you're currently reading the news digest published from 08 Mar 2021 to 15 Mar 2021

featured4

of-interest3

press14

featured

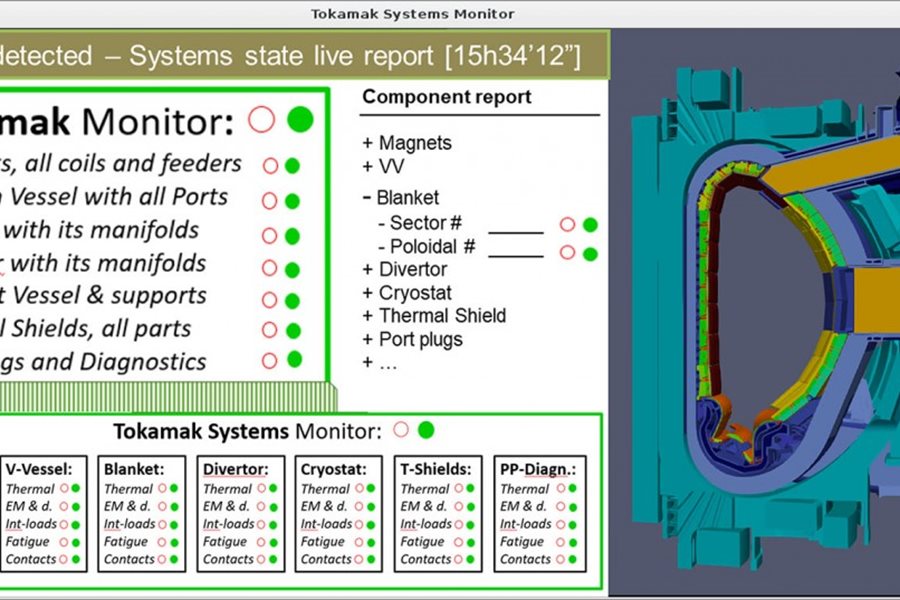

Tokamak systems monitor | A constant health check

ITER, as the first reactor-scale fusion device, will help the world understand more about the necessary tradeoff between maximal performance and equipment lifetime. A new suite of software, the tokamak systems monitor, will assist engineers in striking the right balance—and more. The tokamak systems monitor (TSM) will provide an integrated view of the machine's condition in near real time, with delays generally under 1 second, so operators can see what is going on inside the machine—and if necessary, react immediately. The system, under development by the Port Plugs & Diagnostics Division team, will also provide an even fuller set of information within minutes to help engineers and scientists make adjustments between pulses. While its primarily role will be to follow the use of the machine against design limits as the tokamak progresses though its lifetime, a happy by-product of the way it is being developed is that it can also be used to refine engineering models during the design phase. From a huge volume of data to an intuitive presentation Exploring the operating profile of ITER is a complex task—and even though the machine was designed for robustness, all operations must be performed with extreme care. If sensor data processed by the tokamak systems monitor indicates that one or more systems reacts too far from the expected range, operators will analyze possible causes and make adjustments to home in on exactly what is going on. If on the other hand, all systems behave well, they will increase loads to further optimize the performance against design parameters. The primary source of information used by the TSM diagnostic is a collection of operational instrumentation sensors that are generally provided with the equipment they measure (for example, magnet coils) and that are separate from the specialized diagnostics used to monitor the main plant systems. Complementary data will be taken from plant systems such as water cooling and coil power supplies, as well as from the plasma control system and the diagnostics that measure events from the plasma to the first wall. Even with all this input, the tokamak systems monitor will still have gaps to fill, simply because putting a sensor on every component and in every critical location would be impossible. Using a process called 'reconstruction,' the tokamak systems monitor will take information from local sensors and apply carefully developed and tested analysis and simulation models to figure out the behaviour of the entire machine. The software suite will routinely serve up a health status, and actual machine margins, to operators. At a simple level, one can think of the presentation as lights representing each system, remaining green when all is well, and flipping to amber or red if some action has to be taken. From this simple dashboard, experienced operators will be able drill down much deeper to find out what is happening across the whole plant. Considering the number of interactions between the different systems, it is easy to appreciate the unique value of the tokamak systems monitor. Interleaved reconstruction algorithms and simulation models The tokamak systems monitor starts by applying sophisticated reconstruction algorithms that take sensor data and reconstruct global behaviour of the tokamak, taking into account the timing of each event. The algorithms are said to be 'interleaved' in that any given algorithm may cover several tokamak systems, and any given tokamak system may be served by multiple algorithms. These freshly reconstructed global parameters are then used as input for simulation models—usually based on finite element analysis—to calculate specific engineering data for all points of interest, and compare those with a range of limits to report to the operator. The tokamak systems monitor also archives the output for future use. Through this process, the software is able to deliver specific engineering data for all parts of the machine—including locations where sensors cannot be installed, or where they were installed, but are no longer functioning. The methodology has already been developed and used in various industries and other tokamaks—but none as complex as ITER. The approach used at ITER differs in two ways. 'First, as far as we know, the level of multi-physics in our algorithms and models has never been done before in fusion,' says Daniel Iglesias, Tokamak Systems Monitor Coordinator. 