you're currently reading the news digest published from 01 Jul 2019 to 08 Jul 2019

featured5

of-interest1

image1

press1

featured

Construction | The stage is now set for the next act

Nine years and 382 Newsline issues ago, a lone power shovel began removing the top soil from the area on the ITER platform where the Tokamak Complex now stands. Following two years of clearing and levelling work by France, construction of the ITER installation was beginning in earnest. It may be hard to believe, but this is what the 42-hectare ITER platform looked like in the early months of 2010, just before being transferred from Agence Iter France to the European Domestic Agency, responsible for construction. A vast, featureless, moon-like expanse that—being located in Provence—some described as the largest pétanque court ever created. One by one, the now-familiar buildings and structures have sprung from the earth: nine years into construction civil works are 73 percent complete, concrete has reached its final level in the Tokamak Building, and a massive machine component—the cryostat lower cylinder—is visible, carefully encased in its protective cocoon, waiting to be installed in the Assembly Pit. As conveyed by the images from this latest drone survey (June 2019), the stage is now set for the next act in the project's history: the machine assembly phase, set to begin in May 2020.

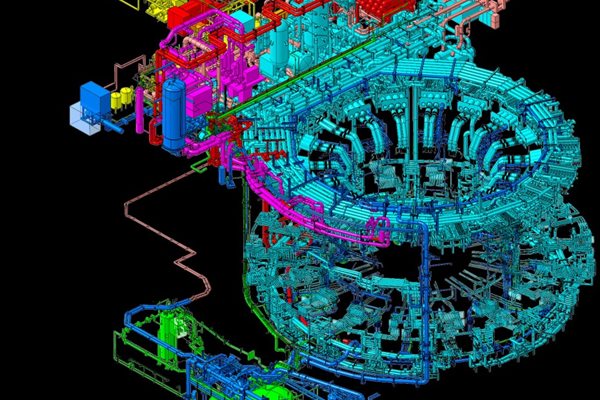

Tokamak cooling system procurement | Global team for better efficiency

A unique work-sharing arrangement is expediting the design and fabrication of ITER's tokamak cooling water system and building the knowledge base that will be critical to plant commissioning and operation. A joint TCWS Project Team—composed of staff from the ITER Organization and the US ITER Project Office—is making strong progress in the procurement of the tokamak cooling water system (TCWS). The hardware required for First Plasma is in production following design finalization in November 2017, and the design of second-phase components is advancing well. The TCWS Project Team was established in late 2018 after US ITER and the ITER Organization agreed on several 'arrangements' for improving the efficiency of system design and fabrication. 'The overarching strategy is to get the job done on schedule, according to committed costs, while assuring quality in terms of function, safety, performance and installation consistency,' says Sergio Orlandi, head of the Plant Engineering Department at ITER. TCWS piping is in fabrication at Schulz XP USA/PCC Energy Group in Robinsonville, Mississippi, and at W. SCHULZ GmbH in Krefeld, Germany. The US facility is unique in its capability for producing large-bore piping extrusions, important given that some of the system piping is 600 mm in diameter. Other components, such as bellows to connect system piping to the cryostat, are in fabrication elsewhere in Europe. 'The Project Team establishes a pool of resources that are shared between the ITER Organization and US ITER. These specialists are working as one team, under a single framework, with the same objectives,' says Donato Lioce, head of the ITER Tokamak Cooling Water System Design Section and TCWS Project Team Leader. Deputy Leader Duke Hughes, based in the US, agrees: 'The implementation of the formal project team structure between US ITER and the ITER Organization creates a unique synergy that the TCWS team leverages to optimize the effectiveness and execution of its work.' Ultimately, nearly 40 km of piping will be manufactured for the TCWS. In addition, the system will require the fabrication of over 100 major industrial pieces of equipment operating with maximum temperatures of 400 °C and maximum pressures of 5 MPa or 50 bar. To execute delivery of system hardware, the arrangements stipulate specific areas where the ITER Organization will be compensated to finalize design and procurement of hardware on behalf of US ITER. Because the cooling water system interfaces with most ITER plant systems and also has components that must comply with French nuclear pressure equipment directives (ESPN), design and fabrication is expedited by engaging ITER resources. This approach also prepares the ITER Organization, as nuclear operator, by building the knowledge to support commissioning and operation in future. US ITER retains responsibility for the system final design, manufacturing and delivery. The ITER Organization is responsible for on-site assembly, installation and commissioning. The TCWS is designed to remove 1 GW of heat from ITER client systems, such as the first-wall/ blanket, vacuum vessel, divertor, and neutral beam injector. In addition, the system provides water chemistry control and draining/drying functions. The system interfaces with the secondary cooling water system, which is being provided by ITER India.

Nobel Laureates | How can science change the world for the better?

