you're currently reading the news digest published from 19 Apr 2021 to 26 Apr 2021

featured4

press15

featured

Machine assembly | First magnet in place

When it travelled the ITER Itinerary last year, or during cold tests in the onsite winding facility, poloidal field coil #6 (PF6) felt rather large and massive. Although only 10 metres in diameter—compared to 24 metres for the largest of the six ring coils that circle the machine—the 330-tonne coil is particularly thick and bulky. But everything is relative. On Thursday 21 April when the coil was extracted from its support frame and lifted 25 metres overhead to be transferred to the assembly pit, the perception of its size changed dramatically: dwarfed by the huge volume of the Hall, it suddenly felt small—a steel frisbee slowly gliding through immensity. PF6 is thick and heavy because it has more conductor layers than any other poloidal field coil and more conductor turns per layer. Sitting at the bottom of the machine, it is known as the 'divertor coil,' whose main function is to create the null field point that allows the removal of helium ash from the plasma. 'In order to have zero magnetic field at the divertor null field point, the bottom magnet needs to generate a field equivalent in intensity to the one created by the plasma current—but with an opposite polarity,' explains Nello Dolgetta of the ITER Magnet Section. 'And this is the reason why, despite its relatively small diameter, PF6 is so heavy. Since the magnetic field is defined by the intensity of the electric current times the number of conductor turns, we have 30 to 50 percent more coil turns in PF6 than in the other poloidal field coils.' PF6 is a European procurement that, for organizational reasons, was manufactured in China by the Institute of Plasma Physics of the Chinese Academy of Sciences (ASIPP). 'The problem we faced was that the first two coils to be installed, PF6 and the much larger PF5, had to be delivered at almost at the same time,' explains Alessandro Bonito-Oliva, the Magnets Programme Manager at the European Domestic Agency Fusion for Energy. 'As there was not enough space in the on-site winding facility to install two parallel production lines we discussed the issue with different Domestic Agencies and eventually determined that ASIPP was the best potential supplier.' Finalized in September 2019, the coil was seven years in the making. In Alessandro's words, it was a 'collective achievement of Europe and China, working together with the ITER Organization to manufacture a first-of-a-kind component that presented a number of technical and organizational challenges.' The coil shipped from Hefei by barge in March 2020, sailed the Yangtze River to Shanghai, and reached the French port of Fos-sur-Mer in June. In order to allow for transport to the ITER construction site, a few portions of the ITER Itinerary had to be adapted or enlarged. The lifting, handling and installation of PF6 on 21 April 2021 was an eight-hour operation that required a complex rigging system capable of rotating the coil and positioning it to within 4 millimetres of tolerance. Composed of a 92-tonne dual crane heavy load beam (also used to lift the first vacuum vessel sector), a 42-tonne lifting frame, and a set of lifting adapters, the rigging brought the total load to approximately 480 tonnes—the third heaviest lift after the cryostat base and vacuum vessel sector #6, transported in May 2020 and April 2021 respectively. On the day before the operation the team performed a lift test, and assessed the risk of not compensating the slight imbalance in the component's centre of gravity caused by a one-tonne feeder interface that sticks out from under the coil on one side. 'The slight tilting of the coil during the lift did not exceed one degree and remained within tolerance,' explains Jens Reich, the head of the Ex-Vessel Delivery & Assembly Division, as the coil settled on its supports in the late afternoon. 'Everything went perfectly smoothly.' Coming after the cryostat base, cryostat lower cylinder, lower cryostat thermal shield and first vacuum vessel sector, the installation of PF6 was the fifth heavy lift of the machine assembly sequence. 'The lessons we learned are many,' adds Jens. 'From an organizational point of view, it was very important to precisely define who is responsible for what at each point of the installation sequence. A strong interaction with our contractors is a pre-condition to avoid any misunderstandings. But above all, what the experience confirmed is the absolute need to test and rehearse, especially when we have to operate such a complex rigging as the one we used in the PF6 operation and will use again for PF1 and the 1,000-tonne central solenoid.' PF6 will remain on its temporary supports for a few years, pending the installation and welding of all nine vacuum vessel sub-assemblies. Once this is completed, the hydraulic system of the temporary supports will slightly lift the coil to anchor it to the toroidal field coil superstructure. A similar sequence will be followed for the next poloidal field coil (PF5, 17 metres in diameter), which is due inside the pit this summer. See a report on the Fusion for Energy website.

