Westinghouse wins major contract for vacuum vessel welding

On Wednesday 25 June, ITER awarded one of the most pivotal responsibilities of tokamak assembly to Westinghouse Electric Company. For the American powerhouse, better known for its decades of nuclear fission plant design and construction, this will be a key opportunity to bring its world-class capabilities and expertise to fusion plant construction.

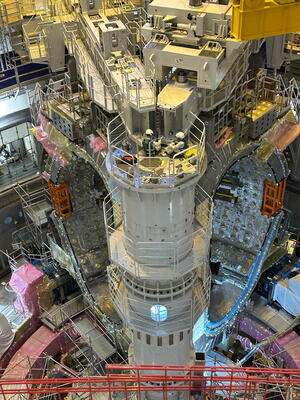

It is no small step. The vacuum vessel is ITER’s most critical component: a hermetically sealed, double-walled steel container that will house the fusion plasma. Nine vacuum vessel sectors, each comprising 40 degrees of the doughnut-shaped chamber, are being contributed by Korea and Europe. Two have already been installed in the tokamak pit. When all the sectors are in place, Westinghouse will commence the most delicate and intensive stage of ITER assembly: simultaneously welding the nine sectors to form a single, circular torus.

The ITER tokamak will provide an unprecedented experimental platform for fusion physicists. The interior volume of the vacuum vessel will be about 1400 m³, enabling a plasma volume of around 840 m³ at its centre. At 19.4 metres across, 11.4 metres high, and—with the blanket and divertor installed—weighing 8,500 tonnes (for reference, that’s more than half the weight of the Brooklyn Bridge!), it will be six times larger than any previous tokamak, reaching industrial scale.

Assembling this remarkable fusion chamber will require equally remarkable skill. Welding causes deformation; welding at this scale and volume will require extraordinary strategy and execution to control the deformation to achieve a perfect result.

ITER’s original plan was to first weld the sectors to each other in groups of three, and then to weld the three triplexes together. Under Director-General Pietro Barabaschi that approach was rejected, considering the risks of generating unpredictable and uncontrollable deformations. Instead, with the new strategy, welding will only commence once all sectors are in place and firmly clamped to each other. This approach will ensure better control and a more uniform distribution of the deformation across the whole vacuum vessel, achieving in this way a regular plasma chamber, essential for the proper operation of the tokamak.

The first stage will be the welding of the outer wall of the vacuum vessel. With wedge-shaped splice plates in place in each field joint, each weld will be approximately 60 millimetres thick and 35 metres long. For each welding step, three groups—each comprised of four robotic welders—will work simultaneously on specific portions of three field joints, spaced 120 degrees apart. Once the required batch of welds is completed, the welding process will shift 40 degrees to the three adjacent field joints, and then finally to the remaining three field joints, completing the circle. The process will then start again on the initial set of field joints, this time focused on a different portion of the joints. This sequential process will continue until the full welding has been completed. Once the outer wall is fully welded, the entire operation will move inside the chamber to repeat the welding process on the inner vacuum vessel wall. In total, more than 10 tonnes of filler material will be used.

Operations will start in 2027 with the assembly and preparation of all the needed equipment. Once the welding process starts, it will proceed 24 hours per day, in three shifts, 6 days per week, with pauses only for radiographic and ultrasonic tests to confirm the quality and precision of the welds. Approximately 60 Westinghouse experts per shift, 180 in total, will be involved from the start of welding operations for the 30-month duration of the work.

Alessandro Bonito-Oliva, who leads ITER Tokamak Delivery, remarked on the herculean nature of the welding project: “Even at ITER, where we are accustomed to singular, first-of-a-kind activities, this welding of the vacuum vessel will be quite unique. To sustain such a level of intensity, at the required level of quality and precision, will be a challenge. In order to be ready for the challenge an intensive R&D and qualification program is presently being carried out. The goal is to arrive at the start of the operation with fully qualified equipment, processes and personnel.”

See the press release published by Westinghouse here.