The Project

- Building ITER

- Projects Underway

- Construction Archives

- Neutral Beam Test Facility

- Assembly Overview

- Tokamak Assembly

- Plant Assembly

- Commissioning

- Assembly Tooling

- Metrology

- Project Milestones

Cryostat Fabrication on Site

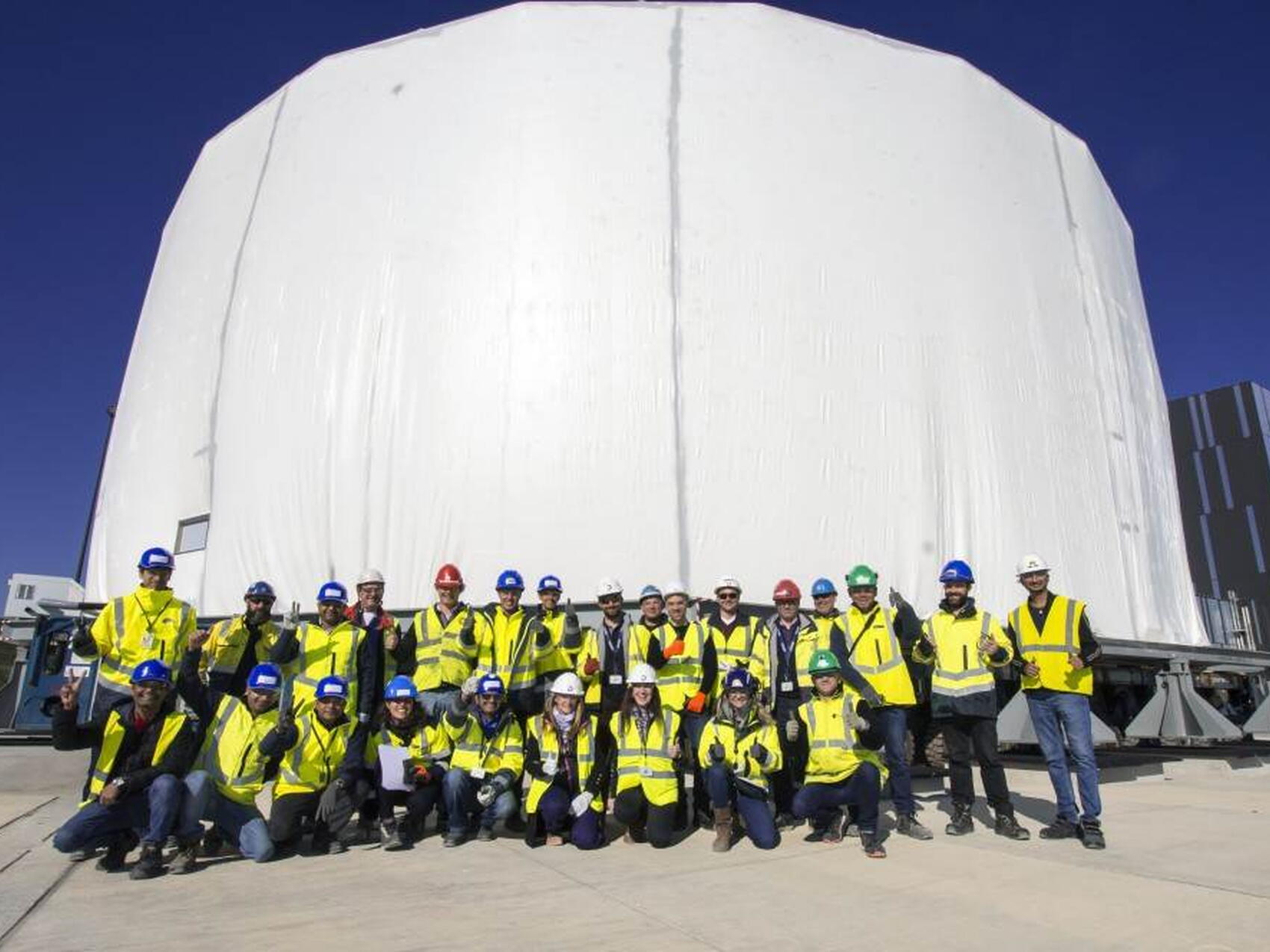

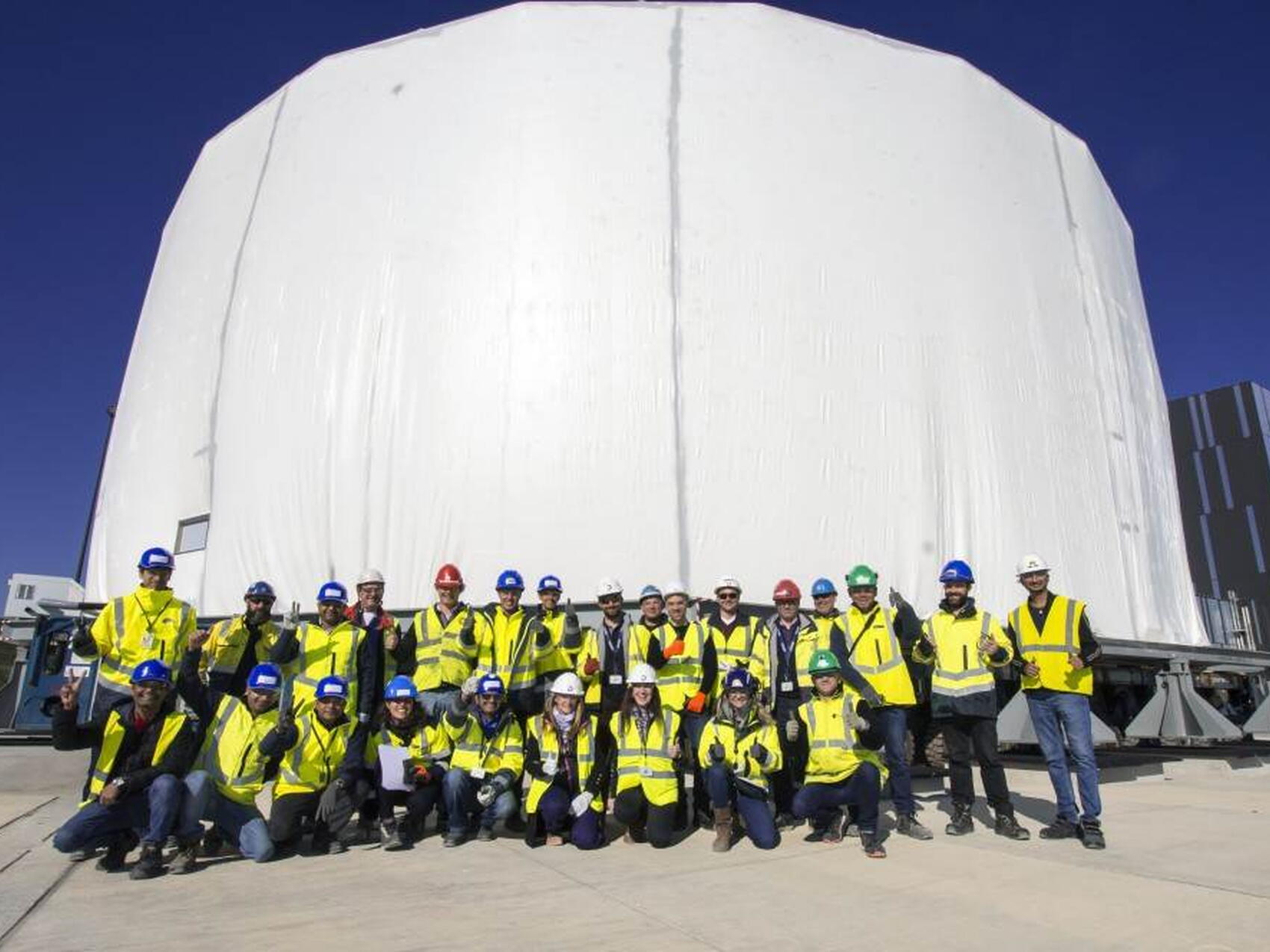

However impressive the figures, the finalization of the ITER cryostat was, first and foremost, the product of a convergence of competencies, creativity and dedication. "The ITER one-team spirit eventually absorbed all the complexities of the project." said ITER Construction Domain Youngeek Jung.

