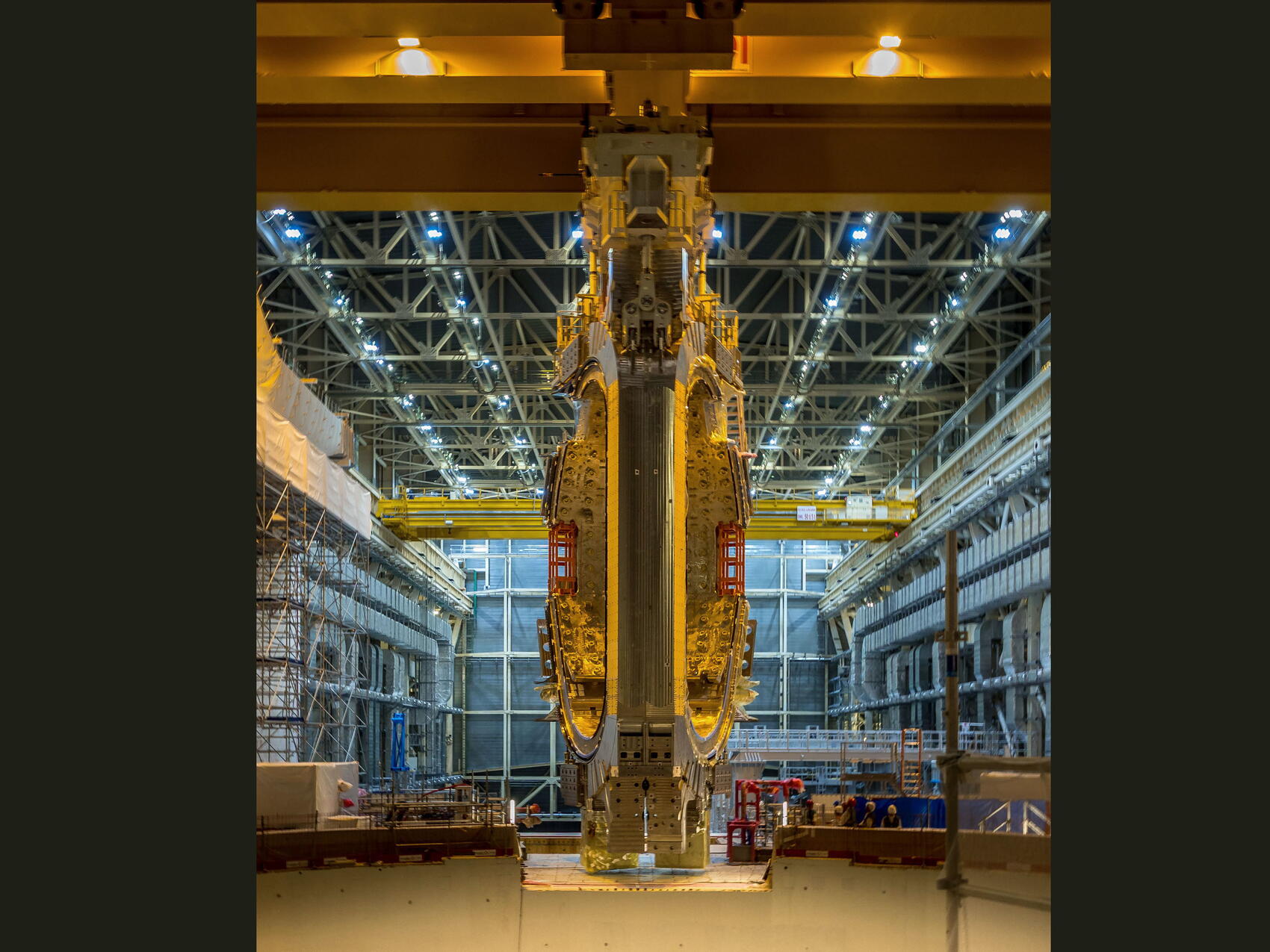

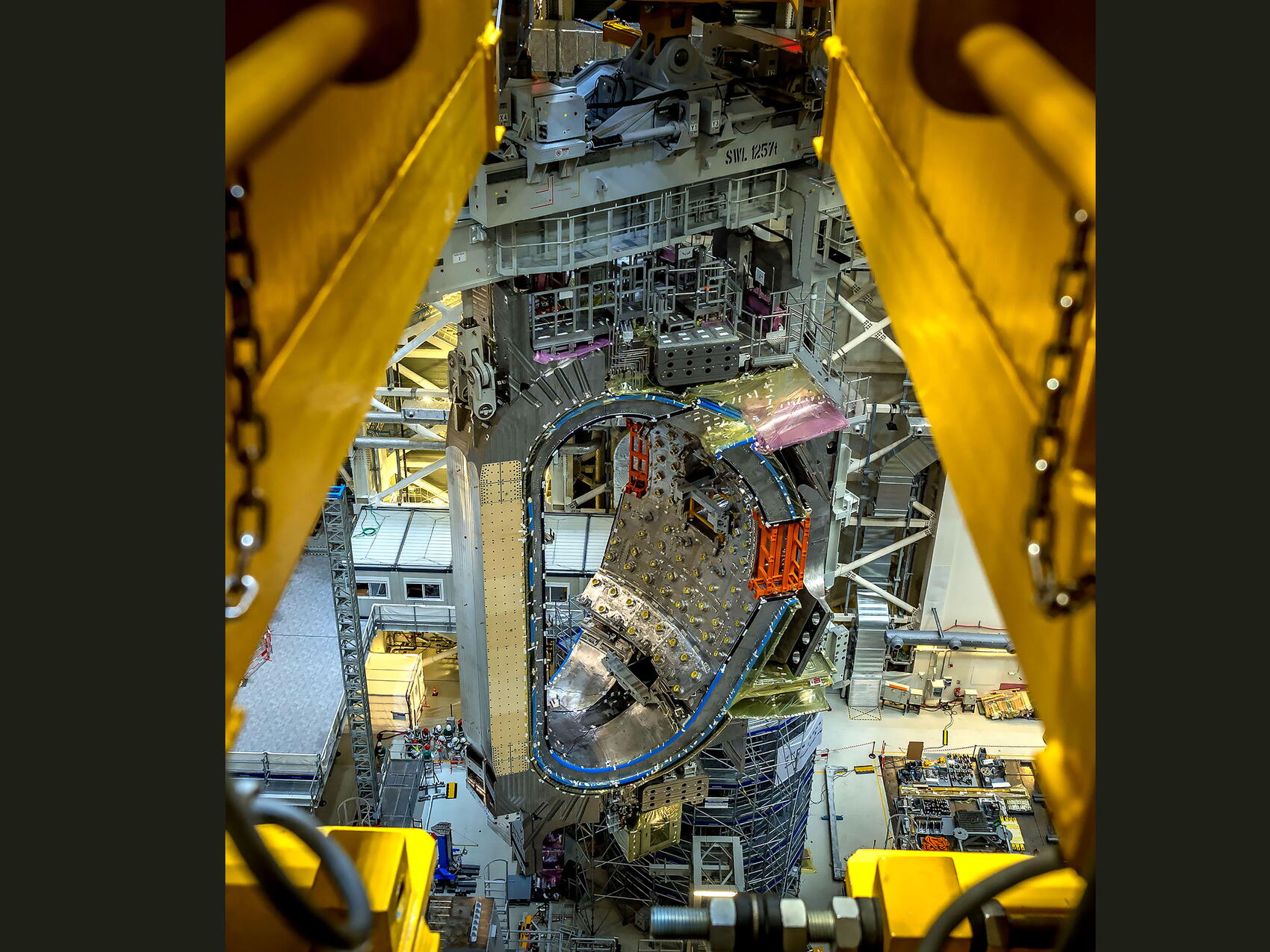

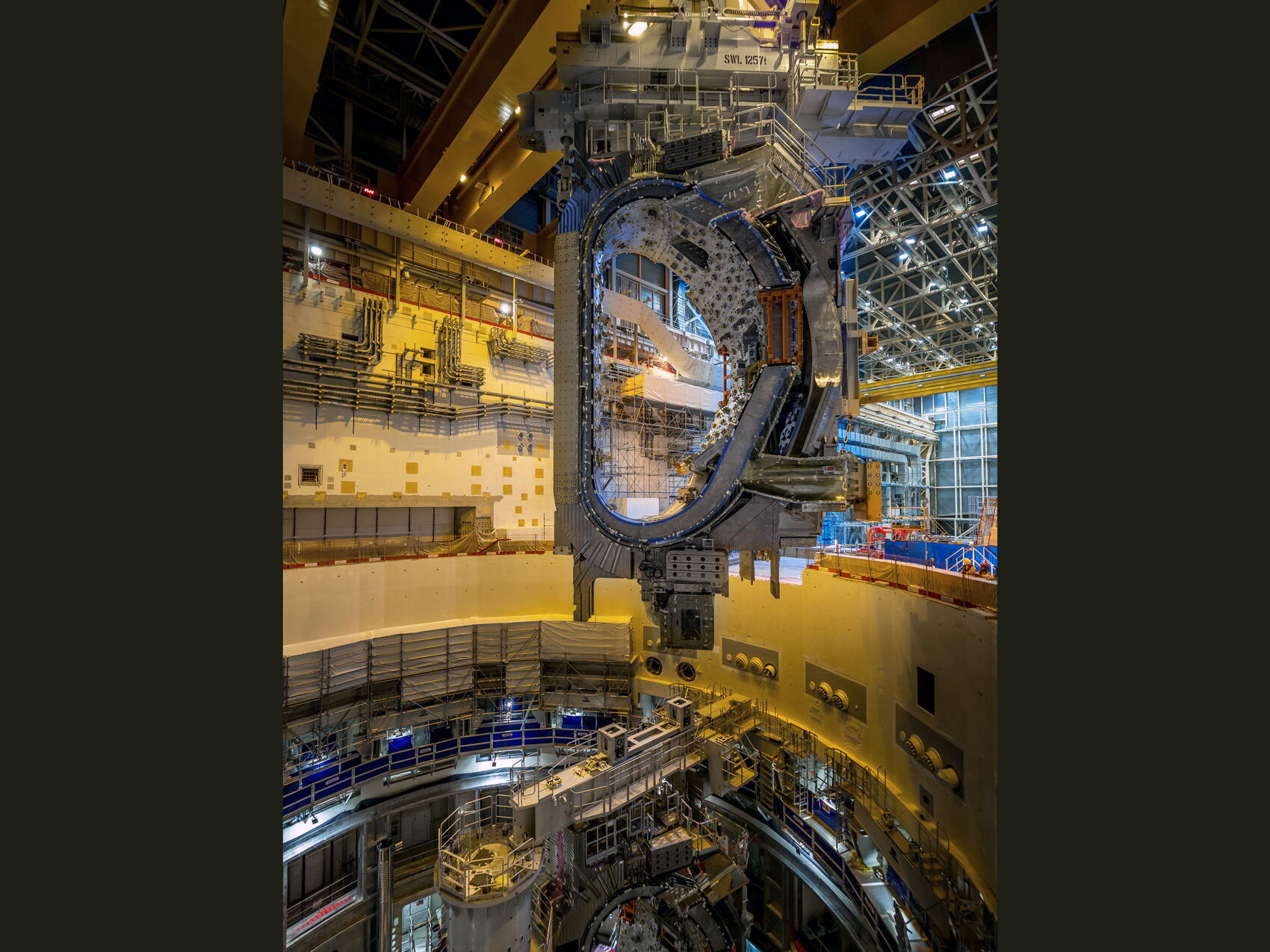

