you're currently reading the news digest published from 14 Feb 2022 to 28 Feb 2022

featured3

of-interest3

video1

press57

featured

Tokamak assembly hold point | The next step in ITER licensing

In January 2022, the French nuclear safety regulator ASN (Autorité de sûreté nucléaire) issued a letter in which it stated that it could not release the ITER Tokamak assembly 'hold point' as was foreseen to happen on 1 February 2022, and requested some further clarifications. These 'hold points' are a customary part of ensuring the 'as-built' safety of any nuclear facility, after ASN provided the decree authorizing the creation of the ITER facility based on a design review in 2012. In this article, Newsline explains the hold point process. In 2012, ASN validated the proposed ITER design and signed the Décret d'autorisation de création of ITER as a nuclear installation. This step authorized the ITER Organization and its Domestic Agencies to proceed with construction, manufacturing, and installation of the ITER facility. However, as with any nuclear installation, ITER is required at each stage to demonstrate that its safety-relevant buildings, civil structures, systems and components conform to the approved design and meet the safety case in the 'as-built' or 'as-installed' condition. To oversee these aspects of safety, ASN has put certain 'hold points' in place as part of the normal regulatory process. For each such hold point to be lifted, ITER must first demonstrate the associated safety elements and receive ASN's approval. The specific hold point now under review was established by ASN in November 2013. Under this hold point ITER cannot begin to weld the first two sections of the vacuum vessel together in the Tokamak pit—an assembly step considered irreversible—until certain safety aspects related to the B2 slab (a 120-metre long, 80-metre wide, and more than 1.5-metre-thick mass of reinforced concrete supporting the Tokamak Complex Building) have been validated. First, ITER must demonstrate the as-built safety performance of this B2 slab. Second, ITER's radiological maps, which calculate the shielding effects of concrete and steel barriers that contain the radiation from the machine, must demonstrate that radiation levels will be safe wherever humans are present without requiring extra shielding material. Technical discussions and requests for information are a normal part of the process, especially in a 'First-of-a-Kind' machine such as ITER, which is also of course a 'First-of-a-Kind' facility for ASN. In its January letter, ASN outlined a number of issues that must be further addressed for this hold point to be lifted. Additional modelling of the B2 slab is needed to confirm that the 'as-built' masses supported by the slab will be safe under extreme conditions. Second, complementary explanation is needed on ITER's radiological maps to demonstrate that radiation protection requirements will be met. And ASN has asked for more analysis to validate the vacuum vessel welding process, to account for some limited dimensional nonconformities the ITER Organization has identified at the interface between the two vacuum vessel sectors now on the ITER site, which require adjustments to the robotic welding procedure. This ASN action has not impacted the ITER assembly schedule to date. As Newsline readers well know, the first full sector subassembly—consisting of the double-walled vacuum vessel sector, a tightly fitted thermal shield, and two toroidal field coils—has been completed and will be transferred into the Tokamak pit in the coming weeks. The fabrication of the second subassembly has begun, but it will take several months to complete, and still more time before it is inserted into the Tokamak pit and preparations can be made for welding. However, as with any such regulatory action, ITER takes these ASN concerns very seriously. Experts are vigorously preparing the additional information and analysis required, with the goal of providing key answers to the ASN during the second quarter of 2022. As Director-General Bigot has stated recently, he is hopeful that this will allow ASN sufficient time to consider the additional information and release the hold point without impacting the ITER assembly schedule.

