A colossus at the centre of the Tokamak pit

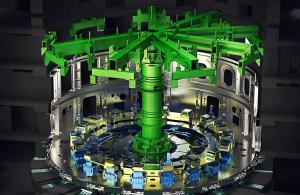

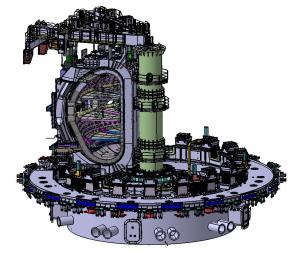

An imposing tool will rise next year in the centre of the Tokamak pit, formed from a trunk-like central column and nine radial beams. During in-pit assembly operations, it will support, align, and stabilize the vacuum vessel sub-assemblies as they are joined and welded.

Together with the giant sector sub-assembly tools (SSATs) and the upending tool, the in-pit assembly tool is the third major purpose-built tool supplied by ITER Korea for activities related to the assembly, including in-field joints, of the vacuum vessel sectors.

- The upending tool is used to raise vacuum vessel sectors from their horizontal delivery configuration to vertical.

- After each "upending" operation, a radial beam is removed from the in-pit column tool and transported by overhead crane to connect to the sector in its vertical orientation.

- The radial beam, suspending its load, is transported to one of the SSAT tools, where it continues to support the weight of the sector as a pair of toroidal field coils and thermal shield panels are rotated inward and attached.

- The completed sector sub-assembly—composed of the vacuum vessel sector (still suspended from its radial beam), two toroidal field coils and thermal shielding—is transported by overhead crane through a purpose-built "sector lifting tool" to the Tokamak Pit.

- During alignment and welding activities, the weight of the sector continues to be supported by the radial beam while the coils and thermal shield are braced from below by gravity supports installed on the cryostat base.