you're currently reading the news digest published from 11 Oct 2021 to 18 Oct 2021

featured3

of-interest1

press16

featured

Cooling water plant | Partners work in lockstep to keep ITER cool

Much of the cooling water plant is now ready for commissioning, thanks to a well-executed plan and close coordination among partners. 'Sooner or later, all heat from the tokamak, the plant and the ITER buildings is released into the atmosphere,' says Alfonso Marquez, Section Leader for plant installation. 'Cold water is pumped out to different clients and buildings, where it picks up the heat. The hot water is then circulated back to our plant, where it is cooled down through a series of steps.' Cooling water circulating under pressure through the ITER installation is responsible for removing the heat load from the ITER vacuum vessel, plasma-facing components, auxiliary and plant systems, and even ITER buildings. Once it has collected the heat, the water is brought down in temperature progressively, circulating through the heat exchangers, the hot basin and finally the cooling towers of the cooling water plant before it is re-injected into the cooling circuit to begin all over again. One of the principle challenges of the cooling plant was designing a system that could handle the huge, but intermittent head loads resulting from the operation of the tokamak, as well as the more 'conventional' demands of the facility and plant. A smart design reduces costs and uses less space The maximum flow of water through the plant is 7,700 cubic metres of water per second—a rate that is reached only during a pulse. 'Because ITER is an experimental reactor, the cooling water plant had to be designed for a pulse that lasts less than one hour,' says Marquez. 'Instead of having a cooling tower two times bigger—that is more expensive and takes up more space—we have a smarter system, which has a smaller footprint and releases the heat load over time. If we had to serve a commercial reactor, where this peak power is maintained, the approach would have been very different. Heat would be generated constantly, and that heat wouldn't be released into the atmosphere—it would be used to generate electricity.' The cooling towers are designed to release a maximum of 500 MW. During a peak, rather than try to process all the heat contained in the hot water at once (1145 MW), some of it is stored in a 9-metre-deep basin, which serves as a heat sink. From there, it is pumped progressively into the cooling tower. Like in any other cooling tower, the conditions are ideal for scaling, bacteria and legionella to grow. To prevent this, ozone and other chemicals are injected into the pipes and cooling tower basins. A well-orchestrated project pays off As part of its commitments to ITER, the Indian Domestic Agency is responsible for the design and fabrication of the heat rejection system. The European agency Fusion for Energy prepared the physical site for the system, excavating and creating the concrete basins and structures. The ITER Organization is responsible for installing all equipment. Many of the components procured in India are too heavy or too large to be shipped in a single piece. The vertical pumps or the cooling tower fans, for example, were tested and commissioned in India before they were taken apart again and shipped in smaller pieces. 'This is what we call 'completely knocked down conditions,' meaning the components were disassembled before being shipped,' explains Marquez. 'Of course, the Indian Domestic Agency also sent us procedures for reassembly. Each of the 13 pumps consists of around 300 components, and we had about one million parts for the cooling towers. We had to involve a specialist contractor, a supplier from Europe, who supported us in assembly. It took 6 months to reassemble the pumps and another 18 months for the cooling towers.' 'The project plan was designed so that work never stopped,' explains Marquez. 'This required a great deal of coordination among different partners. A deviation of two or three days would have led to down time, which costs a lot of money. Fortunately, the Indian Domestic Agency coordinated supplies to a precision of less than a week to keep the contractors here busy. This was challenging, but we succeeded.' 'The first plant building that needs cooling service will be the cryoplant, so the Operation Division has begun commissioning that part of the plant first, 'says Marquez. 'The last thing that needs to be commissioned is the part that cools the ITER Tokamak. The Operation Division is expecting to finish all commissioning one year from now. The cooling water plant will be operational by the end of next summer.'

