The Project

- Building ITER

- Projects Underway

- Construction Archives

- Neutral Beam Test Facility

- Assembly Overview

- Tokamak Assembly

- Plant Assembly

- Commissioning

- Assembly Tooling

- Metrology

- Project Milestones

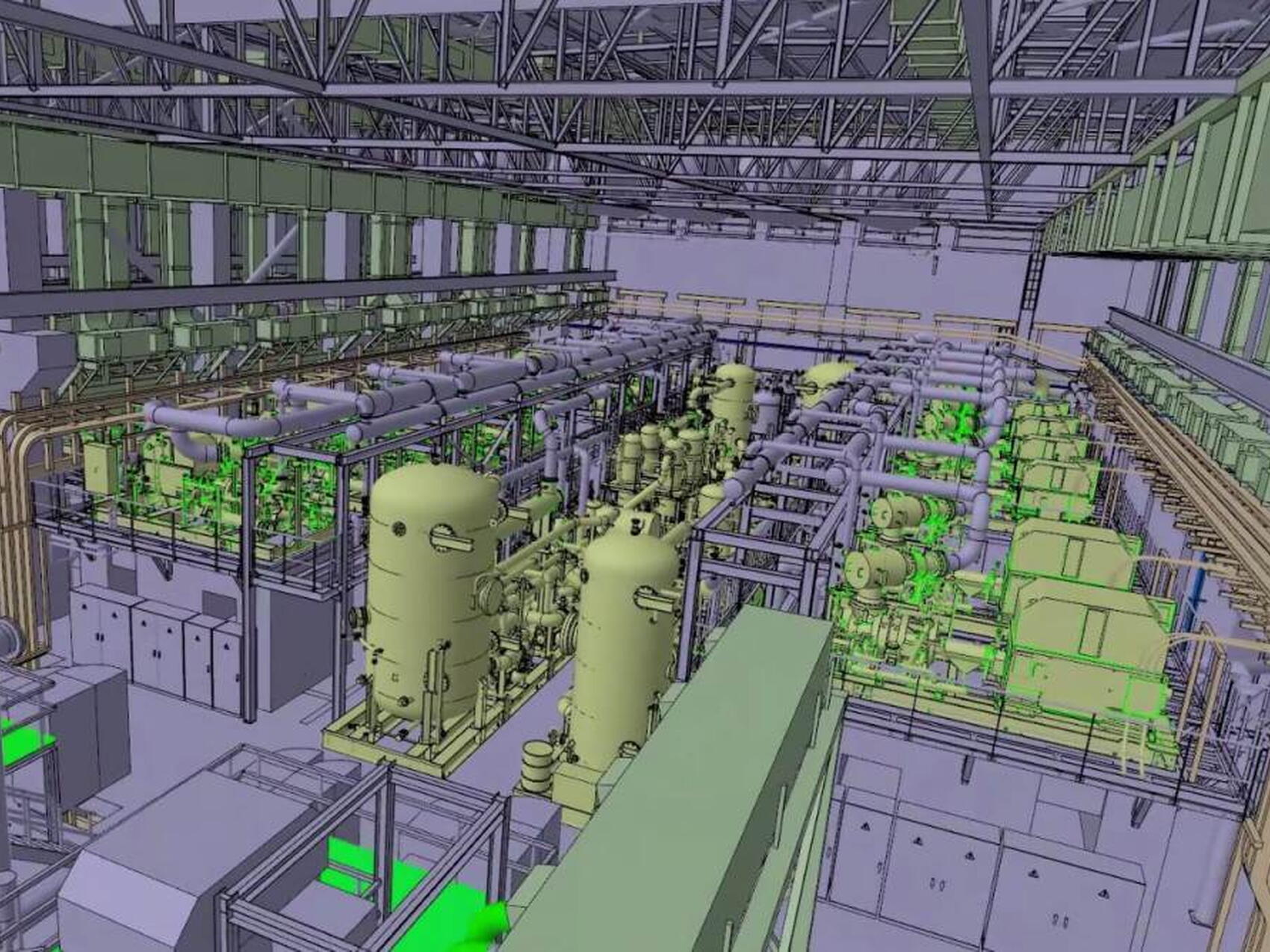

