you're currently reading the news digest published from 09 Sep 2019 to 16 Sep 2019

featured7

press7

featured

Vacuum vessel manufacturing | Last phase for Korean sector #6

On 7 September, contractors from Hyundai Heavy Industries in Ulsan, South Korea, initiated the final fabrication activities for vacuum vessel sector #6: the assembly of four completed segments into the final D-shaped component, plus the installation of upper and lower port stub extensions. At the end of this first-of-a-kind undertaking, the first 440-tonne ITER vacuum vessel sector will be ready for shipment to France. On the shop floor in Ulsan, a curtained-off clean space has been created around the assembly platform that supports the building blocks for ITER first vacuum vessel sector: four poloidal segments ranging in weight from 35 to 125 tonnes. When assembled and welded, the final D-shaped component will measure 13.8 metres in height, 6.6 metres in width, and 7.8 metres in length. All nine sectors needed to form ITER's toroidal plasma chamber are currently in fabrication in the factories of two ITER Members—Korea (for four sectors) and Europe (for five sectors). As the first sector programmed for arrival at ITER, sector #6 has the honour, and the challenge, of 'proceeding first' through every fabrication stage. The lessons learned on sector #6 will facilitate the way for all other sectors. 'We are definitely breaking new ground,' says project director Kyungho Park at Hyundai. 'The ITER vacuum vessel is an absolutely unique component with very complex geometry, hundreds of interfaces to other components, and very strict nuclear safety compliance requirements. Each step of the process has been challenging, from manufacturing qualification and procedures, machining, and welding, to non-destructive examination and tolerances. We are learning and problem solving as we go, and we are making sure that the knowledge and experience we acquire benefits the other sectors.' The vacuum vessel is a double-walled component, with 34 to 75 cm of space between the inner and outer steel shells. 'Space' is rather a misnomer, however, because the interspace will be nearly completely filled with in-wall shielding blocks (packs of borated stainless steel plates), cooling water channels, and steel supporting ribs. The interspace of Sector 6, for example, contains 850 blocks of in-wall shielding and 850 supporting ribs. Inside the vessel, 172 flexible support housings are welded for the attachment of the blanket shield blocks while outside, two port stub extensions are attached to the sector's upper and lower port stubs through splice plates. All of this complexity makes the final assembly stage quite challenging. Activities will be carried out in the following order: TIG welding of the inner shell (full penetration welds), followed by welding of structural ribs (so-called 't-ribs') and flexible support housings, keys, the installation of in-wall shielding, and—in the final activity to complete the segments—TIG welding of the outer shell (full penetration welds). One hundred percent volumetric inspection is required as a nuclear safety requirement. Taking all assembly activities on sector #6 into account, the Hyundai team estimates the total length of full penetration welds at 1,380 metres. In order to increase confidence that the stringent tolerance requirements for the final geometry can be achieved, the Hyundai team—in collaboration with the ITER Organization and the Vacuum Vessel Project Team¹—performed a 'virtual fitting' this summer in which all available dimensional measurements of the completed poloidal segments were processed with specialized software (Space Analyzer) and matched virtually. 'This process was key,' explains Chang Ho Choi, who leads the ITER Vessel Division. 'It allows the demanding tolerances to be achieved by identifying the areas that require reverse engineering to compensate welding deformation and shrinkage.' From 7 to 15 September, the team completd the inner shell welding on all poloidal segments. Six Project Team inspectors, two Agreed Notified Body² inspectors, and the Hyundai quality departments are performing continuous quality control—day and night—as the work advances. A total of 45,000 inspection points are planned and 500 manufacturing documents, including reports, have been developed. ¹ The Vacuum Vessel Project Team reunites staff from the European, Korean, Indian and Russian Domestic Agencies with staff from the ITER Organization in regular meetings to improve the overall efficiency of vacuum vessel procurement execution.² An Agreed Notified Body (ANB) is a private company authorized by the French Nuclear Regulator ASN to assess the conformity of components in the pressure equipment category (ESPN).

Worksite | First pillars for the crane hall

For the overhead cranes to deliver machine components into the Tokamak assembly pit, the rails that carry them need to be extended some 80 metres beyond the temporary wall of the Assembly Hall. The extension, part of a cladded steel structure supported by two parallel rows of ten steel pillars, will form a new volume within the Tokamak Complex — the Crane Hall where the cranes will travel back and forth as assembly work progresses inside the pit. On Wednesday 11 September, the lower section of the first pillar was anchored into the corbel on the south side of the Tokamak Building. Although the steel piece weighs only 28 tonnes (not much by ITER standards ...) a huge crawler crane, with a lifting capacity of 650 tonnes and a boom reaching more than a hundred metres in height, was brought in to perform the operation. Once lifted from the ground, the pillar had to be precisely oriented so that its boltholes could match with the 24 anchors protruding from the concrete plinth in the corbel. A dozen specialists were ready to perform the delicate insertion operation and subsequent bolting. Like with most components—however heavy—nothing beats the precision of the human hand ... By Friday, three lower pillar sections, 13 metres in height, were in place. Each lower section will be topped by a 16-metre-high upper section which, in turn, will support five pre-assembled structural modules for the roof spanning a distance of close to 50 metres. In order to lift the huge modules, a second crawler crane, positioned on the northwest side of the Tokamak Complex, will work in tandem with the one already in place. Designed to withstand the tremendous forces exerted by the movement of the travelling cranes, the finalized structure will weigh approximately 1,800 tonnes and should be completed by February 2020—one month before the official start of the machine assembly phase.

