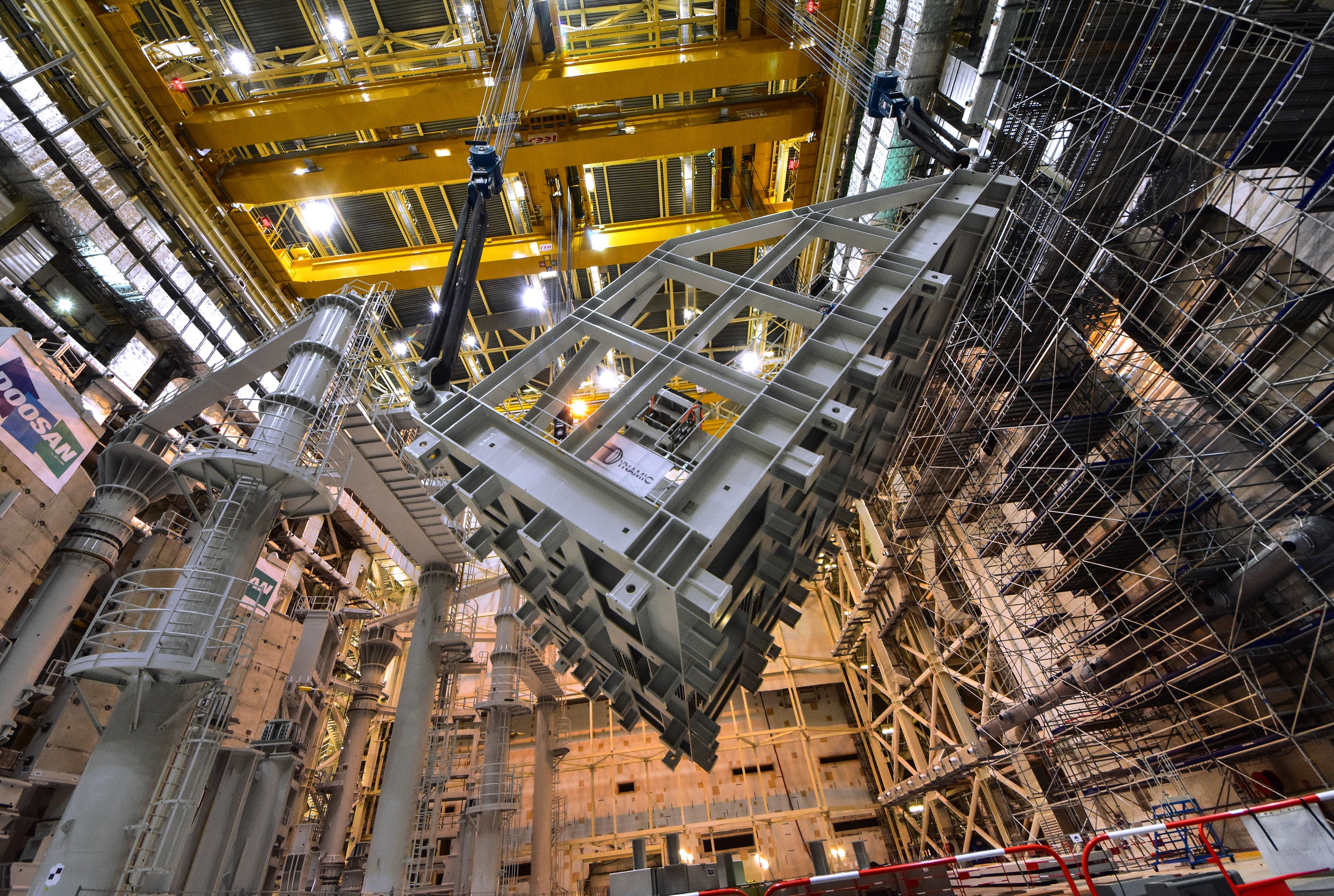

Travelling the entire length of the assembly space (~ 170 metres) the overhead cranes will be the workhorses of the machine assembly phase. For the five years to come, these massive high-precision tools will hold in their hoists and hooks the future of the ITER installation.

"The tasks we have before us are very complicated, and some of them have never been done before," says Bob Shaw, who coordinates machine assembly operations at ITER. "But our philosophy is quite simple: we want to check and test everything possible before actually handling the components."

