you're currently reading the news digest published from 30 Aug 2021 to 06 Sep 2021

featured5

of-interest2

press16

featured

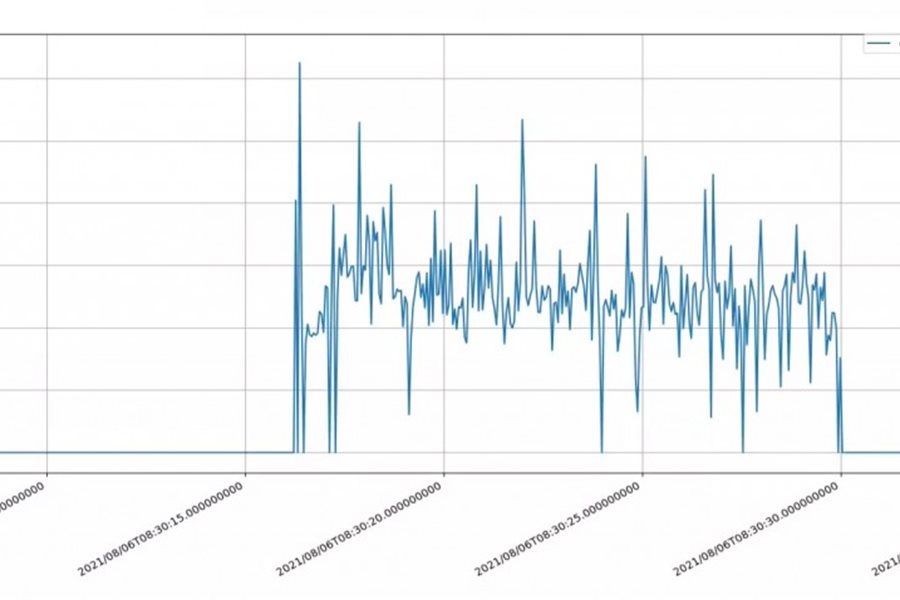

Control systems | Diagnosing the plasma in real time

To do its job well, ITER's plasma control system will need reliable real-time measurements from diagnostic systems. Engineers from the Controls Division have developed a high-performance software base, called a real-time framework, that can facilitate the development and deployment of complex real-time applications such as these. Recent tests on a Thomson scattering diagnostic on the KSTAR tokamak in Korea show that the framework functions successfully in real-world applications. The ITER plasma control system will ensure that each pulse is executed correctly by using data it receives from diagnostic sensors to apply sophisticated algorithms, which in turn generate the commands that control plasma characteristics. Measurements, calculations and actions must be performed precisely on time—something that the operating systems and software that we use in our everyday lives, which are not deterministic, could never guarantee. For ITER's strict time requirements a real-time operating system is required, with mechanisms for managing execution time. The design, development and verification of real-time software is a complex and often lengthy process requiring multiple iterations until all timing relationships are satisfied and the application is stable and predictable. 'This complexity is why the ITER CODAC group has chosen to design and develop a dedicated real-time framework (RTF),' says Control Systems Integration Engineer Woong-Ryol Lee. 'The RTF is a flexible high-performance software base that facilitates the development and deployment of complex real-time applications. Originally developed with the aim of control algorithms, the RTF can also be the basis for real-time data processing applications in ITER diagnostic systems.' In the first practical application of the framework, the Department of Microelectronics and Computer Science of the Lodz University of Technology (Poland)—in cooperation with the ITER CODAC group—has developed a RTF-based prototype system for Thomson scattering diagnostics data acquisition and processing. The system, readied by Dariusz Makowski, allows for acquiring data from a gigasample digitizer, processing real-time algorithms, archiving raw data using the ITER Data Archiving Network, and publishing measurements to the ITER Synchronous Data Network. The algorithms implemented in the system includes detection and integration of pulses in raw data from a Thomson scattering polychromator, noise estimation, and the calculation of plasma electron temperature. Early August, it was time to see the system in action. Thanks to the hospitality of the team responsible for Thomson scattering diagnostics at the KSTAR tokamak, the prototype RTF-based system was installed and configured, enabling functional and performance tests under real working conditions. The tests were important not only for the evaluation of the prototype Thomson scattering system itself, but also for the functionality and performance of the RTF and the developed algorithms. It was the first evaluation of a high-performance data processing application implemented using RTF for the needs of plasma diagnostics. The results obtained confirmed that RTF performs as expected, and that it can be used successfully in applications requiring multi-threaded high-performance data processing. 'The prototype Thomson scattering system using the RTF was able to process data and provide final measurements within 5-6 ms, which is fully enough for a system working with a 20-50 Hz repetition rate,' says Lee. 'Moreover, the RTF hides many details specific to real-time systems (e.g., thread management, inter-thread data transfers, etc.), making the design and development of real-time software much easier and faster. The developed prototype—covering complete data acquisition, the processing path, archiving, as well as measurement publishing—can be used as a reference example for other ITER diagnostic systems.' Due to the limitations associated with the COVID-19 pandemic, the tests were performed remotely. The KSTAR team was responsible for hardware and on-site actions, while the team from Lodz and ITER staff operated the system remotely. 'This was also a great opportunity to invite young students from all institutions involved in the tests to attend the two days of the testing campaign,' says Lee. 'By sharing the experience with students who are at the beginning of their professional careers, and giving them the opportunity to observe science in action, we hope to encourage them to become valuable members of the fusion community.' Participants in this 'real-time' success include Woong-Ryol Lee, Anze Zagar, Stefan Simrock, and Mikyung Park of the ITER Organization; Piotr Perek, Milosz Kadziela, and Dariusz Makowski from the Department of Microelectronics and Computer Science of the Lodz University of Technology; and Jong-Ha Lee, Ha-Jin Kim and Seung-Ju Lee from KSTAR.