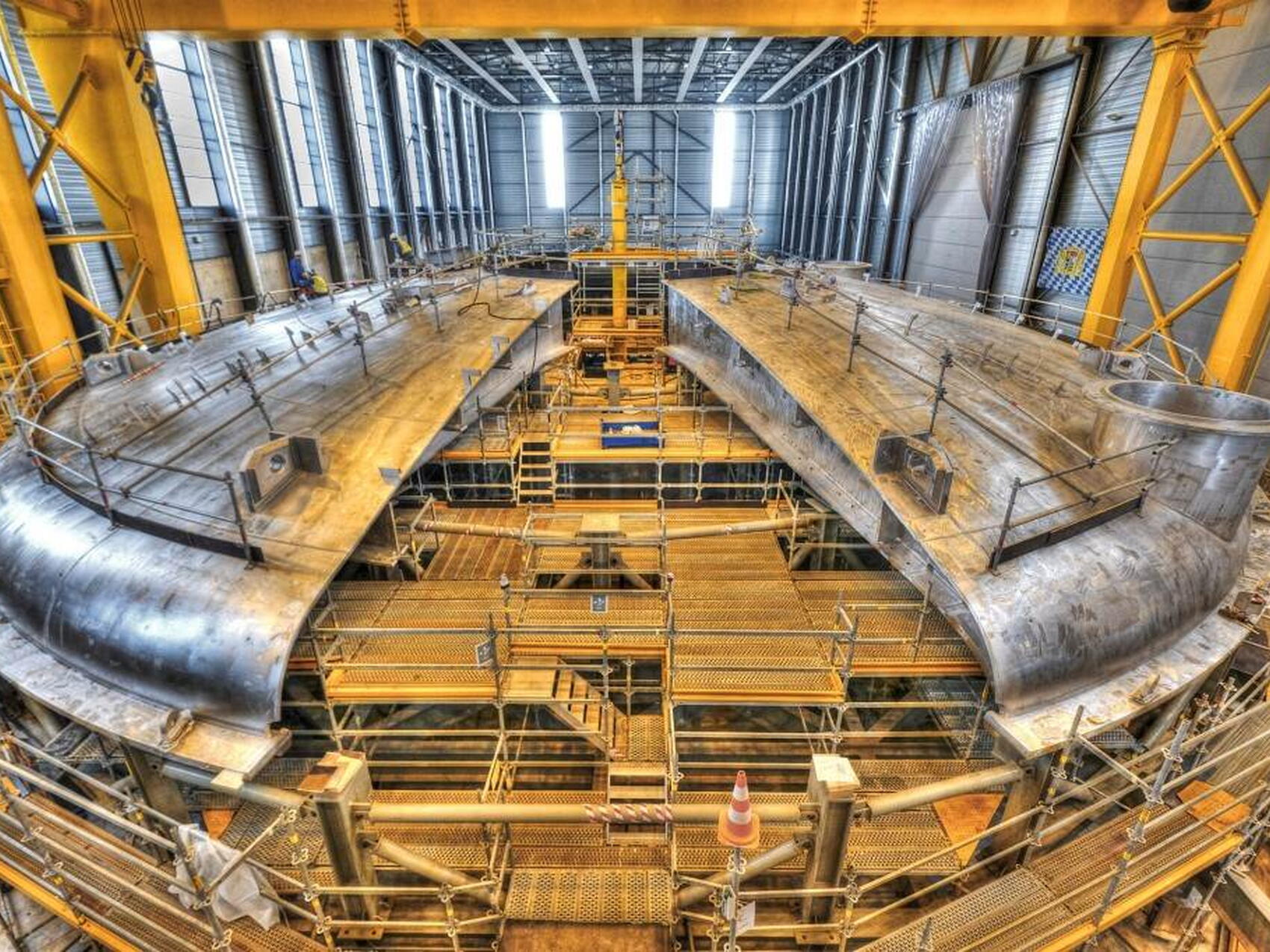

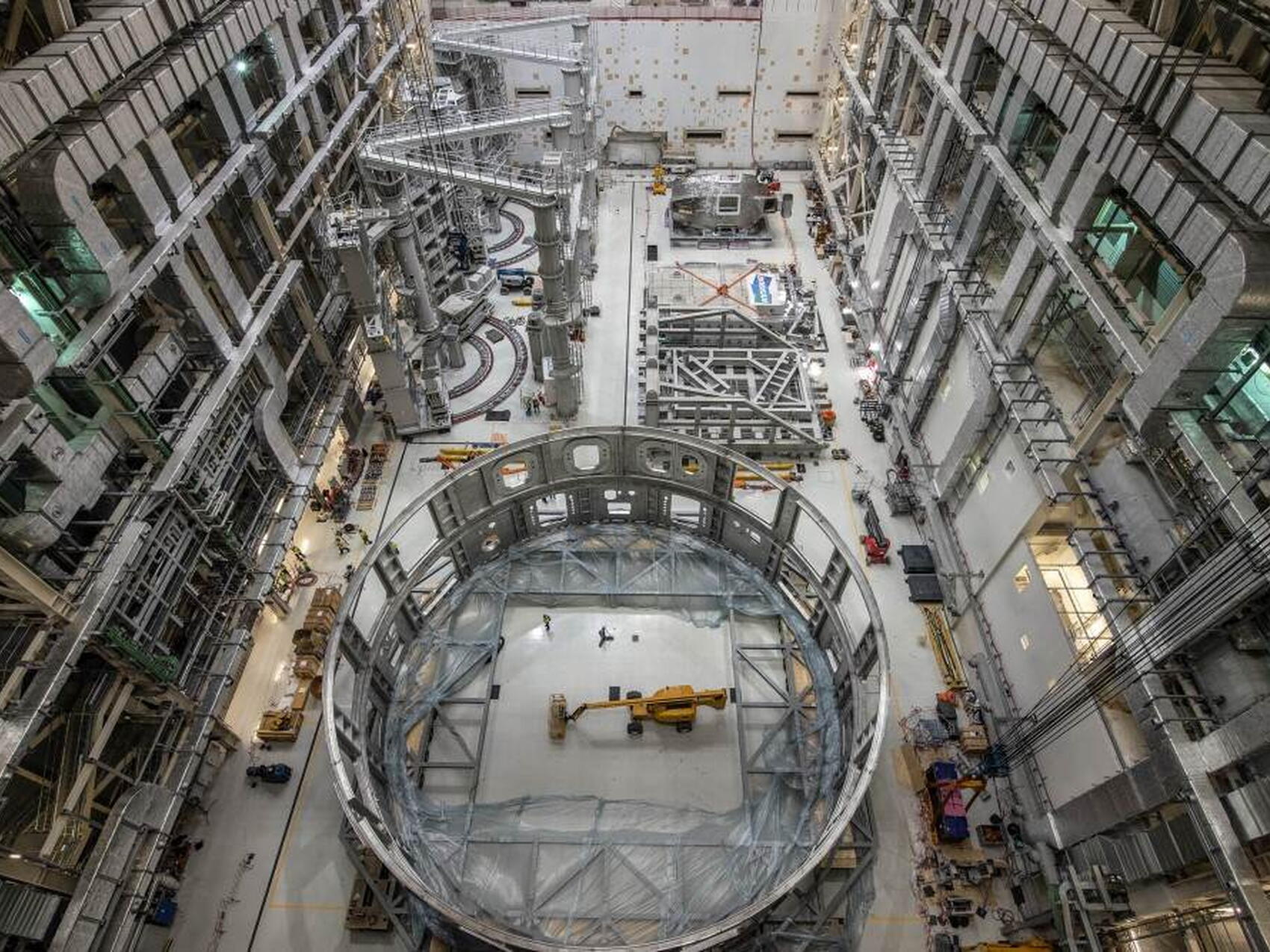

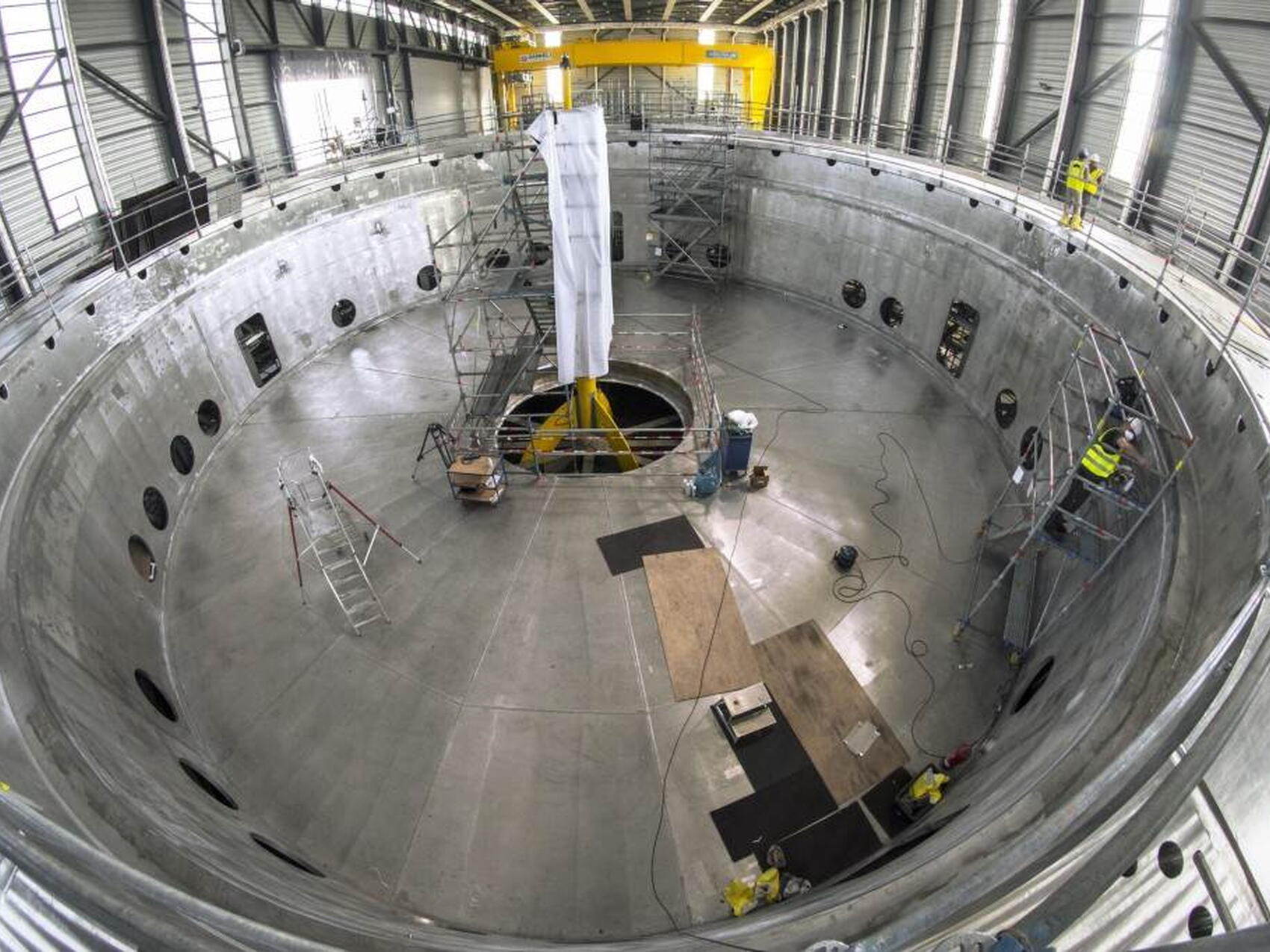

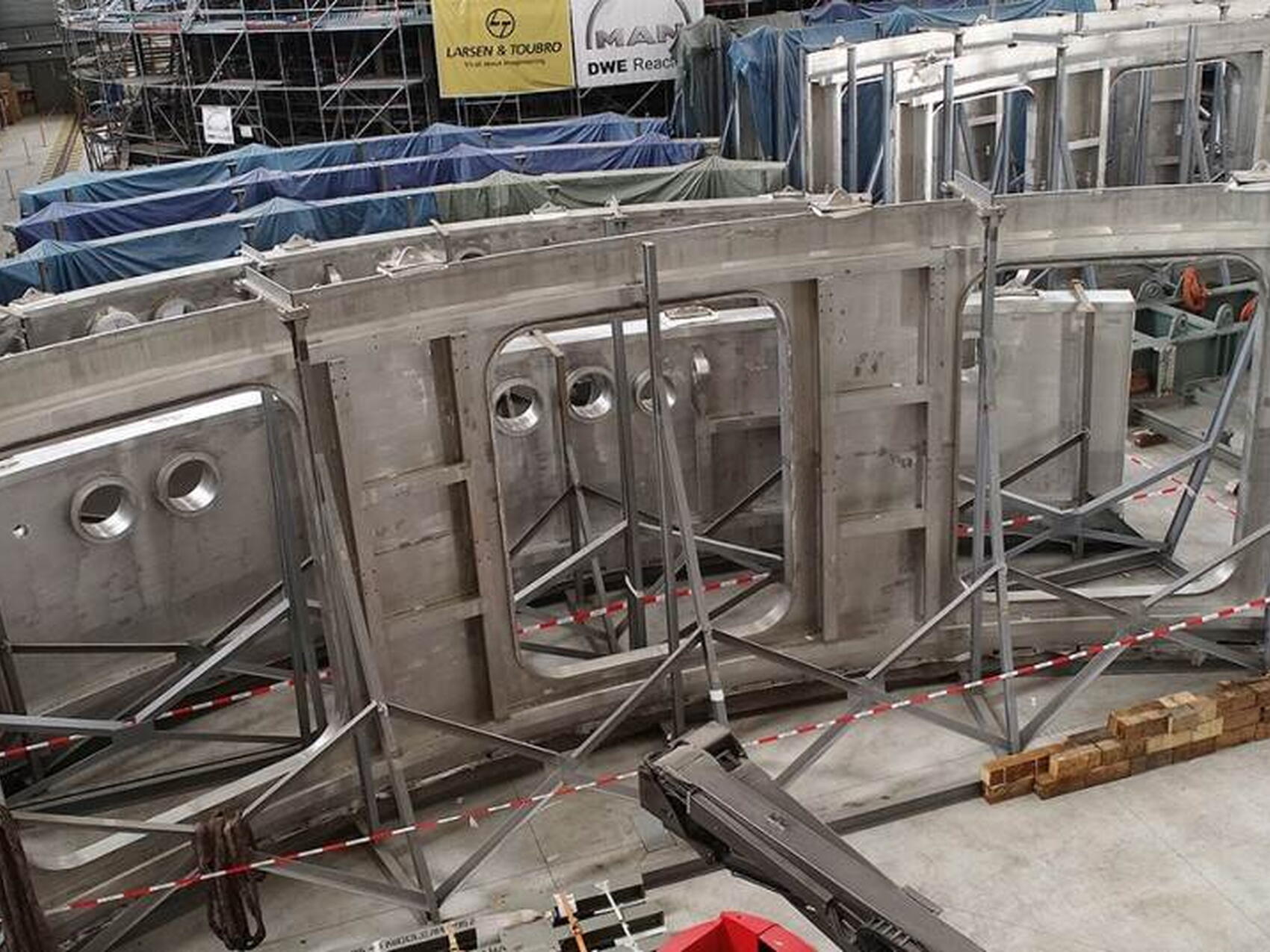

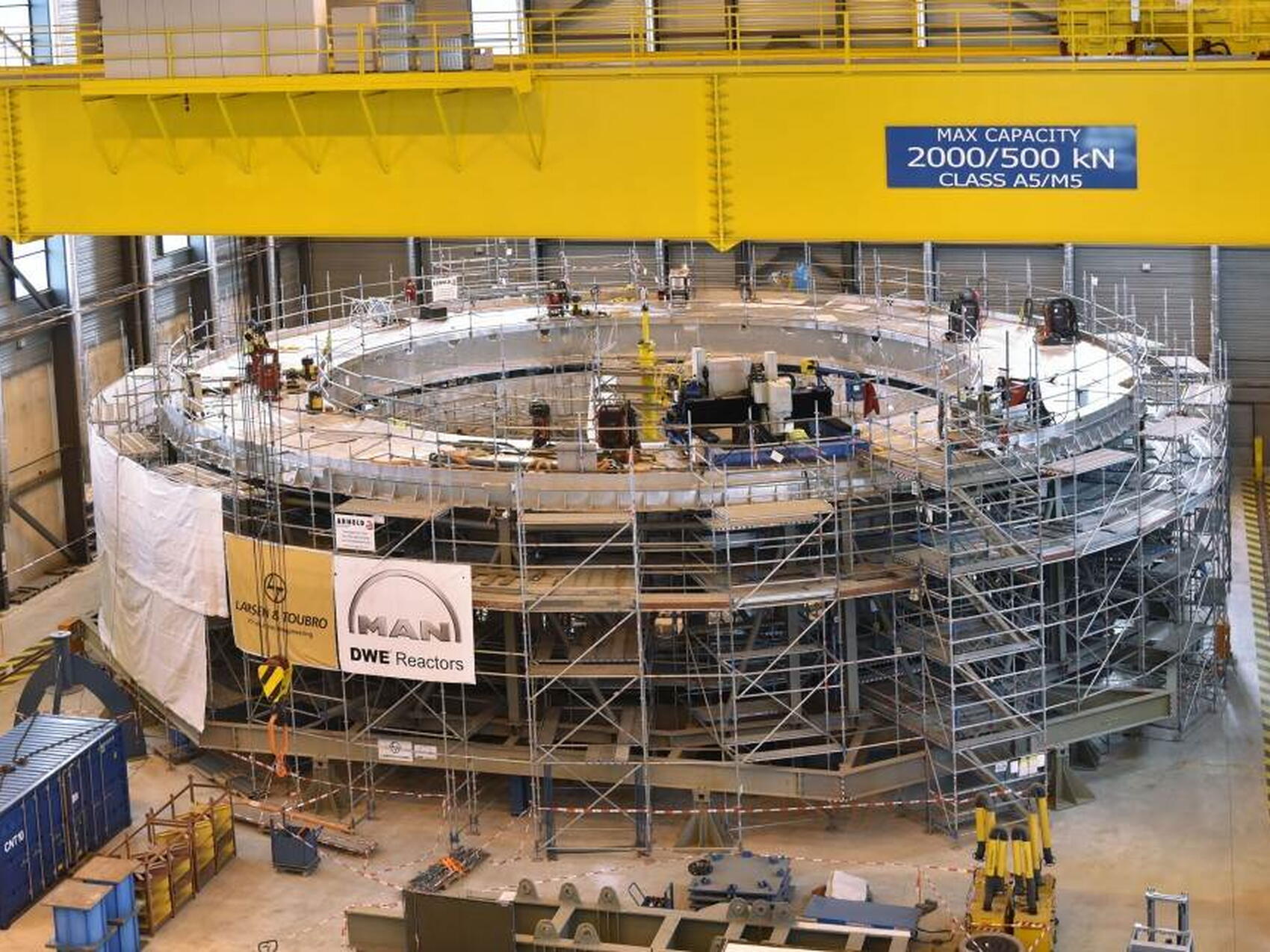