Transport | 300 tonnes of equipment on its way to ITER

A specially designed assembly tool and elements of the cryostat and vacuum vessel thermal shields are part of the shipments travelling now from Korea to ITER. When machine assembly begins officially next year, overhead cranes with a lift capacity of 1,500 tonnes will begin to ferry completed components into the Tokamak Building for installation at the very bottom of the Tokamak Pit. The first of these, and the most spectacular in terms of sheer weight, will be the cryostat base. In parallel, specialized tooling designed by Korea will enter into service next door in the Assembly Hall to manoeuvre, lift and in some cases pre-assemble components before their transfer to the Tokamak Building. Testing is underway now, for example, on the major sector sub-assembly tools (SSATs) that will allow contractors to join two D-shaped toroidal field and thermal shield panels to each 440-tonne vacuum vessel sector. Shipments on their way from Korea now are important to that pre-assembly operation. In one boat that left the port of Ulsan on 29 August is the tool that will 'upend' the vacuum vessel sectors and toroidal field coils from horizontal to vertical so that they can be installed on the SSAT tools. The upending tool is being shipped in two sections for a total of 220 tonnes. Also travelling are elements of the ITER thermal shield—steel panels coated with low-emissivity silver to protect cold components such as the superconducting magnets from thermal radiation. Two large sections—the cylindrical-shaped lower cryostat thermal shield (planned for installation early in the machine assembly sequence inside of the cryostat base) and the vacuum vessel thermal shield (that will be mounted directly on vacuum vessel sector #6 as it is suspended on the SSAT tool next year)—were shipped on two vessels out of the port of Busan on 1 and 15 September. A handling frame for the thermal shield sectors was shipped alongside the upending tool one week earlier. All of these major components are expected at ITER in October. The arrival of the thermal shield for sector #6 of the vacuum vessel completes an ITER Council milestone.

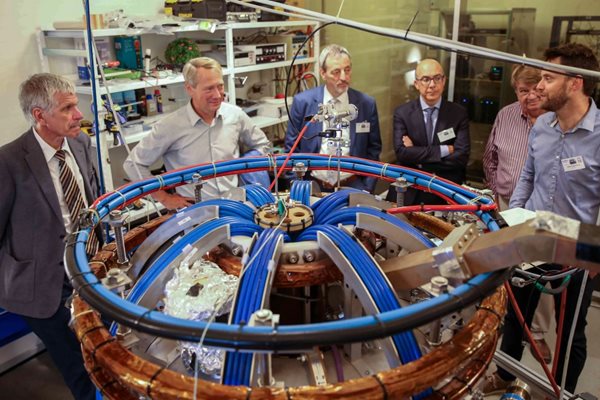

Fusion world | A new tokamak in town

After EAST in China and WEST in France, another of the cardinal points of the compass has been chosen to name a tokamak. Introducing NORTH—the NORdic Tokamak device that is enriching the physics and engineering programs at the Technical University of Denmark by offering students hands-on experience with all the aspects of creating a tokamak plasma. What began as the ST-25 prototype at fusion start-up Tokamak Energy Ltd. (UK) has found a second life, like so many fusion devices, as a research and training instrument at the Technical University of Denmark (DTU). The small spherical tokamak—with a plasma major radius of 25 cm and a plasma volume of ~100 litres—is on permanent loan from Tokamak Energy, according to Søren Bang Korsholm, who works as a senior scientist at DTU. The device arrived on five pallets late last year, and was re-assembled and re-wired by the DTU team in the basement of Building 309 on the DTU campus north of Copenhagen. Student-led projects contributed to equipping the device with an array of diagnostic instruments for measuring density, temperature and magnetic field. 'We are pleased that at the university founded by the person who discovered electromagnetism (Hans Christian Ørsted, 1777-1851), we now have the opportunity to contribute to the practical training of some of the fusion scientists and engineers who will bring fusion energy to the grid.' NORTH produced its first official plasma (7 seconds) at the recent inauguration at DTU on 23 August 2019, performing as expected. ITER Director-General Bernard Bigot tuned in to the event by video conference: 'Today, DTU has joined the worldwide family of operating tokamaks, which ITER will soon belong to. We are all proud to be part of this great quest, which has been the dream of scientists and engineers for more than five decades. We are now closer than ever to making this dream a reality. I wish you the best for the coming years of fusion research at DTU.' 'Although the machine is much smaller than ITER, the basic plasma physics is the same—allowing our students to perform experiments that will prepare them well for working at larger European fusion labs,' says Søren. The newly acquired device is expected to increase the attractiveness of the fusion plasma physics program at the university, but not only. The team aims to make NORTH available to engineering students with an interest in a broader range of topics like diagnostics, materials, energy system analysis, power supply and more, embracing many of the different capabilities required by fusion research and industry. More information about NORTH, including a video, here.More on the start-up Tokamak Energy here.

