you're currently reading the news digest published from 17 May 2021 to 31 May 2021

featured4

of-interest2

publication1

press50

featured

Vacuum vessel welding | Contract awarded to Spanish company

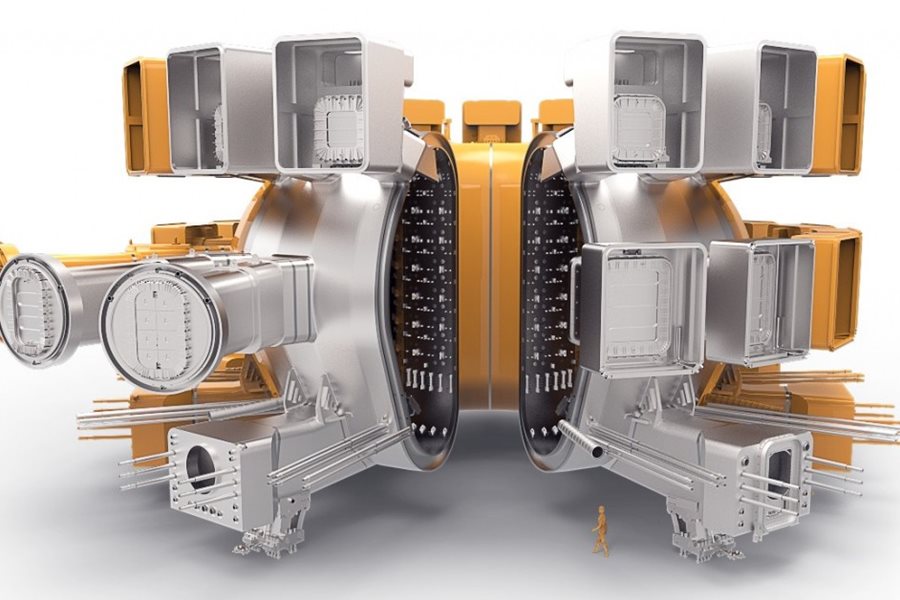

The ITER Organization has concluded a contract with the Spanish company ENSA (Equipos Nucleares SA) for the welding of the ITER vacuum vessel. ENSA is no stranger to the vacuum vessel welding project; since 2012 the company has been working under a phased contract with the ITER Organization to first develop specific welding processes and tools and then to procure the equipment. Phase three of the project—the execution of the welding works—was awarded to the firm in October 2020 following an international competition based on a negotiated procedure. This is the third major machine assembly contract after the TAC1 and TAC2 Tokamak Assembly Contracts were signed in 2019. The scope of the new contract—called VVW2P, for Vacuum Vessel Welding Production Phase—covers the welding of 9 vacuum vessel sector sub-assemblies and 54 ports. (A sub-assembly is the unit formed by one 40-degree vacuum vessel sector, two toroidal field coils, and a 40-degree thermal shield sector.) The estimated duration of the contract is 57 months, with a targeted completion date of March 2025. ENSA estimates peak personnel needs on site at 150 people. Work will take place inside of the restricted space of the Tokamak pit, as the sub-assemblies are successively lowered into place by the TAC-2 ITER Organization assembly contractor and attached to their supports. ENSA contractors will join and weld the vacuum vessel sectors according to a plan that aims to minimize deformation. The first sectors to be welded together in 2022 are sector #6 (already on sub-assembly tooling) and sector #7 (expected from Korea in August 2021). ENSA will be supported by the Indian firm Larsen & Toubro as the sub-contractor for the welding of the major part of the ports. The ENSA team will face a challenging task, evolving in a crowded Tokamak pit environment with co-activity on every side. The weld robots will have access from inside the vessel only, as the thermal shield panels and the toroidal field coils block access to the vessel's outer shell. Weld thickness is consequential—up to 60 mm—and weld shrinkage will have to be managed at every step of the process to ensure the correct shape of the final vessel assembly. Finally, stringent volumetric examination protocols will be required to comply with French nuclear regulations. 'As a nuclear pressure vessel, the ITER vacuum vessel is subject to conformity assessments performed by a body authorized by the French Nuclear Regulator,' explains Frantz de la Burgade, Group Leader for the Sector Modules Delivery & Assembly Division. 'The technical documentation will have to be edited sufficiently in advance to allow enough time for this Agreed Notified Body to review.' During the initial phase of the contract (P0), which has been underway since the kick-off meeting in November 2020, the ENSA team is focusing on a selection of preparatory tasks, including documents, engineering tests, trials, qualification, and training. 'To perform a good weld is one thing; to be in a position to justify it has been perfectly done is an additional challenge,' says De la Burgade. 'The contractor is asked to predict shrinkage behaviour at each step of the assembly process, so that the expected shrinkage can be compensated by the relative pre-positioning of two consecutive sectors in the pit before the welding begins. Another important challenge of the initial phase of the contract is to mobilize experienced operators for both welding and non-destructive examination.' The early team, mobilizing to organize the preparatory activities on site, will be followed by increasing numbers of workers as the tasks begin in the ITER Tokamak pit. A core team of experienced engineers from ENSA is already collaborating with the ITER engineering teams, as they familiarize themselves with the overall construction work packages and the engineering input required for the optimization of work execution. A machining workshop is planned on site for the customization of splice plates—material used to ease the assembly of two consecutive sectors. The company will also dispose of space to install mockups from its facility in Santander, Spain, that had been used during the tool qualification process and that will now serve for the training of operators.