Networks | Ensuring real-time distributed computing at ITER

Many of the control systems at ITER require quick response and a high degree of determinism. If commands go out late, the state of the machine may have changed in the interim, rendering actions useless—and maybe even detrimental. Dozens of computers take part in the tight control loops of measuring, processing, ordering and acting. Most of the control systems (and some other systems) at ITER depend on a platform that enables collaborative processing at the rate of around 1000 operations per second, with a guaranteed delay. 'The requirement for reaction time is 10 microseconds,' says Bertrand Bauvir, Leader of the Central Control Integration Section. 'We can take data in at 10,000 times per second, process it and send commands out. One challenge is to perform the necessary amount of computation on time, because some of the algorithms are fairly complex.' Off-the-shelf technology and skilled software developers The Central Control Integration Section is responsible for the integration and verification of hardware and software components delivered by ITER Member states to guarantee that each piece is able to cooperate seamlessly over the deterministic communication infrastructure. A large part of the integration work involves maintaining the communication network that guarantees the travel time of a message from one computer to another. This guarantee must hold even for multicasting—when a message has to be replicated and sent to more than one other computer. Fortunately, many other organizations have had similar needs—and the real-time networking required by ITER can be achieved with careful software and network design, based on well-vetted commercial-off-the-shelf Ethernet network components. One interesting fact about potential bottlenecks on the network is that it takes more time for light to travel through the optical fibres connecting the buildings to the server room than it takes for an Ethernet switch to replicate and forward a message to multiple destinations. This is because light travels around 1.5 times slower through an optical fibre than in a vacuum, resulting in a best-case latency over optical fibre of about 5 microseconds per kilometre. By contrast, high-performance cut-through Ethernet switches can achieve sub-microsecond packet forwarding time. Another large part of real-time distributed computing is the operating system used on each system. Most do not guarantee a response time, so ITER relies on a real-time version of Red Hat Linux that has been widely used for years. 'All contributions from the Member states have to meet our performance and latency requirements—and all software must behave in a way that does not hinder the performance of other systems connected to the real-time communication network,' says Bauvir. 'We set standards, starting with how to physically connect to the network and how to communicate. Suppliers have to buy the right computers and run the right operating system. They also have to use our software libraries for communication.' But even with standards and guidelines—and good software engineering in different parts of the world—the overall performance of the distributed real-time control function depends on each component collaborating seamlessly. So when a control system component is delivered, Bauvir and colleagues perform verification and commissioning, including quality assessments and functional checks. Bertrand Bauvir is looking forward to seeing it all work. 'Until now we have been integrating what we call utilities,' he says. 'These are control systems for monitoring and distributing electrical supply, cooling water, and so on. In the next six months we will begin to integrate and commission the first equipment that participates in the real-time control of the machine. We will be hooking up the very first real-time computers; many more will follow in the coming years.'

Fusion codes and standards | Award for ITER Japan's Hideo Nakajima

Hideo Nakajima, a senior engineer at ITER Japan, has received an award from the Japan Society of Mechanical Engineers (JSME) for his contribution to the development of codes and standards for fusion facilities. The JSME Codes and Standards Award for International Achievement recognizes outstanding contributions to international exchange, the improvement of international codes and standards, and the development of standardization activities in Japan. The ultimate goal of JSME's codes and standards activity is to establish a construction code for a future fusion facility. A code consists of general requirements and rules for materials, design, fabrication, nondestructive examination, pressure and leak testing, etc. The development of a construction code for ITER, which would define the codes and standards that would ensure the safety and structural integrity of ITER components, started in Japan even before the site selection process was concluded. In July 2002, a Subcommittee on Fusion Reactors was established under JSME's Main Committee on Power Generation Facility Codes, and work began on the development of rules for the vacuum vessel. Once the Procurement Arrangement for toroidal field magnet structures was signed in 2008 between ITER Japan and the ITER Organization, the group turned to the development of rules for superconducting magnet structures, editing the first Japanese and English editions in 2008 followed by revisions in 2013 and 2017. With 30 years of experience in the development and evaluation of cryogenic structural materials, Hideo Nakajima's contribution to material standards—which designated design yield and tensile strengths from room temperature to liquid helium temperature (4K) of JJ1 and 316LN steels used in the coil cases—was invaluable. Mr Nakajima also contributed to the development of the Japanese Industrial Standards (JIS) on testing methods in liquid helium for tensile, elastic-plastic fracture toughness, and fatigue tests of structural materials. Notably, a draft standard of the tensile test was developed in collaboration with the US National Bureau of Standards (currently, the National Institute of Standards and Technology). It was finally published as JIS in Japan, and the American Society for Testing and Materials (ASTM) standard in the United States, respectively. Data measured by ITER Japan according to these standards were also provided to ITER for the design of the ITER magnet system. The March 2021 award from the Japan Society of Mechanical Engineers specifically recognizes Mr Nakajima's career contributions to 'Codes for Fusion Facilities/Rules on Superconducting Magnet Structures.' He received a commendation certificate and award plaque on 23 March 2021.

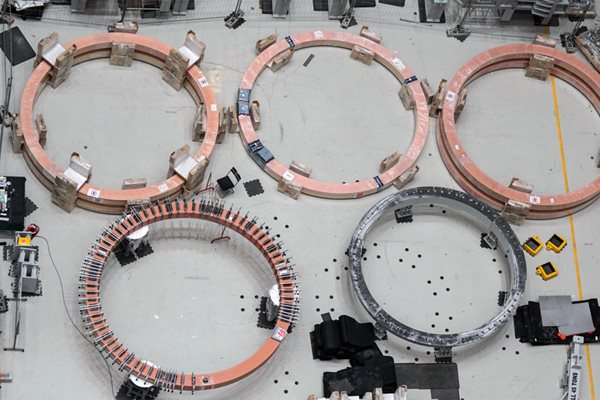

Image of the week | Teams prepare ITER Games?

Arranged unexpectedly in a configuration that can only remind us of the Olympic Games, six pre-compression rings in the ITER Assembly Hall are being prepped for installation. The ITER Organization has its own tradition of 'games'—the ITER Games, which have been held in the nearby village of Vinon-sur-Verdon in collaboration with local sporting clubs since since September 2011. The last edition in 2019 attracted more than 650 participants. The 2020 edition was cancelled because of the pandemic and no one can say if the Games will be back this year. The spirit, however is alive, albeit symbolically... (Photo courtesy Bruno Levesy)