Every year, a group of Nobel Laureates convenes in Lindau, Germany, for a week of interaction with young scientists from all over the world. ITER was invited to take part this year in a panel discussion titled 'How Can Science Change the World for the Better?' Created in 1951 to foster the exchange among scientists of different generations, cultures, and disciplines, the Lindau Nobel Laureate Meetings seek to inspire and excite by creating a forum for interaction between world-recognized specialists and the scientists of the future. For this year's 69th edition—dedicated to physics—580 undergraduates, PhD students and postdoctoral researchers were invited from 89 countries. Thirty-nine Nobel Laureates in Physics took part in the event. For the final panel discussion on 'How Can Science Change the World for the Better?' the ITER Project had a place at the table. Tim Luce, Head of the Science & Operations Department and Chief Scientist, participated in the discussion with Nobel Laureates Steven Chu (1997 Nobel Prize in Physics, former US Secretary of Energy), Vinton Cerf (co-inventor of the internet, now with Google), Adriana Marais (advocate for human space travel to Mars), and Brian Schmidt (2011 Nobel Prize in Physics, Vice-Chancellor of Australian National University). Led by moderator Karan Khemka, the discussion ranged from sustainable development, to the rise of artificial intelligence, to the role of scientists in society. ITER's presence was important, because these young scientists are part of the generation that will need to learn from ITER and put the planet on a path to a fusion-powered economy. No guarantees, but that really could change the world for the better.

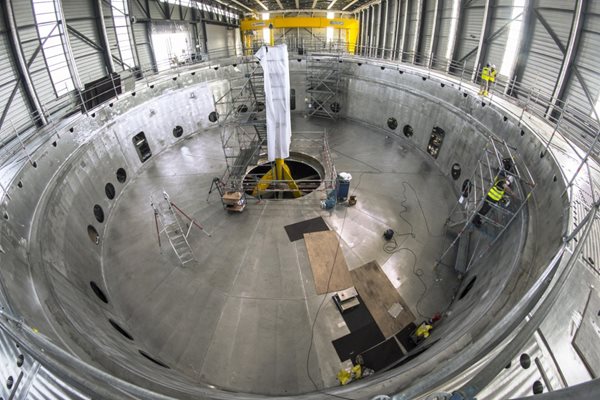

Cryostat | It's happening in the workshop

On a cold night in December 2015, a three-trailer convoy passed through the village of Saint-Paul-lez-Durance, adding its pulsating blue and orange lights to the Christmas illuminations. The convoy carried three 50-tonne steel pieces shaped like so many slices of pie—the first elements of the cryostat base to be assembled on site in the Cryostat Workshop. Two-and-a-half years later, 'physical work' on the 1,250-tonne subcomponent is now finalized. Taking over from the Indian Domestic Agency, which is responsible for the procurement of the cryostat, the ITER Organization will soon proceed with 'pre-assembly work' prior to installing the component in the Tokamak Pit in May 2020. Pre-assembly work will consist of welding handling and support systems to the base structure, attaching 18 bellows under the component's skirt to connect the machine to the cooling water system, and installing a monorail and small trolley to handle the clamps, shins and other elements needed to interface with the building. With the base completed and the lower cylinder safely encased in its protective cocoon, activity in the Cryostat Workshop is now focused on the upper cylinder. In less than two weeks, three out of six tier-one segments have been positioned on their assembly frame. Due largely to the lessons learned in the assembly and welding of the lower cylinder, work is progressing at an exceptionally fast pace. See the gallery below for more details.

Pressurized equipment | ITER can now act as inspector

A component or system under pressure that contains (or might contain) activated elements falls under the category of 'nuclear pressurized equipment.' In ITER, components such as the vacuum vessel, the massive drain tanks that collect water from the cooling circuits in the case of leak or accidental situation, and the nearly 40-kilometre-long network of the Tokamak cooling water piping belong to this category. French nuclear safety regulations, which ITER observes, require that conformity assessments be performed at every stage of the component or system's fabrication. These assessments are performed by specialized companies called 'Agreed Notified Bodies' that provide step-by-step validation of the design/manufacturing/installation processes and eventually deliver the certificate of conformity allowing the component or system to be commissioned. Last week, following a lengthy and rigorous procedure, the ITER Organization successfully passed the audit to act as an Agreed Notified Body. 'We now have internalized this capacity,' says Joëlle Elbez-Uzan, head of the ITER Environmental Protection & Nuclear Safety Division. 'We have acquired the so-called 'Module H', which validates the excellence of our integrated management system of regulatory requirements in the field pressure regulation.' Following this initial validation, Joëlle's Division will be audited every year by the certification agency Bureau Veritas. For ITER, the internalization of a formerly contracted strategic function (and a costly one at that) translates into considerable savings.

of-interest

ITER and science journalism

What happens when hundreds of science journalists from more than 50 countries get together? A lot of questions get asked ... Earlier this month, the 11th World Conference of Science Journalists (WCSJ2019) took place in Lausanne, Switzerland, with the stated ambition of 'strengthening the professional, ethical and technical skills of science journalists by increasing their knowledge of recent developments in science and improving their understanding of the forces that shape our world.' ITER was there. As one of the world's most ambitious—and complex—scientific projects, ITER has the responsibility to nurture close and open relationships with journalists around the world who may be interested in finding out more. Journalists communicate with the audiences that need to understand fusion—how it works, what are the advantages of this form of energy, and how it could become an integral part of their lives and those of future generations. During the weeklong event, the ITER stand—with a cinematic booth showing drone footage of the worksite—was a first point of contact for journalists. ITER Director-General Bernard Bigot was also interviewed live by Science magazine's European news editor Eric Hand. Finally, a group of 25 journalists elected to take the train to ITER on the last day of the conference, where they were given an in-depth tour of construction. ITER's doors have always been open to the media. Our presence at the WCSJ2019 was a way to reaffirm this commitment to transparency.