Spherical tokamak | MAST's divertor concept yields positive results

During the first months of experimentation on the MAST Upgrade tokamak in the United Kingdom, an innovative plasma exhaust concept has demonstrated positive results, reducing by tenfold the heat loads at the divertor area of the machine. One of the fundamental engineering challenges in designing a commercial fusion reactor is how best to manage the power exhaust and the removal of impurity particles during plasma operation. Heat-exhaust systems must be capable of withstanding the large heat and particle fluxes, while at the same time allowing as high performance as possible from the core plasma. In tokamaks, the impurities and exhaust are driven to the divertor strike points at the bottom of the vacuum vessel for evacuation and recycling. In ITER, the divertor is the component that must resist the highest heat fluxes of the machine, as much as 20 MW per square metre (10 times the heat load of a spacecraft re-entering Earth's atmosphere). High as that is, however, future tokamak reactors will have to cope with higher. Without an exhaust system that can handle the intense heat, materials will require regular replacement—affecting the amount of time the reactor can remain on line. MAST Upgrade is a spherical tokamak at the Culham Centre for Fusion Energy (UK) that is exploring the route to compact fusion power plants. Since beginning operation in October 2020, it has been testing a new type of exhaust system, called the 'Super-X divertor,'—a technology originally developed by the University of Texas. This unique component is designed to spread the arriving heat over a much larger area, increasing the distance the evacuating particles have to travel to be exhausted and injecting a gas to bring the temperatures down (see an animation of the Super-X divertor on the MAST Upgrade website). Super-X has already demonstrated at least a tenfold reduction in the heat on divertor materials—'from a blowtorch level down to more like that you'd find in a car engine,' says MAST Upgrade's Lead Scientist Andrew Kirk in a report published this month. Results from the MAST Upgrade campaigns will inform the ongoing design of the European demonstration power plant, DEMO, although a Super-X divertor is not currently planned in the baseline design of that device. Results will also be followed closely by the team designing STEP (Spherical Tokamak for Energy Production)—the UK Atomic Energy Authority's program to design and construct a prototype of a compact fusion energy plant. Read the original article on the MAST Upgrade website. Read about the MAST Upgrade opening ceremony held on Wednesday 26 May 2021.