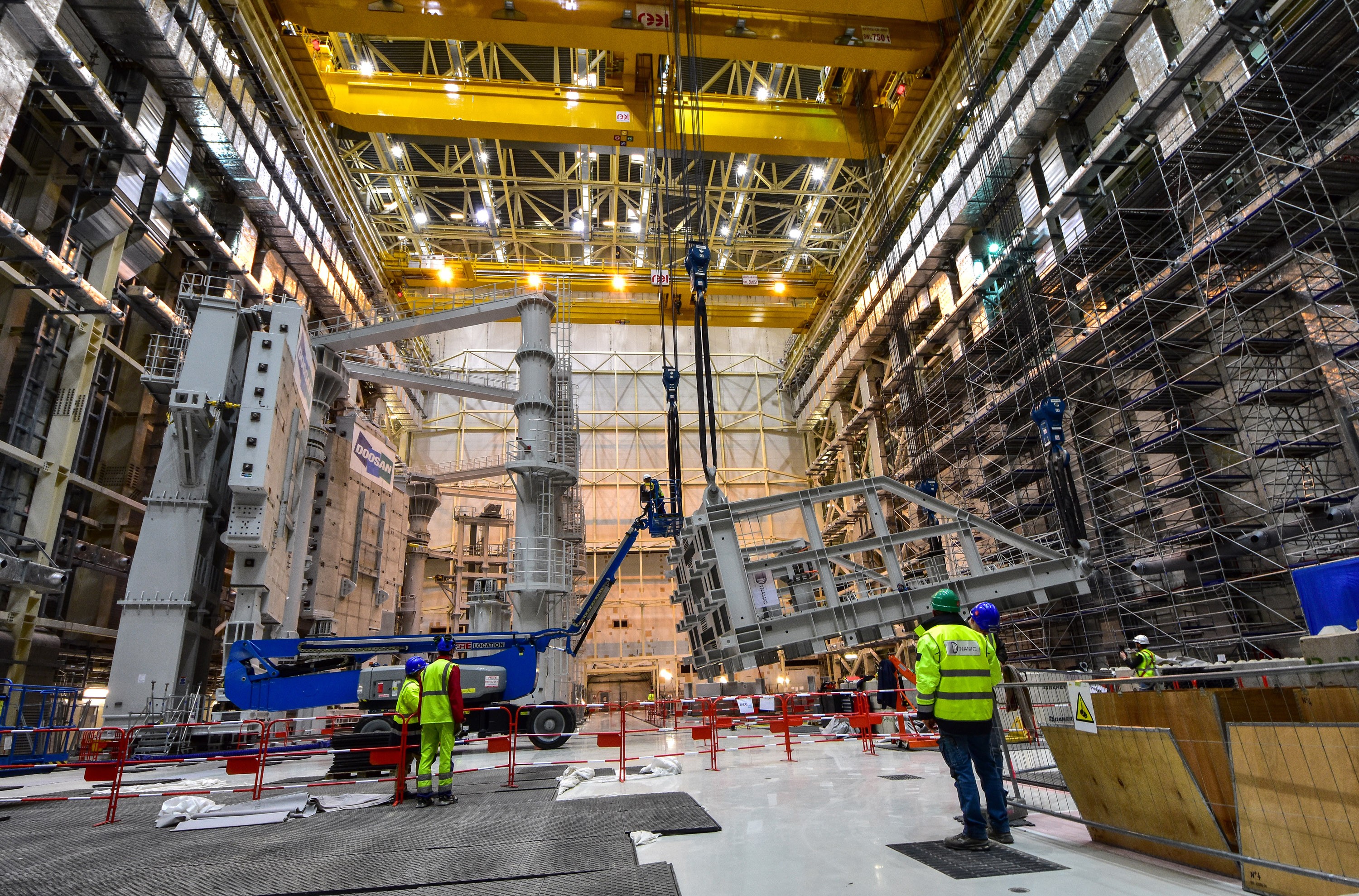

Bob, his ITER colleagues and the contractors involved in the assembly activities are testing "processes"—not just the lifting system and the loads to be handled, but their interaction and the whole kinematics of upending, transporting and manipulating charges that can be as heavy as four fully loaded Boeing 747s.

"The more you prepare, the fewer problems you are likely to encounter," says Bob. "What we are doing is out of an abundance of caution."