Engineering | US to deliver "tough" electronics to ITER

ITER, a machine that will imitate the sun, will also mimic the sun's extreme environment: intense heat, strong magnetic fields and radiation. A team at US ITER has been toughening up critical components of ITER's vacuum system so they can withstand those harsh conditions. Neutrons, an energetic by-product of the fusion reactions in the ITER device, will not travel in docile single file as they leave the plasma. When running at full power, ITER's plasma is projected to generate billions and billions of neutrons*, each one with 14.1 MeV (mega-electron-volts) of energy. Shielding reduces the neutron flux, but neutrons are sub-atomic in size and can scatter and slip between the atoms in concrete. The shielding reduces the number of neutrons to about a million per second per square centimetre outside the protective bioshield. 'Five hundred megawatts of plasma power will be a sustained radiation environment that the fusion community hasn't experienced before,' says US ITER's Kurt Vetter. Vetter leads the teams for electron cyclotron and ion cyclotron heating transmission lines and for instrumentation and controls. Vetter's group has been designing and building the radiation hardened ('rad hard,' for short) electronics supporting ITER's vacuum auxiliary system. The electronics will be mounted at 68 locations just outside a protective bioshield to monitor the vacuum system for leaks and other potential issues. US ITER engineers are not the first to face this problem. Aviation and aerospace engineers need to design around the effects of cosmic radiation in the upper atmosphere and space. On Earth, numerous smaller fusion devices have contended with neutron-yielding plasmas. But radiation from those experiments is orders of magnitude smaller than what ITER will generate. Neutrons, while short-lived, are a source of both direct and indirect radiation immediately around the tokamak. ITER will restrict access to this area and further protects staff and instrumentation with a 3.2-metre-thick concrete bioshield. But some of these neutrons, and the gamma rays they spawn when interacting with the cooling water around the tokamak, can still threaten nearby equipment. Consequently, sensitive components need to be rad hard—designed and built with years of radiation exposure in mind. That includes the vacuum auxiliary system components being delivered by US ITER. * Their precise amount has been calculated. It is in excess of 1.77 multiplied by 10 followed by 27 zeros... Continue reading the article on the US ITER website.

Image of the week | The lighthouse in the pit

Like a lighthouse (without a beacon) the central column rises more than 20 metres above the floor of the assembly pit. The massive structure does not belong to the tokamak, however: once connected to an array of nine radial beams it will form the backbone of a 600-tonne temporary tool that will support, align, and stabilize the vacuum vessel sub-assemblies as they are joined and welded. The tool is designed to support a total nominal weight of 5,400 tonnes. On 27 March 2021, the first and sturdiest segment of the central column (the 70-tonne bottom cylinder) was lowered into the assembly pit and carefully inserted into the circular opening at the bottom of the cryostat base. Metrology confirmed that the structure was placed within 2 millimetres of its nominal position inside of the Tokamak Global Coordinate System (TGCS). Five months later, on 20 August, the remaining four sections were successively installed and assembled, bringing the column to its full height. Each of the nine radial beams will be supported by the central column on one side and the concrete bioshield on the other through brackets embedded in the L2 level of the bioshield wall. On 30 August, the first of these brackets, called a radial beam support, was successfully installed in port cell #12. Everything is in place for a first 'insertion' test. Later this week, the overhead cranes will lift a test radial beam (without its load) and insert it into the Tokamak pit in order to confirm the alignment between the central column and the radial beam support. This is one of the 27 steps leading to the installation of the first 1,200-tonne vacuum vessel sub-assembly, planned for late October.