Cryoplant

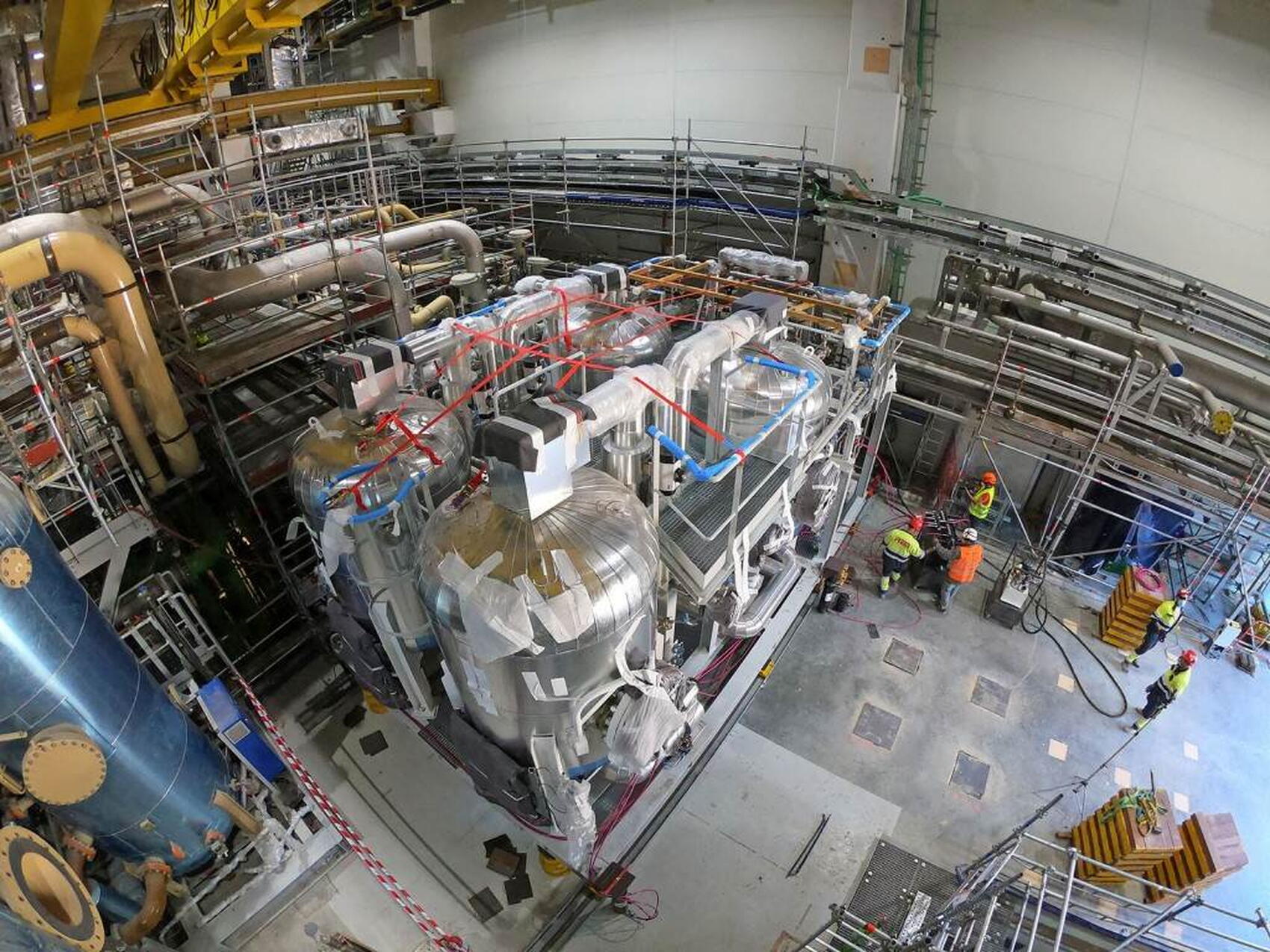

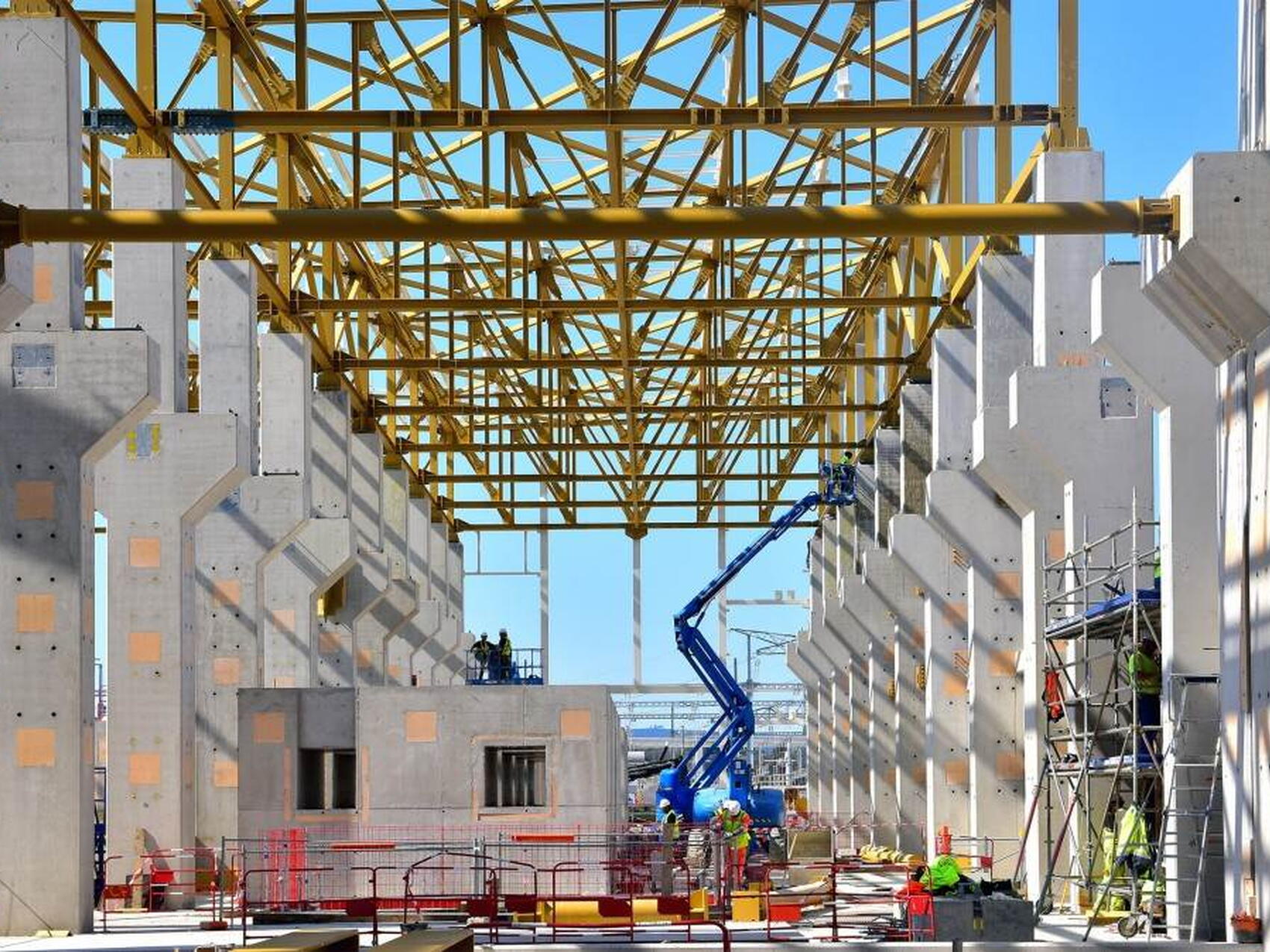

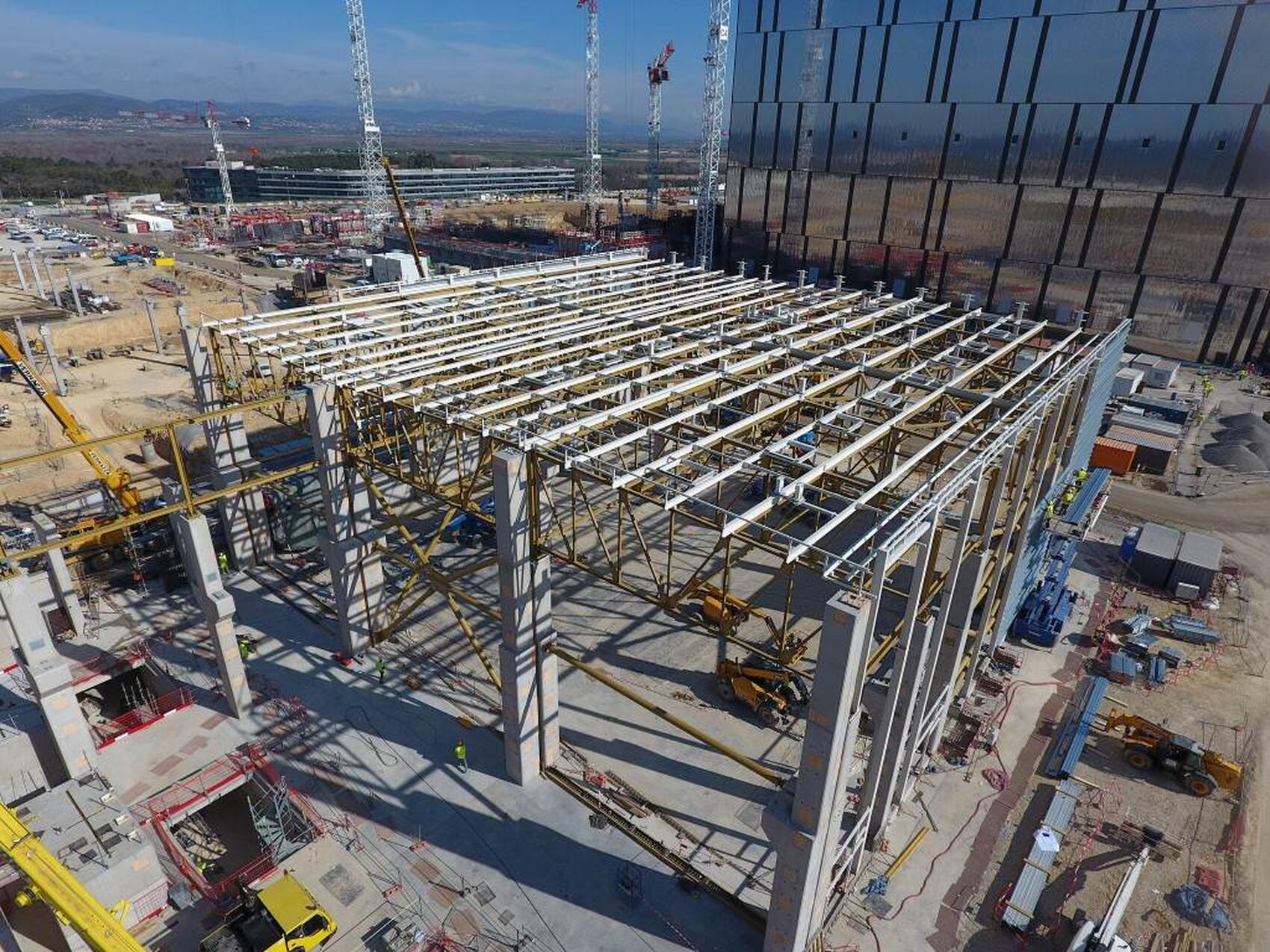

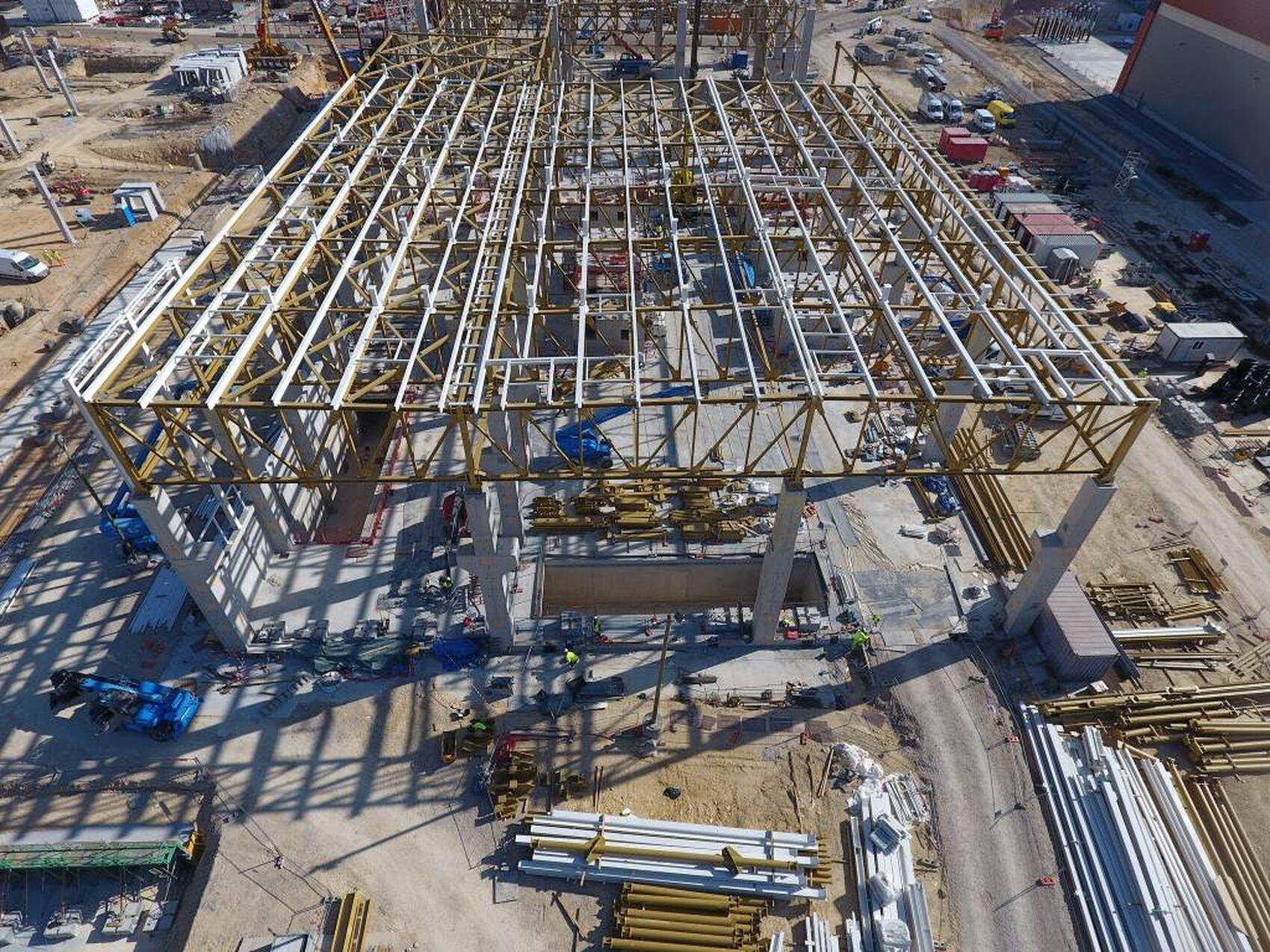

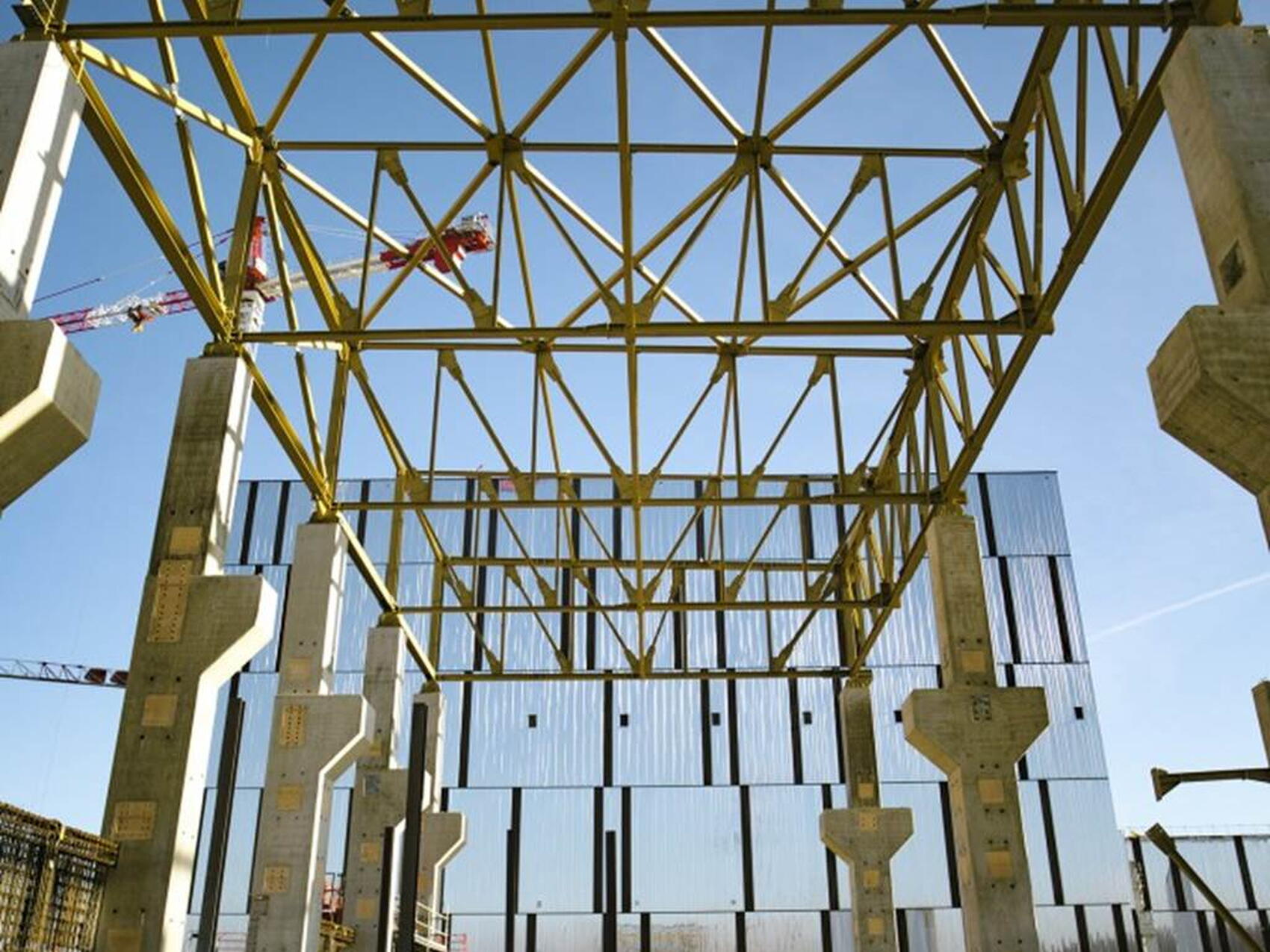

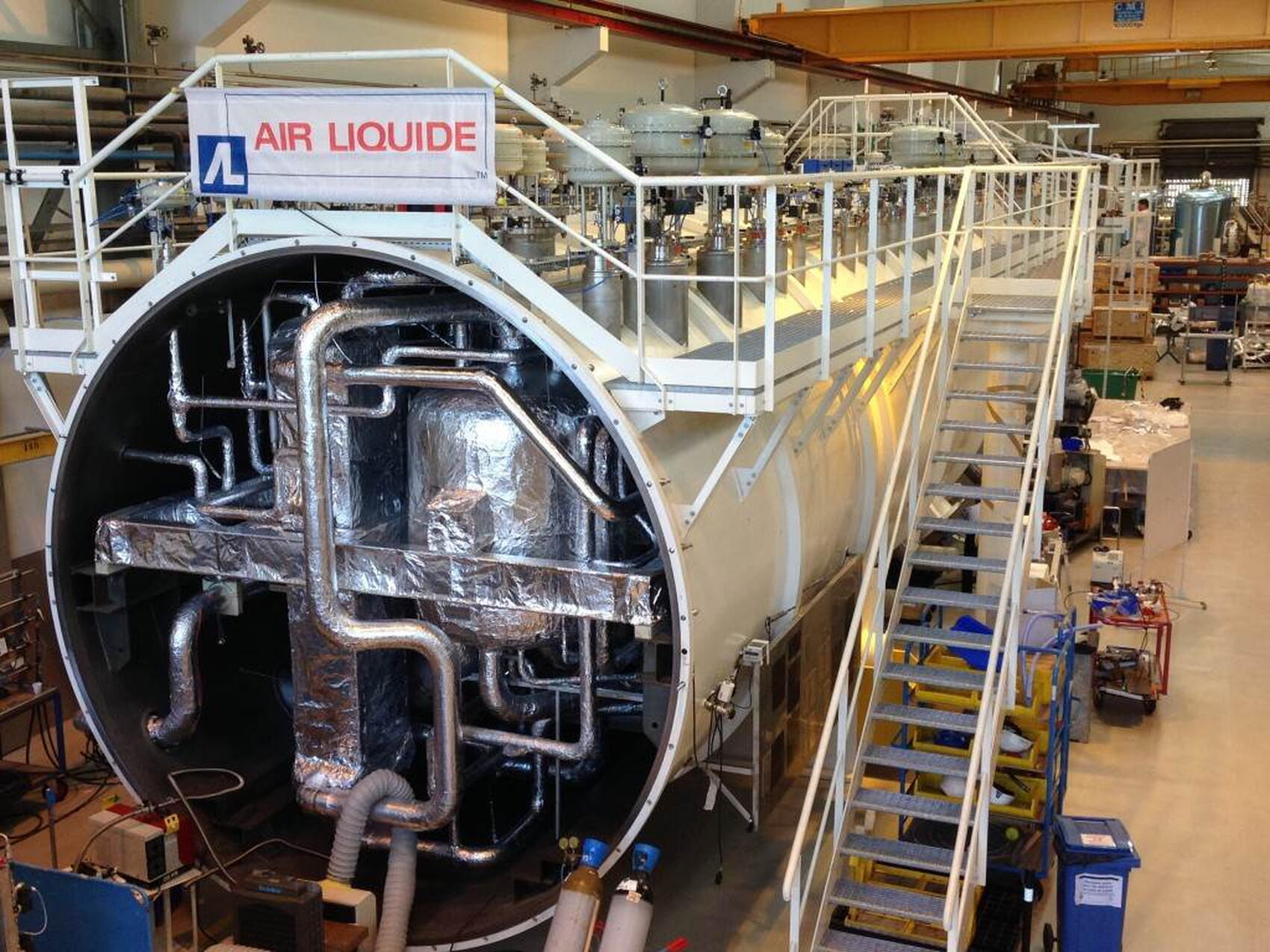