Contract management | E-procurement helps to simplify and streamline

The Procurement & Contracts Division at the ITER Organization is rolling out a new e-procurement tool that will simplify and streamline contract management and free the team up to do more of what it does best ... adding value to the project through closer collaboration with stakeholders and commercially savvy relationships with contractors. At the ITER Organization, a team of 40 manages the award of approximately EUR 400 million of contracts per year. After a focus in recent years on the major assembly construction contracts, the team is now shifting over to the performance management of the contracts, their amendments and claims, and working to ensure on-time execution. There are also new strategies to define, new contracts to tender and award in the engineering and science/operation domains, and one last large construction site contract to open for competition—the Hot Cell Complex (launch expected in 2022). These are document-heavy activities that, in the past, Procurement & Contracts would have managed across a number of internal software platforms. But as part of a new push for corporate digitalization, the division has introduced an e-procurement tool that creates a centralized source for procurement managers, suppliers and ITER stakeholders alike, offering significant synergies and reducing the quantity of manual and repetitive actions. 'As a public organization, ITER needs absolute transparency and traceability in its procurement processes, and we need to be able to prove fair treatment in the competitive process,' stresses Christophe Dorschner, who heads the Procurement & Contracts Division. 'Everything we can do to streamline and improve our processes helps us to support the delivery of the ITER Project.' The Division's new electronic procurement tool, 'I-PROC,' is based on SAP's Ariba solution—an industry-standard used widely around the globe. The team has intentionally sought to remain within the boundaries of the tool, instead of creating a bespoke ITER version. 'We are adapting our way of working and approach to the tool, instead of the reverse,' says Dorschner. 'This is time and money saving, and also ensures that we are moving toward simplifying, not complicating, our procurement processes.' The team worked with outside consultants to create the initial technical specifications and to configure the tool; it also benefitted from extensive support from ITER's Information Technology (IT) Division. Daphne Crowther, the Division member responsible for the e-procurement project, emphasizes that less time spent in manual operations related to document management and traceability frees up time for human interaction. 'We are bringing more value to the contract negotiation process by focusing on research and supplier sourcing at the front end of each tender, and on negotiation, risk management and efficiency once the supplier has been selected. Having a centralized tool also helps us to better support the contract responsible officers across the organization during the execution of the contract, and facilitates our interaction with ITER stakeholders in the legal, finance, quality project control units.' The roll out of I-PROC began on 15 September in selected departments, part of a phased introduction that will allow the team to clear any bugs in the system—hand in hand with user—as they arise. 'We have to train approximately 350 users inside our organization, as well as accompany at least 400 active suppliers during this transition,' says Crowther. Procurement & Contracts describes the adoption of a new e-procurement tool as a 'transformative' project that ensures that the ITER Organization is keeping up with best practice in the procurement domain. 'The Procurement & Contracts Division now has a tool that is better suited to the project phase ahead, where we expect lots of intense interaction with suppliers and contract responsible officers, says Nagaich Nalinish, who heads the Corporate Domain. 'It is also the first step in a larger corporate effort to advance the digitalization of the ITER Organization, and to simplify and declutter our processes.'

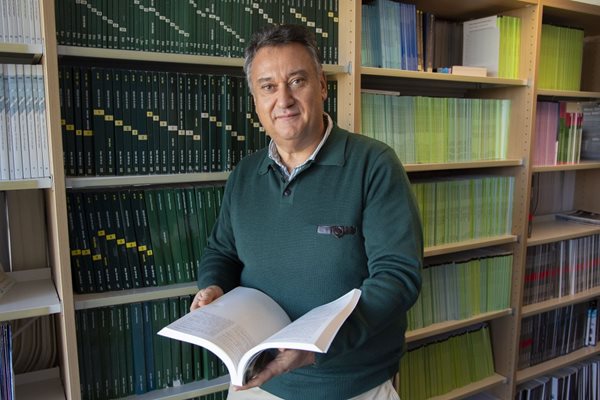

American Physical Society | Alberto Loarte elected Fellow

Alberto Loarte, head of the ITER Science Division, has been elected as a Fellow of the American Physical Society (APS). Loarte was nominated by the APS Division of Plasma Physics (DPP). In the Fellowship citation he is recognized for 'seminal contributions to the understanding of phenomena controlling thermal and particle fluxes to material surfaces in magnetically confined systems including plasma detachment, edge-localized modes, and their control.' The APS Fellowship Program recognizes members who may have made advances in physics through original research and publication, or made significant innovative contributions in the application of physics to science and technology. They may also have made significant contributions to the teaching of physics or service and participation in the activities of the Society. Fellowship is a distinct honour signifying recognition by one's professional peers. Each year, no more than 0.5 percent of the Society's membership (excluding student members) is recognized by their peers for election to the status of Fellow of the American Physical Society. The team Loarte leads at the ITER Organization is responsible for developing the ITER Research Plan, the Plasma Control System and associated algorithms, and building a world class integrated modelling and analysis infrastructure, the Integrated Modelling and Analysis Suite. The team also actively coordinates physics R&D activities to support the ITER Research Plan with the fusion communities of the ITER Members through the International Tokamak Physics Activities (ITPA), the ITER Scientist Fellow Network, and the Monaco-ITER Postdoctoral Fellowship Program. Loarte earned a PhD in Atomic and Nuclear Physics from the Universidad Complutense de Madrid, Spain, and carried out his PhD and postdoctoral research at the Joint European Torus (JET). He started his long-term association with ITER at that time when he was appointed member of the ITER Physics Expert Group on Divertor Modelling and Databases in 1994. After that, he joined the EFDA-Close Support Unit at the Max Planck Institut für Plasmaphysik in Garching, Germany, where he was responsible for the EFDA Technology Programme in the area of plasma-wall interactions for ITER. In 2008, he joined the ITER Organization's Science Division and continued his involvement with the ITPA as co-Chair of the Edge Plasma and Pedestal Physics and Transport and Confinement topical groups. Loarte is co-author of 762 papers in peer-reviewed journals, which have been cited 20,245 times, and has played a leading role in the development of the edge plasma physics basis behind the design of the ITER Tokamak. The full list of 2021 APS Fellows can be consulted here.

of-interest

Fusion PhDs to gather in November

Join fellow fusion PhD candidates from all over Europe next month at the annual PhD Event organized by the European Fusion Education Network, FuseNet. The event, held on line from 22 to 23 November 2021, will feature high-profile keynote speakers, a top-notch scientific program and the much anticipate PechaKucha contest, where students present their research in 20 slides, 20 seconds per slide. There will also be moments to "gather" thanks to creative on-line offerings through the event platform Gather.town. Registration is open through 31 October 2021 here. See all information on the FuseNet website.