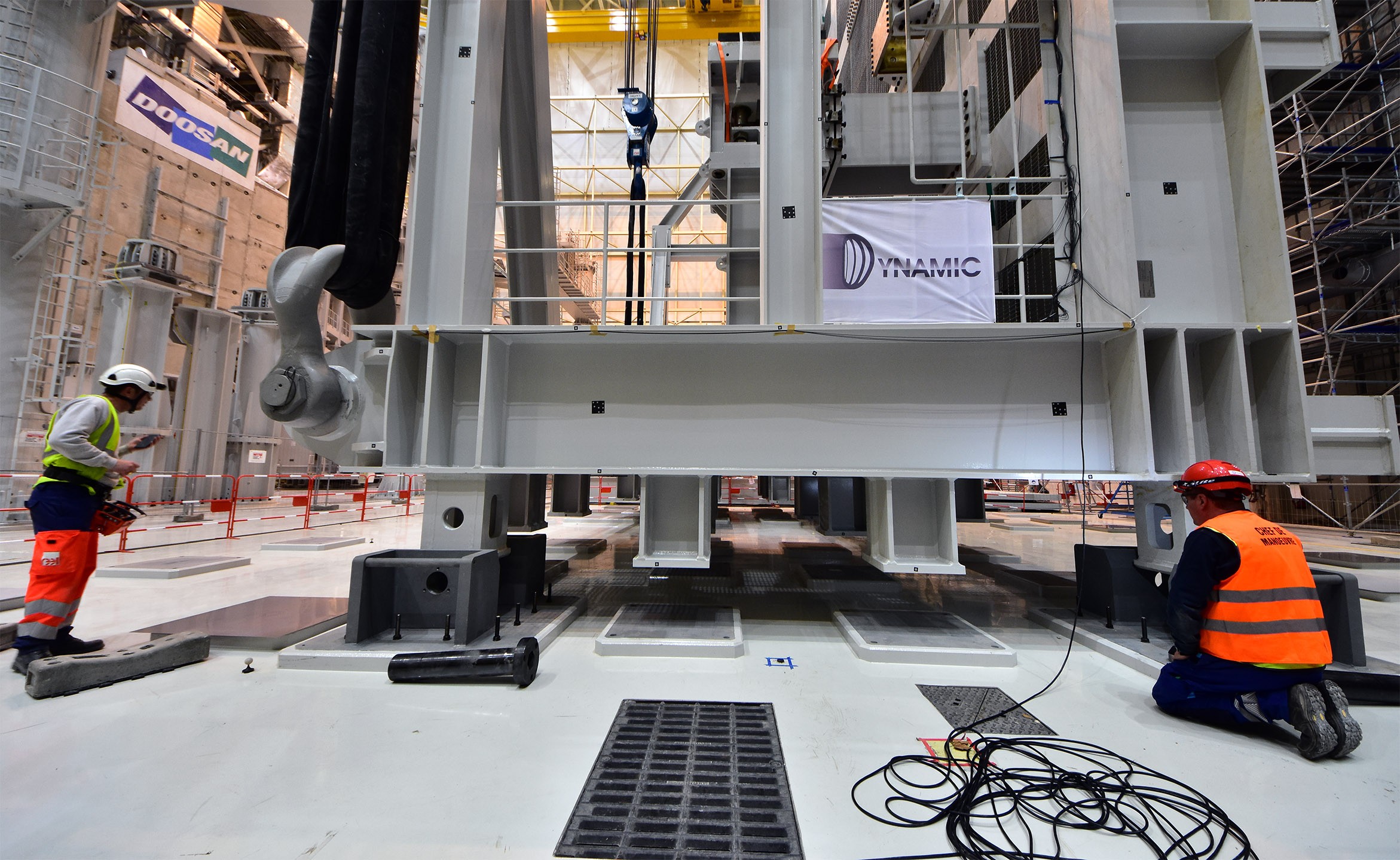

Last week's operation was one of the very first steps into the testing of some of the processes that will be implemented in the upcoming assembly phase.

One of the most delicate operations that the team will soon face is the handling of the vacuum vessel sectors and the D-shaped toroidal field coils that need be combined into "sub-assemblies" before they are lowered into the Tokamak pit.

Prior to their transfer into the "wings" of the sector sub-assembly tools (SSATs), the very large and very heavy components will need to transition from their horizontal delivery positions to upright.

