A first glimpse at the colossus

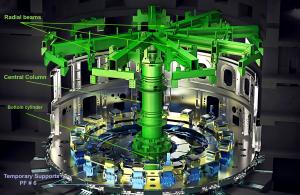

Imagine a 600-tonne umbrella, with a central shaft more than 4 metres in diameter and ribs as thick as the girders of a travelling crane—this is what the central column and the nine radial beams of the in-pit assembly tool will look like once they are installed inside the tokamak pit.

Designed for a nominal load of 5,400 tonnes, the temporary tool will support, align, and stabilize the vacuum vessel sub-assemblies as they are joined and welded. In just a few weeks, after the installation of the first poloidal field coil, the first central column segment will be lifted into the assembly pit and anchored to the basemat.

The bottom cylinder will be installed once poloidal field coil #6 has been lowered to rest on its temporary supports. Depending on the other activities in both the Assembly Hall and the assembly pit, the other sections will be lifted one by one or by pairs, extending the installation operations well into the summer.

As for the radial beams, they will arrive in the pit supporting each vertical vacuum vessel sub-assembly as it travels by overhead crane. Once installed, the beams (and their loads) are supported between the central column and the concrete bioshield.

In addition to its weight-bearing role, the colossus at the centre of the pit will provide a physical manifestation of the machine axis, prior to the welding of the pre-assemblies. Equipped with a number of fiducial targets, the central column will allow for the ultra-precise positioning and alignment of the toroidal field coils. Fiducial targets on the radial beams will fulfil the same role for the vacuum vessel sectors.