'In a tokamak you have several events that are really fast and that involve a whole lot of different phenomena. Typically, the different impacts—for example, heat transfer phenomena, static and transient electromagnetics, dynamic (inertial) phenomena, and the stress fields—are analyzed in isolation. But of course in reality, these things happen at the same time and their effects overlap. In a tokamak the overlaps are more substantial and involve a larger variety of engineering disciplines than in common industries, so we need to reconstruct and then simulate many of them all together in order to get a complete picture of what is happening inside the machine. This multi-physics, or multi-disciplinary engineering, is one of our big challenges.' 'The second thing that's unique,' adds Sergey Sadakov, Tokamak Systems Monitor Engineer, 'is that unlike all industrial applications of similar diagnostic systems, we are taking an unusually large step from current machines to ITER. Some of the modern tokamaks do have some instrumentation and use some reconstruction algorithms. But if you compare the volume of instrumentation and the variety of parameters they have to reconstruct with what we do at ITER, the difference is one or two orders of magnitude. We are taking one giant step up to several tens of thousands of channels of data coming in, and several hundred reconstruction algorithms and simulation models running simultaneously. This is the future of fusion, the dawning of an industrial approach.' Refining engineering models well before the machine becomes operational 'Our development strategy is to have six releases of the software suite, each with consequently wider functionality,' says Iglesias. 'In a year we will demonstrate the first working version—of course with limited functionality, but with the basic ingredients. And then the development will be incremental. The full system will be ready at the end of 2024, to be integrated before First Plasma. The upgrades will keep coming even after the machine begins operation. Once the ITER Tokamak is operating we will start with the validation phase, and then I'm sure we'll have a lot of ideas on how it can be improved.' But even now, years before the reactor becomes operational, the tokamak systems monitor simulation tools are playing an important role. By comparing the output from the simulators to the engineering models used in design, scientists and engineers are able to make changes to engineering models far in advance. 'Thanks to the development of the simulation models, we are already able to check the designs and make sure any cross-couplings are handled well,' says Alexander Alekseev, Senior Advisor on tokamak engineering to the ITER Director-General. 'So well before First Plasma, this system is already adding value to the development of the ITER machine.'

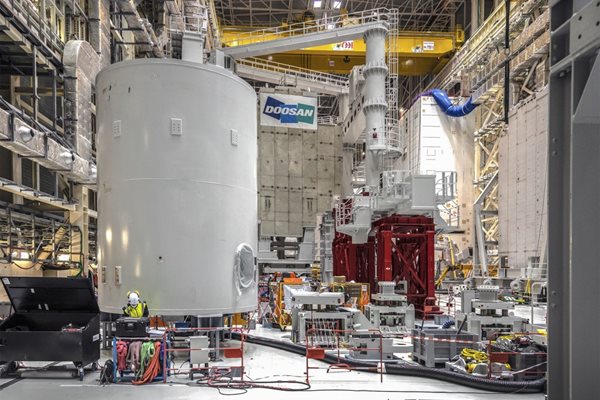

Assembly tools | A first glimpse at the colossus

Imagine a 600-tonne umbrella, with a central shaft more than 4 metres in diameter and ribs as thick as the girders of a travelling crane—this is what the central column and the nine radial beams of the in-pit assembly tool will look like once they are installed inside the Tokamak pit. Designed for a nominal load of 5,400 tonnes, the temporary tool will support, align, and stabilize the vacuum vessel sub-assemblies as they are joined and welded. In just a few weeks, after the installation of the first poloidal field coil, the first central column segment will be lifted into the assembly pit and anchored to the basemat. The bottom cylinder will be installed once poloidal field coil #6 has been lowered to rest on its temporary supports. Depending on the other activities in both the Assembly Hall and the assembly pit, the other sections will be lifted one by one or by pairs, extending the installation operations well into the summer. As for the radial beams, they will arrive in the pit supporting each vertical vacuum vessel sub-assembly as it travels by overhead crane. Once installed, the beams (and their loads) are supported between the central column and the concrete bioshield. In addition to its weight-bearing role, the colossus at the centre of the pit will provide a physical manifestation of the machine axis, prior to the welding of the pre-assemblies. Equipped with a number of fiducial targets, the central column will allow for the ultra-precise positioning and alignment of the toroidal field coils. Fiducial targets on the radial beams will fulfil the same role for the vacuum vessel sectors.