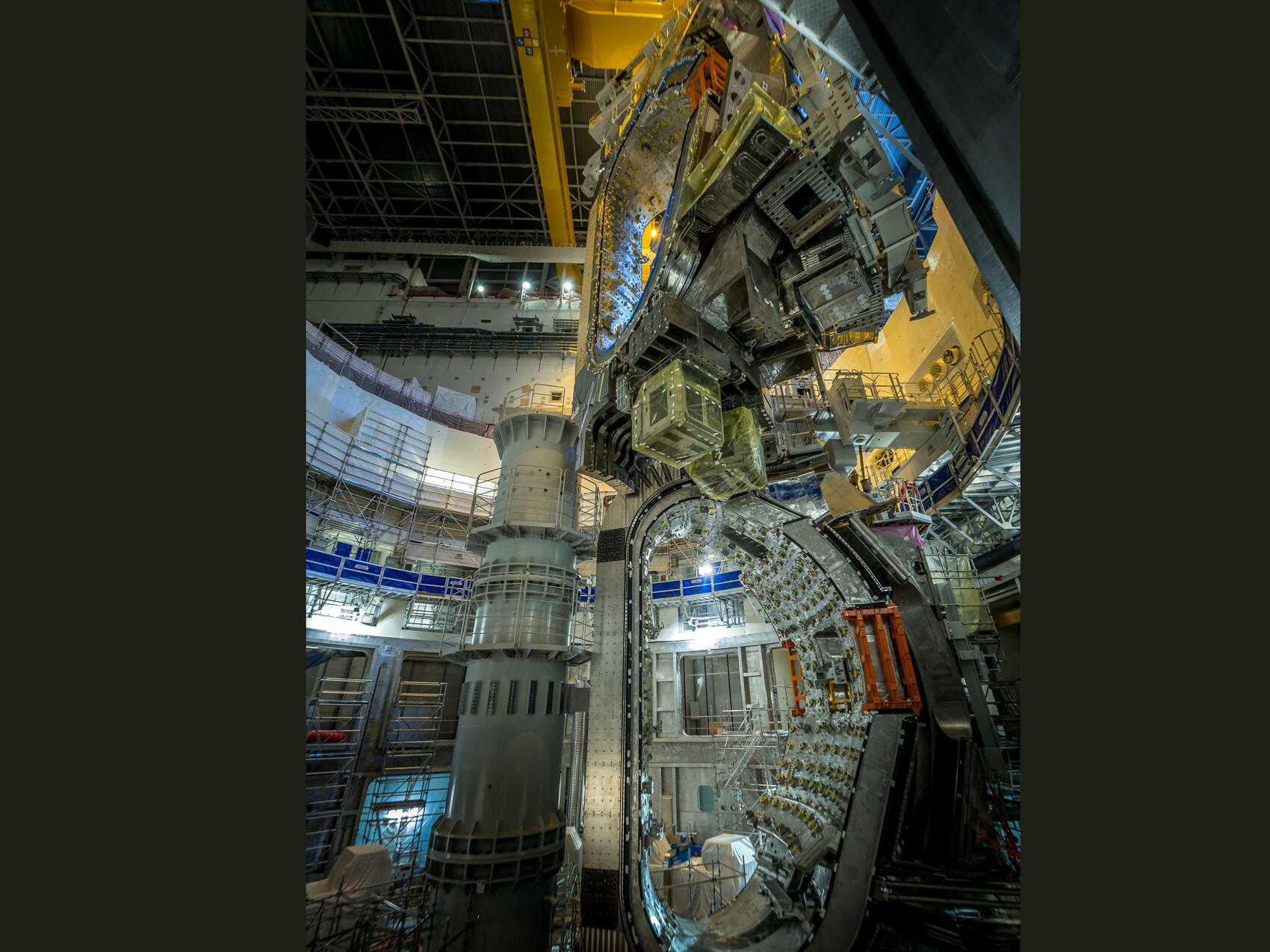

Two sector modules side by side in the pit

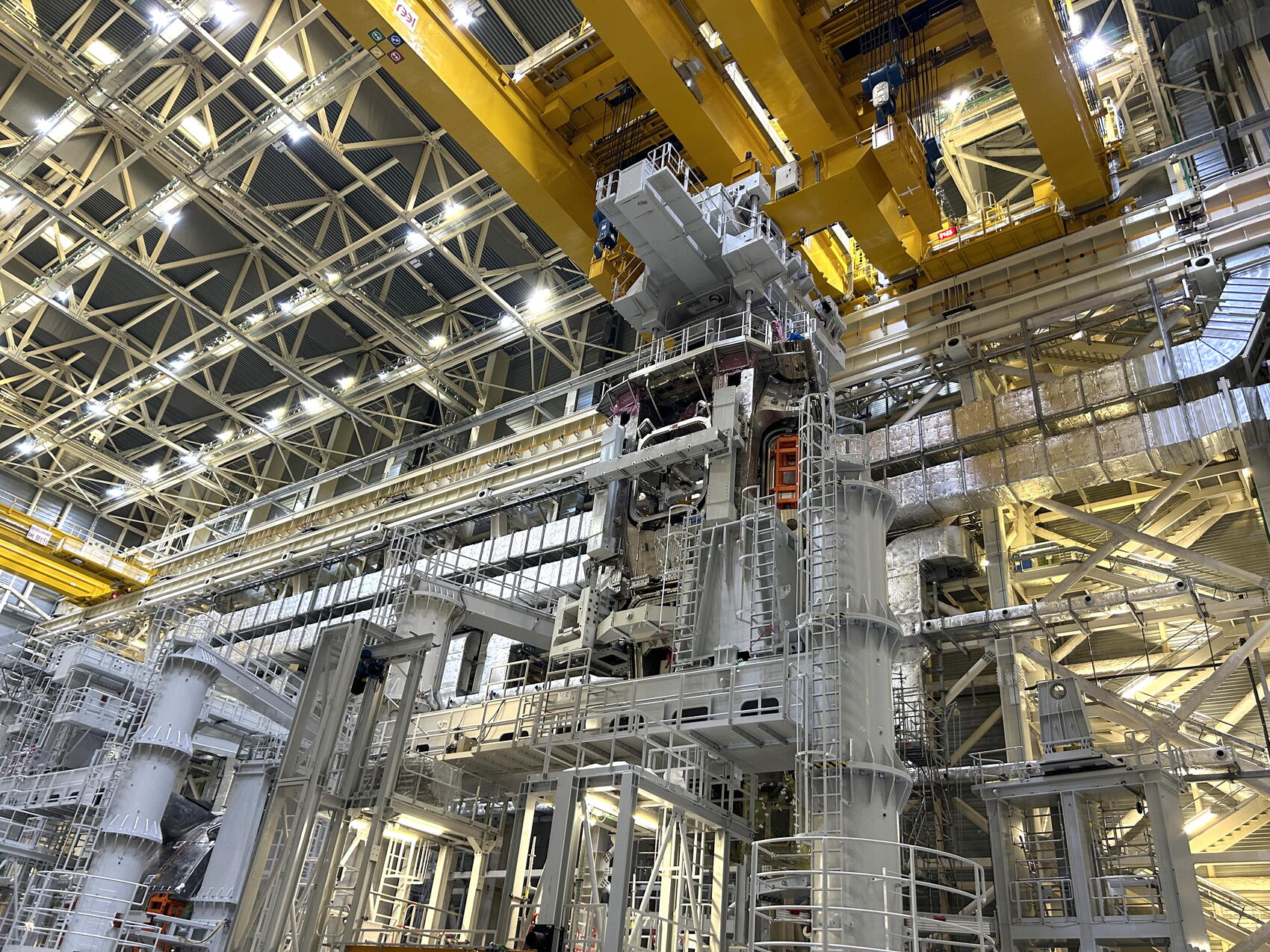