Machine assembly | An elbow joint's odyssey

A journey through the ITER warehouse system. Walking among the spartan aisles and towering shelves of the massive ITER warehouse is like walking through the self-serve area at the back of an IKEA store. But instead of bookcases and bed frames, this warehouse is home to parts for the world's largest nuclear fusion facility, from multi-tonne tokamak components to tiny pieces of hardware smaller than walnuts. Like the 90° elbow joint that Daniel Mittag has just plucked from a box on shelf 31-B-03-C. 'We need to track it and preserve it just like everything else,' says Daniel. 'This joint has been custom designed, you can't run down the street and buy this at the hardware store, so if it goes missing, we are talking big delays for the project.' The ITER warehouse system is overseen by the Construction Management Office (CMO), which provides transversal support for the construction and logistics activities on the worksite. ITER's global logistics service provider Daher is in charge of warehouse services, however as the leader of the CMO's Integrated Material & Logistics Management Group Daniel is ultimately responsible for the 1.5 million components currently being stored in the system. 'I started working in logistics when I was unloading boxes in a warehouse as a high school job and I've been doing it ever since,' says Daniel, who is now two decades into this career. 'This is the most challenging mission I've had because the project is so complex and we need to give everybody at ITER 100% service, whether for a first-of-kind component like a vacuum vessel sector or something like this elbow joint.' The elbow joint in question began its journey to the ITER warehouse about five years ago when it was a mere digital concept in a 3D drawing. One of ITER's missions is to test the generation of tritium needed for high-performance nuclear fusion reactions. Jamal Ait El Mousse is one of the ITER engineers who has worked on the tritium breeding system, including the tritium extraction system (for processing) and the tritium accountancy system. These tritium subsystems have to fit into a tight space in the machine without interfering with other infrastructure, so the routing system required lots of twists and turns—hence Jamal needed the 90° elbow joints. The joints had to meet nuclear pressure equipment regulation (ESPN) and nuclear safety standards (ASN) in France while also being standard-size so they could be made on conventional machines. The design was done with the help of a Spanish subcontractor and then, once it was approved in late 2019, 22 elbow joints were added to a larger purchase order that was sent onto one of the ITER suppliers, W. Schulz (Germany). From pipe material sourced in China, Schulz cut and machined the elbow joints to ITER standards. In December 2020, the finished joints were inspected by Schulz quality control officers as well as an independent inspector hired by the ITER Organization. Once cleared, they were added to Packing List PL0121177, combined with other orders, and entrusted to the transporter AStrans for the 1,100-kilometre trip to ITER. 'It's an amazing logistics process,' says Jamal. 'It's a little component but its journey shows the global cooperation that is behind ITER.' Storage was another puzzle to solve. ITER has a main 36,000m² warehouse on the northern edge of its site in Saint-Paul-lez-Durance and five 6,000m² storage facilities near the port in Fos-sur-Mer. An item's initial location depends on available space and storage requirements (D for outdoors, C for indoors, B for temperature control, and A for humidity and temperature control). Because of its radioactive confinement role in the tritium system, the elbow joint was classified as a Protection Important Component (PIC) and given a C classification for the main warehouse, so this is where it was delivered by AStrans. On average, four or five shipments arrive at the main warehouse each day. Once the box with the elbow joint was unloaded, Daher warehouse personnel carried out a Level 3 inspection, checking for quantity, cleanliness and damage. (There are four types of inspections, from Level 1, where each component needs meticulous inspection, to Level 4 where only the main box is inspected for transit damage.) Then, the storage process could begin. The elbow joint had been logged into ITER's SmartPlant® storage database before it arrived as expected material; now, the software assigned it to a shelf based on its weight and available space and issued a label. The preservation code on the label called for the elbow joint to be checked every six months; as a result, it has undergone two additional warehouse inspections since arriving at ITER. The elbow joint will be used sometime after June 2022 when the piping system is assembled in the Tokamak Building. It is already part of Hand-Over-Package 1266, but there are more steps before the elbow joint has its moment in the sun. Other documents need to be generated so that assembly instructions are ready at the same time as the part (such as engineering and construction work packages). Then, after final ITER approval, a Material Issuing Report will be printed and later this year, a contractor will receive the elbow joint along with the other components needed to assemble the tritium piping system. It's unlikely that anybody from the design or warehouse team will ever see the elbow joint after its installation, but that doesn't diminish the sense of satisfaction. 'There are many logistics managers doing something important,' says Daniel, 'but what we are doing in our ITER warehouse is important for the whole world.'

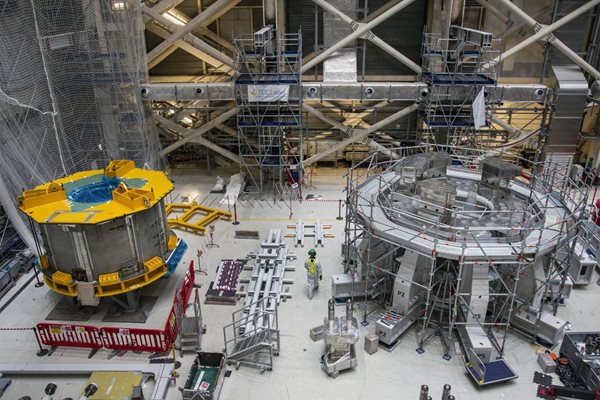

Image of the week | From table to platform

As the yellow lifting tools and devices are progressively removed from the central solenoid module on the left, the platform to the right is being equipped for the first stages of assembly. This central solenoid module is the first¹ in a set of six that, once stacked, connected and compressed, will form the most powerful industrial magnet ever constructed. Positioned at the center of the ITER tokamak, this 18-metre-tall magnet is the key component that will allow a powerful current to be induced in the ITER plasma and maintained during long plasma pulses. The assembly operations will take place in the Assembly Hall, on the massive platform to the right of the image. The stack, totaling 1,000 tonnes when all six modules are in place, will be supported by nine 'lower key blocks' arranged in a circle, four of which are already in place on the platform. On the floor, in front of the platform, a fifth sits upside down with its locating rods pointing up. Removable hydraulic jacks inside the key blocks will exert huge pressure (210 meganewtons²) on the module stack and keep it in mechanical compression. In approximately one month, the module will be moved from the table to the platform and the assembly process will begin in earnest. ¹ A second central solenoid module has already been delivered to ITER. ² A meganewton (MN) is a unit of force corresponding to the force required to accelerate a mass of one million kilograms by one metre per second.

of-interest

A third way to fusion?