Fusion community | A place to meet

Scientific cooperation is not about exchanging data, ideas and theories only. It builds on basic human dynamics, personal interactions, arguments, jokes, smiles and the whole spectrum of emotions that is common to the men and women of this world. When different groups working on the same experiment are separated by immense stretches of land and ocean, there is a need for a 'meeting place'—even if it is partly a virtual one. In late 2019, EUROfusion—the consortium of European fusion research institutes—began planning for a remote experiment centre where European scientists working on the Euro-Japanese JT-60SA satellite tokamak experiment would gather as a group to interact with their Japanese colleagues. 'The idea was to bring people together in the same room rather than having them connect individually from their office. It was about re-creating an atmosphere,' says Gerardo Giruzzi who led the preparation for the scientific participation of EUROfusion in the JT-60SA project. Four months later, the COVID pandemic struck, imposing limitations on gatherings and travel. What had been a simple need to facilitate team cohesion and communication within the JT-60SA project now became a necessity for the broader worldwide fusion community. The remote experiment centre now exists. It is located in a renovated building on the vast domain of Château de Cadarache, a few kilometres from the ITER site. On Friday 12 March, the French Alternative Energies and Atomic Energy Commission (CEA), which provided the building, handed over a symbolic key to the Institute for Magnetic Fusion Research (IRFM) which will operate it. The 300 m² facility will comprise a large 'participation room,' along with meeting spaces that are fully equipped with giant screens and sophisticated communication tools. 'The remote experiment centre originated from the needs of the JT-60SA teams,' explains Frédéric Imbeaux, the head of the Fusion Plasma Physics Department at EUROfusion. 'But we will be able to use it for collaborating with EAST and HL-2M in China, DIII-D in the United States, JET in the United Kingdom, and of course IRFM and ITER. We have also entered discussions with the Fusion Department at Aix-Marseille University. This tool can contribute to establishing the fusion community of tomorrow.'

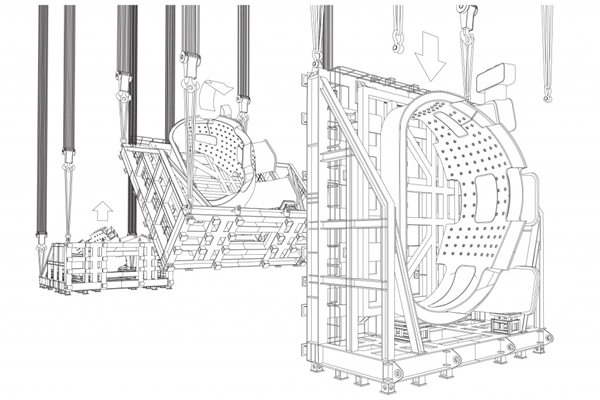

Vacuum vessel sector | Lift and tilt

The first ITER vacuum vessel sector—as tall as a telephone pole and as heavy as 300 small cars—will soon be suspended several metres above the floor of the Assembly Hall and slowly 'upended' mid-air from horizontal to vertical. Once vertical, the first-of-a-kind component will be transferred across the Hall and docked inside of standing giant #2—one of two V-shaped sector sub-assembly tools anchored to the floor of the Assembly Hall. It will remain there for approximately five months, as other vacuum vessel sub-components (thermal shield panels and two D-shaped toroidal field coils) are rotated toward the sector and attached in order to complete the first 'sub-assembly' of the nine-part ITER vacuum vessel. It has been seven months since the Korean Domestic Agency delivered vacuum vessel sector #6 to the ITER construction team. After final acceptance tests in September, the assembly teams worked to complete a number of installation tasks while the component was horizontal. One of the main activities was the welding of small, cylindrical attachments called 'bosses' to the outer skin of the sector. Because drilling is forbidden in nuclear pressure vessels like ITER's, instrumentation, instrumentation cables, and cable trays must be affixed to the attachments instead of to the vessel wall itself. During this period, for example, assembly contractors installed 120 magnetic sensors*. 'A number of steps were involved,' says Yunxing Ma, from ITER's In-Vessel Diagnostics Section. 'The metal cases containing the magnetic sensors were first welded to the bosses (four per sensor); then, the signal cables were routed and girded. We carried out electrical tests to verify signal continuity, and metrology to measure the as-installed positions of the sensors with respect to the datum.' In a later phase, when the sector is in the Tokamak pit, the cables will be connected with the backend signal transmission network in order to link the sensors to the data acquisition system. Sector #6 is now ready for the next phase in assembly. As a first step, it will be transferred in a horizontal position on its assembly frame to the purpose-built upending tool. Cables from the double overhead crane will descend to connect to the corners of the tool so that the upending frame (and load) can be lifted. As the component is suspended mid-air, cables on one side will be winched to bring vacuum vessel sector #6 to an upright position. Finally, as lift and alignment units are brought in to connect to the sector in its vertical position, the upending tool can be disengaged and lowered back to the floor. The ITER Newsline will have a full report. * Densely distributed and spanning two full poloidal arrays, these sensors will deliver high-resolution magnetic field measurements across the entire vacuum vessel, providing key data for reconstructing the 'magnetic field map'—critical information for plasma operation.

