you're currently reading the news digest published from 21 Jun 2021 to 28 Jun 2021

featured3

of-interest1

press22

featured

Components | The fine art of preservation

To keep components and materials in good condition prior to entering service, a set of actions needs to be performed. These activities, which are specific to a given piece of equipment, are collectively referred to as 'preservation activities.' At ITER, equipment passes through three preservation stages from delivery to commissioning. Stage one, under the responsibility of Integrated Logistics Management (ILM), begins when a component arrives on site and is placed in storage. Stage two begins when equipment is issued from storage and put in the care of the works contractor for installation. Stage three covers the period after installation, but prior to commissioning. During this third stage, responsibilities typically fall under the general services contractor or a maintenance contractor. A small central preservation team coordinates the preservation activities and tracks the equipment over the three stages, 'We liaise with the responsible parties during each of the stages to make sure the equipment has clearly defined preservation requirements, and a responsible party is assigned to perform the activities,' says Richard Brown, Maintenance Management Officer in the Operations Division. 'We also make sure the activities are planned and scheduled, and that any issues that are uncovered are recorded and followed up.' Preserving captive components Preservation is particularly critical for 'captive' components that may need preserving for a decade or longer before entering service. A captive component is typically a large item that, once installed, can no longer be easily removed. It is closed in either by a building structure or by other large equipment. Examples of captive equipment are the cryostat support bearings (CSBs) and the four large tanks in the drain tank room. The 18 bearings, each about the size of a dining room table, are installed in the Tokamak pit. These bearings allow some relative movement in the cryostat to buffer expansion due to temperature changes, or excessive loads that hit the vacuum vessel in the cryostat. The preservation activities include regularly monitoring the air humidity conditions in the Tokamak pit and performing visual checks for signs of grease, moisture or other aggressors. Preservation activities for the four large stainless-steel tanks include performing visual inspections to check for any signs of corrosion, and to ensure that the tanks are protected from any co-activities that could result in cross-contamination. For example, particular care needs to be taken to ensure that the stainless-steel tanks are not contaminated by dust from other forms of steel—a real risk when somebody is cutting or working with carbon steel as part of construction activities in the area. Tracking all preservation activities 'Some of the activities may seem rather simple,' says Brown. 'They are nevertheless critical to ensuring the equipment is retained in good condition, and to reducing the risk of problems occurring when the system is commissioned. For example, motors and pumps need to be turned regularly to avoid brinelling (the permanent indentation of a hard surface) of the bearings, valves have to be greased and operated to avoid seizure, and vessels need to be kept inerted (filled with inert gas to keep air from coming in and moisture from developing) to prevent corrosion. The challenge is to keep track of all activities and ensure the responsibility for executing them is clear at all stages.' Over time, preservation will become more challenging. More first-of-a-kind equipment will be installed as assembly and construction progresses. This means that both the volume, but also the complexity of preservation activities, will increase substantially. 'In addition to managing the preservation activities associated with conventional plant equipment, we will also have some preservation requirements that are quite specific to ITER systems,' says Brown. 'For example, the gyrotrons used in the electron cyclotron heating system must have the quality of the vacuum maintained during long term storage. This means the internal ion pump must remain connected to a high voltage power supply. For cases like this we have to make sure that the correct provisions are in place before the items are received on site.' To stay on top of all activities, the preservation team helped define a process that starts before equipment is delivered on site. Before delivery, the technical responsible officer (TRO) ensures that the preservation requirements are defined and available. Usually, these are based on the original manufacturer's recommendations, but in cases where nothing is prescribed by the manufacturer, the TRO relies on standard guidelines for the type of equipment to write the preservation requirements. 'The preservation team ensures that the requirements are clearly communicated to whoever is responsible for performing the activities, and that any findings from the activities are reported,' says Brown. 'Last year we began using a set of key performance indicators to help monitor progress and help everyone to understand what parts of the process we need to improve.' New software provides real-time reporting and information sharing To help improve the overall implementation of the process, ITER is rolling out a new piece of web-based software called SPMat Mobile Companion, which will allow real-time reporting on preservation activities in the field. The software runs on any tablet or handheld device to allow technicians to record the activities directly. The new system will also allow TROs to get more up-to-date reports on the preservation activities carried out on their equipment. The software includes a workflow engine that allows people to schedule tasks, define to-do lists and receive alerts to stay on top of activities. The new system provides better traceability and auditability, especially for safety-critical, protection-important components. 'We went live with the new software in May,' says Brown. 'We are steadily expanding the scope of the equipment managed in the new tool, and we are training users. The new software makes it easier for people in the field to perform preservation activities, and it provides more detailed and up-to date information for equipment owners.'

