The Project

- Building ITER

- Projects Underway

- Construction Archives

- Neutral Beam Test Facility

- Assembly Overview

- Tokamak Assembly

- Plant Assembly

- Commissioning

- Assembly Tooling

- Metrology

- Project Milestones

Cryostat Workshop

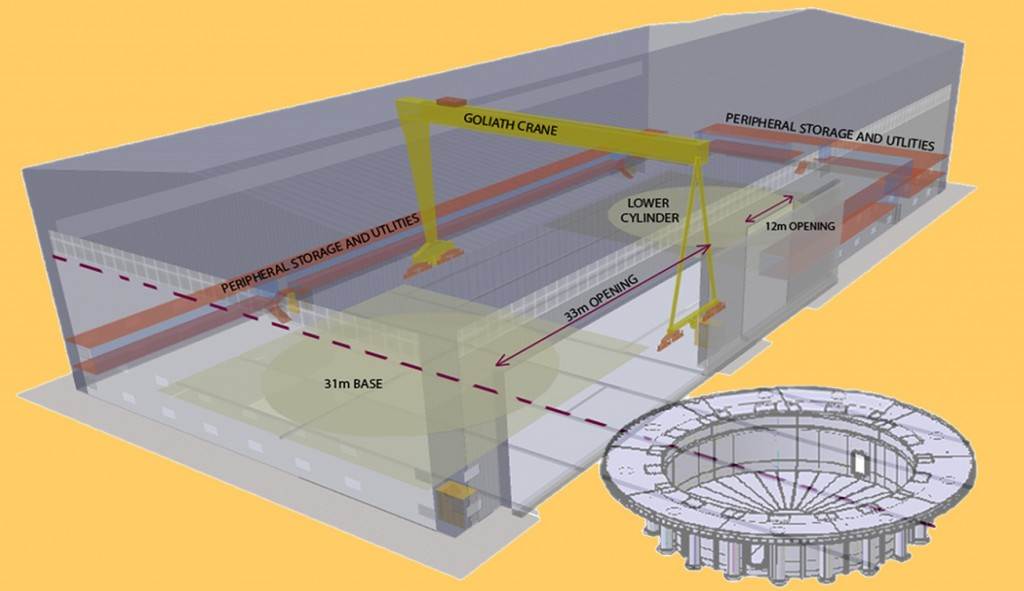

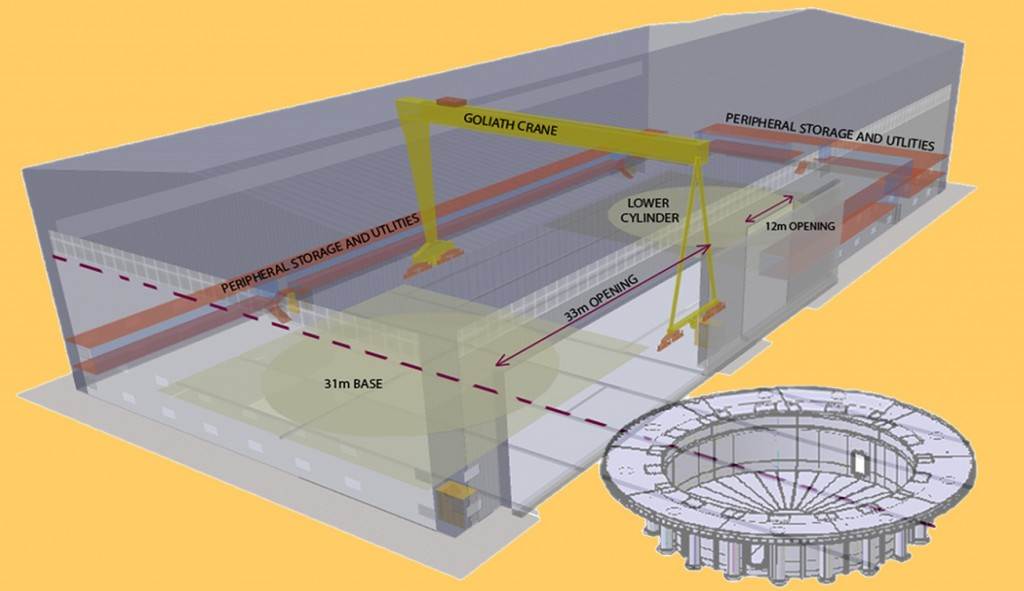

The Cryostat Workshop was built by the Indian Domestic Agency for the assembly and welding of four ITER cryostat sections (2016-2022). The Workshop now houses assembly-related activities.