Cryolines | India's INOXCVA completes full scope

All angles, bends and turns, a complex system of cryolines produced in India will distribute the cooling power generated by the ITER cryoplant to clients throughout the installation. Four years after manufacturing was initiated, the last batch left INOXCVA's Vadodara facility in July 2021. Cryolines begin their long journey in the ITER cryoplant—where the cooling fluids are produced—and continue along an elevated bridge to the Tokamak Building about 100 metres away to bring cryogenic fluids to the machine's magnets, thermal shield and cryopumps. Ranging from 25 to 1000 millimetres in diameter, cryolines can host up to six or seven process pipes that are devoted to a specific fluid, flow direction or function; each process pipe is carefully and individually insulated to prevent thermal losses. Shipped in spools, or sections, cryolines are connected on site by highly trained welders. More than 500 sections in all will be installed in the Tokamak Complex. INOXCVA India, a company with a quarter-century of experience in cryogenics, was responsible for manufacturing approximately 4 km of cryolines (operating at temperatures ranging from -269 to -193 °C) and about 6 km of return lines for warm gases. The manufacturing of spools began in 2017 in a specially constructed workshop complete with a clean room devoted to the most delicate and sensitive operations. (See this 2019 report from the factory floor in Vadodara.) The last batch, sealed under a pressurized nitrogen atmosphere and tightly wrapped in protective material, left the company's Vadodara facility on 29 July 2021. A small ceremony to mark the milestone was remotely attended by Sh. K.N. Vyas, Secretary, Department of Atomic Energy; Bernard Bigot, Director-General of the ITER Organization; and Shashank Chaturvedi, Director of the Institute for Plasma Research. This brings the Indian Domestic Agency closer to completing one of its largest procurement packages—cryolines and cryodistribution, second only in value to the procurement of the ITER cryostat. See photos of the event here.

Toroidal field coils | Eight now on site

With eight D-shaped magnet coils on site and two travelling, the project has officially passed the halfway mark in the procurement of 19 toroidal field coils. Eighteen toroidal field coils, placed vertically around the ITER plasma chamber, will produce the magnetic field that will confine the plasma particles; a nineteenth will be supplied to the project as a spare. The coils will be associated by pair with each vacuum vessel sector. Two tools have been erected in the ITER Assembly Hall for this sub-assembly activity, and the first operation is underway on vacuum vessel sector #6. From niobium-tin conductor supplied by ITER Members China, Europe, Japan, Korea, Russia and the United States, two procuring agencies—the Domestic Agencies of Europe and Japan—are carrying out the complex winding and casing tasks necessary to delivering the final coils. On Friday 3 September, the European agency Fusion for Energy delivered TF6—the eighth coil to arrive on site. To date, five coils have been delivered by Europe and three from Japan; another two Japanese coils are travelling toward ITER now. One of ITER's longest-lead procurement programs has reached the halfway mark in terms of deliveries.

of-interest

European Fusion Teacher Day 2021: 1 October

The European Fusion Education Network, FuseNet, is organizing its second annual European Fusion Teacher Day on 1 October 2021. Open to all secondary school science and physics teachers in Europe, the virtual event aims to introduce educators to nuclear fusion and exchange about how the subject can be taught in school. The ultimate goal is to increase exposure of students to the subject at the secondary level in order to spark interest and enthusiasm in the field.Because the event is open to educators across Europe, the half-day program begins with local sessions via Zoom. After the local sessions, participants will come together for a global livestream from 15.00-17.00 CEST before returning to a local follow-up session. The ITER Organization is one of the featured participants during the global livestream. Participation is free and registration is open now. See this page to learn more.Three hundred teachers participated in last year's event. Read more about the first European Fusion Teacher Day here.

Fusion-based intellectual property filings on the rise

The journal Fusion Engineering and Design has published an article reporting research done by George Washington University's Business School on the growth of fusion patent filings. This paper, written by Elias G. Carayannis and John Draper, and entitled 'The growth of intellectual property ownership in the private-sector fusion industry,' examines the increase in applications for fusion-related patents over the past several years. In particular, Carayannis and Draper focus on the patents of Fusion Industry Association (FIA) members. FIA is a US-based trade association and brings together private-sector fusion energy companies. This paper not only examines how many patents these FIA members have introduced, but also organizes the patents by type to show the variety of technology being created and protected as intellectual property. Most of these patents have not yet been granted, but the increase of filing activity highlights the rapid expansion of fusion projects and technology in recent years. See the full article here. (Elias G. Carayannis, John Draper (2021), The growth of intellectual property ownership in the private-sector fusion industry, Fusion Engineering and Design, Volume 173, 112815, ISSN 0920-3796.)