you're currently reading the news digest published from 15 Oct 2018 to 22 Oct 2018

featured6

of-interest1

press14

featured

Construction | A new team of problem solvers

Integrating the many systems that make up the Tokamak machine is a lot like delivering a clash-free layout for the engine room of a modern nuclear submarine, only on a much grander scale. Introducing the HIT team—a group of engineers, designers and contractors that has been selected to take a hard look at the overall integration of systems in ITER's main nuclear buildings and to propose solutions for clashes and constructability issues. They have been chosen from engineering and construction departments at ITER, the European Domestic Agency buildings team, contractors, suppliers, and the Domestic Agencies. A core team of about eighty people who, while remaining under the responsibility of their original line management, are sharing office space near the construction site in order to perform 'joint integration work'—that is, to ensure that i's have been dotted and t's crossed before the large-scale assembly and installation of plant systems begins in the Tokamak Complex. Formed in March 2018 by the ITER Director-General, the HIT—for Holistic Integration Team—has been given the role of 'collaborative system design integrator,' says coordinator Miikka Kotamaki. 'We are in charge of delivering a clash-free design and optimized system installation sequences for every area in the Tokamak Complex.' The HIT team works by area (i.e., by building and level), and assesses all available system design elements for completeness, consistency and constructability. The group has developed an 'integration lifecycle' that it works through to ensure that all issues have been resolved (see below). 'The integration cycle is a kind of 'Snakes and Ladders' template, based on the previously tried-and-tested model of the Buildings Infrastructure and Power Supplies (BIPS) Project Team,' says Deputy Coordinator Roger James Holt. "We use it to make sure that all 'ladders' are climbed at the right time and 'snakes' avoided." (More on the integration lifecycle here.) It was in executing this kind of step-by-step assessment that one part of the HIT team began looking more closely at the passage of services and utilities through the Tokamak Complex walls and floors. As the massive structure rises, thousands of openings have been left in the civil works for the passage of ventilation, electricity and cooling water. These openings will eventually be backfilled with concrete—but first, 'placeholders' must be installed, such as tubes for the future passage of piping or sleeves for electrical cabling. The initial design concept proposed stainless steel frames to support the placeholders—each one machined off site to match the particular layout requirements of each opening (see diagram, right). 'This solution seemed to present a long list of disadvantages,' says Caroline Dixon, technical lead for the ENGAGE team developing detail design of the backfilling of the openings. 'Each frame had to be custom designed; manufacturing was costly and time consuming; and the weight of the final frames—up to 500 kgs—would have made specialized handling tooling necessary in the Tokamak Complex.' The team concluded that—while the custom-made frame may be justified in particularly complex openings—the majority would be just as well served by a simpler, standardized solution. By benchmarking practices at other large construction sites and working with local industry to adapt a solution for ITER, the HIT engineers arrived at a modular solution with adjustable positioning elements. 'The solution is like modular shelving—lighter and more flexible, easier and cheaper to fabricate and install, and based on standardized elements that can be stored in bulk on site.' Provided with a table indicating the exact location of the penetrations that must be reserved in each opening, installation contractors can put together the required support system right in the field. The flexibility, ease-of handling, and lower cost of the solution clearly convinced ITER Organization management, which recently gave its approval during a monthly review meeting with the HIT team. It was just one demonstration among many of the positive impact the HIT team has had since its formation six months ago. 'This design solution is a concrete example of how the HIT team is identifying and resolving problems associated with the co-existence of numerous services to be located in the same area/room of the Tokamak Complex Building before assembly and installation works get underway,' says Bernard Bigot, ITER Director-General. 'By taking a high-level view of all plant systems in the Tokamak Complex and executing concurrent engineering activities, the HIT is critical to secure the project's assembly phase schedule and cost.'

Fusion world | Large fusion conference opens in Gandhi's hometown

Mahatma Gandhi, whose mandir (a Hindi word for 'temple' or 'place of learning') is hosting the 27th edition of the International Atomic Energy Agency's Fusion Energy Conference, would have blessed this crowd. More than one thousand men and women from around the world gathered in his hometown to share knowledge and experience in order to solve one of humankind's most daunting challenges. Hosting the world's largest fusion energy conference 'is an honour that India deserves,' said Meera Venkatesh of the International Atomic Energy Agency (IAEA) in her inaugural address. India, which entered fusion research in the early 1970s, has risen in a few decades to the forefront of the discipline. As a nation of close to 1.4 billion inhabitants, heavily dependent on fossil fuels (81.4 percent) for electricity generation, India sees its future in nuclear energy in all its forms. 'It is clearly an essential option for energy safety,' said Rajagopala Chidambaram, a key architect of the country's nuclear program and the former Chair of India's Atomic Energy Commission. 'I don't see any other option on the horizon.' For Nawal Prinja, another figure from India's nuclear sector who spoke on the first morning of the conference: 'Fusion is our future. Fusion technology is already working; what's missing is the extraction of energy from fusion reactions.' Half-joking, half-serious, Chidambaram described fusion as 'a physicist's delight but a huge headache for the engineer.' And this is what the five-day IAEA Fuesion Energy Conference will be about: exploring conceptual delights and technological headaches, the breakthroughs and the obstacles on the way to realizing the Promethean dream of harnessing fusion energy. Fifty years ago in Novosibirsk, at the third gathering of what was then called the Conference on Plasma Physics and Controlled Nuclear Fusion Research, a new type of fusion device, christened with the Russian acronym 'tokamak,' entered centre stage (see box below). Today, the hopes of the worldwide fusion community rest on the largest tokamak ever built and the first designed to deliver a net energy production. ITER, whose progress toward First Plasma was presented by Director-General Bernard Bigot at the opening session of the conference, will be the focus, whether directly or not, of a large part of the presentations and posters. With ITER now 58 percent of the way to First Plasma, a new era in fusion energy research has opened. It is against this background that, in Mahatma Gandhi's Ahmedabad-Gandhinagar, scientists and engineers from 40 countries will present and discuss the key physics and technology issues of fusion research ... for the benefit of all mankind.

