Cryostat

It's happening in the workshop

8 Jul 2019

On a cold night in December 2015, a three-trailer convoy passed through the village of Saint-Paul-lez-Durance, adding its pulsating blue and orange lights to the Christmas illuminations. The convoy carried three 50-tonne steel pieces shaped like so many slices of pie—the first elements of the cryostat base to be assembled on site in the Cryostat Workshop.

Resembling a soup dish, or an upside down hat, the cryostat base is the heaviest single component of the ITER machine. It is also the first major lift of the ITER assembly phase. By March 2020, the completion of the Tokamak Building roof and the extension of the assembly crane rails will permit this component to be installed in the Tokamak Pit.

Two-and-a-half years later, "physical work" on the 1,250-tonne subcomponent is now finalized. Taking over from the Indian Domestic Agency, which is responsible for the procurement of the cryostat, the ITER Organization will soon proceed with "pre-assembly work" prior to installing the component in the Tokamak Pit in May 2020.

Pre-assembly work will consist of welding handling and support systems to the base structure, attaching 18 bellows under the component's skirt to connect the machine to the cooling water system, and installing a monorail and small trolley to handle the clamps, shins and other elements needed to interface with the building.

Work has begun in the workshop on the cryostat upper cylinder. Several of the first-tier segments have already been unwrapped and installed on the assembly platform.

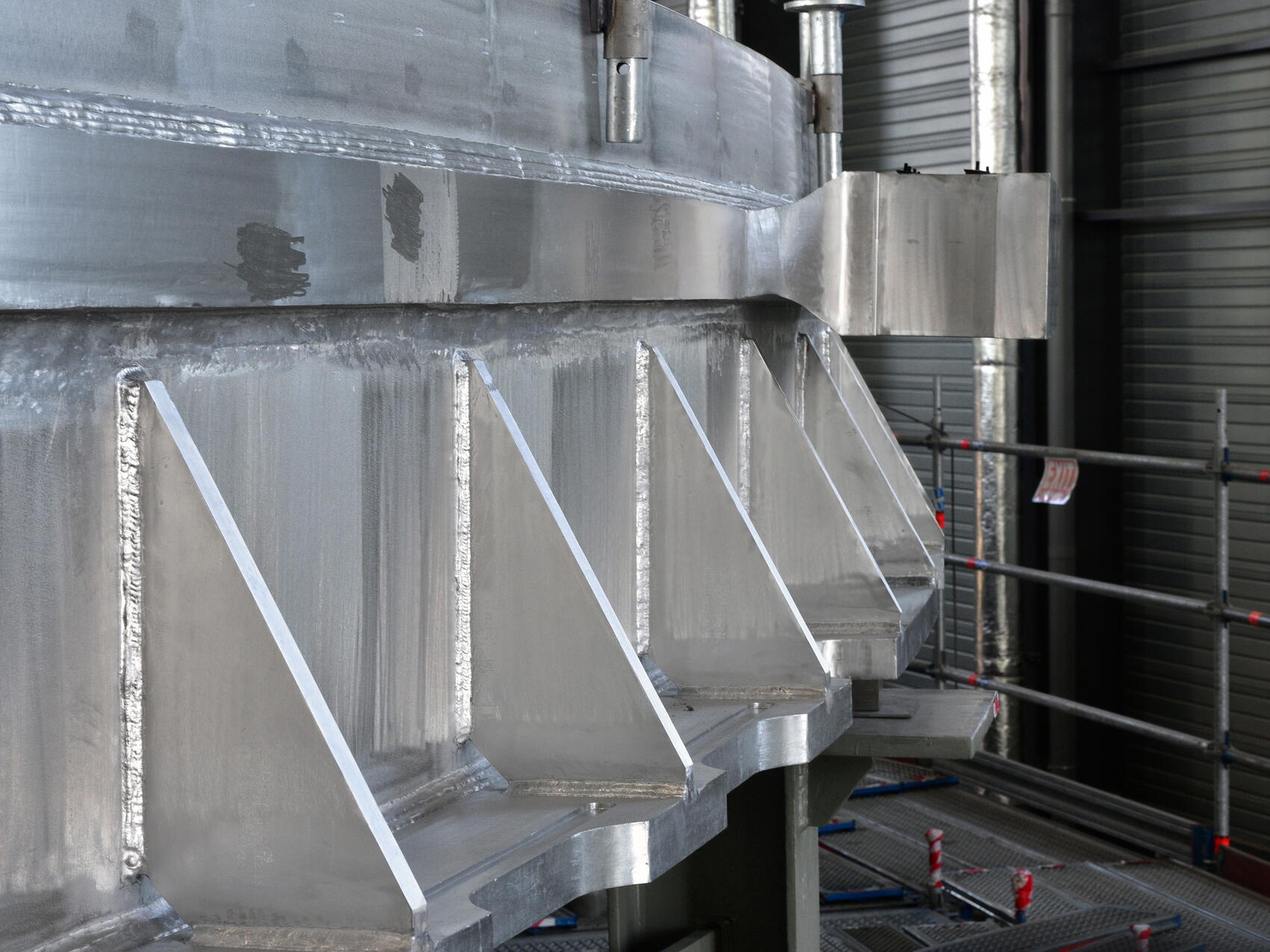

With the base completed and the lower cylinder safely encased in its protective cocoon, activity in the Cryostat Workshop is now focused on the upper cylinder. In less than two weeks, three out of six tier-one segments have been positioned on their assembly frame. Due largely to the lessons learned in the assembly and welding of the lower cylinder, work is progressing at an exceptionally fast pace.

See the gallery below for more details.