There are presently two approaches to realizing hydrogen fusion. One, implemented in tokamaks and stellarators, consists in heating a very tenuous plasma to temperatures in the 100 million degrees Celsius range and to confine it in a magnetic cage—this is magnetic fusion. Another, called inertial fusion, is implemented in installations such as the American National Ignition Facility (NIF) or the French Laser Mégajoule. In inertial fusion an array of hundreds of powerful lasers, precisely focused, is used to compress to extreme density (and hence very high temperature) tiny hydrogen-filled capsules inside which fusion reactions can occur. Now, a third approach is being considered and experimented at NASA's Glenn Research Center, in Cleveland, Ohio. Called 'lattice confinement fusion,' it could one day provide enough power to operate small space probes or rovers for planetary exploration. In lattice confinement fusion (LCF), a beam of gamma rays is directed at a sample of erbium or titanium saturated with deuterium nuclei (deuteron). Occasionally, gamma rays of sufficient energy will break apart a deuteron in the metal lattice into its constituent proton and neutron. The energetic neutron has a chance of colliding with another deuteron in the lattice, imparting it with some of its energy. And sometimes that energy is enough for deuterons to fuse into a helium-3 nucleus (helion) and give off useful energy. A leftover neutron could provide the push for another energetic deuteron elsewhere in the lattice. 'Our work represents just the first step toward realizing that goal,' say the scientists involved in this endeavour. 'If the reaction rates can be significantly boosted, LCF may open an entirely new door for generating clean nuclear energy, both for space missions and for the many people who could use it here on Earth.' Read more about lattice confinement fusion on the IEEE Spectrum here.

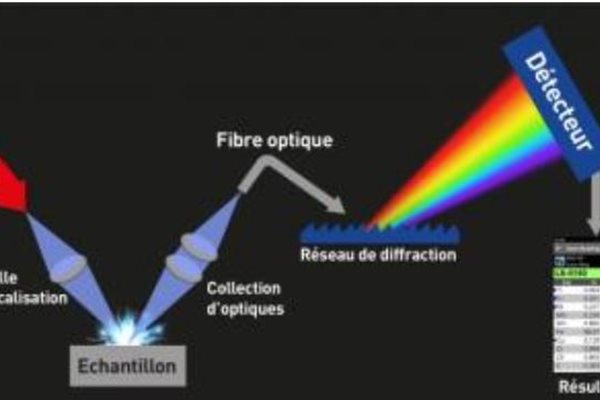

WEST is first to test fibered LIBS measurements

During the operation of a fusion machine, it is important to know the surface composition of the plasma-facing components, which can evolve over time (erosion, oxidation...) and modify plasma interaction conditions. The team at the WEST tokamak in France is testing a new kind of diagnostic, called the fibered LIBS (for Laser-Induced Breakdown Spectroscopy), to characterize internal surfaces of WEST and later ITER. In LIBS, a high-intensity pulsed laser beam is focused on the surface to be analyzed. The laser/matter interaction leads to the ablation of the material and the creation of a plasma plume. The spectral analysis of the plasma emission gives access to the elemental composition of the ablated material and thus the composition of the material under study. Installed on an inspection robot equipped with an articulated arm, the LIBS tool consists of an optical fibre carrying the incident laser light and the light emitted during the interaction of the laser beam with the material under study. The diagnostic can not only characterize all internal surfaces of the machine and follow their evolution, but also (in ITER) monitor tritium concentration in the first wall and detect eventual helium bubbles in plasma-facing components coming from the interaction of fusion neutrons with the materials. The first tests were carried out in December 2021. Read the original article in English or in French.

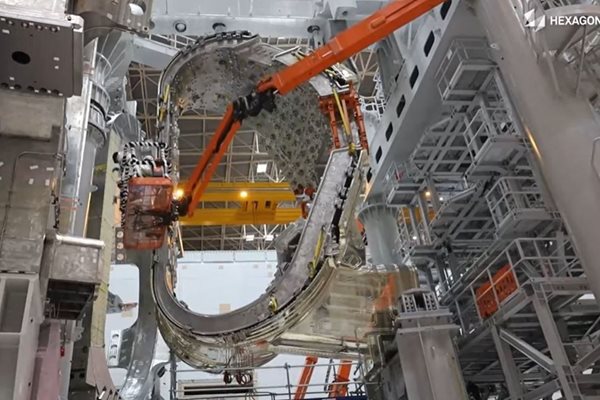

Metrology-assisted machine assembly

The global manufacturing intelligence firm Hexagon AB is providing metrology support to ITER for the precise assembly of components during the machine assembly phase. In this promotional video you can watch how the huge components of ITER's first vacuum vessel sub-assembly are brought together with assembly tolerances of just 1 mm. See the video here.