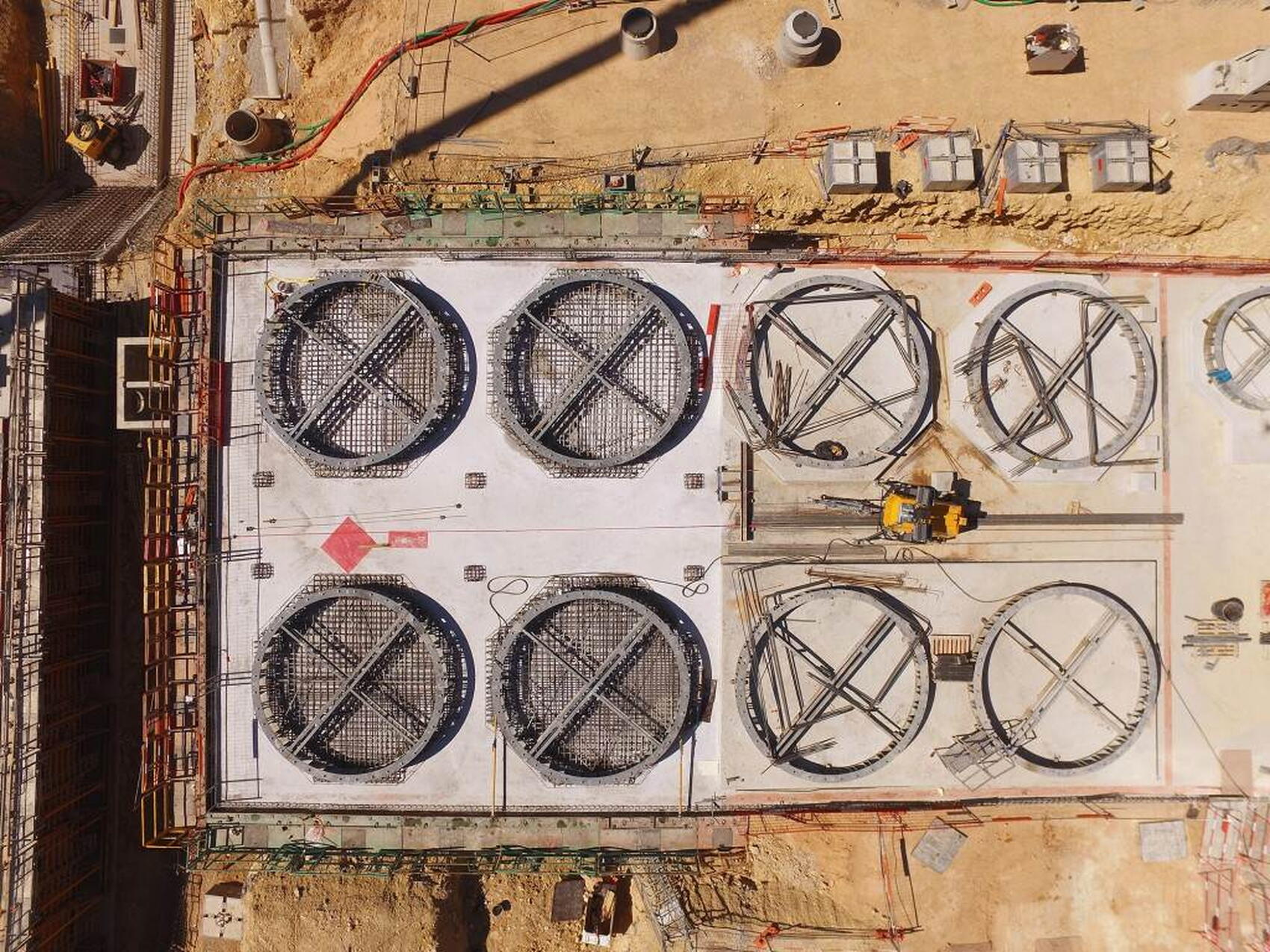

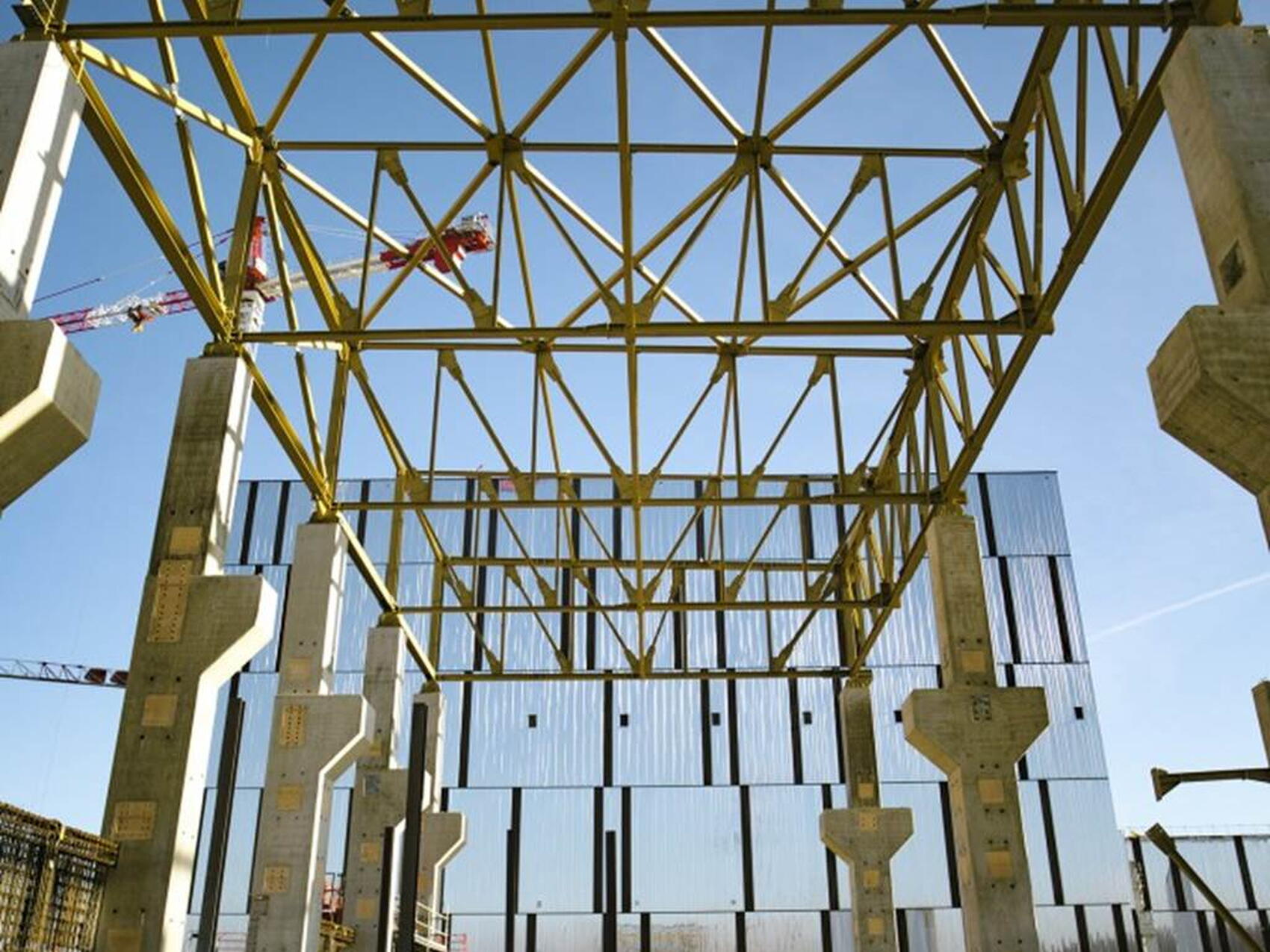

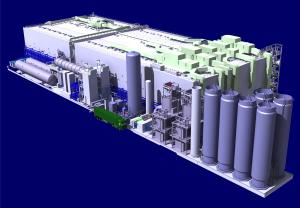

The ITER cryoplant, under construction now, comprises 5,400 m² of covered buildings plus a large exterior area for the storage of helium and nitrogen.

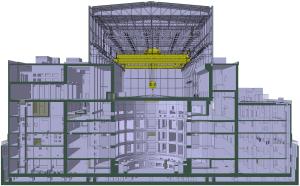

The extensive cryogenic power needed to cool the ITER magnets, thermal shield and cryopumps will be delivered from a single location on the ITER site—an 8,000 m² area not far from the Tokamak Complex that houses the cryoplant infrastructure.

