ITER NEWSLINE

-

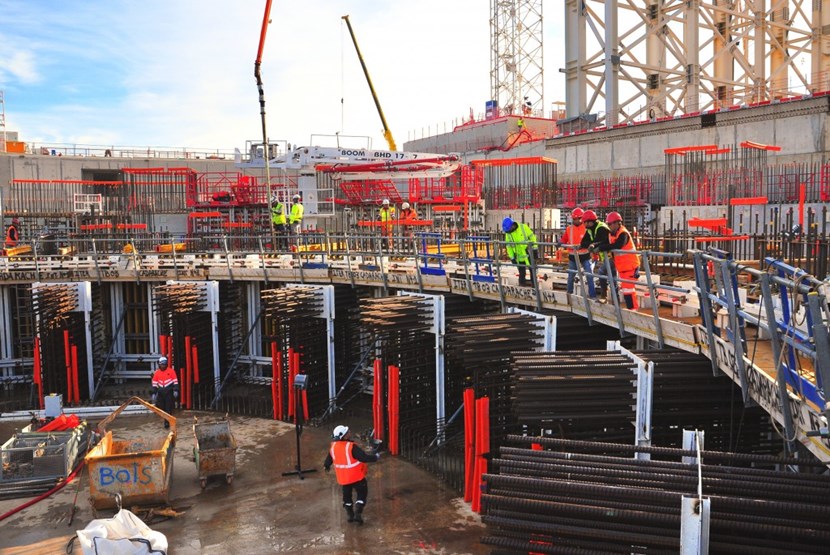

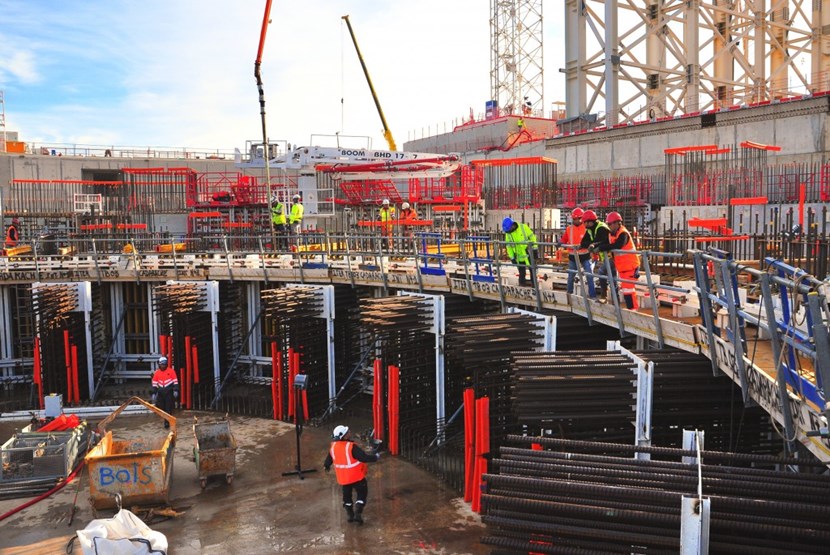

Pouring the protective circle

R.A.

Pouring the protective circle

Since construction of the ground support structure for the Tokamak Complex began in 2010, huge volumes of concrete have been poured to form the edifice's seismic foundations, retaining walls, and basemat. Since November 2014 work has been underway on the Complex's basement-level walls and pillars.

In the early hours of Wednesday, 21 October, workers poured the first 200° segment of the bioshield, in an all-day operation that took some 15 hours to complete.

But concrete pouring in a nuclear building is never routine, with each pour day marking the end of months of calculations, modellization and painstaking preparation.

For the ITER bioshield—the 3.2-metre-thick "ring fortress" surrounding the machine, whose role is to protect workers and the environment from the radiation generated by the fusion reaction—preparations have been particularly complex. Realizing a "perfect pour" for such a massive and strategic structure is so important that it was practised in a specially constructed full-scale mockup on the platform.

The density of the lattice of steel reinforcement makes the use of traditional concrete vibrators—used to encourage the concrete to reach every recess—impractical. As a consequence, an extra-fluid, self-compacting concrete was selected by the contractors and trialled in the on-site mockup.

At the end of the day 600 m³ of concrete were in place (centre circle), filling over half of the bioshield's circumference.

The conclusive results allowed pouring operations to begin. In the early hours of Wednesday, 21 October, workers poured the first 200° segment of the bioshield, in an all-day operation that took some 15 hours to complete.

As dusk settled on the ITER site 600 m³ of concrete were in place, filling over half of the bioshield's circumference. The pouring of the remaining 160° segment is scheduled in January 2016.

return to the latest published articles