you're currently reading the news digest published from 25 Apr 2022 to 02 May 2022

featured5

of-interest1

press12

featured

Video | Travel with us to ... and through ... ITER

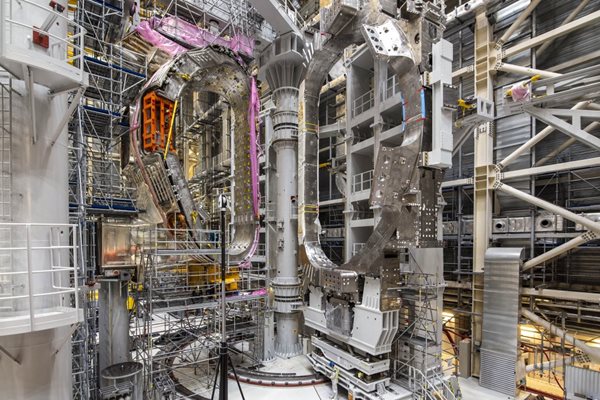

The latest drone video from the ITER Organization takes you deep inside the work underway in Saint-Paul-lez-Durance to build the world's largest tokamak. ITER is the project of many superlatives. It is the largest fusion energy project in the world, with the broadest international participation of any science project on record. It is the most ambitious device of its class, with fully twice the linear dimensions of the largest tokamak operating today and ten times its volume of plasma, capable of fusion experiments that set records for duration and fusion power production. ITER will be the only device in the world capable of creating a burning plasma—one in which the heat from the fusion reaction is confined within the plasma efficiently enough for the fusion power to dominate the plasma heating. Millions of components sourced across 30 nations and three continents—and shipped by boat, plane, rail and road—are coming together on a 42-hectare (100-acre) 'platform' where the ITER machine and supporting plant are under construction. Thousands of people are contributing their unique skills and their passion. Today, the project has completed 76 percent of the work scope to First Plasma (including all design, manufacturing, building construction, transport, and assembly and installation activities). Eighty-five percent of physical infrastructure (buildings, networks, drainage, services) is in place. Second best to seeing construction in person, is a fly-through by drone ... Watch 'ITER: Flying over ... and through' (April 2022) in English or in French.

Liquid nitrogen | Fill it up, please!

A white, vapour-like plume escapes from a valve on top of the cryoplant's liquid nitrogen storage tank. Like the smoke coming out of a cardinals' conclave, it delivers an important message: the first cryogenic system in the ITER installation has entered the commissioning phase. The fill-up began last week as liquid nitrogen was pumped out of a succession of Air Liquide trucks into the cryoplant's giant 300-cubic-metre, 20-metre-tall vertical tank. During the commissioning phase, the tank will be 80% filled to verify the rate of evaporation, which should not exceed 0.16 percent of the total volume per day. Liquid nitrogen (LN2) has multiple applications in the ITER installation, both at the commissioning and operational phases. Once ITER enters operation, LN2 will be used to cool-down gaseous helium in the 80 K loop's heat exchangers before it is sent to the Tokamak's thermal shields; it will also be used to 'pre-cool' gaseous helium in the liquid helium cold boxes. LN2 will also be needed to initiate the distillation process that separates nitrogen from ambient air, to trap impurities in the gaseous helium purification systems, and again as a cooler to maintain gaseous helium temperature between minus 173° C and minus 193° C in the helium storage and quench tanks. During pre-commissioning, gaseous nitrogen is essentially used as a 'drier' for the absorber beds in the cold boxes, the charcoal elements in the recovery and purification system, and the liquid helium compressors' oil removal system. Whether in gaseous or liquid form, nitrogen will be in strong demand at ITER. By chance, it is also quite abundant as it accounts for 78 percent of the air we breathe. Once the distillation-from-air process is initiated in the on-site gaseous nitrogen generator, the system's production capacity will reach approximately 50 tonnes per day.

