Busy month ahead

This year at ITER, the month of March will not only mark the coming of spring. It will also set into motion a series of spectacular operations in the assembly theatre—a space that extends from the entrance of the Assembly Hall to the depths of the assembly pit.

In approximately two weeks the first 400-tonne vacuum sector (#6), now equipped with the sensors and cables that will feed data from the plasma to the diagnostic devices, will be "upended" and positioned on one of the giant sector sub-assembly tools in preparation for the first sub-assembly operation. In a months-long series of assembly steps, it will be paired with two toroidal field coils and thermal shield panels to form the first 1,200-tonne subunit of the central ITER vessel.

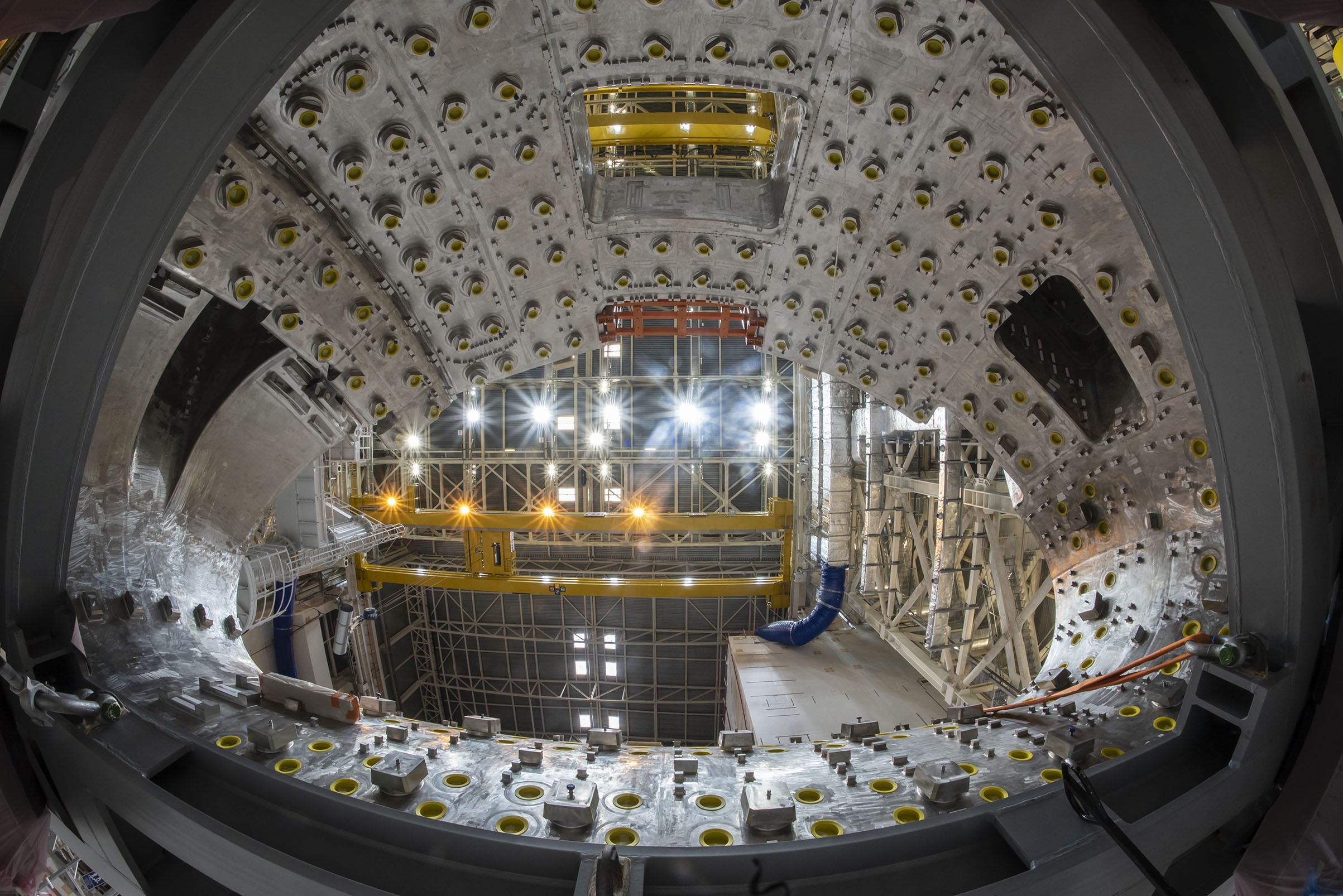

At around the same time the first component of the in-pit assembly tool—the central column—will be bolted to the massive embedded plate on the floor of the assembly pit. The 600-tonne temporary assembly tool must be in place in time to support the weight of the vacuum vessel subassemblies as they are progressively brought into the pit and welded. Drilling activities are underway now to prepare for the installation of this trunk-like colossus.