In the northeast corner of the ITER platform, the 6,000-square-metre Cryostat Workshop was built to house the assembly of the four main cryostat sections from 54 smaller segments manufactured in India.

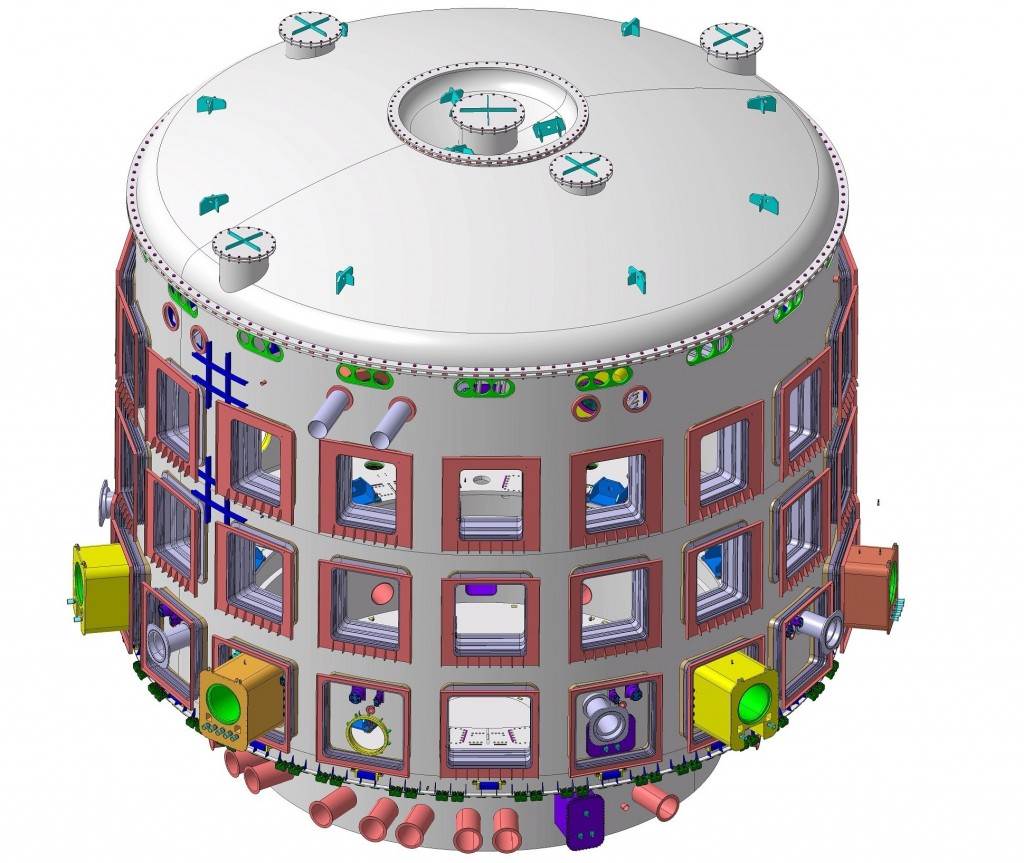

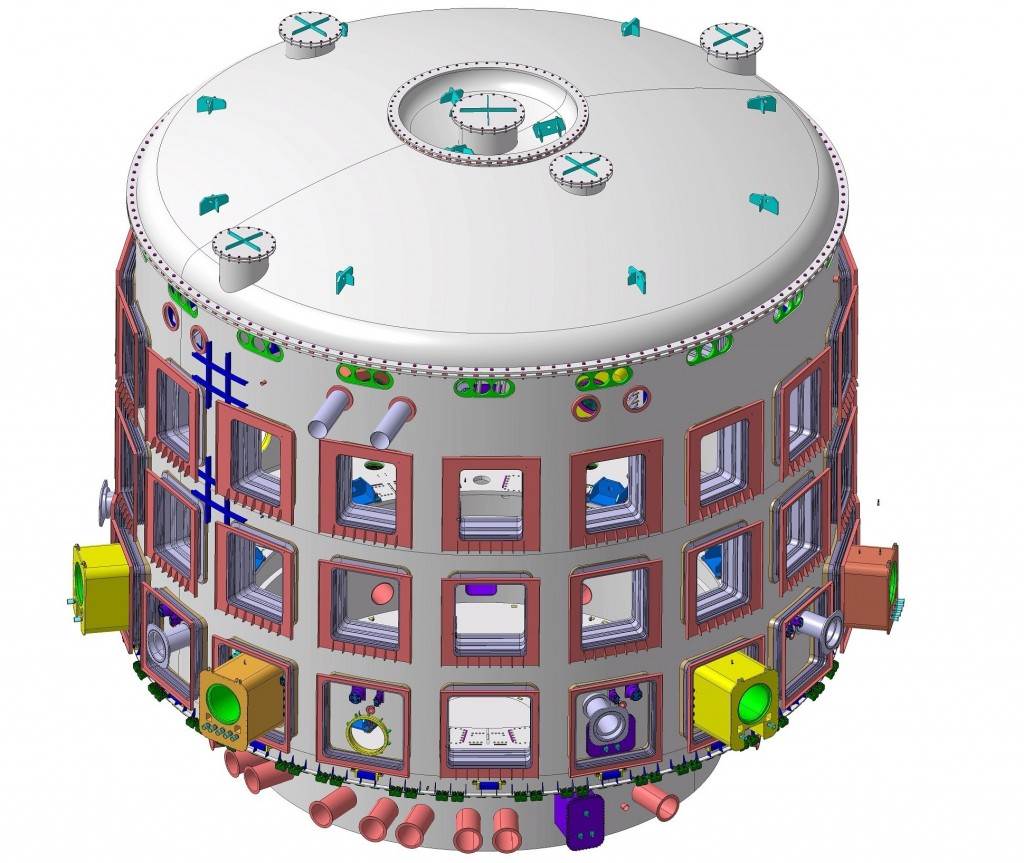

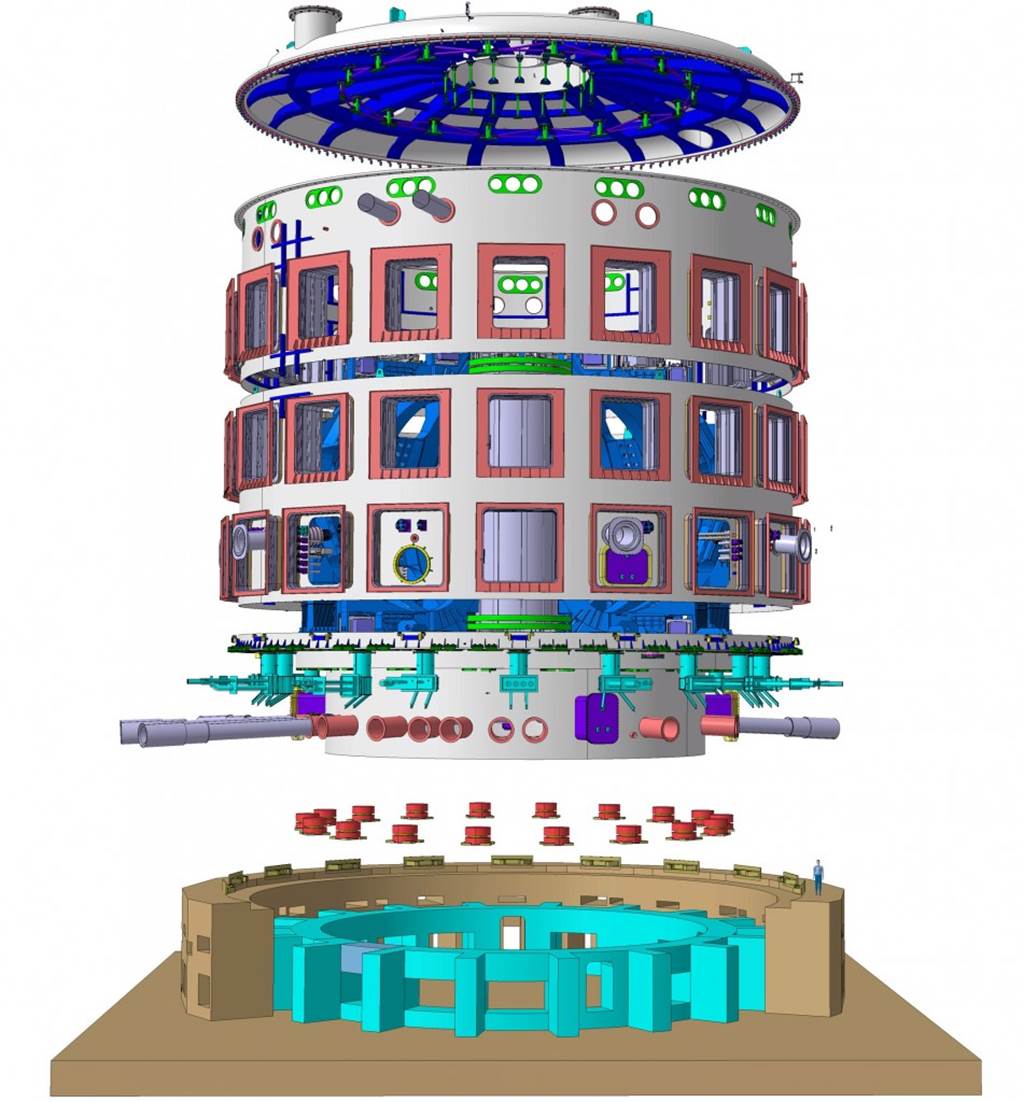

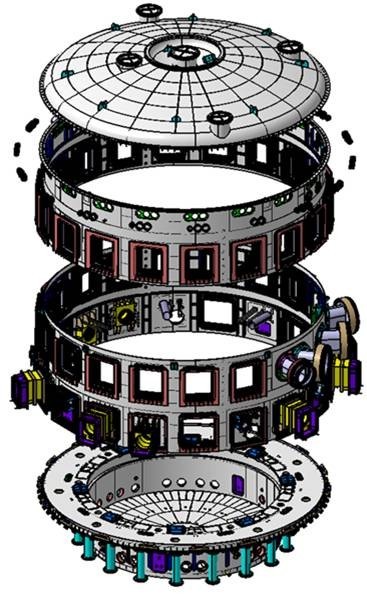

The cryostat is the vacuum-tight container that will surround the ITER vacuum vessel and superconducting magnets. The base section of the cryostat was the first large component installed in the Tokamak Pit; the top lid of the cryostat will be the last, set into place after the installation of the vacuum vessel and magnets.

Like the largest poloidal field coils, the size and weight of the main cryostat segments made travel along the ITER Itinerary impossible. The cryostat base section—1,250 tonnes—is the single largest load of ITER Tokamak assembly; the lower cylinder, upper cylinder and top lid weigh in the range of 600-800 tonnes each. Once welded together, the cryostat will measure nearly 30 metres in diameter and as many in height. Two sections of the cryostat have already been installed in the Tokamak pit—the base and lower cylinder—and welded together. The upper two sections are currently stored on the ITER platform under protective wrapping.

Assembly operations in the Cryostat Workshop took place on two 30 x 30 metre platforms that also acted as transport platforms as the sections left the building powered by self-propelled modular transporters.

Since the completion of cryostat section assembly in 2022, the building has been repurposed as a machine assembly workshop.

See this page to learn all about cryostat assembly.

Cryostat Workshop facts:

- Construction: June 2013-November 2014

- Length: 110 metres

- Width: 50 metres

- Height: 27 metres

- Cryostat section assembly: 2016-2022

Photo gallery