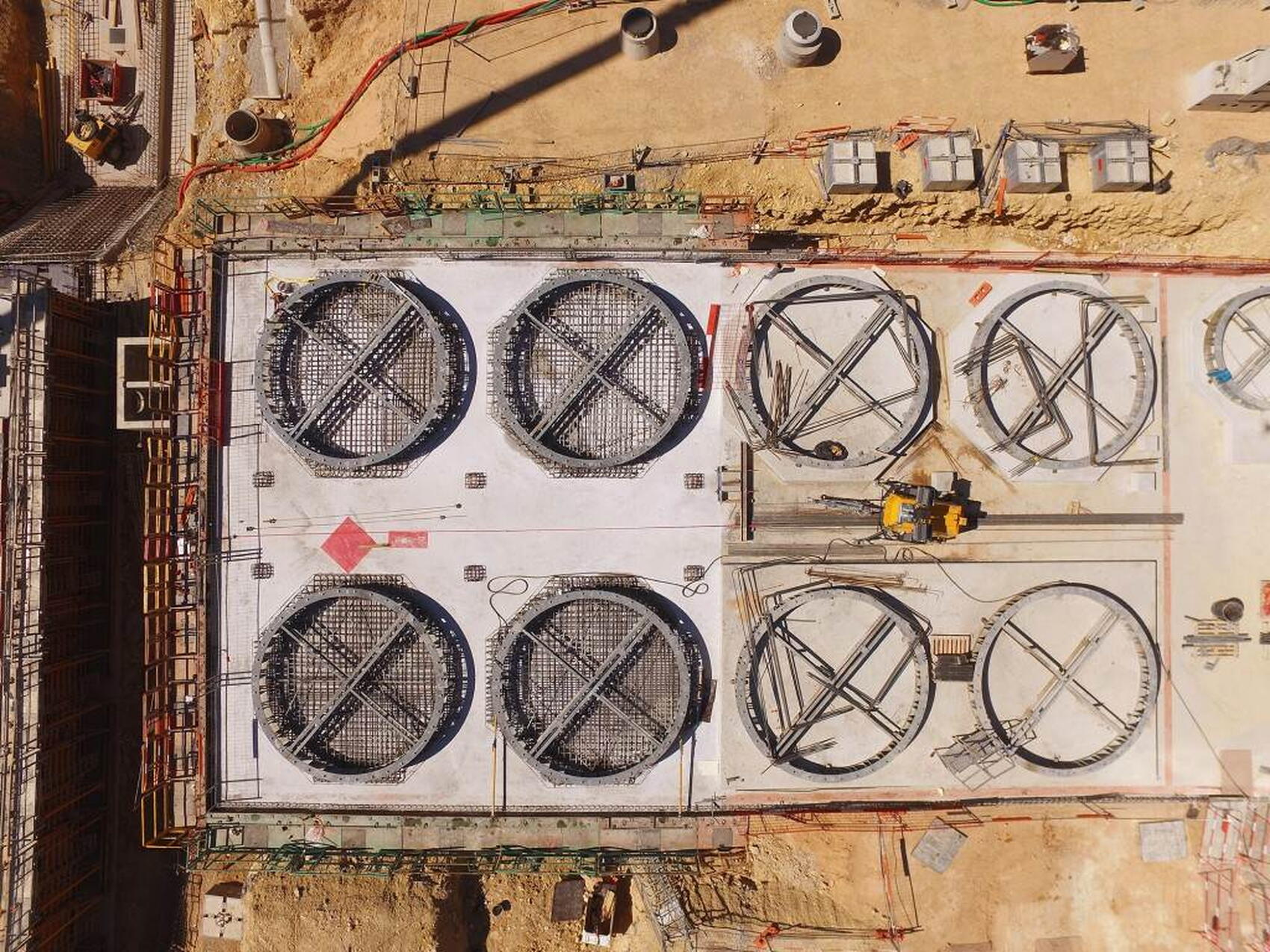

The soccer-field-size installation comprises 5,400 m² of covered buildings plus a large exterior area for the storage of helium and nitrogen in liquid and gaseous forms.