Image of the week | First central solenoid module on its way

It's a long way from San Diego to Houston. From the Pacific shores to the Gulf of Mexico, the road stretches approximately 2,400 kilometres through Southern California, Arizona, New Mexico and the better part of Texas. The itinerary could be that of a road movie—vast desert expanses, lone gas stations, endless strips of asphalt... On 21 June, the first module of the tokamak's central solenoid—the 'beating heart' of ITER—left the General Atomics factory in the San Diego suburbs to embark on the first leg of the long journey to ITER. The convoy transporting the 4.3-metre-wide, 113-tonne module is scheduled to reach the port of Houston this week. Procured by US ITER, the component is expected at Marseille harbour in August and on site the following month. Click here to view a TV coverage of the convoy's departure and an interview of General Atomics' Director of Engineering and Projects, John Smith.

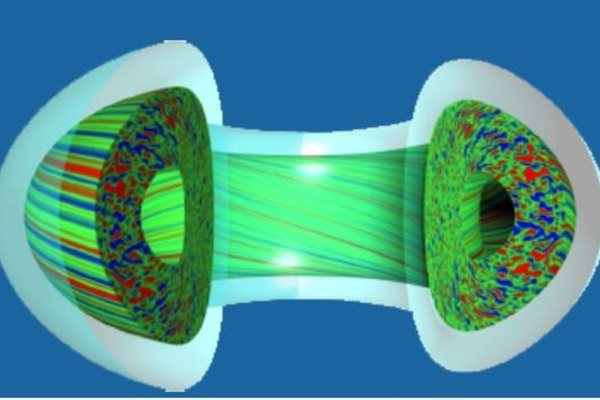

Plasma heating | Japan completes gyrotrons

To achieve extreme temperatures in the core of the plasma, ITER will rely on three external heating systems. One of them—electron cyclotron resonance heating—relies on the electromagnetic-wave-generating power of 24 slim, silver gyrotrons. Gyrotrons have been in development for decades as scientists worked to bring their performance to the levels required at ITER. Now, high-power, high-frequency gyrotrons are a reality. Of the 24 required gyrotrons, Japan has been tasked by the ITER Organization with fabricating 8. The National Institutes for Quantum and Radioactive Science and Technology (QST) and Canon Electron Tubes & Devices Co., Ltd. (CETD) have completed the full manufacturing scope, and the four gyrotrons required for installation before First Plasma have passed all testing. QST and CETD began the research and development of gyrotrons in 1993, and by 2008 they had developed the world's first gyrotron satisfying ITER's power requirements. After further adjustments to increase the durability of the gyrotrons, manufacturing began and the eight devices assigned to Japan were completed in May 2021. Before the gyrotrons can be shipped to France, they must undergo rigorous performance tests. The gyrotron must withstand prolonged use under intense conditions and generate enough power to heat the plasma and maintain efficiency. Gyrotron testing at ITER requires electrical efficiency of more than 50% (50% of input electric energy converted to electromagnetic-wave power), and the success rate of repeated gyrotron operation must be at least 90%. Now that four of Japan's gyrotrons have passed testing, plans are being made to transport them from their nests at QST to the ITER complex. The ultimate goal is to have all eight gyrotrons on site by 2024. Once the gyrotrons arrive, they will be installed as part of the electron cyclotron resonance heating (ECRH) system, one of three methods (alongside neutral beam injection and ion cyclotron heating) ITER will use to heat plasma to its required temperature. ECRH works by heating electrons through intense beams of electromagnetic radiation, which can be directed to heat specific areas of plasma as needed. The gyrotrons wait in their boxes now, cool and silent in their dormancy. But soon, as pieces of the ITER machine come together, they will hum with energy and ignite First Plasma. Please see the original press release in Japanese. Read more about the ITER gyrotrons here.

of-interest

IAEA Technical Meeting on Fusion Data Processing announced

IAEA Technical Meeting on Fusion Data Processing, Validation and Analysis will take place from 30 November to 3 December 2021 in Chengdu, China, with both in-person and remote participation foreseen. The objective of the meeting is to provide a forum for discussing topics of relevance to fusion data processing, validation and analysis with a view to addressing the needs of next-step fusion devices such as ITER. The validation and analysis of experimental data obtained from diagnostics used to characterize fusion plasmas are crucial for a knowledge-based understanding of the physical processes governing the dynamics of these plasmas. The meeting aims, in particular, at fostering discussions about research and development advancements in these topics made in the current major fusion confinement devices. A special focus will be placed upon data analysis for ITER and DEMO, with particular attention paid to opportunities for the use of Artificial Intelligence for control activities. More details, including how to contribute, can be found here.