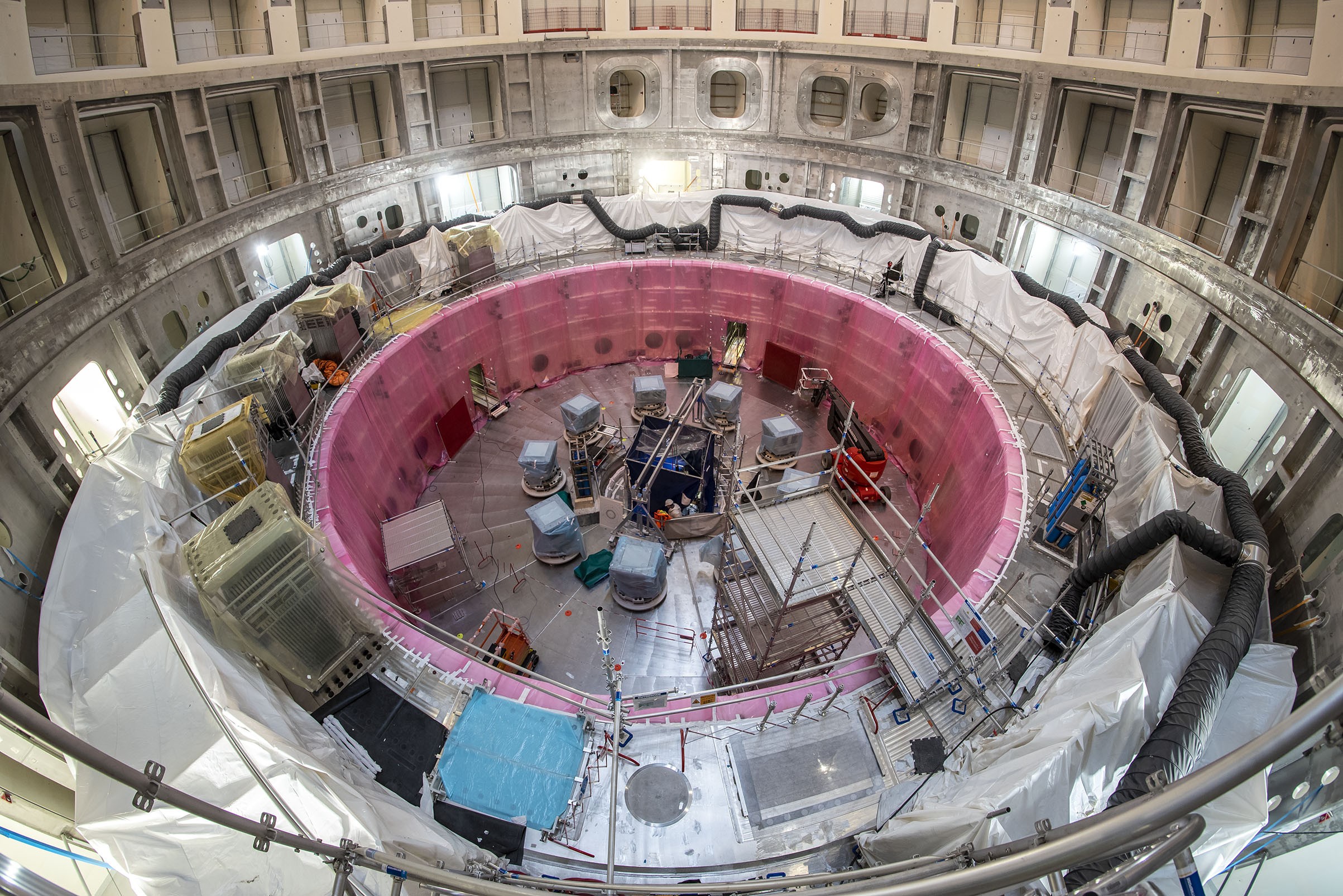

By end March, the lower pre-compression rings and spares will be pre-positioned in the pit prior to their final installation when the tokamak torus is complete. Six rings will help the toroidal field coils push back against the electromagnetic forces of the ITER machine in operation. Made of fiberglass laminate, the pre-compression rings have an inner diameter of 5 metres and weigh approximately 3 tonnes each.

Finally, a major operation—both symbolic and spectacular—is scheduled in April: the temporary positioning of the first ITER coil, poloidal field coil #6, at the bottom of the 30-metre-deep machine pit.

More information in the image gallery below.