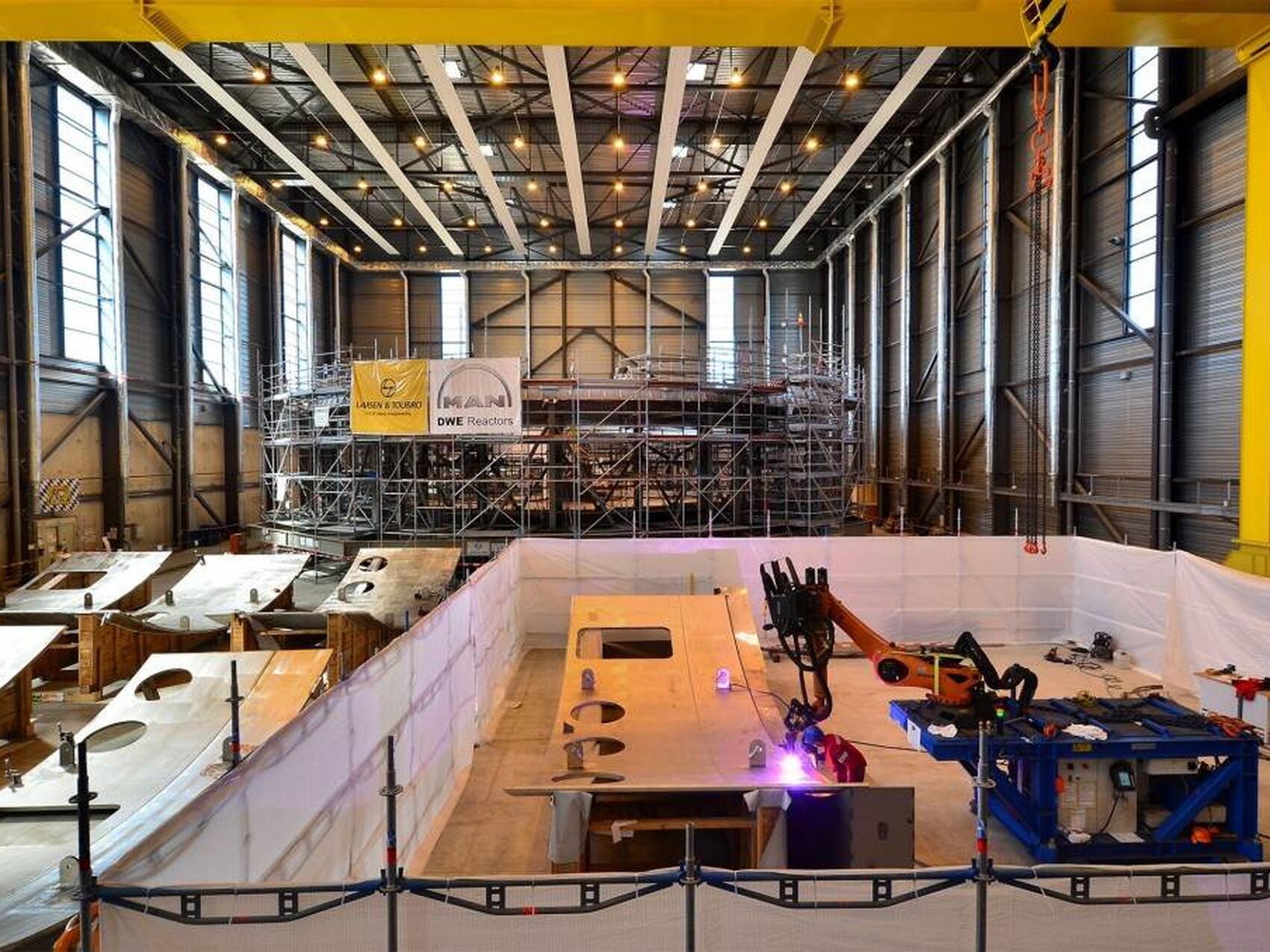

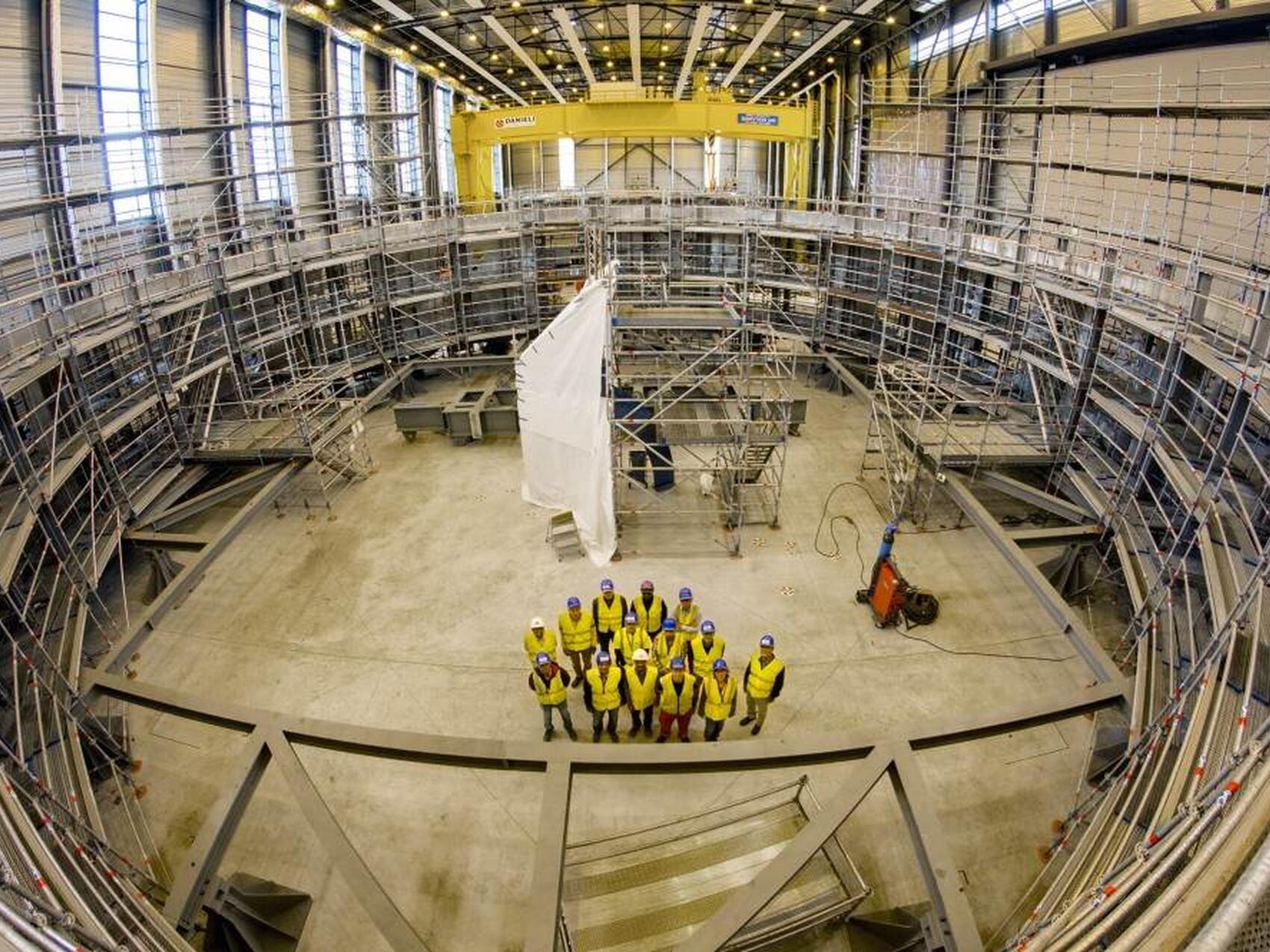

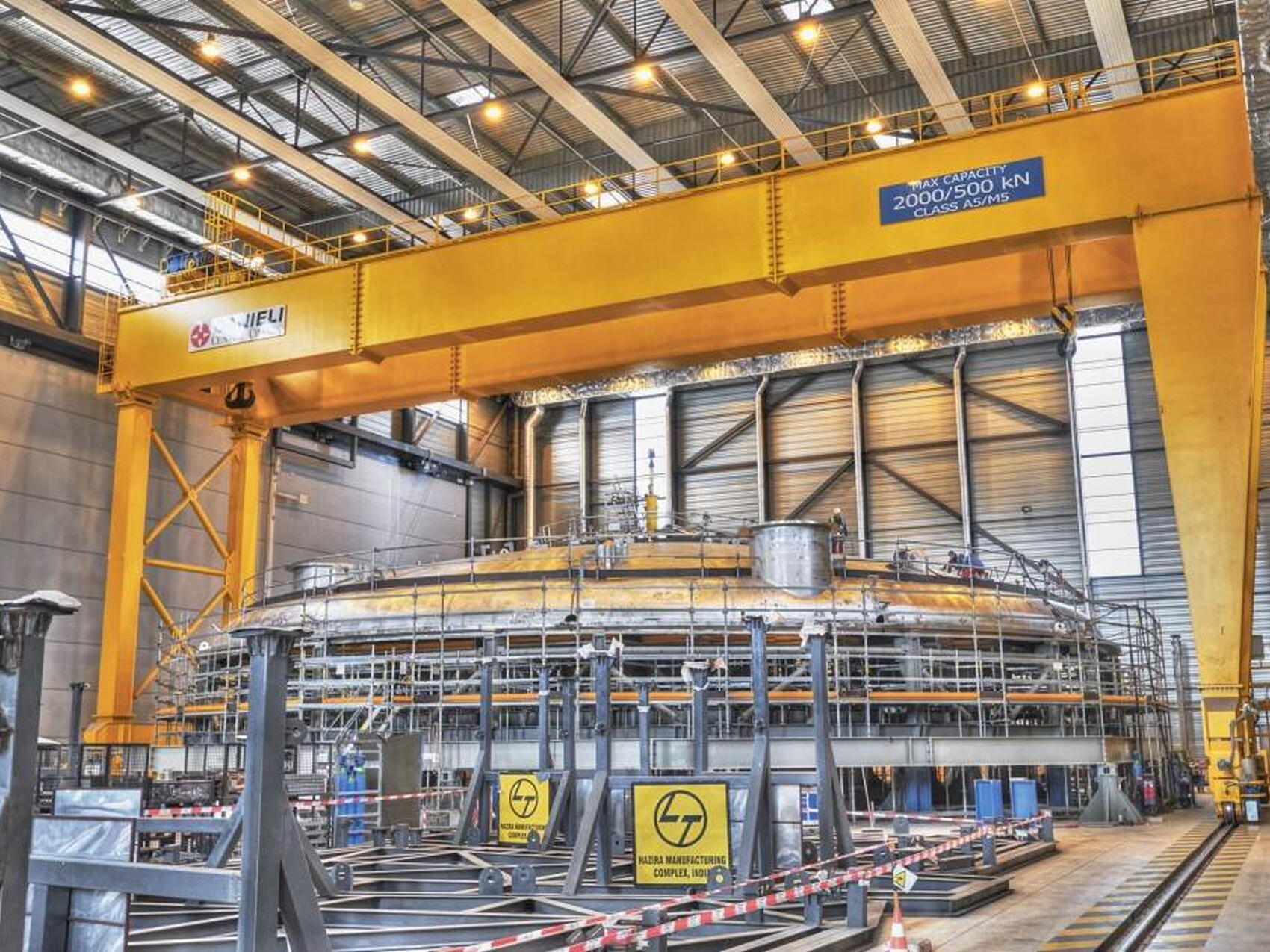

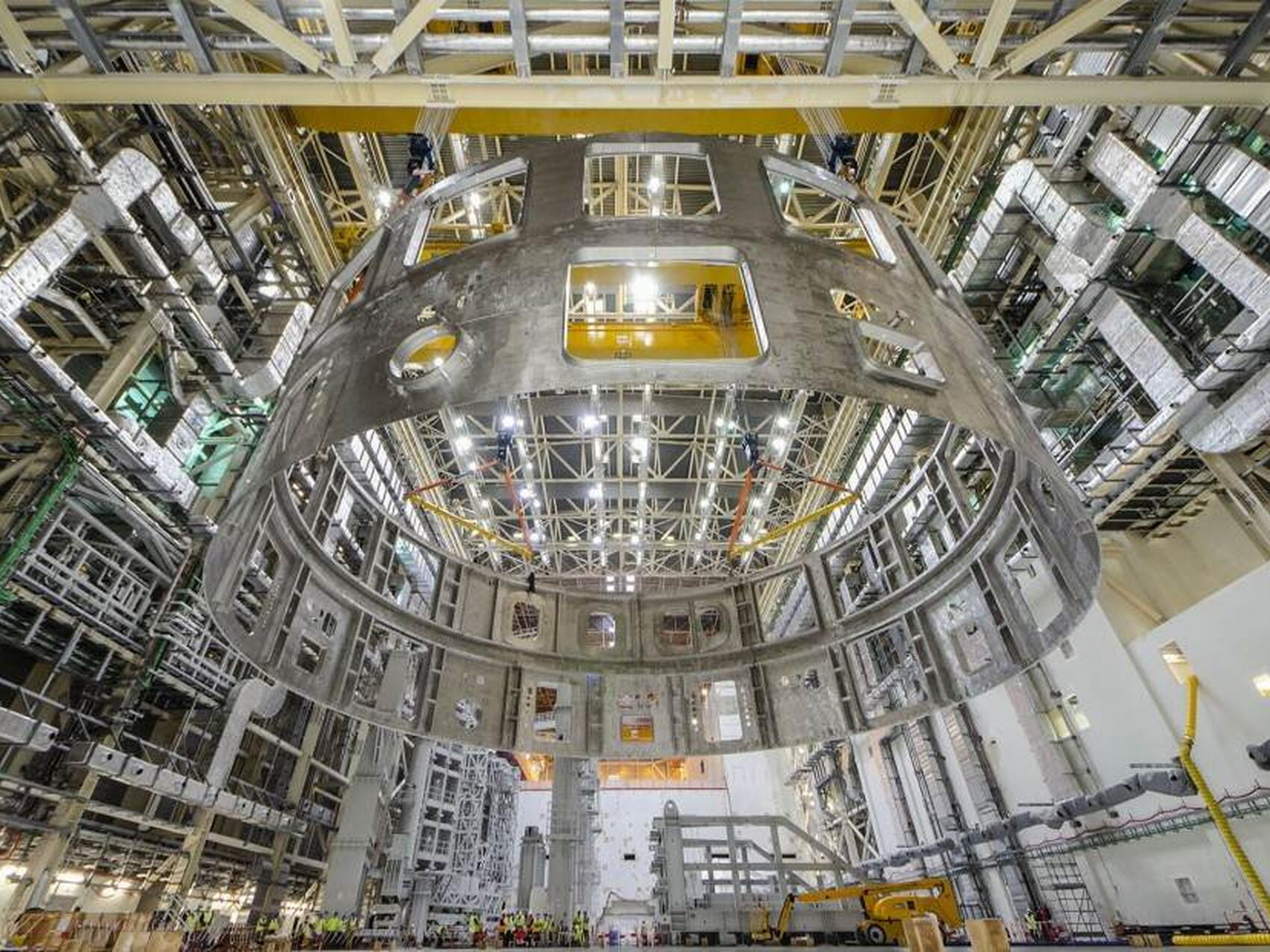

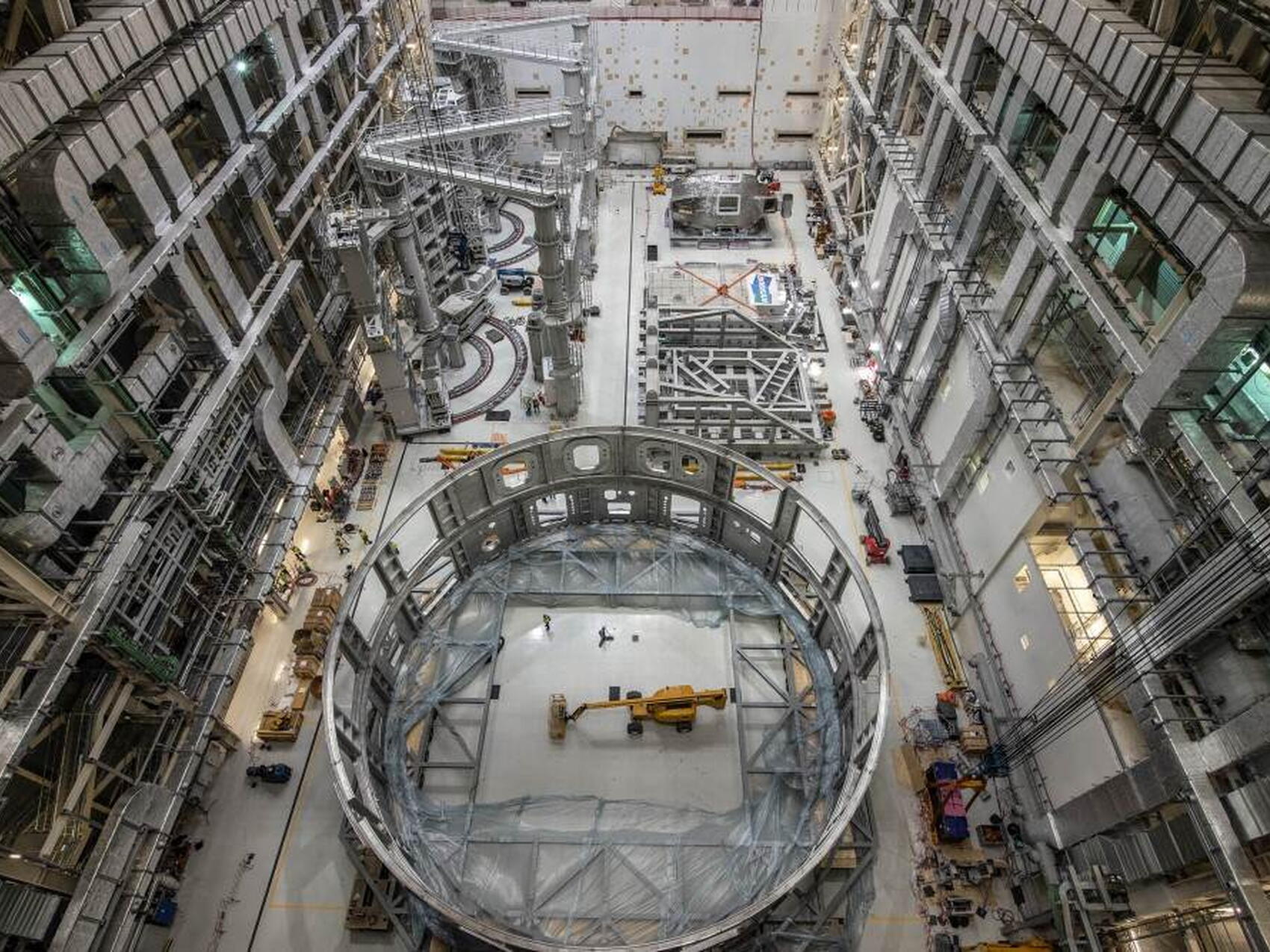