Machine assembly | Stay tuned for a remarkable lift

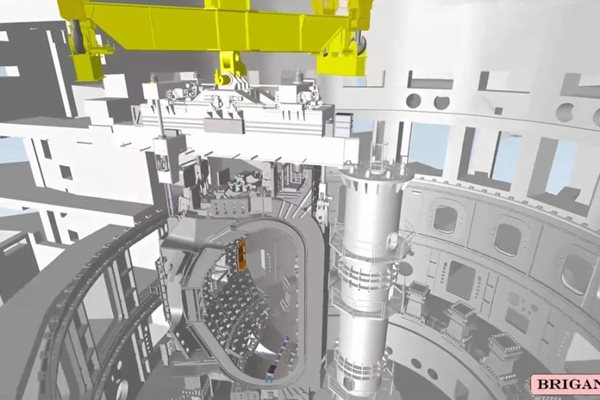

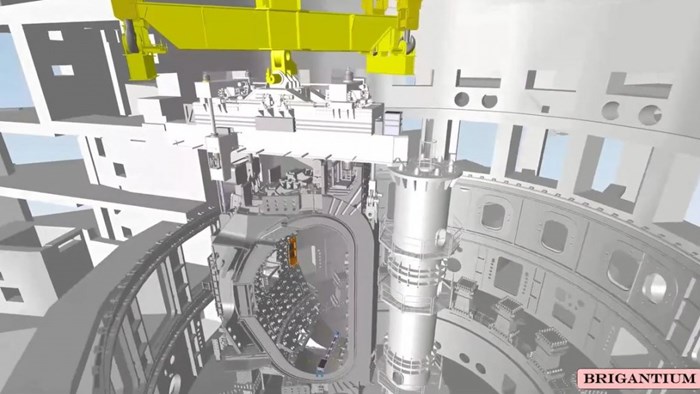

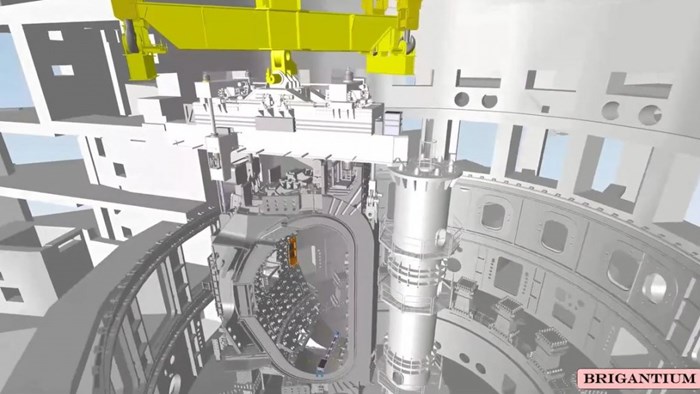

Inside the ITER assembly theatre, a major lift event is imminent. This 3D animation takes us through the steps that will be necessary to transport the first 1,200-tonne section of the vacuum vessel into the Tokamak pit.  Vacuum vessel sector #6 will always have a special place in the ITER story. Of the nine sectors that will form the torus-shaped plasma chamber, it was the first to be received (in August 2020), the first to get fitted with instrumentation, the first to be upended to vertical, and the first to be docked in a standing sector sub-assembly tool. The 440-tonne double-walled steel sector manufactured by Hyundai Heavy Industries and supplied by the Korean Domestic Agency for ITER spent just about one year in vertical tooling, as elements were added to create the first complete 'sub-assembly' of the vacuum vessel. A complete set of vacuum vessel thermal shielding plus two toroidal field magnet coils were positioned with the highest degree of accuracy and adjusted with precision by the actuators of the tool. Lessons learned with these first-of-a-kind operations have already facilitated work on subsequent sectors. Now, the ITER Organization construction teams, including the TAC-2 assembly contractor DYNAMIC, are preparing for the crowning event in the sequence—the transfer by overhead crane of the 1,250-tonne, 40° section from tooling into the Tokamak assembly pit. The final preparatory rigging activities are underway. Because the 40° section must be lifted over the rim of the bioshield on its way to the pit—and because the large mass to be lifted necessitates the use of a rigging attachment called the 'dual crane heavy lifting beam' that adds to the height of the ensemble—the lift will be one of the tallest assemblies to be handled by the overhead crane system. In the 3D animation above, you can see how the different rigging elements combine to carry out the necessary steps, from extraction from the tool, to rotation, transfer, and descent. - The dual crane heavy lifting beam (in yellow) allows the cranes to work in tandem and facilitates the rotation of the sub-assembly from its tooling orientation to the orientation required for installation in the pit. - The sector lifting tool (in grey, directly underneath) connects directly to the beam supporting the sub-assembly, and has a balancing control system to precisely position the load's centre of gravity. - The radial beam that supports the assembly directly, and which played a role in docking the vacuum vessel sector in tooling, is designed to continue to support the sub-assembly during in-pit sector-to-sector welding by bracing itself between the tall centre column in the pit and brackets on the surrounding wall. This long-planned operation is imminent. At the centre of the first-completed sub-assembly of the ITER vacuum vessel, sector #6 will once again be a trailblazer. The animation is also on the ITER Organization's YouTube page (courtesy of Brigantium Engineering).