Opportunities | Bringing the ITER Business Forum to Washington

Every second year, a two-day ITER Business Forum is held to invite existing and potential suppliers for the ITER Project—laboratories, universities, and companies large and small—to learn about upcoming opportunities to compete for contracts and to present their relevant technological capabilities. Following the IBF-19 meeting held earlier this year in Antibes, a number of those present noted the relatively light participation by US companies. Last week, the US House Science Committee invited ITER to use their chambers to hold an abbreviated 'ITER US Business Forum' to bring the message to Washington. Interest proved to be keen. Approximately 90 participants attended: from multinational powerhouse companies such Bechtel, Areva, and Skanska, to small businesses specializing in beryllium machining, robotics and remote handling, nuclear system components, and unique diagnostic instruments. Some companies present are already suppliers for the US Domestic Agency, or are at least familiar with the calls for tender issued from the US ITER Procurement Office. What was new, for nearly all concerned, were the opportunities available to compete directly for contracts with the ITER Organization. In a brief presentation, the ITER Director-General described the status of project progress, then laid out a series of opportunities corresponding to coming areas of ITER need: control engineering, tritium systems, the Hot Cell Complex, and more. Ned Sauthoff, Head of the US ITER Project Office, spoke briefly about US procurement opportunities, and Mickey Wade, Director of Advanced Fusion Systems at General Atomics, gave his perspective on the unique value of being an industrial supplier to the project. The discussions that followed were lively. Beyond the ITER exhibit showing project progress, and handouts on current calls for tender, participants could join any of seven Skype conversations in the room, connected directly with ITER experts at the worksite. Sergio Orlandi, Director of ITER's Plant Engineering Department, was on hand to discuss upcoming needs for ITER's cooling water systems. Tim Luce, ITER's Chief Scientist, spoke with companies interested in working on ITER's scientific computing challenges. Christophe Dorschner, Director of ITER's Procurement and Contracts Division, was available to answer questions about the competition process. All parties agreed that it was a fruitful exchange. And the primary goal—raising awareness among US companies for the business opportunities at ITER—was certainly met.

World Energy Congress | Fusion "at a time of transition"

In the United Arab Emirates, Abu Dhabi is often referred to as a tourism hotspot that combines luxury and ancient traditions. In September, Abu Dhabi was in the spotlight for another reason: the city hosted the 24th edition of the World Energy Congress, held for the first time in a Middle Eastern—and OPEC—member country. The 24th edition of the World Energy Congress took place from 9 to 12 September in the Abu Dhabi National Exhibition Centre. Under the umbrella theme of "Energy for Prosperity," the Congress turned out to be a global platform where decision makers, researchers and government representatives shared their opinions and views on a strategy for a collaborative, sustainable and innovative energy future. 'This global gathering comes at a time of great transition in the energy sector, presenting challenges and opportunities that we must, as an industry, address,' said the country's Minister of Energy & Industry, H.E. Eng. Suhail Mohamed Faraj Al Mazrouei, during the opening speech. 'It is through foresight, commitment and unity that we can and will collectively meet the growing energy demands the world is facing.' The country made a number of announcements at the Congress, pledging, for example, to aim to reduce its carbon footprint by 70 percent by 2050 through combined investment in nuclear and renewables. ITER participated in discussions on the potential of fusion. On the first day of the conference, ITER Chief Strategist Omae Takayoshi was invited to be part of a panel on how breakthrough technologies would drive the energy transition. 'I strongly believe that ITER is an innovation model by itself,' he told participants. 'In a very close future, a combination of new industrial technologies such as artificial intelligence, the 'internet of things,' and computer science will be applied to build and assemble the oversize components and operate the ITER machine.' The ITER walk-in cinema and stand were also present throughout the week, to introduce some of the conference's 15,000 participants with the world's most ambitious fusion energy project.

Image of the week | ITER games, 9th edition

Meeting new people, competing for fun and getting to know about the many sports associations active in the ITER vicinity—this is what the ITER games have been about for the past eight years. In 2011, when the first edition was held, the idea was to create an event that would facilitate the integration of the ITER personnel into their new environment. The event—which was popular from the outset—now attracts more than 650 people from the ITER community. On Saturday 14 September, a mix of "ITER people" and of residents from local communities gathered in the neighbouring village of Vinon-sur-Verdon for the ninth edition of what is now a very well-attended tradition.