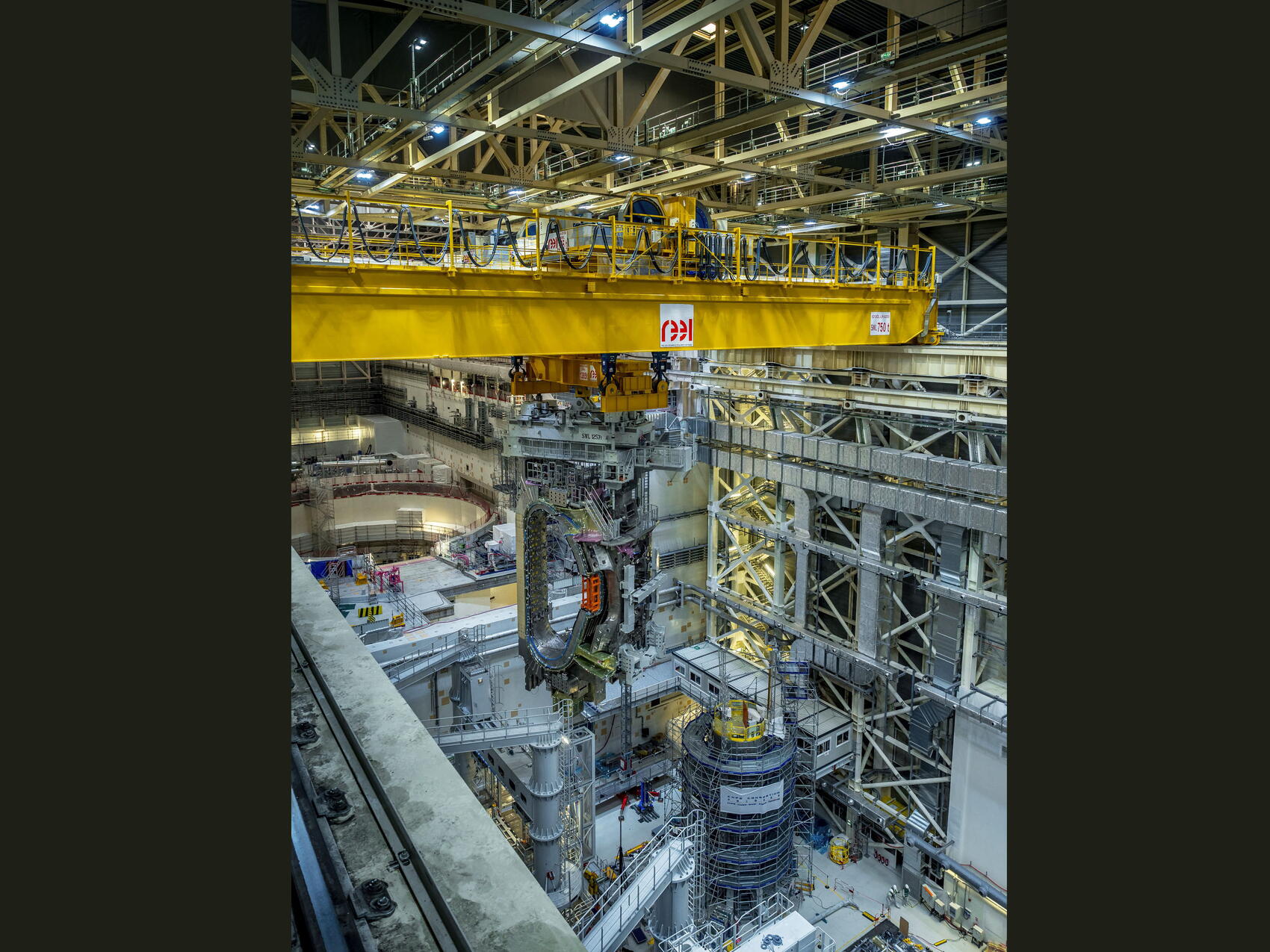

There is a new arrival in the tokamak pit—one that upends the perception of space and volume that regular observers had become accustomed to. With the successful insertion of sector module #6 on 18 June, there are now two vacuum vessel sector modules positioned side by side. From every vantage point, it is a spectacular sight.

Two sector modules in two months! Following the insertion of the first of nine vacuum vessel sector modules in April, the assembly teams successfully transferred a second on 17-18 June.