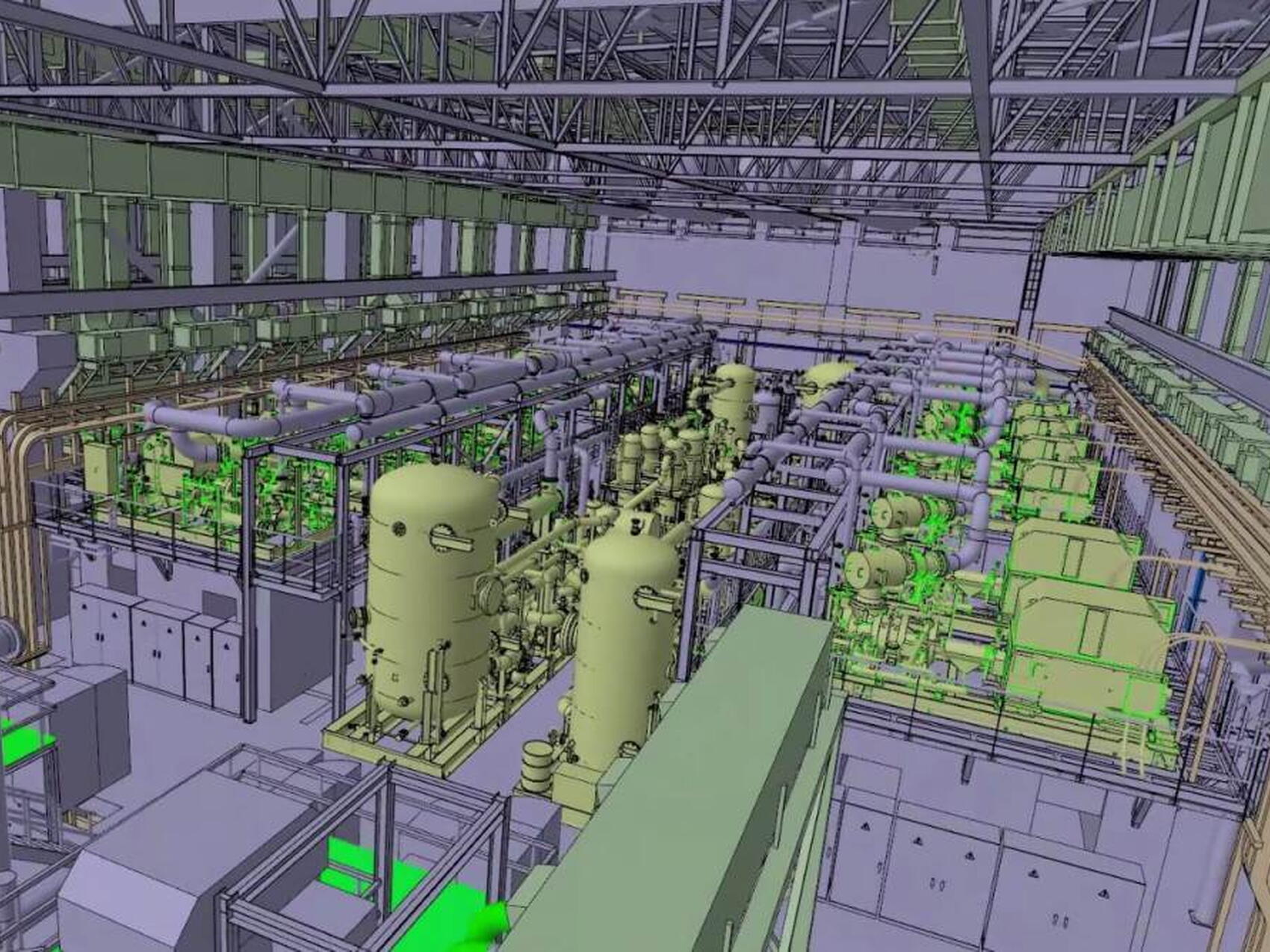

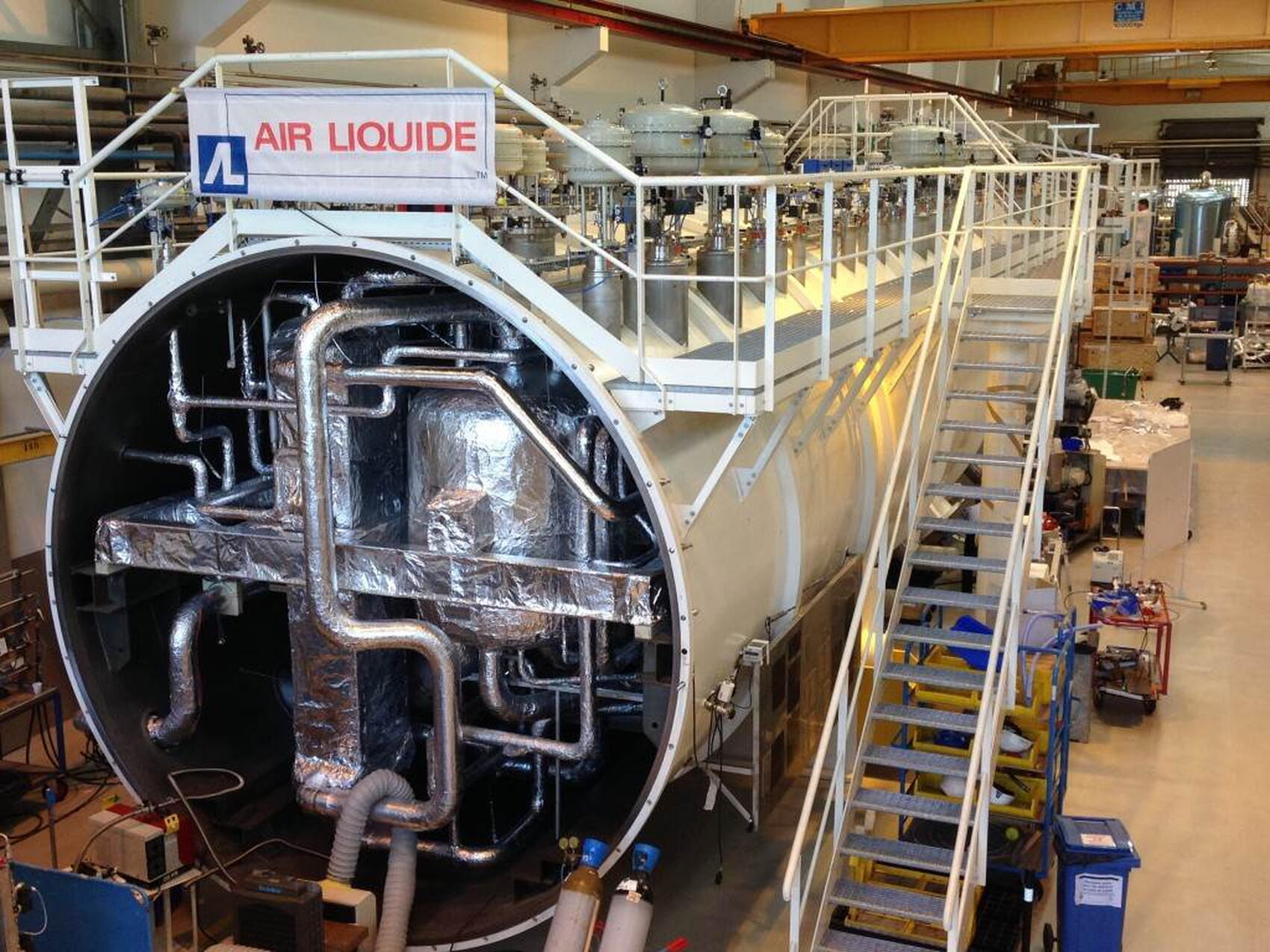

In the Cold Box Building, which occupies approximately 40 percent of the covered space, three identical helium refrigerators will work in parallel to provide liquid helium (LHe) to the major clients for cooling—ITER's 10,000 tonnes of superconducting magnets plus the cryosorption panels that ensure high-quality vacuum to the large volumes of the cryostat (8,500 m³) and vacuum vessel (1,400 m³). The three units will provide a total average cooling capacity of 75 kW at 4.5 K (-269 °C) at a maximum cumulated liquefaction rate of 12,300 litres per hour.