ITER | A day in the life of

Seven hundred people took part in the ITER Organization's latest Open Doors Day event on Saturday 20 October. ITER opened its doors on a beautiful autumn day to the delight of 700 members of the public, students, staff and families. The highlight—as always—was gaining exceptional access to areas of the worksite that are usually cordoned off due to the pace of work on site and the density of contractors and equipment. This time, visitors were accompanied by group of 50 through the cathedralesque galleries of the Tokamak Building and out to the central well where the ITER machine will be assembled. To prepare for that visit, to understand the world-changing science that will take place in that space, guests that day had access to the ITER Visitors Centre and additional hands-on exhibits that were offered by partners Agence Iter France, local association Les Petits Debrouillards ('Little Problem Solvers'), and ITER's own tabletop science exhibit. Open Doors Day is a biannual event hosted by the ITER Organization and the European agency for ITER, Fusion for Energy. On Saturday, 50 volunteers from the ITER Organization, Fusion for Energy, ITER's Management-as-Agent contractor MOMENTUM, and European contractors Engage, Apave and Dalkia were hosts for the day. Scroll through the gallery below for scenes from the day.

Langmuir probes | Have heatshield, will travel

Delivering components to the ITER site requires massive logistics ... most of the time. At others, an airline passenger's pocket suffices. Of course, it is a matter of size—the five 'Langmuir probe' heat shield mockups that were delivered by hand last week by He Kaihui of the Chinese Domestic Agency are no bigger than (and look quite like) a bullet. Langmuir probes were developed in the early 1920s by American physicist Irving Langmuir (1881-1957) to measure the temperature and density of ionized gases—a state of matter for which Langmuir coined the word 'plasma.' 'A Langmuir probe is basically an electrode that is inserted into the plasma,' explains Diagnostics Physicist Christopher Watts, who was on the receiving end of the delivery. 'The electrode is hooked up to a voltage and, as the voltage varies, electrons and ions are 'sucked in.'' By counting the electrons, you have the density. For the temperature, if a high voltage is needed to pull out the electrons, it means the electrons have lots of energy and the plasma is hot; in the same way, a low voltage means the plasma is cold. In ITER the plasma is so hot that no probe would survive insertion. There is, however, a reasonably 'cool' place inside the machine located in the most unexpected component: the divertor, whose 'targets' are exposed to heat loads close to those at the surface of the Sun. Thanks to the neutral gas that is puffed in to cool the plasma in the vicinity of the divertor, the gaps between adjacent targets are blessed with an almost balmy climate: the temperature is in the range of 2,500 °C and—provided the probe is encased in a proper heat shield—its chances of survival are high. 'The probes are partially sacrificial components,' says Watts. 'We'll mount 400, and over the total we do not expect to lose more than 10 percent.' In this perspective, the efficiency of the probe's tungsten heat shield is of crucial importance. Designed by China's Southwestern Institute of Physics (SWIP) and manufactured by Xiamen Tungsten Corp. the five mockups (out of a total of 18) that He Kaihui delivered to ITER will go through a series of tests ... that will require quite a bit of travelling. Twelve of the mockups will go to Germany to Research Instruments, Gmbh where each will be brazed and bonded to a tungsten 'monoblock.' (Monoblocks are the building bricks of the divertor targets, and there will be approximately 300,000 of them in the divertor.) Similar tests will be conducted in Japan on the other six mockups. As tungsten is notoriously difficult to bond, both the German and Japanese tests will verify the mechanical resistance of the heat shield plus monoblock assembly. Of the 12 assemblies tested in Germany, six will be cut and closely analyzed, while the six others will head to QST in Japan to be exposed to powerful halogen lights that will deliver heat loads representative of those actually experienced in the divertor area. Following halogen exposure, the assemblies will be flown to the Dutch Institute for Fundamental Energy Research (DIFFER) to be placed inside the Magnum PSI plasma generator and experience the real thing at last: particle and heat fluxes as intense as those of an ITER plasma.