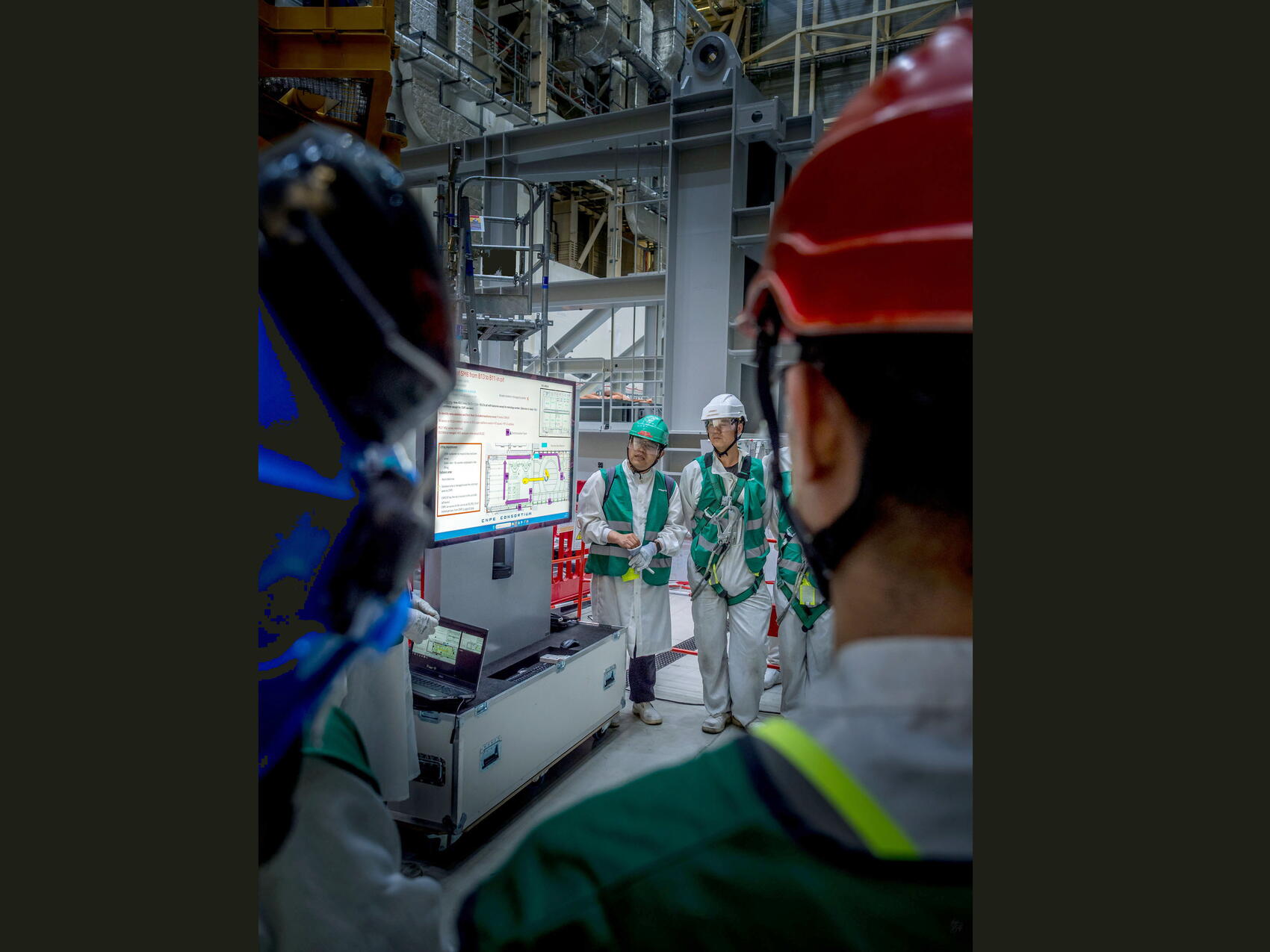

The complete lift operation unfolded over three 12-hour shifts—beginning early on Tuesday with a trial lift and ending late the next day with a final in-pit metrology survey. In a departure from the April insertion, the most spectacular part of the operation happened during the 6:00 p.m. to 6:00 a.m. shift, with the ITER Organization construction team, CNPE assembly contractor team, crane operators, metrologists, health and safety officers and observers working throughout the night.

“We integrated many lessons learned from the first sector module in our planning, and made some changes to the overall organization,” says mechanical engineer Mathieu Demeyere, who supervised the operation for the Assembly & Commissioning Support Division. “One of the things we did differently was to proceed directly to the lift and transfer operation after the positive results were in from the pre-trial test. Last time we had waited until morning, and the load had remained suspended under the cranes without movement all night.”

Most other aspects of the operation were identical. Sector modules #7 and #6 are so similar that the small differences between them (slightly more piping welded on one than the other) did not affect the rigging. The latest sector module followed the same trajectory as the first—vertical extraction from sub-assembly tooling, pivot, transfer across the Assembly Hall and over the tokamak pit wall, pivot and lowering to landing position. Special care was required during the lowering, however, due to the fact that a sector is already installed in the pit. “We proceeded especially slowly during module descent in order to control the ‘swing’ created by the inevitable pendulum effect,” says Demeyere. “And we paused the operation as soon as our instruments detected that movement was increasing.”

Sector module #6 now rests on temporary supports in the tokamak pit and the crane has been disconnected. The two modules in the pit are close to one another but they do not touch—there is approximately 15 cm of space between them.

Back in the Assembly Hall, vacuum vessel sector #8 will soon take the place of sector #6 in sub-sector tooling and the process of creating a sector module will begin again. With each complete operation, and there have been three (the first sector module #6 that had to be removed for repair, sector module #7, and sector module #6 again), lessons have been learned and activities optimized resulting in time saved against the calendar: three weeks for sector module #7 and six weeks for sector module #6.

“This latest milestone achieved ahead of schedule is the result of hard work performed over the last few years by the repair and sector module assembly teams. All of this would not have been possible without the collaboration and commitment of our industrial partners. We will continue this impressive team effort for the next sectors in line.”

See the gallery below for more images of the operation.