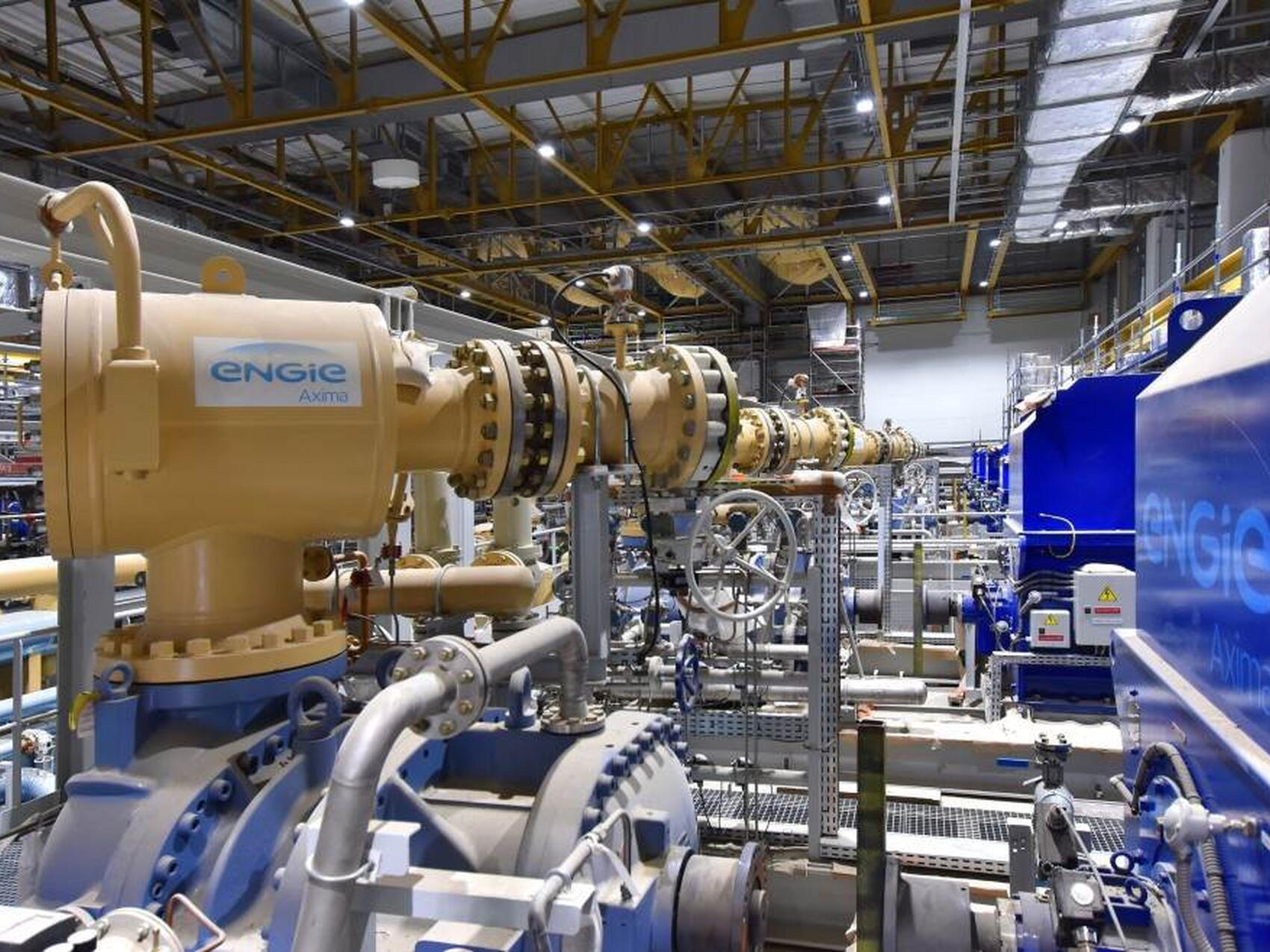

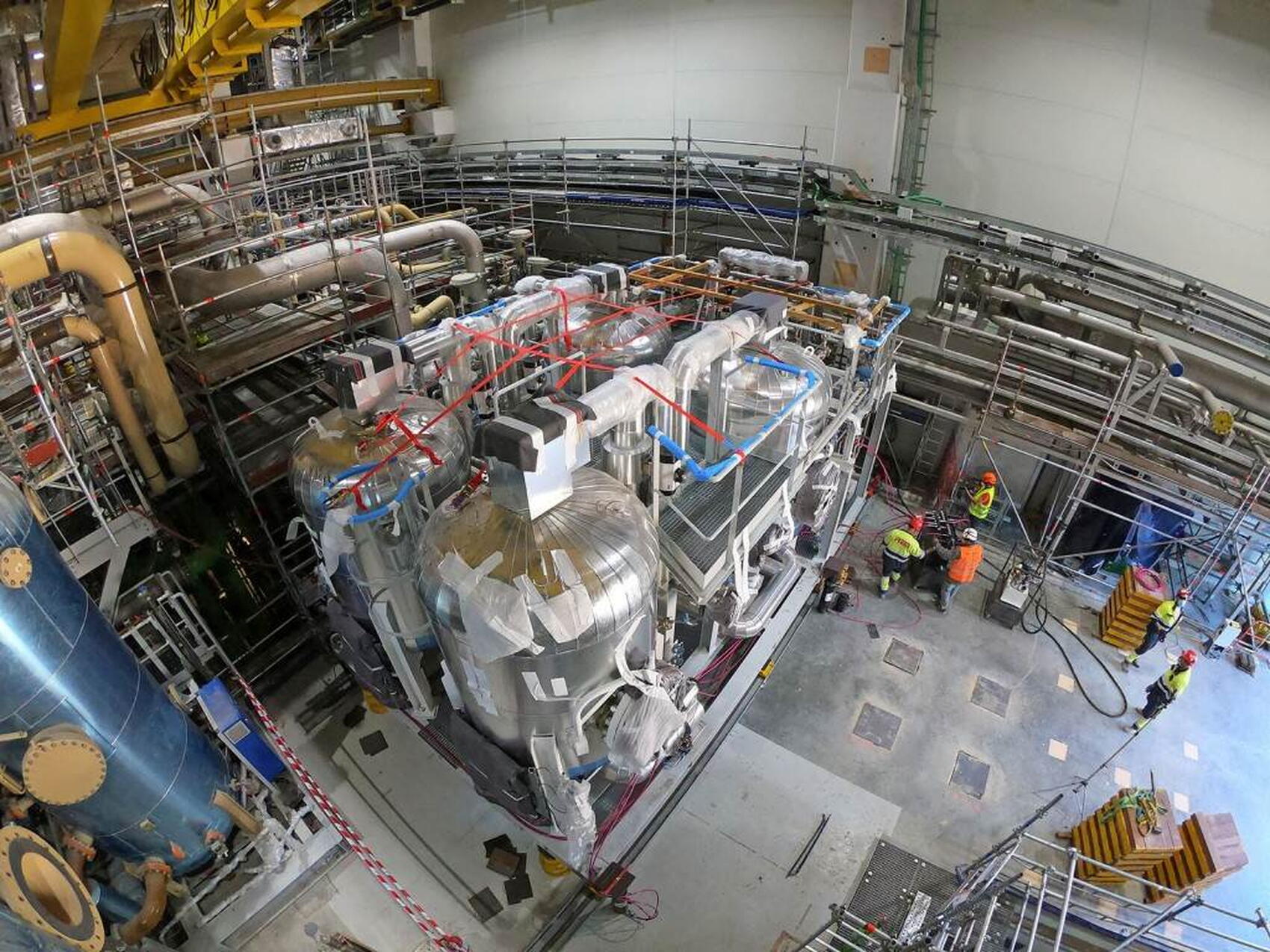

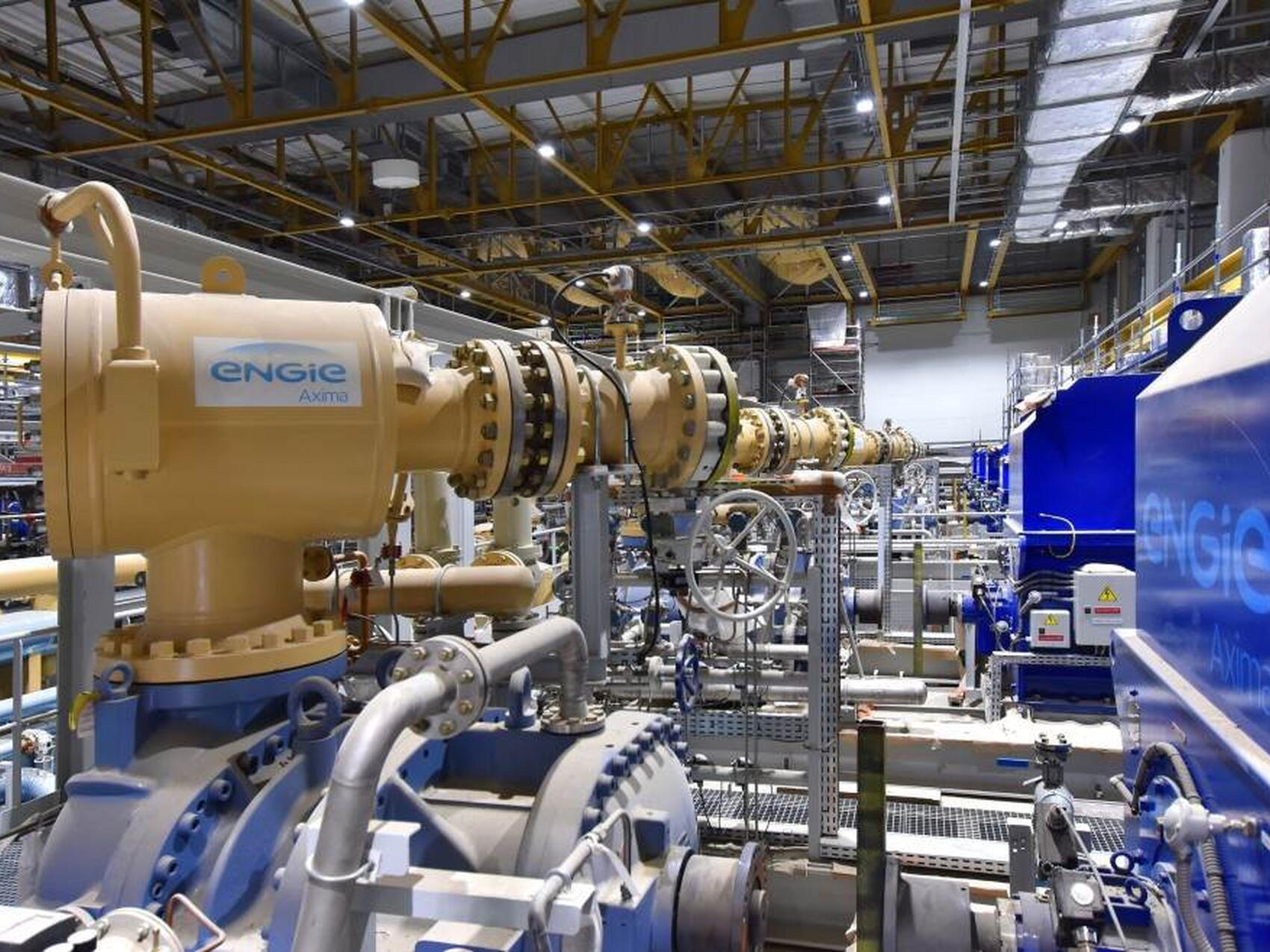

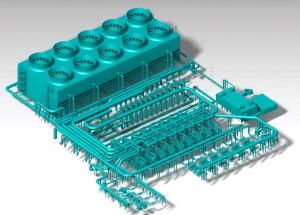

The cryoplant will also produce liquid nitrogen (LN₂) to be used as a ''pre-cooler'' in the liquid helium plant and for the refrigeration of the ITER thermal shield. The compressors for the nitrogen plant will be housed in the Compressor Building, next to the 18 compressors that will be required for the operation of the helium refrigerators; the two nitrogen cold boxes will be located outside of the building in the exterior area. Lost nitrogen will be extracted directly from the atmosphere in a gaseous nitrogen generator with a production capacity of 50 tonnes per day, and then processed in the two liquid nitrogen refrigerators with a maximum capacity of 1300 kW at 80 K.

A heat recovery system will be installed in the Compressor Building to recover up to 12 MW of heat from cooling water that circulates to evacuate the heat generated by the compressors. This recuperated thermal energy will be used in the heating of the ITER buildings themselves.

The LN₂ plant (blue, under the responsibility of Europe) will produce liquid nitrogen at a temperature of minus 196 °C to be used as a ''pre-cooler'' in the LHe plant (yellow, procured by the ITER Organization). Nearly 25 tonnes of liquid helium—at minus 269 °C—will circulate through a five-kilometre network of pipes, pumps and valves procured by India (the first part of the network is shown in green) in order to cool the superconducting magnets, the thermal shield, vacuum cryopumps, and certain diagnostics.

Cooling fluids generated in the cryoplant will travel along process lines installed 13 metres above platform level on a bridge that runs to the Tokamak Building; from there, approximately five kilometres of cryolines will distribute gas and liquid helium to the different "clients." The ITER magnets will consume 45 percent of cryogenic power followed by the thermal shield (40 percent) and the cryopumps (15 percent). Nearly 25 tonnes of liquid helium at minus 269 °C will circulate in the ITER installation during operation.

ITER's cryoplant has been designed to operate over a wide range of ITER plasma scenarios, from short plasma pulses (a few hundred seconds) with 700 MW of fusion power, to long plasma pulses of 3,000 seconds with 365 MW of fusion power. A number of unique features will also guarantee high reliability and availability despite unprecedented dynamic heat loads caused by magnetic field variations and fusion neutrons.

Three parties are sharing responsibility for the plant's procurement: the ITER Organization, responsible for the liquid helium plants; Europe, in charge of the liquid nitrogen plant and auxiliary systems as well as the construction of the cryoplant infrastructure on site; and India, whose contractors are procuring the cryolines, the warm lines and cryodistribution components.