Vacuum vessel sector #6 will always have a special place in the ITER story. Of the nine sectors that will form the torus-shaped plasma chamber, it was the first to be received (in August 2020), the first to get fitted with instrumentation, the first to be upended to vertical, and the first to be docked in a standing sector sub-assembly tool. The 440-tonne double-walled steel sector manufactured by Hyundai Heavy Industries and supplied by the Korean Domestic Agency for ITER spent just about one year in vertical tooling, as elements were added to create the first complete 'sub-assembly' of the vacuum vessel. A complete set of vacuum vessel thermal shielding plus two toroidal field magnet coils were positioned with the highest degree of accuracy and adjusted with precision by the actuators of the tool. Lessons learned with these first-of-a-kind operations have already facilitated work on subsequent sectors. Now, the ITER Organization construction teams, including the TAC-2 assembly contractor DYNAMIC, are preparing for the crowning event in the sequence—the transfer by overhead crane of the 1,250-tonne, 40° section from tooling into the Tokamak assembly pit. The final preparatory rigging activities are underway. Because the 40° section must be lifted over the rim of the bioshield on its way to the pit—and because the large mass to be lifted necessitates the use of a rigging attachment called the 'dual crane heavy lifting beam' that adds to the height of the ensemble—the lift will be one of the tallest assemblies to be handled by the overhead crane system. In the 3D animation above, you can see how the different rigging elements combine to carry out the necessary steps, from extraction from the tool, to rotation, transfer, and descent. - The dual crane heavy lifting beam (in yellow) allows the cranes to work in tandem and facilitates the rotation of the sub-assembly from its tooling orientation to the orientation required for installation in the pit. - The sector lifting tool (in grey, directly underneath) connects directly to the beam supporting the sub-assembly, and has a balancing control system to precisely position the load's centre of gravity. - The radial beam that supports the assembly directly, and which played a role in docking the vacuum vessel sector in tooling, is designed to continue to support the sub-assembly during in-pit sector-to-sector welding by bracing itself between the tall centre column in the pit and brackets on the surrounding wall. This long-planned operation is imminent. At the centre of the first-completed sub-assembly of the ITER vacuum vessel, sector #6 will once again be a trailblazer. The animation is also on the ITER Organization's YouTube page (courtesy of Brigantium Engineering).

Central solenoid | All one needs to begin stacking

A beginner's Erector Set? Elements for an innovative board game? Not quite: these three circular structures and the tools and accessories scattered about are all one needs to begin building the ITER central solenoid, a massive, 18-metre-tall magnet weighing in excess of 1,000 tonnes. The yellow structure at the bottom left is the 'lifting fixture,' a bespoke tool that will handle each of the six central solenoid modules by exerting a strong radial force from the outside, clutching and securing them in a 220 kN (kilonewton) embrace. To the right of the lifting fixture, awaiting assembly, is the circular helium manifold plate that will support the C-shaped pipe connected to the magnet's cooling circuit. Wrapped in pink protective plastic at the upper left of the image is the first of the six modules that will be stacked, connected and held together by a set of tie plates to form the central solenoid. Manufactured by General Atomics in California, the central solenoid modules are the most emblematic of US Domestic Agency contributions to ITER. To the right of the module sits the assembly platform. Nine circular fiberglass plate are already in place for ground insulation and height adjustment. The future stack of modules, in its support structure, will rise 18 metres. Delivered in September last year, verified and equipped throughout the fall and winter, the first central solenoid module will be lifted and positioned on the assembly platform this summer.

Image of the week | First European coil in tooling

The D-shaped coil that is presently attached to the right wing of sub-assembly tool #1 (SSAT-1) was the first to be delivered to ITER in April 2020. Manufactured by Europe in Italy, toroidal field coil #9 (TF9) inaugurated the regular series of arrivals from Europe and Japan that has brought to 12 the total number of toroidal field coils presently on site... with a 13th (TF17, also from Europe) expected at the end of the week. On 25 April, the 337-tonne TF9 was lifted, upended and installed into SSAT-1. Together with vacuum vessel sector #1(7) from Korea, toroidal field coil #8 from Japan and the corresponding thermal shield segments (also from Korea), TF9 will be part of the second sector module to be installed in the assembly pit.

of-interest

New video on fusion from the Financial Times

The Financial Times channel FT Rethink produces multimedia content that focuses on "the people, technology, strategies and systems moving us from an economy that is wasteful, idle, lopsided and dirty towards one that is circular, lean, inclusive and clean." In a video published on 21 April 2022, the channel turns its lens to nuclear fusion and its "enormous potential" as an energy source. Join host Anjana Ahuja to learn more about fusion science, recent breakthroughs in the field, and growing interest from private investors in "Making the heart of a star power the world."