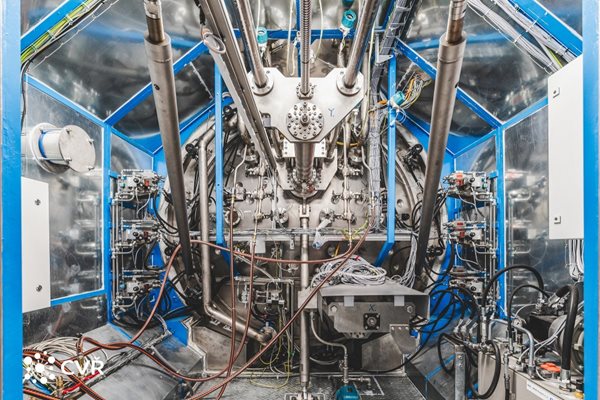

Manufacturing | A blast of heat to test Europe's plasma-facing components

At the HELCZA experimental and testing facility in the Czech Republic, the European Domestic Agency is about to begin high heat flux tests on blanket first wall prototypes. Blanket first wall panels are the detachable, front-facing elements of the ITER blanket that are designed to withstand the heat flux from the plasma. Depending on their position inside the vacuum vessel, the panels are subject to either 'normal' heat flux (2 MW/m²) or 'enhanced' heat flux (4.7 MW/m²). For the European Domestic Agency, which is responsible for procuring the 'normal' heat flux first wall panels, the high heat flux validation of first wall prototypes will provide important feedback in view of the start of series production. HELCZA (for High Energy Load Czech Assembly) is designed for this purpose, with a capacity to test ITER plasma-facing components with heat flux densities in the range of several MW/m². Located at the Research Centre Řež in Plzeň, it was financed by the European Domestic Agency (Fusion for Energy) with the support of the European Union and the Ministry of Education, Youth and Sports of the Czech Republic. HELCZA is designed for cyclic heat loading, with an 800 kW electron beam gun emitting electrons at 55 kV acceleration voltage. The facility is also equipped with a set of advanced diagnostics to monitor component behaviour during testing, and a beryllium management system to ensure the safety of the operators before, during and after the test campaigns. Performance tests on Europe's first wall full-scale prototypes will start in the next weeks. See the original article on the Fusion for Energy website. Read more about HELCZA here.

Image of week | Architectural challenges and solutions

An installation as massive as ITER, with a main complex rising 60 metres above ground and construction spreading over 42 hectares, could be a terrible eyesore and an offense to the beauty of its rural surroundings. On the contrary, at ITER—thanks to the effort that went into its design and architecture—the scientific installation adds a spectacular touch to the landscape. The architects at the Parisian firm ENIA, who planned the exterior aspect of the ITER buildings, wanted them to blend into the natural environment and at the same time express the highly technical nature of the research work being performed within. The solution they chose, a cladding that alternates mirror-like stainless steel panels and grey-lacquered metal stripes, has proved efficient: on certain days, under certain light conditions, the buildings seem to disappear as they reflect the shades and colours of the changing skies. In designing ITER Headquarters, Rudy Ricciotti—the award-winning architect of the Mucem museum in Marseille—and his local partner, Laurent Bonhomme, faced a different challenge: combining the functional requirements of a large office building with the daring architectural gesture that ITER deserved. In their vision, the five-storey, 165-metre-long construction situated slightly below the ITER construction platform should be a 'visual pedestal [...] a horizontal monolith responding to the exuberant verticality of the Tokamak Complex." Here too, the architects succeeded. As is obvious in this picture, part of our most recent drone survey, architecture has bestowed a unique and unexpected beauty on ITER.

of-interest

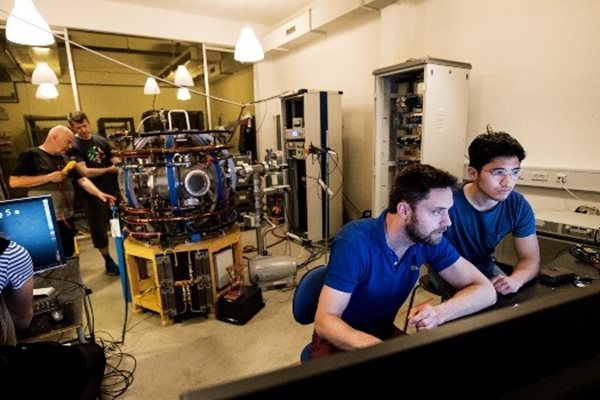

"Fusioneers" unite in Denmark

Four Danish universities have collaborated to create DANfusion, a government-funded consortium allowing researchers to work together and share resources as they study fusion physics and engineering. DANfusion includes research groups from the Technical University of Denmark, Aarhus University, Aalborg University, and the University of Southern Denmark. Through DANfusion funding, researchers will have the opportunity to visit national and international fusion experiments to gain greater knowledge in their field, and to accumulate hands-on experience through fusion-relevant summer schools and resources like the Technical University of Denmark's NORTH tokamak. The overarching goal of DANfusion is to strengthen the bond among national scientific communities through shared knowledge and united research efforts. Read the EUROfusion announcement here.

ITER International School: new dates

The ITER Organization plans a regular, one-week ITER International School for young scientists and engineers around a specific theme. The School locations alternate between France and one of the seven ITER Members. Before the global pandemic made travel and gathering impossible, a 2020 ITER International School, co-organized with Aix-Marseille University (France), was planned on the topic of "The Impact and Consequences of Energetic Particles in Fusion Plasmas." First pushed back to 2021, the decision has now been made to hold this School in summer 2023. More details will be provided on the re-scheduled IIS 2020 in autumn 2022 on this ITER webpage. In the interim, a summer 2022 ITER International School will be hosted by the US Burning Plasma Organization. Further details will be published about IIS 2022 on the ITER website in autumn 2021.