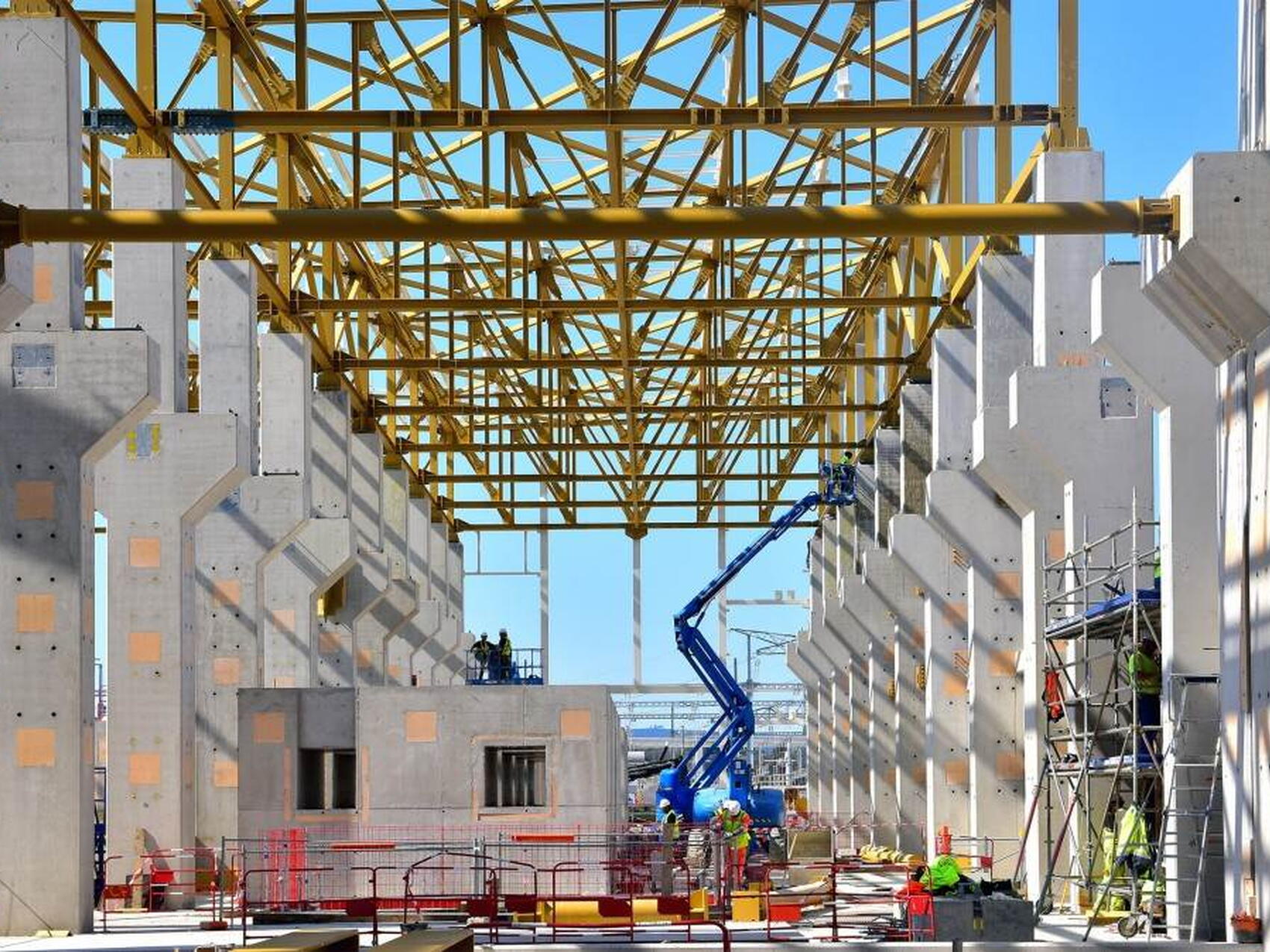

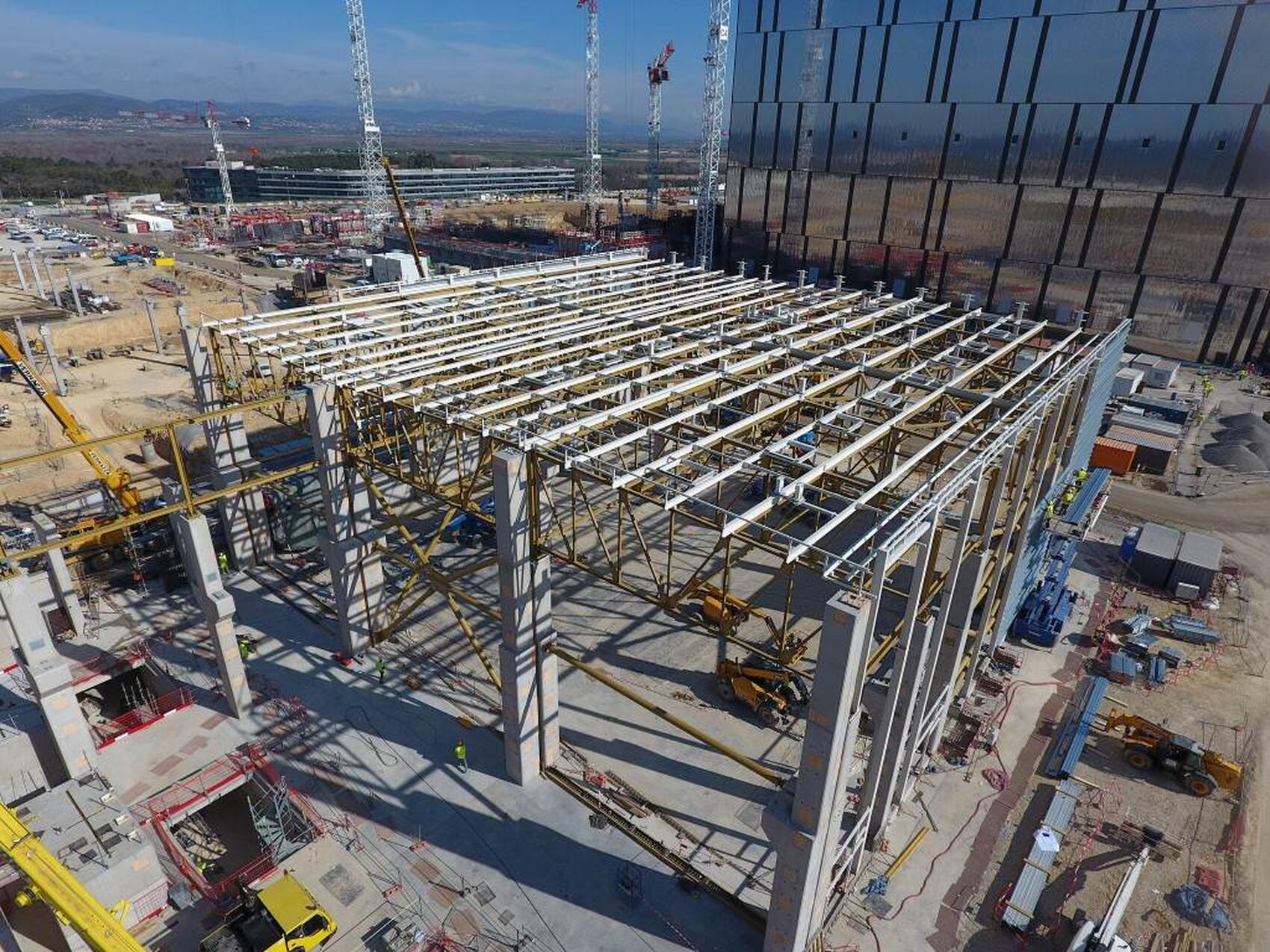

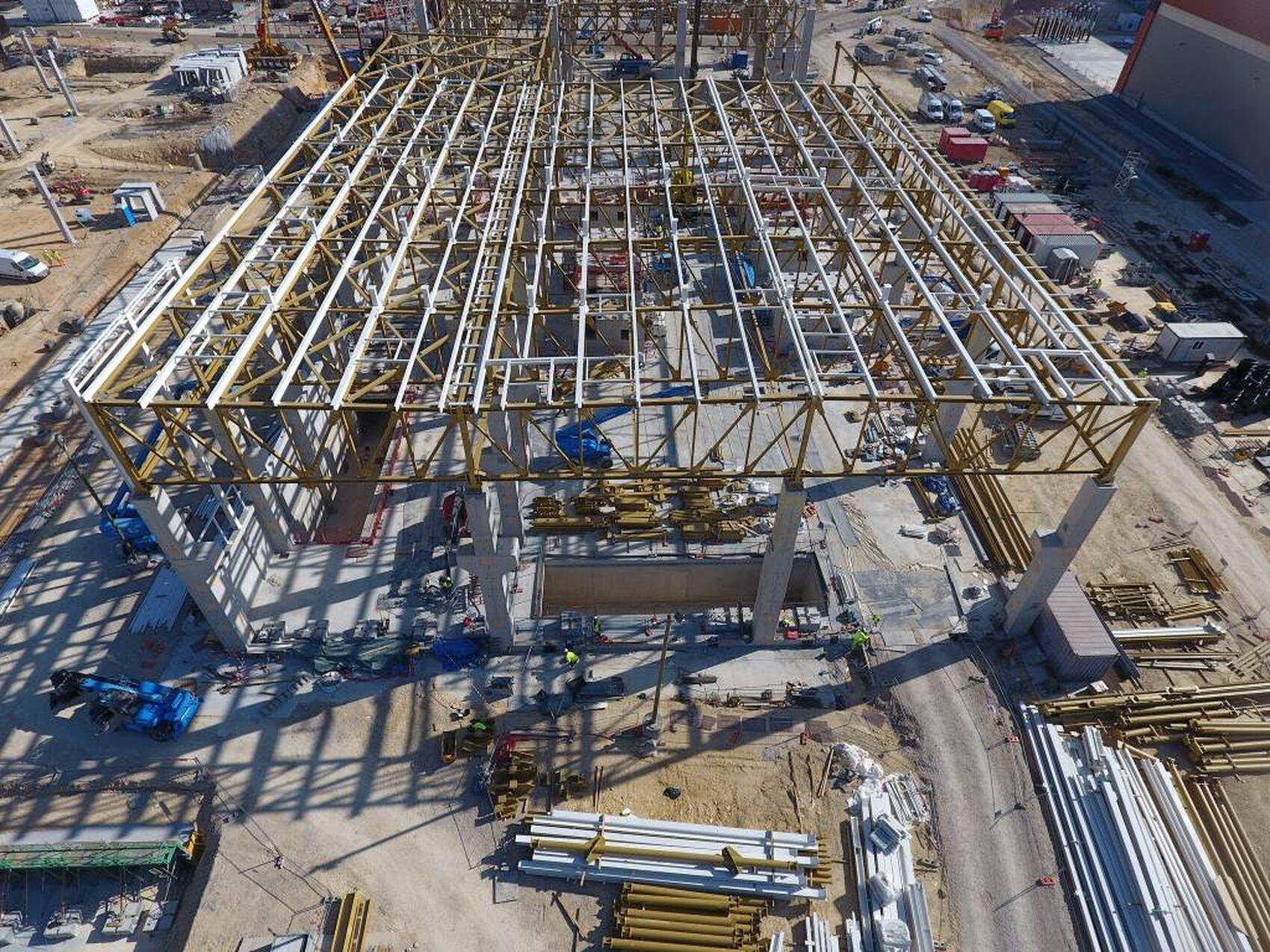

Construction of the ITER cryoplant was completed in 2017; today, all mechanical installation has been completed and commissioning activities are underway.

More on the use of cryogenic technology at ITER here.

Learn more by watching this recent video.

Cryoplant facts:

- Construction: October 2015-September 2017

- Total area: 8,000 m²

- Building dimensions: Height 20 m, Length 120 m, Width 45 m

- Cold Box Building (liquid helium plant): 2,000 m²

- Compressor Building (compressors, liquid nitrogen plant): 3,400 m²

- Size of exterior storage area: 2,600 m²

- LHe total average cooling capacity: 75 kW at 4.5 K

- LHe liquefaction: 12,300 litres/hour

- LN₂ total average cooling capacity: 1300 kW at 80 K

- GN₂ liquefaction: 50 tonnes/day

Photo Gallery