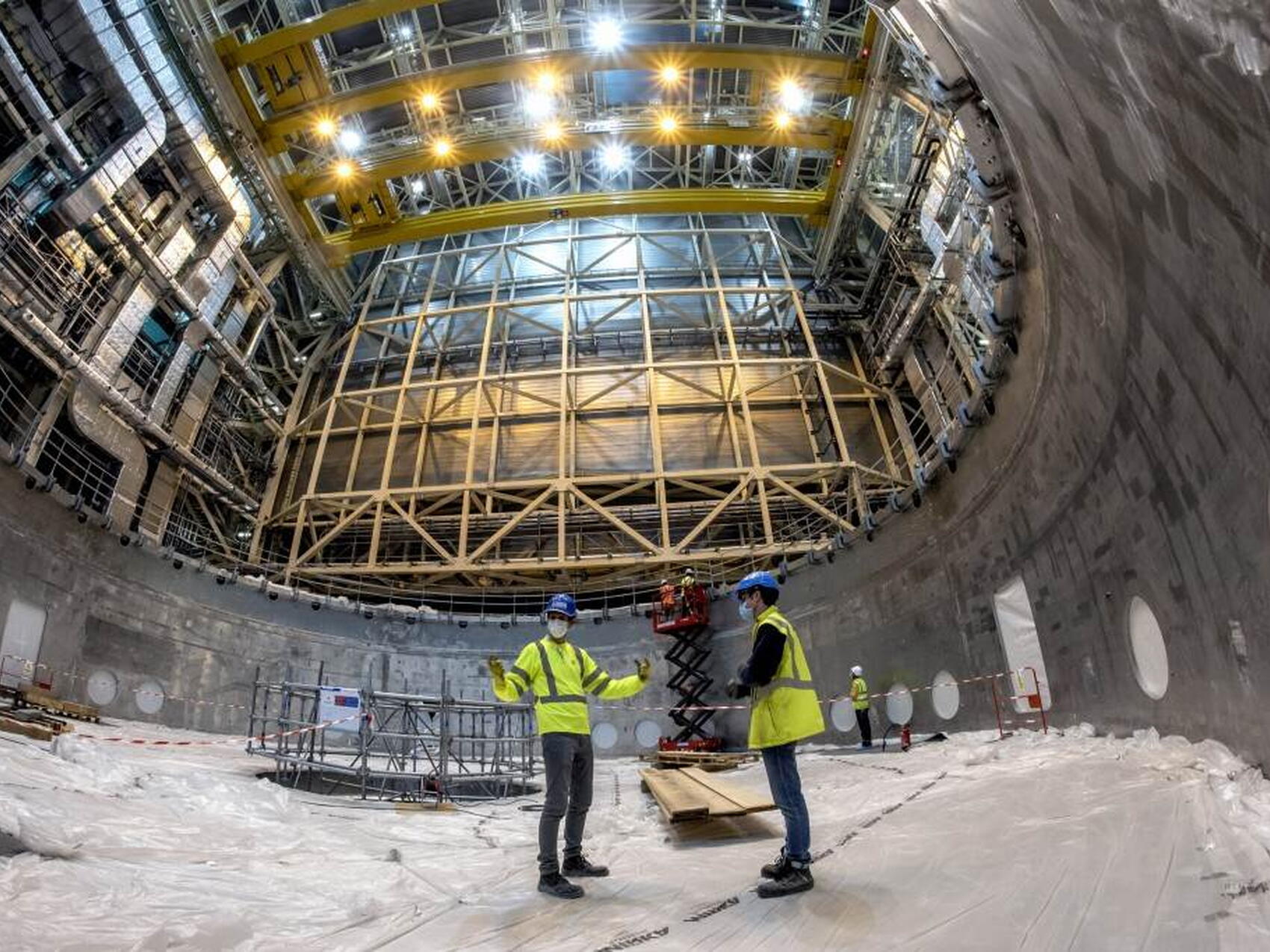

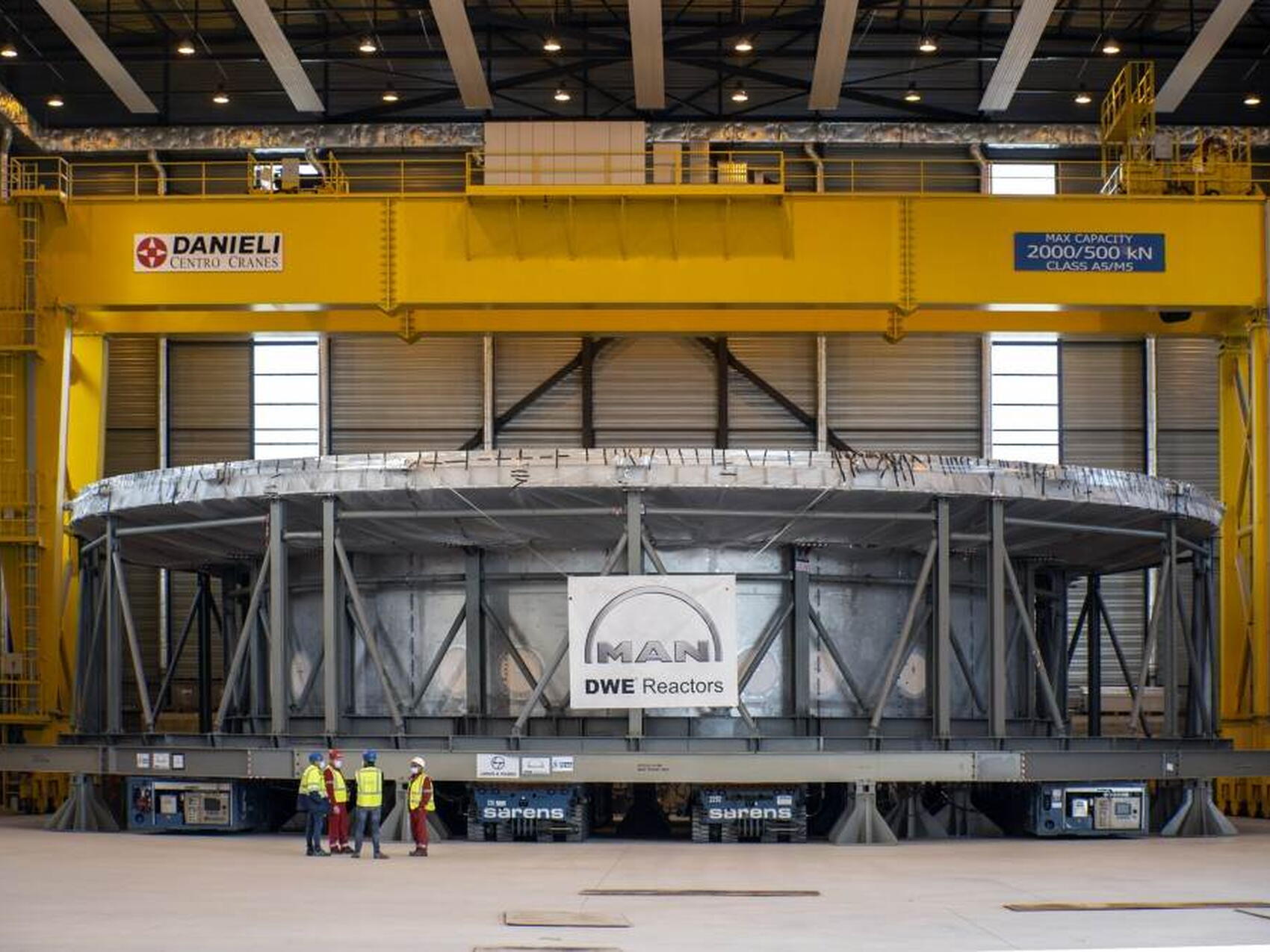

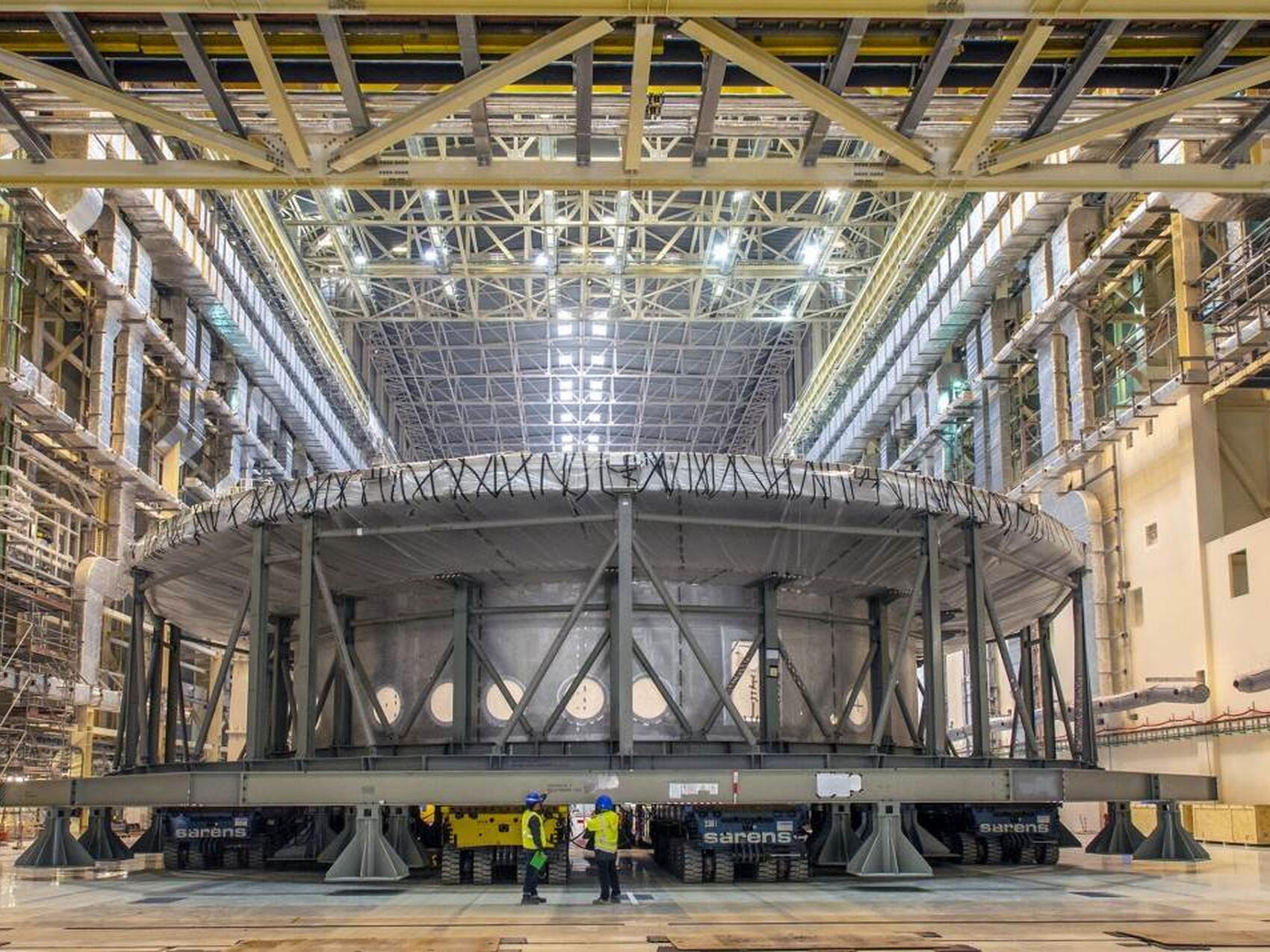

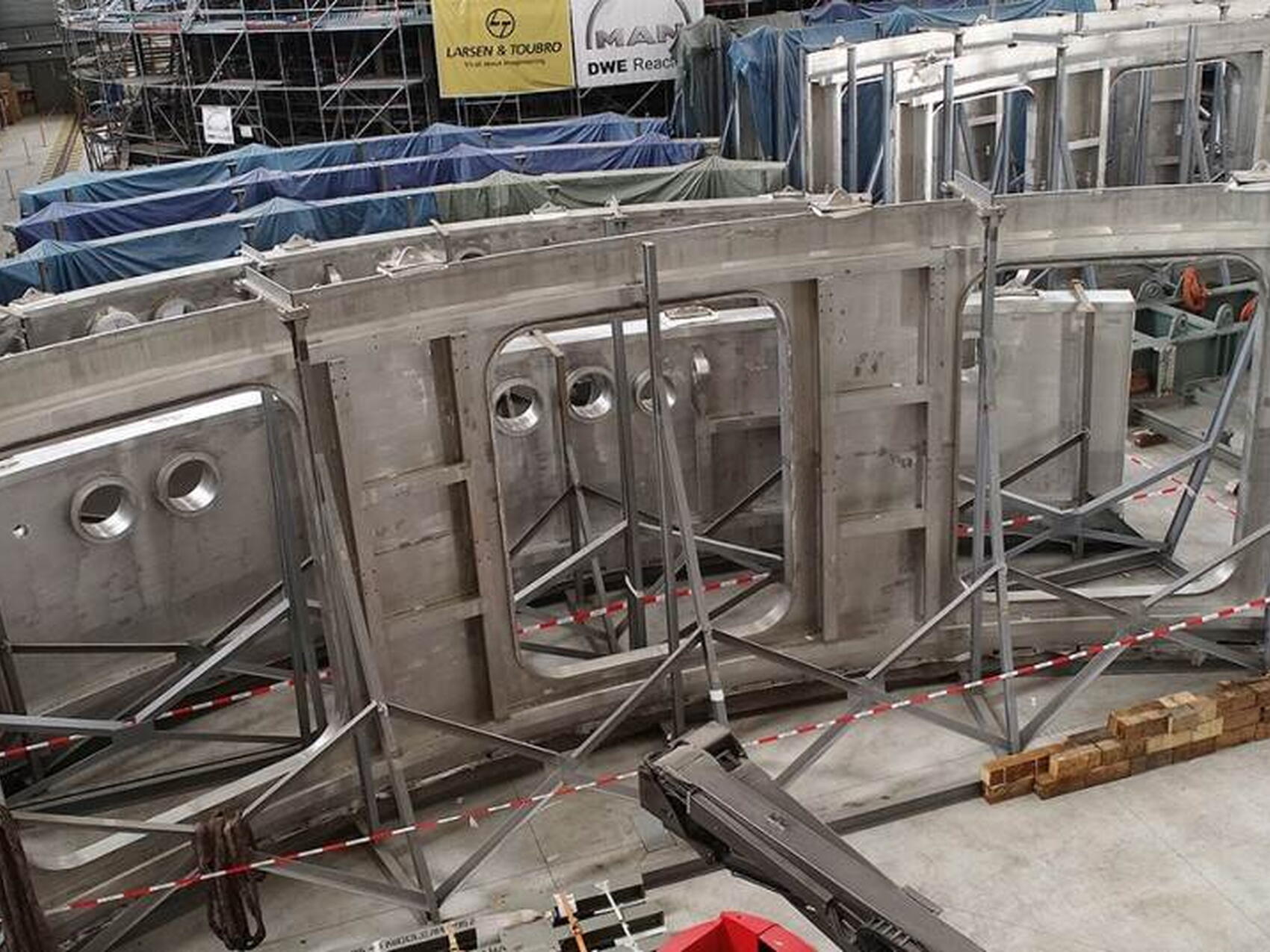

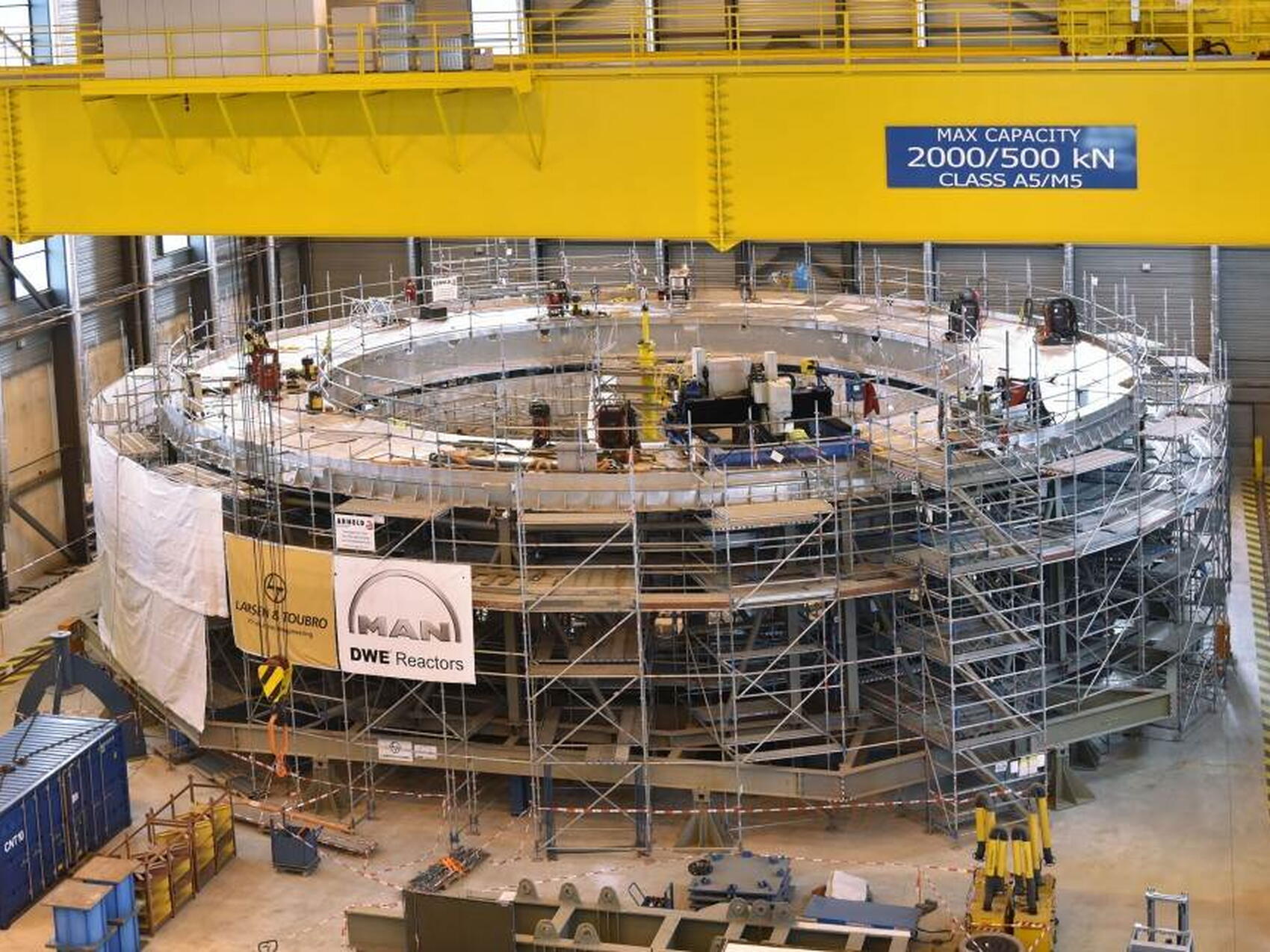

