The Project

- Building ITER

- Projects Underway

- Construction Archives

- Neutral Beam Test Facility

- Assembly Overview

- Tokamak Assembly

- Plant Assembly

- Commissioning

- Assembly Tooling

- Metrology

- Project Milestones

Tokamak Complex

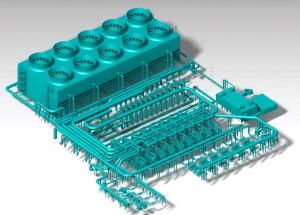

Tokamak Complex assembly contractors are installing equipment now in the lowest level of the Tokamak and Diagnostics buildings (B2 and B2/Mezzanine), progressing around the Tokamak Pit in a counterclockwise direction before moving up to level B1.

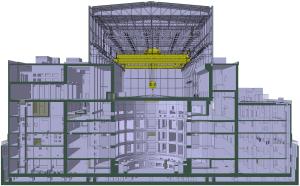

At the heart of the ITER scientific installation is the Tokamak Complex, a 400,000-tonne edifice that reunites the Tritium, Tokamak, and Diagnostic buildings.

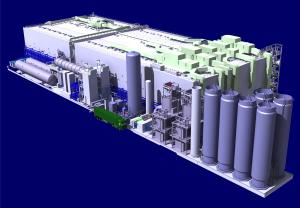

Eighty metres tall (including basement levels), 120 metres long and 80 metres wide, the Tokamak Complex dominates the ITER platform. The seven-storey structure will house not only the ITER Tokamak, but also more than 30 different plant systems that are necessary for the machine's operation.

The Tokamak Complex is a nuclear-rated structure of reinforced concrete that is supported on aseismic isolators. The roof is 60 metres above ground level; the basement floor is approximately 11 metres below. The mid-plane of the machine has been located approximately at the level of the platform.

Construction of the massive edifice required just over 10 years and millions of work hours. It was carried out by European Domestic Agency contractor VFR (comprising French companies VINCI Construction Grands Projets, Razel-Bec, Dodin Campenon Bernard, Campenon Bernard Sud-Est, GTM Sud and Chantiers Modernes Sud, and the Spanish firm Ferrovial Agroman). The construction contract signed for the Tokamak Complex also included the construction of the ITER Assembly Building; the Radiofrequency Heating Building; technical infrastructure for heating, ventilation and air conditioning; a cleaning facility and site services building; the cryoplant compressor and coldbox buildings; the control buildings; the fast discharge and switching network resistor building; and three bridges. A second contract, signed in 2013, covered the mechanical and electrical equipment in the building suite (electricity, lighting, fire protection, elevators, HVAC ...).

Following the completion of Tokamak Complex foundations in August 2014, work proceeded on the concrete walls and floors of the structure (outlined in green in the drawing above). Tens of thousands of embedded plates have been cast into the concrete of the floors, walls and ceilings of the building to provide anchoring for the systems and equipment.

In parallel, contractors completed the ITER bioshield—a circular structure in the centre of the Tokamak Building that forms the machine well, or pit. Six-storeys tall and pierced all around by openings for systems and equipment, the bioshield is up to 3.2 metres thick.

Following the completion of the crane hall, a vast open space at the top of the Tokamak Building that allows the cranes to access the Tokamak Pit, the European Domestic Agency Fusion for Energy transferred the building to the ITER Organization in March 2020 for the start of machine assembly. The last civil engineering project, the Tritium Building, was completed in late 2023.

Tokamak Complex facts:

- Construction: 2014-2023

- Concrete required: 100,000 cubic metres

- Steel reinforcement: 30,000 tonnes

- Thickness of basemat: 1.5 metres

- Number of stories: 7

- Total weight (buildings, equipment and machinery): 440,000 tonnes

- Contractor for civil work (TB03): French-Spanish consortium VFR (VINCI Construction Grands Projets, Razel-Bec, Dodin Campenon Bernard, Campenon Bernard Sud-Est, GTM Sud, Chantiers Modernes Sud, Ferrovial Agroman)

- Contractor for mechanical and electrical equipment (TB04): Franco-German consortium GDF Suez Group/M+W Group

Photo Gallery