you're currently reading the news digest published from 15 Feb 2021 to 01 Mar 2021

featured4

of-interest2

press25

featured

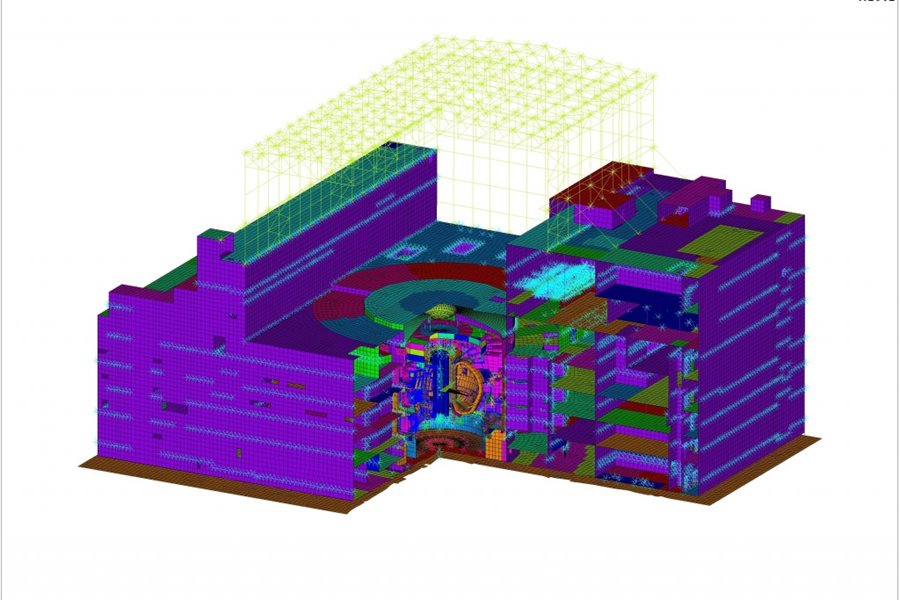

Seismic analysis | Collaboration helps to keep ITER on solid ground

At ITER, system designers have to ensure that their equipment will withstand earthquakes, large and small. Equipment required for the safety of ITER has to be designed to an SL-2 earthquake, which corresponds to a seismic event predicted to occur only once every 10,000 years. Responsibility for integrated seismic analysis lies with the Integrated Engineering Analysis Section, whose broader mission is to help define loads of various types. 'Helping to define seismic loads is just one of our activities,' says Section Leader Tyge Schioler. 'We do the same for static electromagnetic fields, or transient electromagnetic loads during disruptions. And we help define thermal loads during transient events.' 'We provide advice and support on methodology and best practices for analyses. We write documents that say how to perform an analysis, for example. And we also provide direct support, where a designer will come to us with a specific problem, and we give one-off recommendations.' To help analyze seismic loads, teams at ITER and the European Domestic Agency, Fusion for Energy, use a software package called ANSYS to build finite element models that relate acceleration to the natural frequencies of a given structure. The frequency of a structure is a function of mass and stiffness, where stiffness is a property defined by how far something moves when a given amount of force is applied. The smaller the movement, the stiffer the structure is said to be. 'When a structure is made out of just steel or concrete, modelling is easy,' says Schioler. 'However, most structures are made of several different materials, and our models have to take this heterogeneity into account. Our most complex model is the one that represents the ITER Tokamak and Tokamak Complex as a whole.' The baseline model of seismic loads in the Tokamak Complex Not surprisingly, much of the seismic analysis focuses on defining the loads in the Tokamak Complex, which includes the Diagnostic and Tritium buildings, and the Tokamak building itself. These buildings sit on anti-seismic bearings, which isolate the structures horizontally. The anti-seismic pads are very stiff vertically, which means that if the ground moves vertically, the building will move with it. By contrast, the rubber in the anti-seismic bearings provides horizontal flexibility. When the ground moves horizontally, the building stays relatively still, and the equipment inside the building experiences very little acceleration. 'The internal deformation of the building structures is not so high,' explains Schioler. 'If you have a horizontal earthquake, the majority of the deformation will be in those anti-seismic bearings. The building is basically just a rigid block that sits on top of that.' Nevertheless, the equipment housed within the buildings has to be designed to withstand whatever movement there is. Since each piece of equipment behaves differently based on the natural frequency of the equipment, manufacturers need input to help them meet the requirements for safety and reliability. The baseline for seismic loads was developed in 2016 through collaboration between ITER, Fusion for Energy, and Fusion for Energy contractors. 'It took a huge amount of work to build the models and go through all the quality assurance processes,' says Schioler. 'We described how every part of the building moves during an earthquake. And we defined what's called the design floor response spectra, which are graphs of acceleration versus frequency. These graphs are given to equipment manufacturers to indicate the acceleration they need to consider in their designs of pumps, valves, cubicles and anything else that sits in a given location on a given floor.' The teams also use models to define relative displacements between different points. For example, the vacuum vessel might bounce up and down a little bit, and the building a bit less. This relative motion might compromise a pipe running between the two structures. But to predict how a pipe bends the models need more than just the relative motion: they also need information on the natural frequency of the pipe. 'Figuring out whether or not the pipe will be okay can actually end up being quite complex work,' says Schioler. A day in the life 'On a typical day, we advise equipment owners about how to interpret and apply the baseline loads,' says Schioler. 'We also very often provide advice on analysis methodology, and on the many ways calculations might be done. If somebody wants to outsource work, we can help with the technical specifications to make sure what they need is correctly specified.' The Integrated Engineering Analyses Section provides advice on the selection of codes and standards and any relevant material selection topics, including non-destructive testing for welds and joints. In some cases, equipment qualification is too complex to accomplish purely through calculations; instead, experiments must be performed—for example, a motor might be placed on a shaking table that simulates an earthquake to test the motor's reaction. 'Most importantly, our job is to quantify how safe the buildings and equipment are—and we rely on close partnerships to do that,' says Schioler. 'Fusion for Energy is responsible for the design of the civil structure. We look closely at what they do, and run calculations in parallel to make sure we come to the same conclusions. Together we have to assess this 300,000-tonne reactor building and check that every single bit of reinforced concrete in there will be okay in the event of an earthquake.' 'This is an excellent example of successful cooperation between ITER, Fusion for Energy, and Fusion for Energy contractors,' says Schioler. 'We trust what they do. They trust what we do. We rely on them. We talk to each other all the time and make sure that we work together in a good way.'