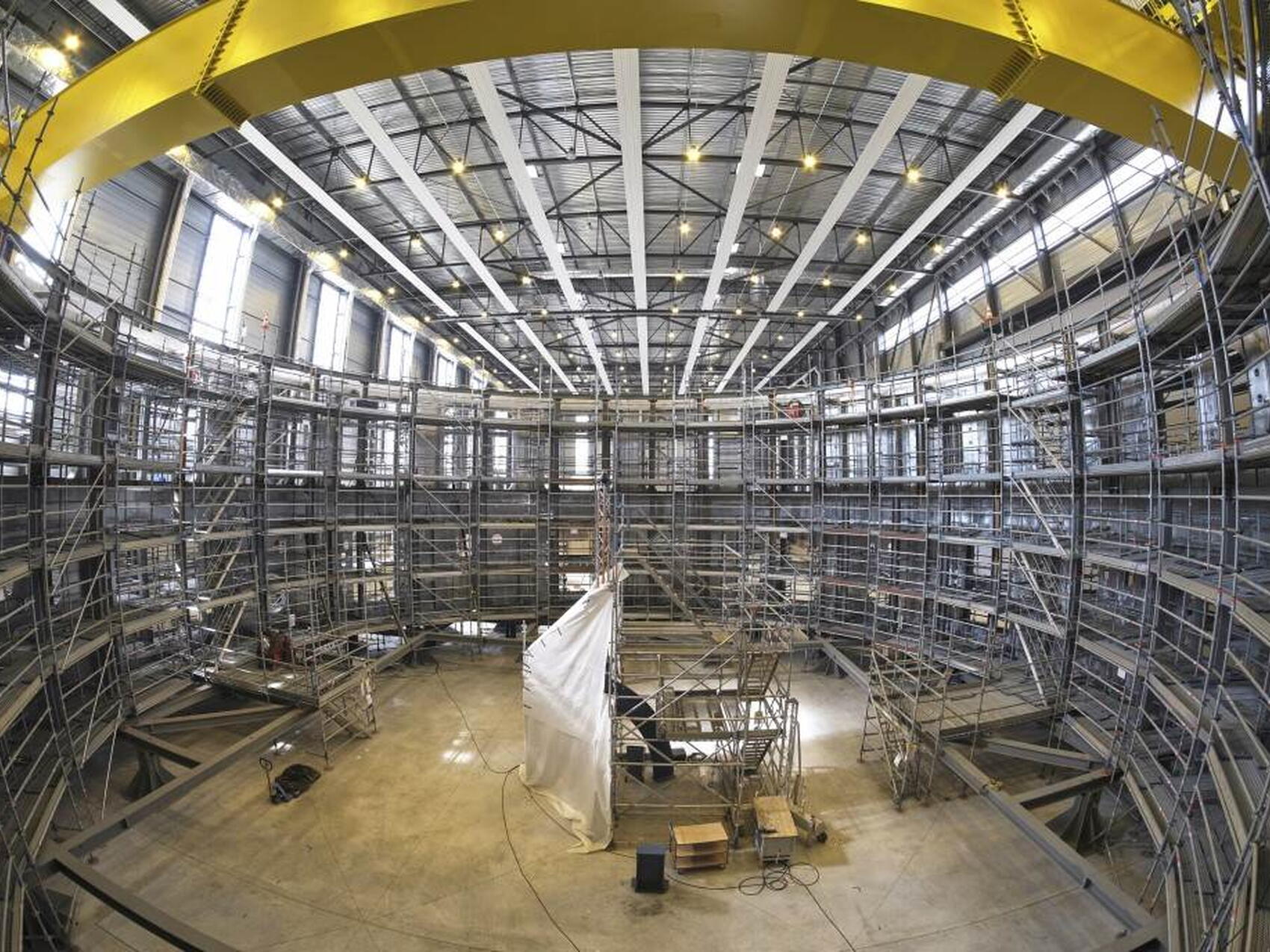

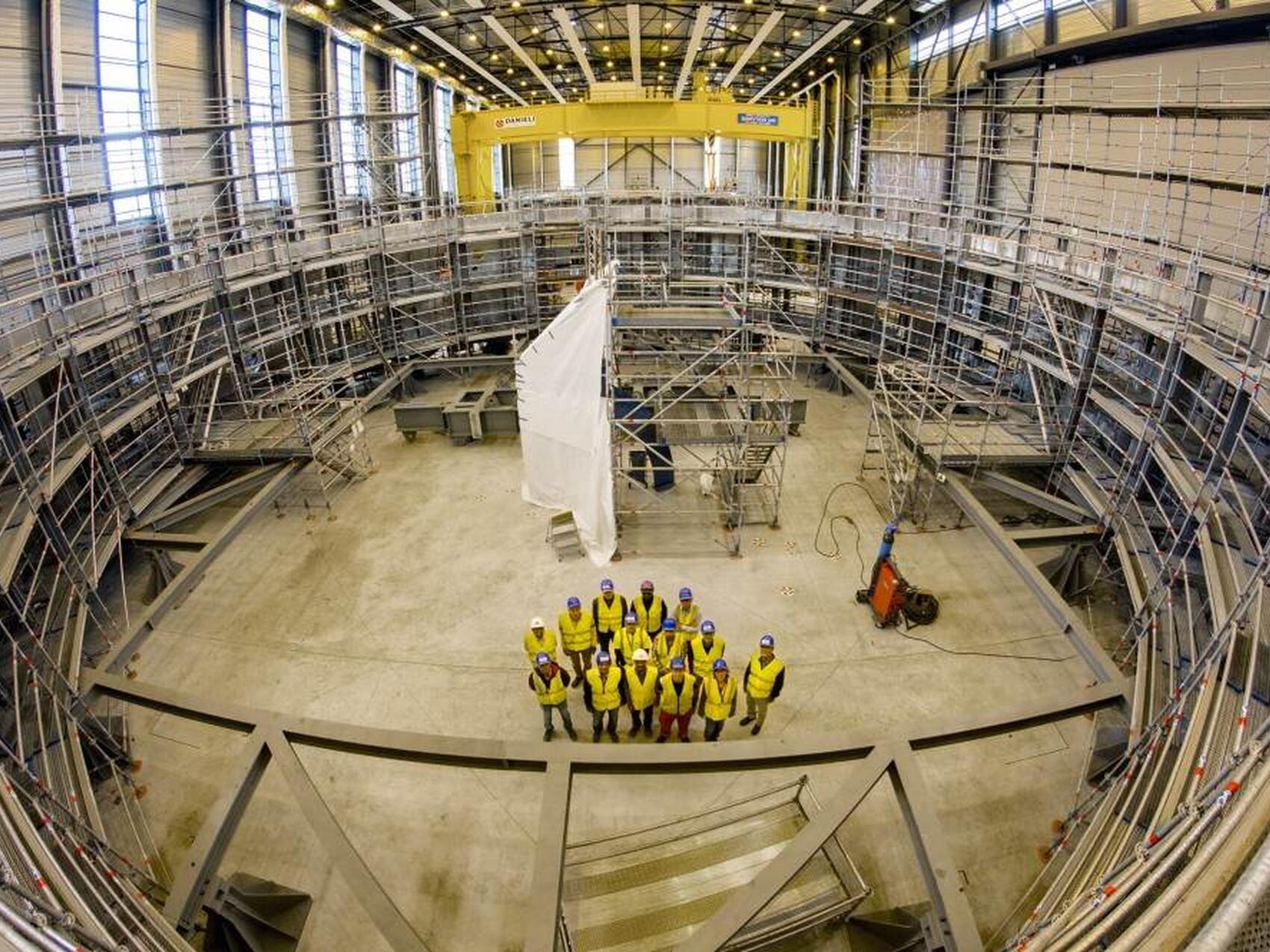

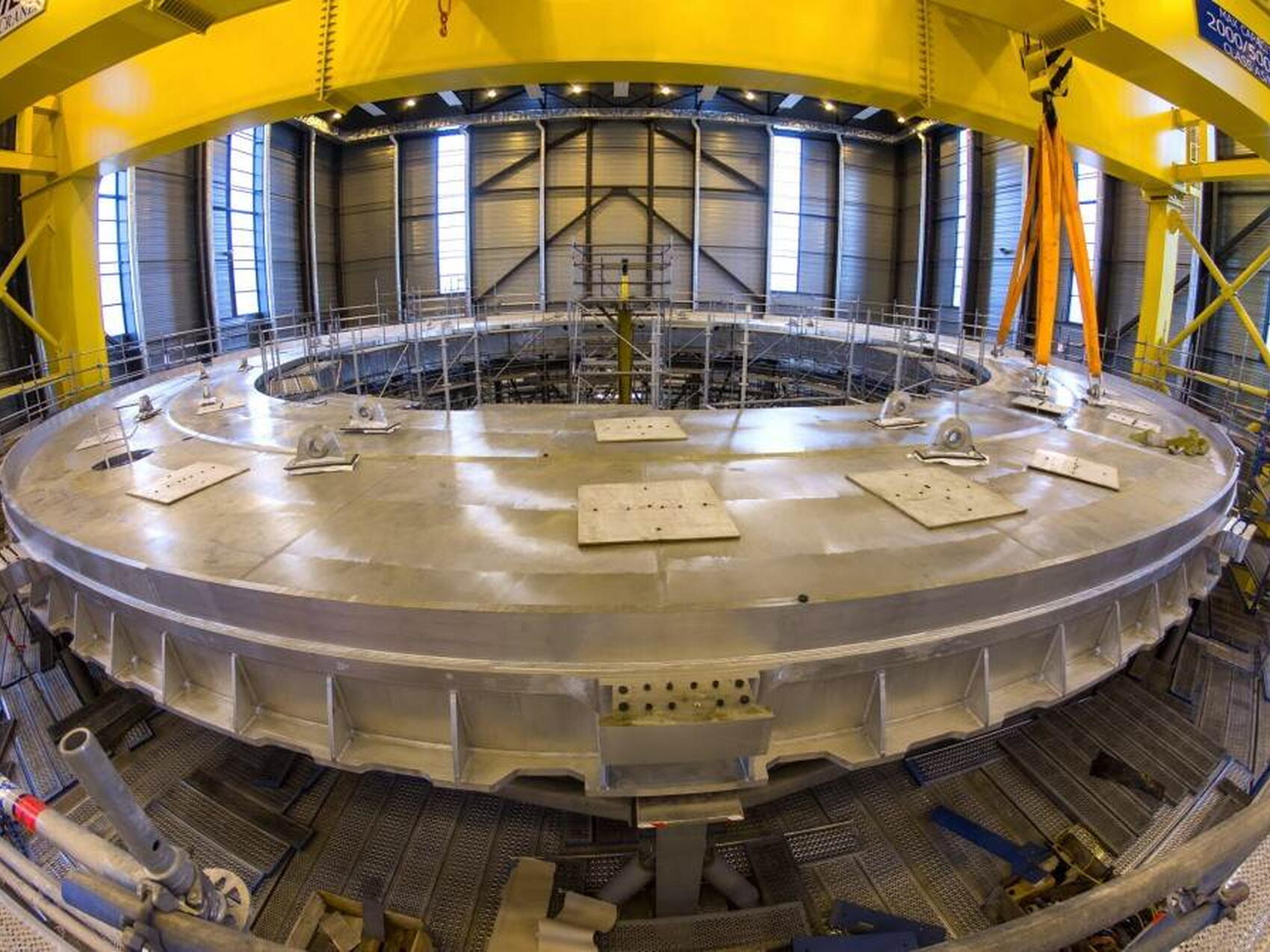

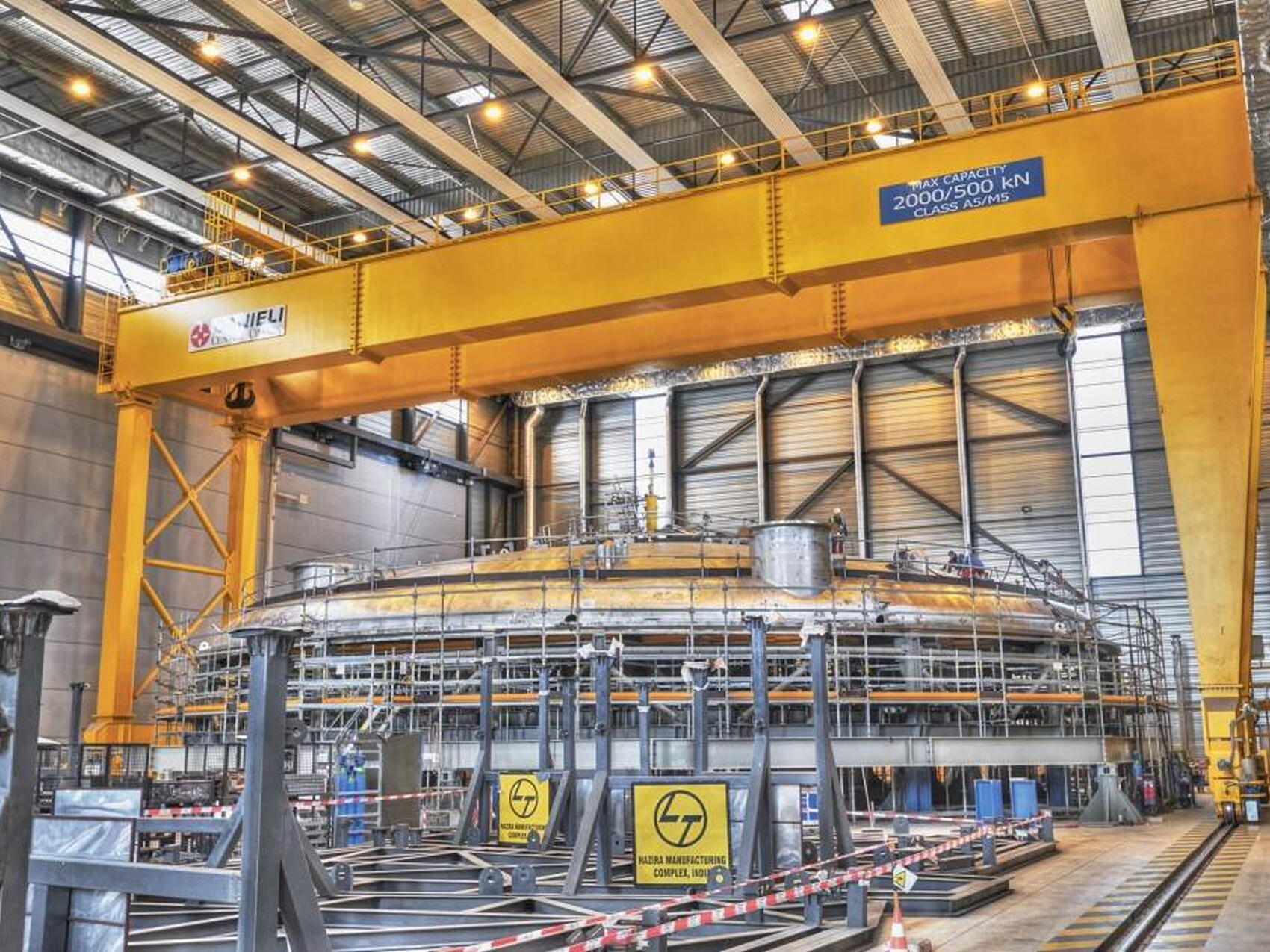

In a 5,000-square-metre workshop on site, the Indian Domestic Agency oversaw the assembly of the sections of the cryostat—a huge vacuum containment vessel that is also the single largest component of the ITER machine.

