Last phase for Europe's sector #5

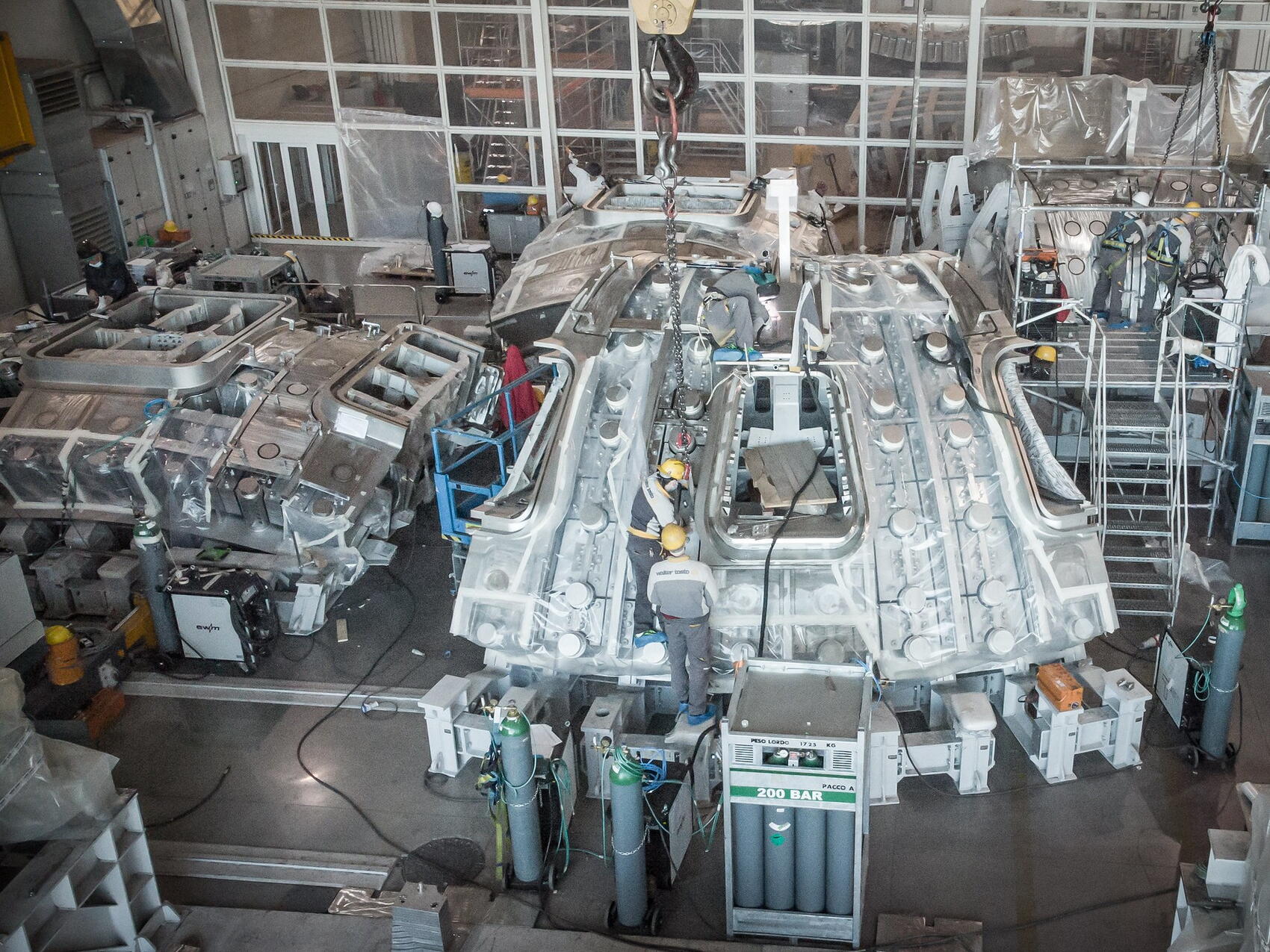

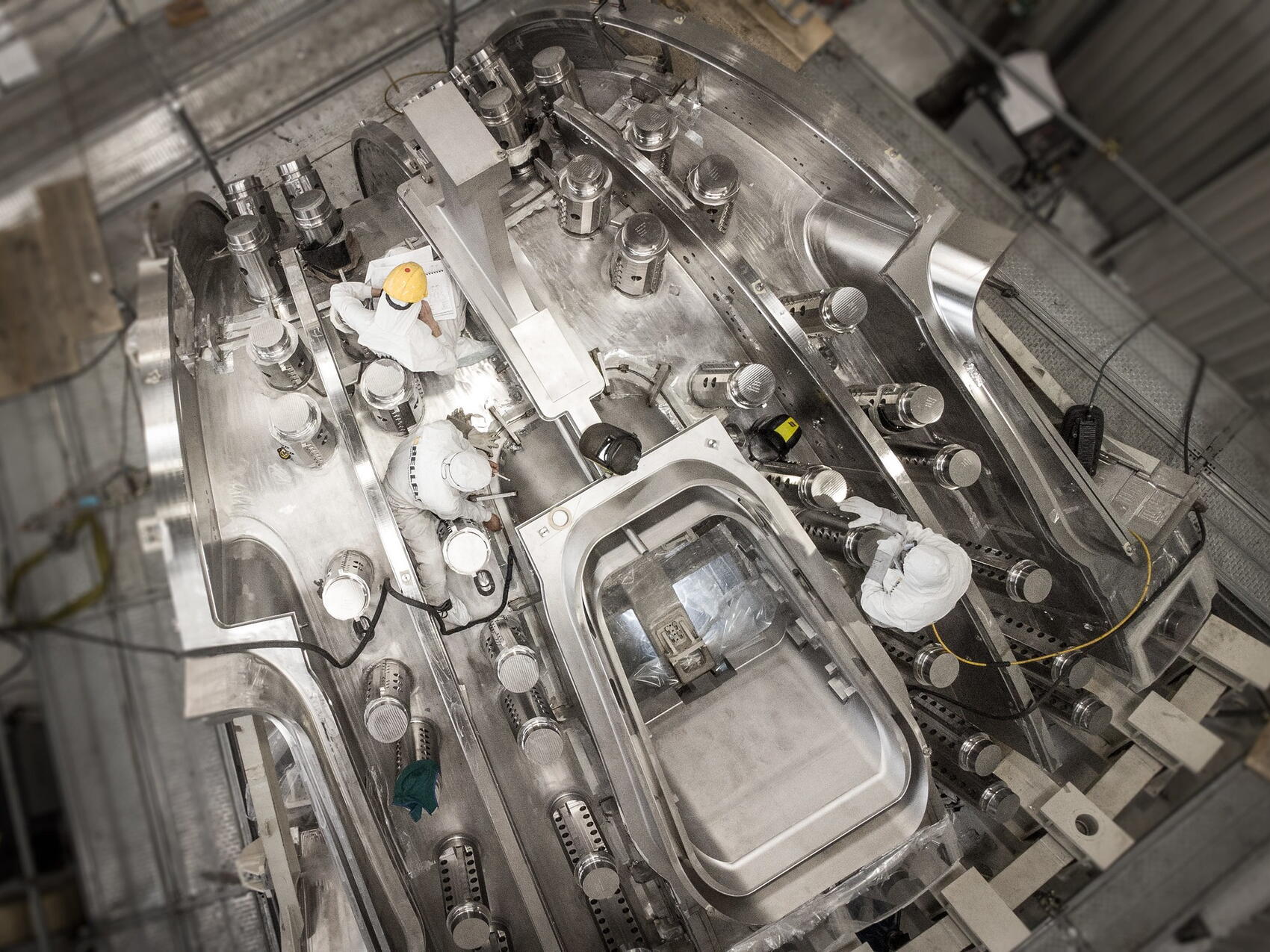

The first European vacuum vessel sector is entering an important and critical phase: the assembly and welding of four segments into the D-shaped sector. Under the supervision of the European Domestic Agency, the AMW consortium (Ansaldo Nucleare, Mangiarotti, Walter Tosto), supported by an extended network of sub-suppliers located in France, Germany and Spain, is ready for the challenge.

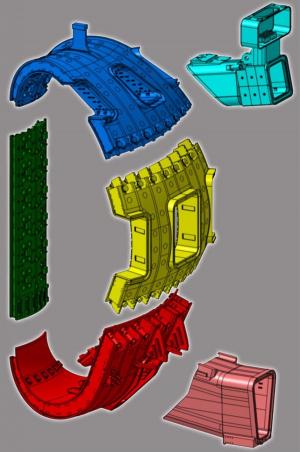

Vacuum vessel sector #5 will be the first of five sectors delivered to ITER by the European Domestic Agency. It has been more than nine years in the making, leading the pack as the European AMW consortium carried out extensive R&D and prototyping, learned to organize manufacturing tasks among the consortium members, and pioneered advanced welding and inspection techniques. The double-wall structure of the vacuum vessel, complex geometry, French nuclear safety regulations, and new rules and restrictions imposed by the Covid-19 pandemic are some of the challenges highlighted by engineers in a recent report by Fusion for Energy, the European Domestic Agency.

The four segments that make up Sector #5 are in the last stages of completion; only some final machining and non-destructive evaluation tests remain before the four segments will be positioned on a vast assembly platform and welded together. Four other sectors are in various stages of fabrication in Europe; Korea is also supplying four sectors. See more detail about European manufacturing in the gallery below.

See more images in the gallery below.

See the original story on the Fusion for Energy website.