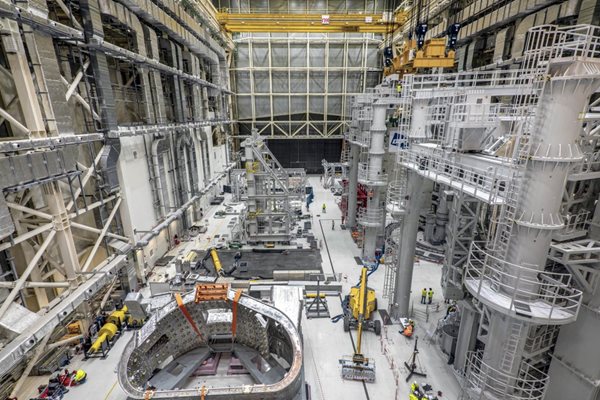

Assembly preparation | Busy month ahead

This year at ITER, the month of March will not only mark the coming of spring. It will also set into motion a series of spectacular operations in the assembly theatre—a space that extends from the entrance of the Assembly Hall to the depths of the Assembly Pit. In approximately two weeks the first 400-tonne vacuum sector (#6), now equipped with the sensors and cables that will feed data from the plasma to the diagnostic devices, will be 'upended' and positioned on one of the giant sector sub-assembly tools in preparation for the first sub-assembly operation. In a months-long series of assembly steps, it will be paired with two toroidal field coils and thermal shield panels to form the first 1,200-tonne subunit of the central ITER vessel. At around the same time the first component of the in-pit assembly tool—the central column—will be bolted to the massive embedded plate on the floor of the assembly pit. The 600-tonne temporary assembly tool must be in place in time to support the weight of the vacuum vessel subassemblies as they are progressively brought into the pit and welded. Drilling activities are underway now to prepare for the installation of this trunk-like colossus. By end March, the lower pre-compression rings and spares will be pre-positioned in the pit prior to their final installation when the tokamak torus is complete. Six rings will help the toroidal field coils push back against the electromagnetic forces of the ITER machine in operation. Made of fiberglass laminate, the pre-compression rings have an inner diameter of 5 metres and weigh approximately 3 tonnes each. Finally, a major operation—both symbolic and spectacular—is scheduled in April: the temporary positioning of the first ITER coil, poloidal field coil #6, at the bottom of the 30-metre-deep machine pit. More information in the image gallery below.