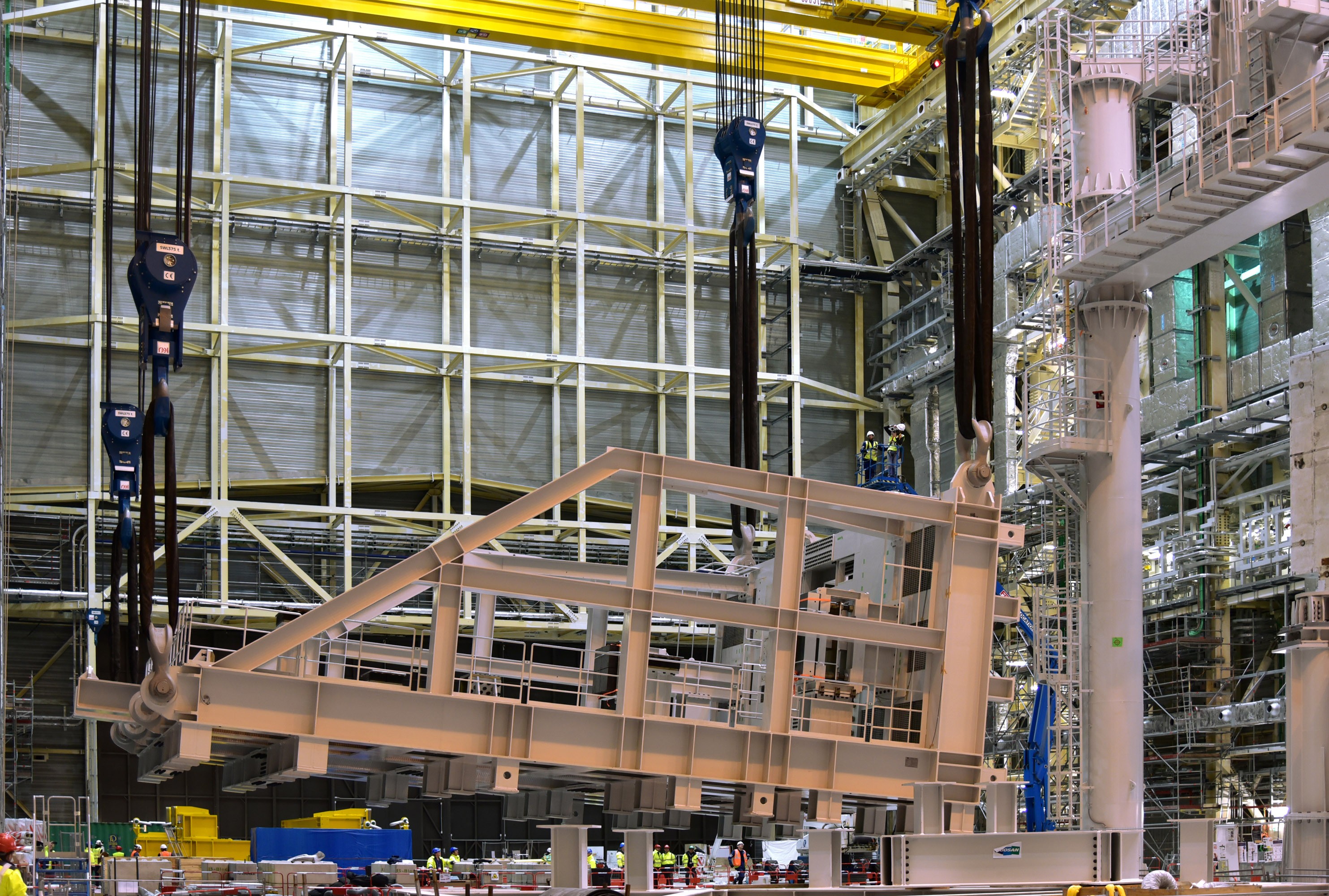

A bespoke lifting device (the "

upending tool") has been designed for this purpose. Like a massive steel cradle, it will accommodate the components during the horizontal-to-vertical transition, before their subsequent transfer to the SSATs.

Last week's "dry run" with the empty upending tool has already delivered a wealth of data. The team now knows where to make improvements—such as slight adaptations to the cranes' software—and photogrammetry has provided a "baseline" for deformation reference.

In about one month, when the cranes are available again¹, another series of tests will be performed, this time with loads representative of the actual components.

(¹) The cranes are now being moved to the Tokamak Building to undergo a month-long series of commissioning and load tests designed to set up the cranes, and demonstrate the structural integrity of the load path.

Click here to view a time-lapse video.