of-interest

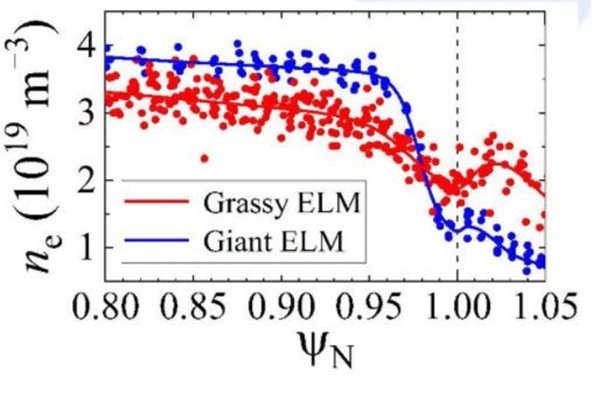

A promising pathway for high-performance fusion plasmas?

Cooperative research between the DIII-D National Fusion Facility in USA and the Institute of Plasma Physics (ASIPP) of the Hefei Institutes of Physical Science (HFIPS) in China has identified a key approach to creating plasma conditions that will be necessary for steady-state operation of ITER. This new approach shows promise in avoiding potential edge instabilities in the plasma that can pose increased plasma-material interaction challenges. Plasma instabilities known as edge-localized modes (ELMs) are a challenge to stable operation of fusion reactors. Effective ELM control is particularly important in high-confinement, steady-state fusion plasmas such as ITER. The research at DIII-D and EAST found that maintaining high density at the edge of the plasma and a high density ratio between the pedestal bottom and top can reduce the severity of ELMs. "Combining ELM control with high fusion performance will be critical for efficient operation of ITER and the power plants that come after it," said XU Guosheng. "These results are an important step toward practical fusion energy." One approach to ELM control has been creating plasma conditions in which ELMs may occur, but are much smaller. Known as "grassy" ELMs, these conditions have been achieved on other devices, but often under parameters that are not suitable for large, long pulse devices like ITER. Experiments on DIII-D demonstrated a grassy ELM regime at an ITER-relevant parameters. Read the full press release here.

Register for the Remote ITER Business Meeting

In lieu of an in-person ITER Business Forum this year, the ITER Organization is planning a two-day Remote ITER Business Meeting, from 6 to 7 April 2021. The purpose is the same: to inform the business community about upcoming contract opportunities at ITER and to create the opportunity for businesses to meet and plan together through B2B meetings. It will also be possible to meet project specialists in one-to-one Skype sessions on a variety of topics, including how to set up a business in the south of France with the Welcome Around ITER network and specific contract opportunities (Hot Cell, maintenance services, Tritium Plant, remote maintenance, and European contract opportunities through Fusion for Energy). To participate, fill out your pre-registration form on this website: https://www.iter.org/ribm2021. The deadline is 6 April 2021.

EUROfusion awards 16 research grants

The EUROfusion consortium has announced the award of 16 fusion energy research grants across Europe for the development of innovative new ideas and techniques. EUROfusion makes grants available on behalf of the European Commission's Euratom program. In its meeting on 3 March 2021, the General Assembly of EUROfusion selected 16 out of 72 Enabling Research proposals based on the recommendations of the scientific boards in four research categories. EUROfusion will invest a total of € 20.1 million in these projects, of which € 9.9 million comes as a contribution from the consortium. The four research categories are: materials, theory and modelling, technology and systems, and inertial fusion. View the list of the recipients and their projects on the EUROfusion website.