you're currently reading the news digest published from 16 Nov 2020 to 23 Nov 2020

featured3

image1

press17

featured

27th ITER Council | Assembly moves ahead

The Twenty-Seventh Meeting of the ITER Council took place by videoconference on 18 and 19 November 2020, chaired by LUO Delong from China. Representatives of the seven ITER Members evaluated project progress and achievements since the previous meeting in June, and noted that: "The project has largely managed to continue its robust performance, both with respect to Members' delivery of first-of-a-kind components and worksite installation and assembly activities." Over two days, the ITER Council evaluated the progress of manufacturing, construction, and assembly, including the impact of the COVID-19 pandemic. Major milestones reached in recent months—including the installation of the cryostat lower cylinder and the start of cryostat welding in the Tokamak pit, the arrival of the first vacuum vessel sector, the start of poloidal field cold testing, sustained plant installation activities, successful assembly tool qualification, and the arrival of four D-shaped coils—were celebrated, and the ITER Organization and Domestic Agencies received commendation for the "resourcefulness and resolute implementation" of a continuity plan under challenging COVID-19 conditions. Some impacts on the schedule towards achieving First Plasma in 2025 have been identified, but still remain to be assessed after consideration of mitigation measures. Read the press release in English and in French.

Cryodistribution | Blowing cold and hot

If the cryodistribution system were a railroad, the cryogenic termination cold box would be its main switch. A massive structure packed with pipes, valves, electrical feedthroughs and pneumatic actuators, the termination cold box collects the cooling fluids from the cryoplant and redirects them to the Tokamak Building over an elevated bridge. Once inside the building, another set of smaller cold boxes, called 'auxiliary' boxes, dispatches the fluids to their different clients— supercritical helium at 4.7 K to the magnets and cryopumps, gaseous helium at 80 K to the thermal shield. During operation, the ITER superconducting magnet system (all 10,000 tonnes of it), the cryopumps and the thermal shield must be kept at cryogenic temperature. But when maintenance is scheduled, this huge mass of frigid components must be brought back up to room temperature. 'Because of the considerable mass of the superconducting magnets, and of the quality of the machine's vacuum insulation, it would take several weeks for the ultra-cold components to warm up and allow maintenance,' explains David Grillot, the head of ITER Cryogenic System Section. Hence the second mission of the cryogenic termination cold box: to bring the magnets and their environment to room temperature. Magnets are maintained at cryogenic temperature by a constant flow of supercritical helium (neither liquid nor gaseous, but a bit of both) from the cryoplant systems. When the time comes to warm up the machine, the cooling fluid from the cryoplant is diverted to a parallel circuit that takes it through a set of powerful electrical heaters before being blown into the magnets. 'Let's say that instead of continuing to blow very cold, we blow warmer and warmer, with small increments on the order of one degree per hour in order to prevent mechanical constraints,' says Grillot. 'Progressively, over the course of a few days, the magnets' temperature rises from that of a winter night on Pluto to that of a balmy spring day in Provence, and the machine become accessible for maintenance operations.' Procured by ITER India, the cryogenic termination cold box is manufactured by the Swiss company Linde Kryotechnik AG. Installation in the cryoplant began in early July and should be completed by the end of this month.

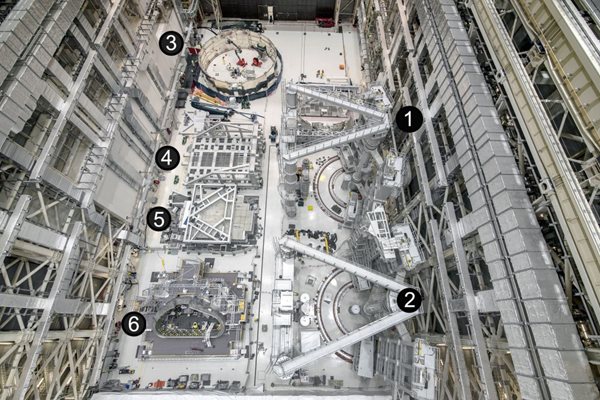

Pre-assembly activities | Captured from on high

With assembly tools standing 22 metres tall, massive bridge cranes straddling the width of the building, and alien-shaped components placed at regular intervals on its perfectly smooth floor, the ITER Assembly Hall is the place where one takes full measure of the size and complexity of the ITER machine. These images captured from on high show the many ongoing activities in the hall, from the finalization of the works on the silver-plated lower cylinder thermal shield at one end of the 97-metre-long building, to the equipment of the vacuum vessel sector at the other. 1 — 2: The twin sector sub-assembly tools (SSATs) will pre-assemble each vacuum vessel sector with its thermal shielding and a pair of toroidal field coils. 3: The silver-plated lower cylinder thermal shield (20 metres in diameter, 50 tonnes) will fit inside the soup-dish-shaped depression of the cryostat base to form a heat barrier protecting the magnets at superconducting temperature. It will be inserted into the assembly pit near the end of the year. 4: The upending tool is tasked to handle the vacuum vessels sectors (440 tonnes) and toroidal field coils (360 tonnes). Once securely clamped into the massive steel structure, the components will be lifted, upended from horizontal to vertical in mid-air, unclamped and delivered into the arms of one of the SSAT tools for pre-assembly. 5: This steel structure is used to attach dummy loads to the upending tool. It is sitting on the pair of dummy loads that were used for testing the sector sub-assembly tools and the overhead crane load path. 6: Delivered to ITER on 7 August, vacuum vessel sector #6 is undergoing a number of installation activities prior to pre-assembly operations next year. The welding of approximately 800 diagnostic bosses has been finalized; now it is the turn of small studs and clips. 7: Both inboard and outboard sections of the vacuum vessel thermal shield have been placed into their respective lifting tools. Upending tests are scheduled in the coming days.