Vacuum vessel | Last phase for Europe's sector #5

The first European vacuum vessel sector is entering an important and critical phase: the assembly and welding of four segments into the D-shaped sector. Under the supervision of the European Domestic Agency, the AMW consortium (Ansaldo Nucleare, Mangiarotti, Walter Tosto), supported by an extended network of sub-suppliers located in France, Germany and Spain, is ready for the challenge. Vacuum vessel sector #5 will be the first of five sectors delivered to ITER by the European Domestic Agency. It has been more than nine years in the making, leading the pack as the European AMW consortium carried out extensive R&D and prototyping, learned to organize manufacturing tasks among the consortium members, and pioneered advanced welding and inspection techniques. The double-wall structure of the vacuum vessel, complex geometry, French nuclear safety regulations, and new rules and restrictions imposed by the Covid-19 pandemic are some of the challenges highlighted by engineers in a recent report by Fusion for Energy, the European Domestic Agency. The four segments that make up Sector #5 are in the last stages of completion; only some final machining and non-destructive evaluation tests remain before the four segments will be positioned on a vast assembly platform and welded together. Four other sectors are in various stages of fabrication in Europe; Korea is also supplying four sectors. See more detail about European manufacturing in the gallery below. See the original story on the Fusion for Energy website.

Magnet system | Second coil comes out of the cold

A second ring-shaped poloidal field coil has successfully passed all thermal testing. Following in the footsteps of poloidal field coil #6 (PF6), which completed all tests in December 2020, PF5 is the second ring-shaped coil (out of six) to check all the boxes. Procured by the European Domestic Agency Fusion for Energy, and produced on site at ITER in collaboration with European contractors ASG Superconductors S.p.A., CNIM, Dalkia, Veolia, Mammoet, Criotec Impianti SpA, Elytt Energy, ALSYOM, SEA Alp, and SEIV, this 17-metre-in-diameter, 340-tonne coil will be ready for assembly in the ITER Tokamak pit when its turn comes later this year. During thermal testing, the coil was inserted into a dedicated cryogenic chamber and cooled down to approximately 80 K (-193 °C), then cycled between cooldown and warmup. To learn more about ITER poloidal field coils, see this page.

of-interest

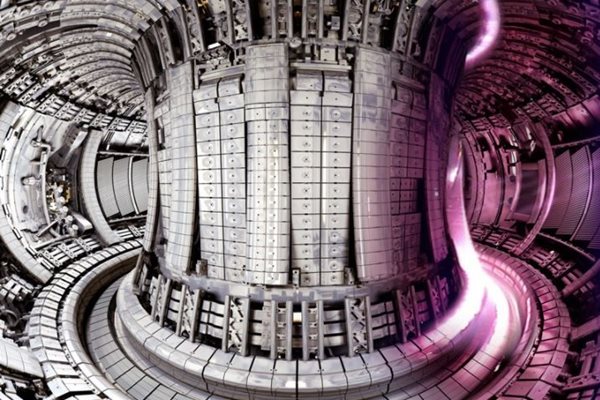

JET: A crucial "dress rehearsal"

An article published on 22 February 2021 in Nature highlights the importance of the upcoming campaign on the JET tokamak (UK) for ITER. "Nuclear fusion experiments with deuterium and tritium at the Joint European Torus are a crucial dress rehearsal for the mega-experiment," writes author Elizabeth Gibney. "JET's experiments will help scientists to predict how the plasma in the ITER tokamak will behave and to craft the mega-experiment's operating settings." Chief ITER scientist Tim Luce agrees. "It's the closest we can get to achieving ITER conditions in present-day machines." JET will be running experiments with hydrogen isotopes tritium and deuterium—the very fuel mix that ITER will use. Some experiments will use just tritium; others will combine deuterium and tritium in equal proportions. Both types of experiment are important, the author explains, because a key goal is to understand the effect of tritium's larger mass on plasma behaviour (tritium has two neutrons in its nucleus, whereas deuterium has one and hydrogen has none). That will help in predicting the impact of using different isotopes in ITER. Read the full article here.

Nuclear News: "A good time for fusion"

"A [US] fusion plant is still years away, but it is definitely getting closer." So concludes the Editor-in-Chief of Nuclear News, the American Nuclear Society's flagship publication, in the preface to the January 2021 issue. Nuclear News dedicates more than 50 pages to fusion energy, at a time when there is an increasing groundswell of interest in fusion in the United States and coalescence around the idea of constructing a fusion pilot plant. Highlights include a major contribution by ITER Director-General Bernard Bigot on the role of ITER; an article on public/private partnerships as the ideal way of advancing technology; features on fusion safety and the regulatory environment; input from startups looking to commercialize fusion energy; and an editorial by US ITER Project Office Director Kathy McCarthy, Associate Laboratory Director for Fusion and Fission Energy and Science at Oak Ridge National Laboratory. See a preview of the issue, or subscribe on the American Nuclear Society's website.