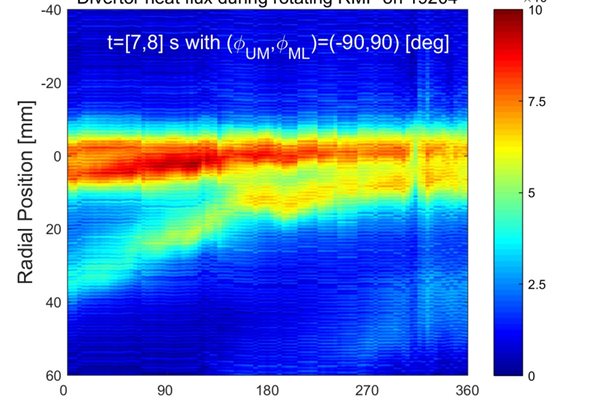

Physics | 10th ITER International School in January

The ITER International School aims to prepare young scientists/engineers for work in the field of nuclear fusion and in research applications associated with the ITER Project. The 10th edition will be held from 21 to 25 January in Daejeon, Korea. The 10th ITER International School (IIS) will be held on 21-25 January 2019 at the Korea Advanced Institute of Science and Technology (KAIST) on the subject of 'The Physics and Technology of Power Flux Handling in Tokamaks.' This subject has an interdisciplinary character: power flux handling in tokamaks is key challenge for the development of nuclear fusion, but one that can only be resolved through the integration of physics-based approaches to decrease power fluxes on the tokamak wall together with technological developments for tokamak wall components. The choice of ''school format'' for IIS was adopted due to the need to prepare future scientists/engineers on a range of different topics and to provide them with a wide overview of the interdisciplinary skills required by the ITER Project. The first ITER school—in July 2007 in Aix-en-Provence, France—was organized on the topic of turbulent transport in fusion plasmas. Eight different editions have followed: Fukuoka, Japan, on magnetic confinement (2008); Aix-en-Provence on plasma-surface interactions (2009); Austin, Texas (US) on magneto-hydro-dynamics (2010); Aix-en-Provence on energetic particles (2011); Ahmedabad, India, on radio-frequency heating (2012); Aix-en-Provence on high performance computing in fusion science (2014); Hefei, China, on transport and pedestal physics in tokamaks (2015); and finally Aix-en-Provence on the physics of disruptions and control (2017). Further information on the school can be found here.

On site | Safety has no holiday

Don your helmet, put on safety goggles and gloves, step into your steel-capped work boots, and slip into a bright yellow vest—these are basic safety rules for anyone going onto the ITER worksite. But safety is so much more. 'Spot the seven mistakes'—what sounds like a game is serious business. Several workers in their bright work gear look at a section of scaffolding and start counting potential safety hazards. There is a broken plank at the top level, the ladder is missing a step, and a piece of safety railing hangs loose. Other stands offer the opportunity to prove one's knowledge in handling oil spills, safely managing the transfer of heavy loads, or using first aid equipment. For four days, the fair-like atmosphere of Safety Week took over one end of a large car park at ITER. Once every year, the 850 workers of the French-Spanish consortium VFR (comprising French companies VINCI, Razel-Bec, Dodin Campenon Bernard, Campenon Bernard Sud-Est, GTM Sud and Chantiers Modernes Sud, and the Spanish firm Ferrovial Agroman) refresh their knowledge about safety rules and regulations at the workplace—a tradition adopted from VINCI, which organizes the event at all its branches worldwide. Safety at the workplace is also an important issue for ITER Director-General Bernard Bigot. Before touring the stands with the safety training exercises, he told the workers: 'We are developing an energy source that is safe and environmentally friendly. Demonstrating that we are also serious about safety at the work place will give further credence to our message.' While we have experienced some safety incidents resulting in injuries, so far ITER has had no fatal accident on the construction site due to unsafe work practices. 'I want us to keep up this record until the completion of the ITER Project.' 'Safety is the only thing that has no holiday,' says Prabhat Kumar, Deputy to the Site Construction Director at ITER, ahead of an award ceremony for the contractors with the best safety record that happens to coincide with Safety Week. Winning contractors for the second quarter of 2018 are the French companies SEMA (stainless steel waterproofing in the Tokamak Building) and Métal Concept (building of steel structures in the cryoplant). According to Kumar, the safety awards serve as an additional incentive for all companies to improve their health and safety performance.

of-interest

£50 million MAST upgrade concludes

Five years of construction work to upgrade the spherical tokamak MAST (UK) have been brought to a close and experiments are set to begin early next year. MAST Upgrade will contribute to the knowledge base for ITER by helping to resolve key plasma physics issues. It will be the first tokamak to trial the Super-X divertor—a novel way to exhaust heat loads from large fusion reactors, which spreads the power loads in the divertor area of the machine. Other features of the upgrade include an increase in the pulse length by a factor approaching ten, additional heating power, and better control and pumping capabilities to contain the resulting higher temperature, longer-pulse plasmas. A ceremony was held on 18 October at the UK's Culham Centre for Fusion Energy (CCFE). See the full report here.