4.7 MW/m²—will be armoured with beryllium, a metal chosen for its high melting point and its low atomic number (minimal impact on plasma performance). The 460 plasma-facing first wall panels will require about 12 tonnes of beryllium to cover a surface of 610 m². The beryllium used in the manufacture of ITER components will be non-radioactive; however, measures, systems and actions must be implemented to control and prevent any beryllium exposure to workers, operators and the public. In the original plans, the receipt and trial fitting activities of first-wall panels were to take place in the ITER Hot Cell Complex. Changes related to the staged approach to ITER construction, however, now mean that the Hot Cell Complex will only become available at the end of 2028. 'A second solution is needed,' explains Paul Stewart, an engineer with the Facilities, Logistics & Management Division. 'We opted to design a civil structure for beryllium handling, but with the flexibility to support machine assembly activities from 2020 to 2023. For this reason, the building has been named the 'Tokamak Assembly Preparatory Building (TAPB).' The 1600 m² building will be a one-storey structure with a full basement, unloading dock and lifting platform. A 250 m² mezzanine will be added in TAPB Phase-2, to provide for the HVAC equipment necessary to house beryllium in the facility. On the list of activities that could be housed in the TAPB Phase-1 building are: In-vessel mockups and trials: a space for assembly mockups to permit the training and qualification of procedures, processes and operators. Vacuum laboratory support: spill-over space for the site acceptance tests, maintenance, or storage of vacuum components. Magnet infrastructure facilities for ITER: space to receive, inspect, test and, if necessary, repair large magnet components; magnet assembly mockups for training and qualification purposes. The control of the beryllium risk must comply with the requirements of French Decree No. 2012-1248 of 9 November 2012. The key safety function of the TAPB building is therefore the confinement of beryllium in order to protect the workers, the public and the environment (by providing static and dynamic confinement). Design work began two years ago; now, construction has started on site. The building is expected to be completed in the summer of 2020, just as the first major machine assembly activities are getting underway in the Tokamak Building.

Site Services Building | All equipment installed

Standing alongside the Assembly Hall, the Site Services Building is not the most spectacular edifice on the ITER platform. It is however one of the most strategic, as it hosts the equipment that distributes a large number of industrial support services and systems that are indispensable for plant operation. The 80-metre-long building is a rather standard structure, whose construction began back in January 2015 under the responsibility of the European Domestic Agency, Fusion for Energy. What makes it unique is the density and variety of its equipment—demineralized water plant, chiller systems, air compressors, dozens of pumps and kilometres of pipes installed by contractors Demont and Cestaro Rossi under the supervision of the ITER Organization's Construction Management-as Agent contractor MOMENTUM in collaboration with the ITER construction team for plant installation (CTPI). At a small celebration on Thursday 23 May, ITER Director-General Bernard Bigot stressed 'the multiple roles that have been interwoven to bring this building and its systems to completion,' and formulated his appreciation for 'the successful collaboration between all stakeholders with energy, enthusiasm and teamwork.' MOMENTUM will now shoulder the responsibility for maintaining these systems in full readiness—in collaboration with the CTPI team—until the ITER Organization is ready for full system commissioning. Adding to the symbolic importance of the event, the members of the Management Advisory Committee, who happened to be convening at ITER Headquarters, took a break from their discussions to attend the ceremony on site.

of-interest

First crane hall columns

High above the concrete fortress that will house the ITER Tokamak, a steel lattice of pillars and beams will soon rise to complete the structure—both providing a roof (once covered over with cladding) and providing sheltered manoeuvring room for the heavy assembly cranes that will be travelling back and forth from the Assembly Hall carrying components. Twenty steel pillars (ten on either side) will support the roof structure as well as resist the tremendous forces exerted by the movement of the bridge cranes. The lower segments of the pillars (see photo) will be directly anchored in the concrete of the Tokamak Building, either on concrete columns or on weight-bearing "brackets" called corbels. The rest of the roof structure will be assembled in five modules on the ground and lifted into place by crane. The roof of the Tokamak Building will weigh approximately 2,000 tonnes. Read the full story on the Fusion for Energy website.