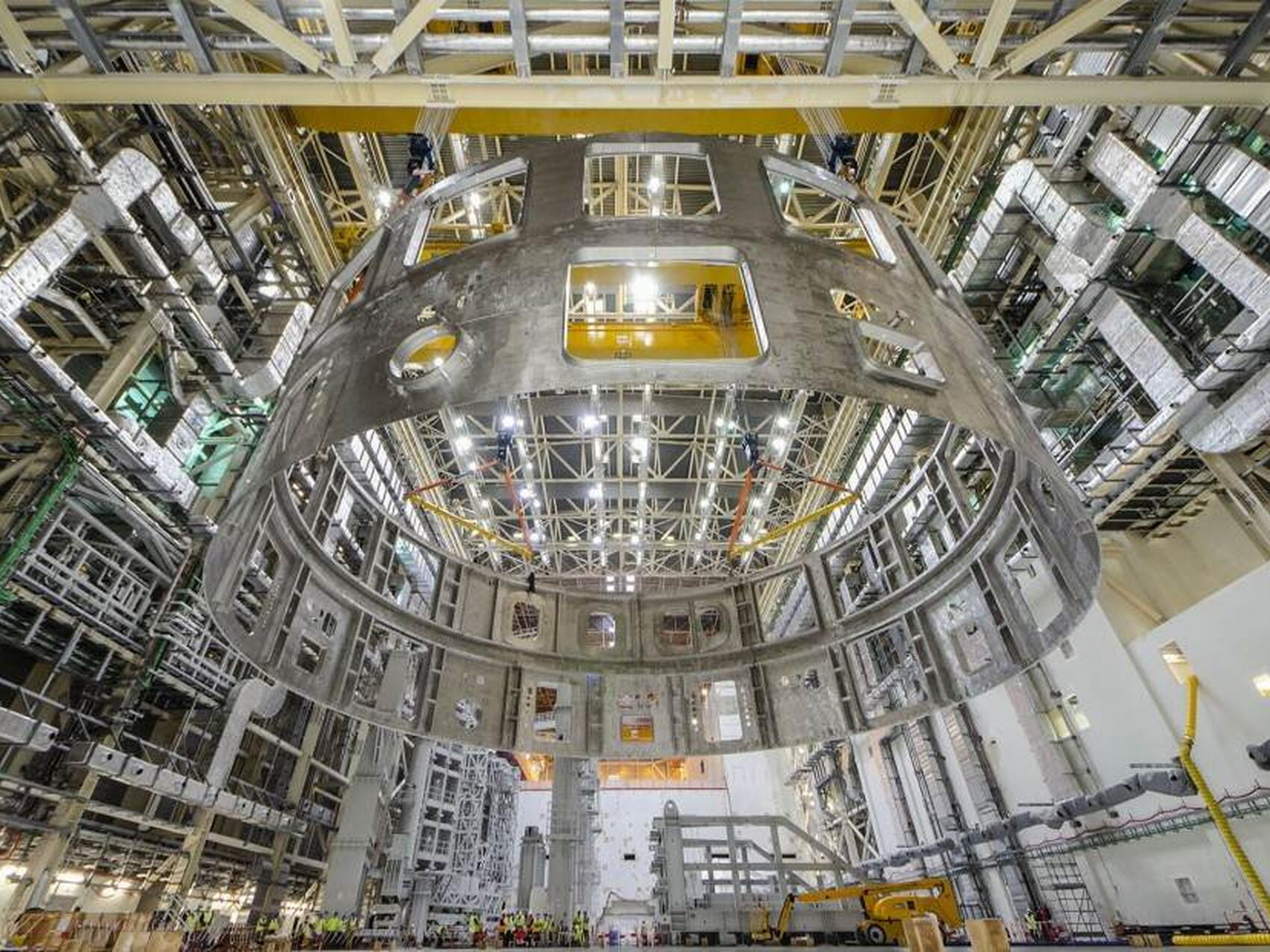

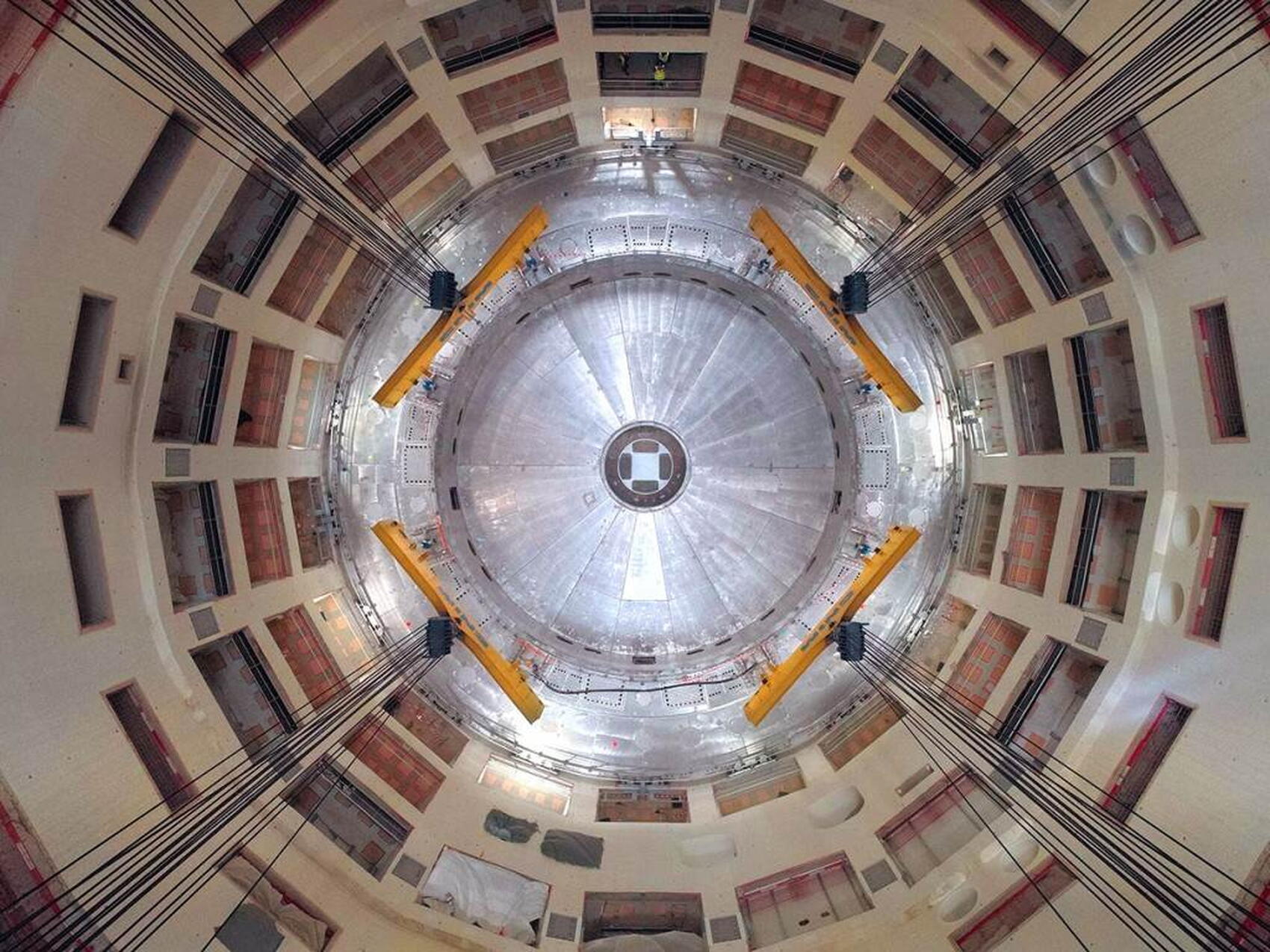

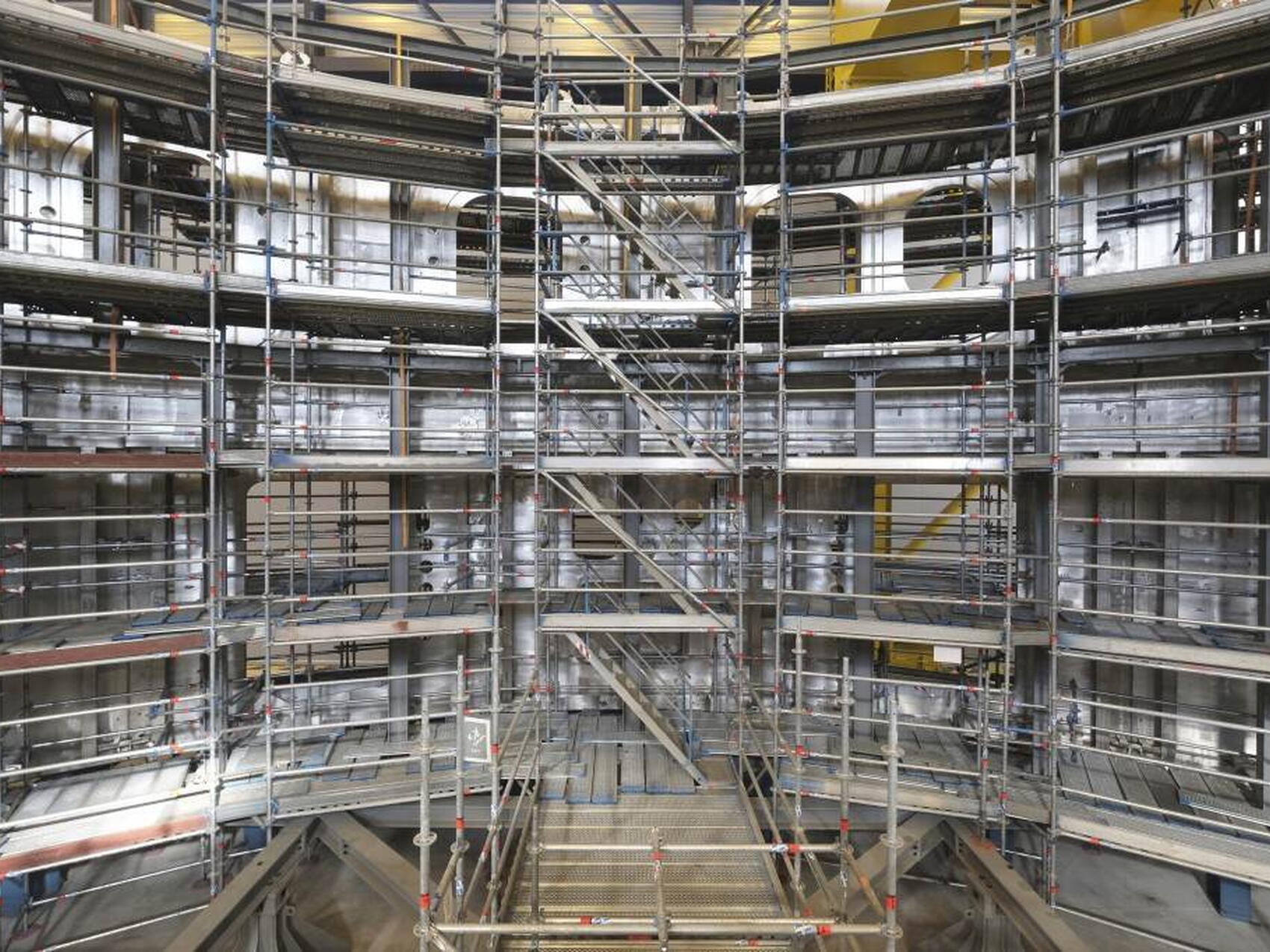

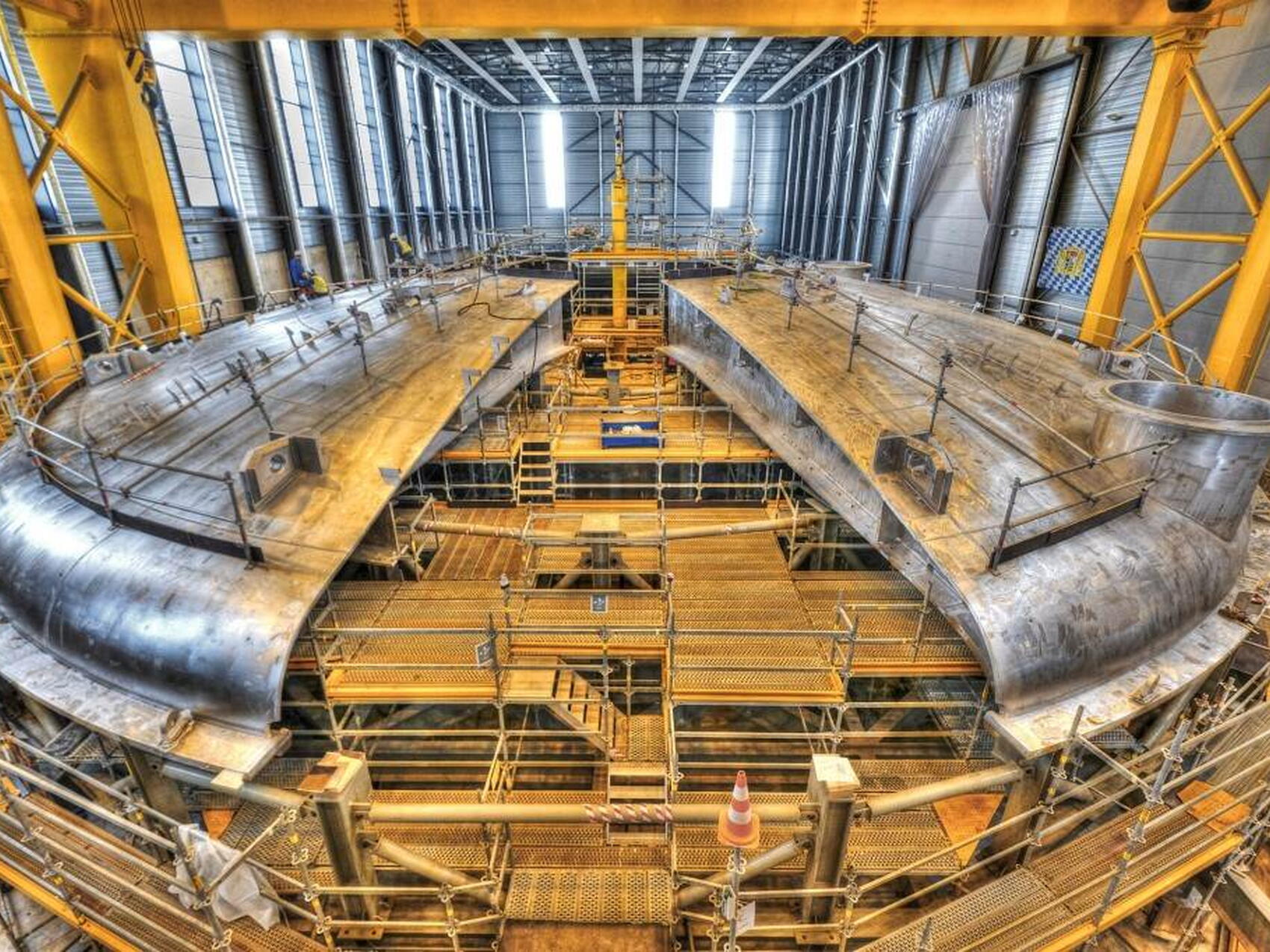

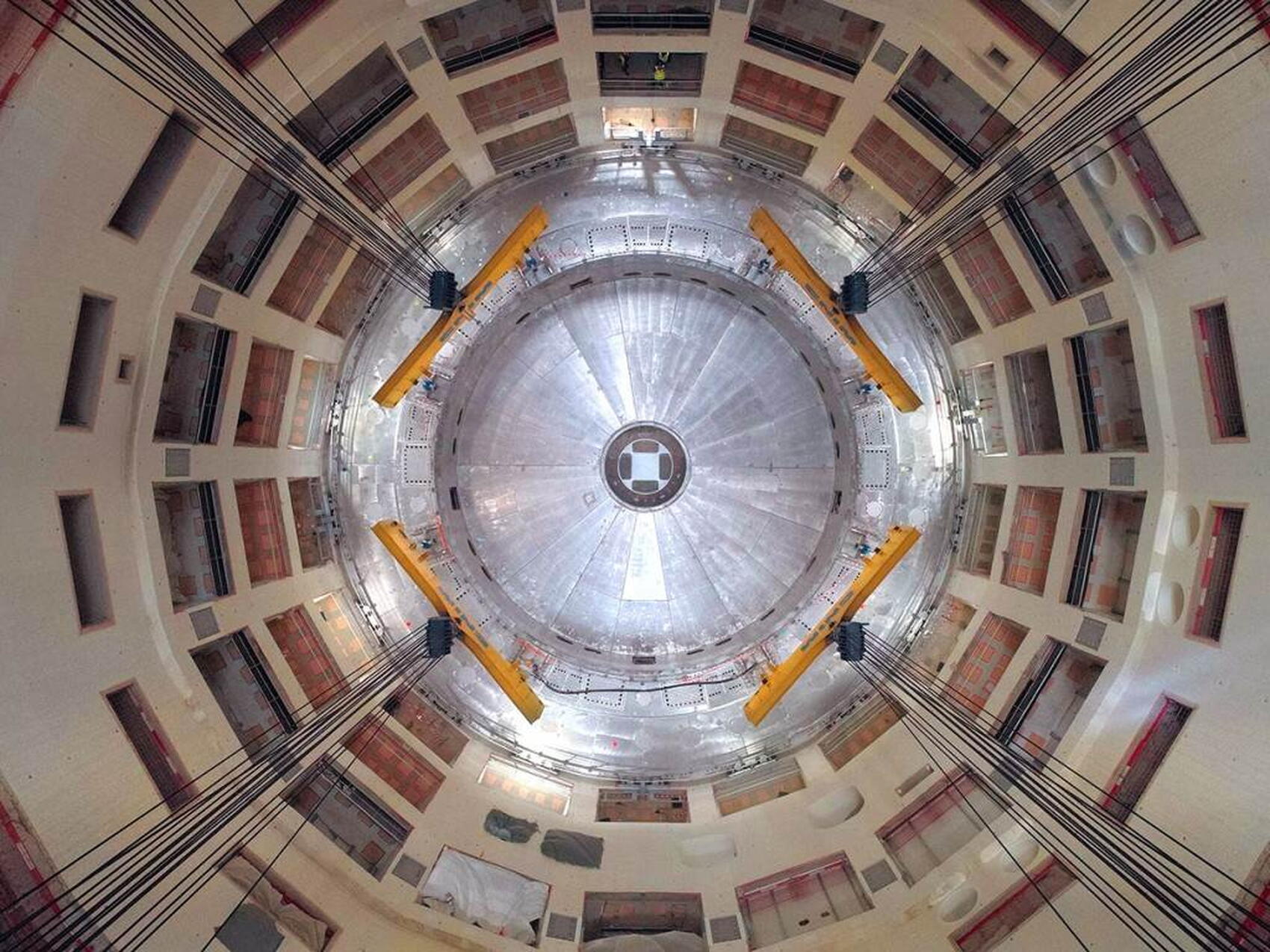

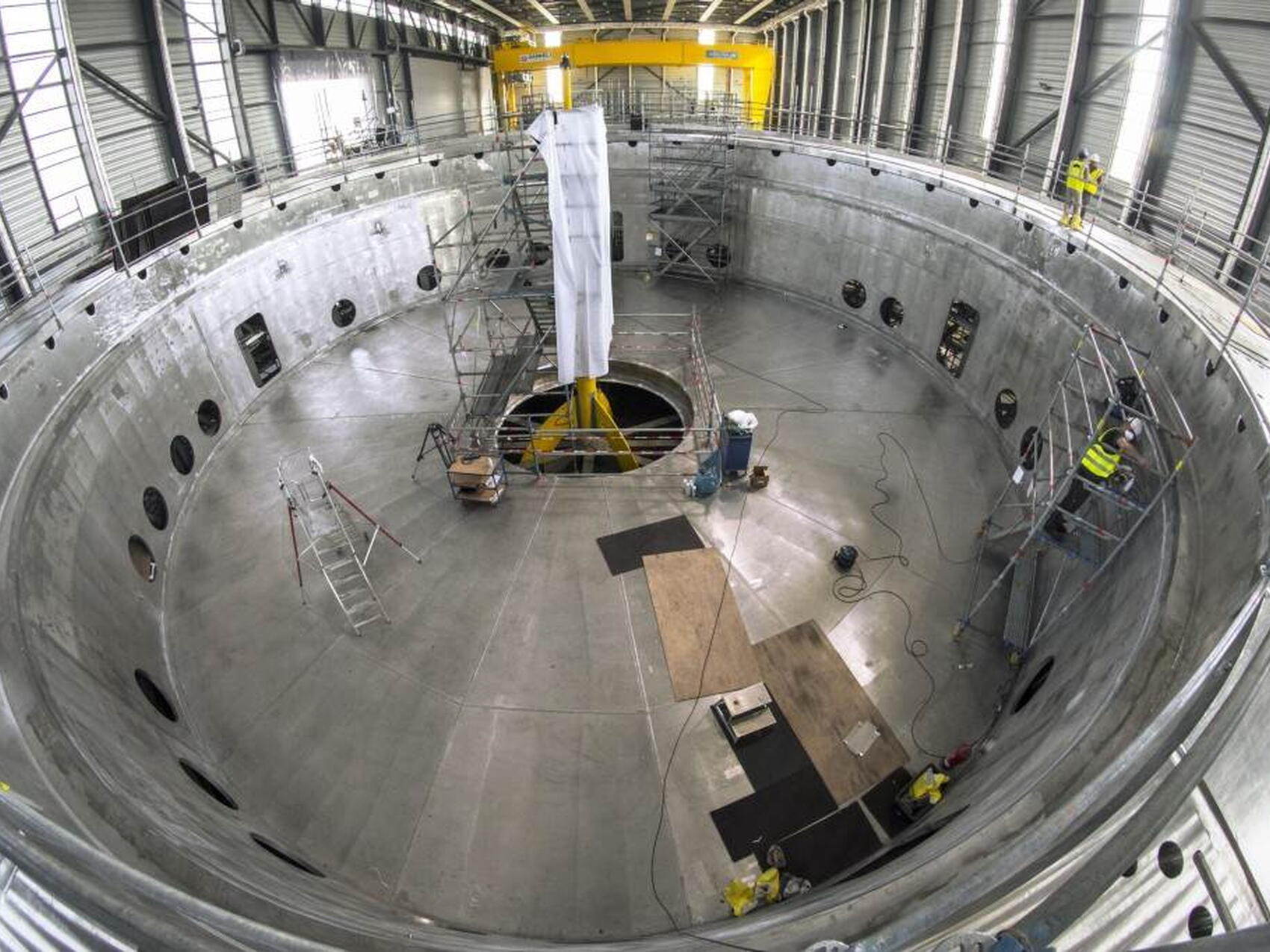

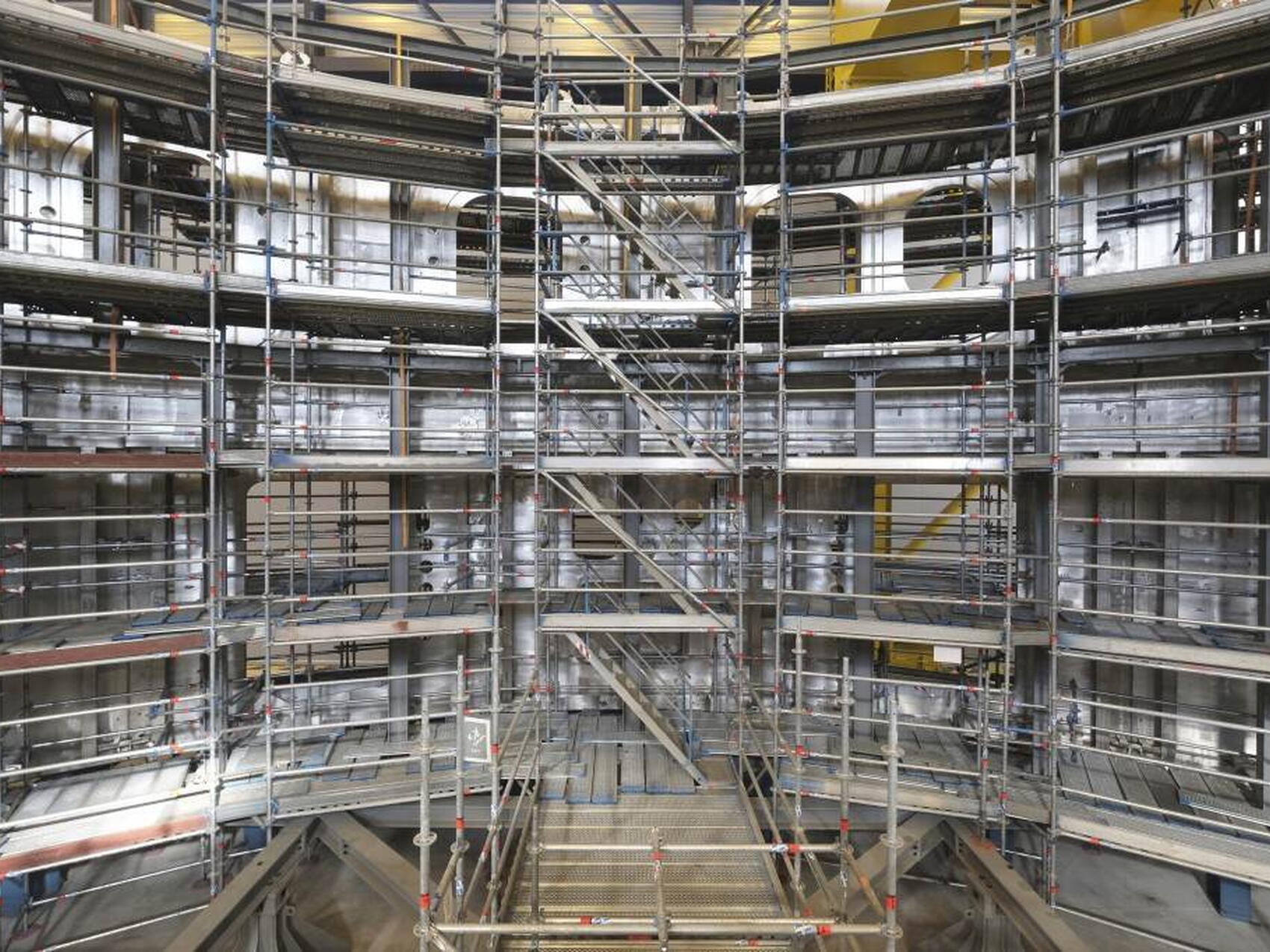

Completely surrounding the vacuum vessel and superconducting magnets, the 29 x 29 metre cryostat has two important roles to play—providing a vacuum environment to critical "cold" components (the magnets operating at 4.5 K and thermal shield operating at 80 K), and contributing structural reinforcement by supporting the mass of the machine and transferring horizontal and rotational forces to the radial walls.

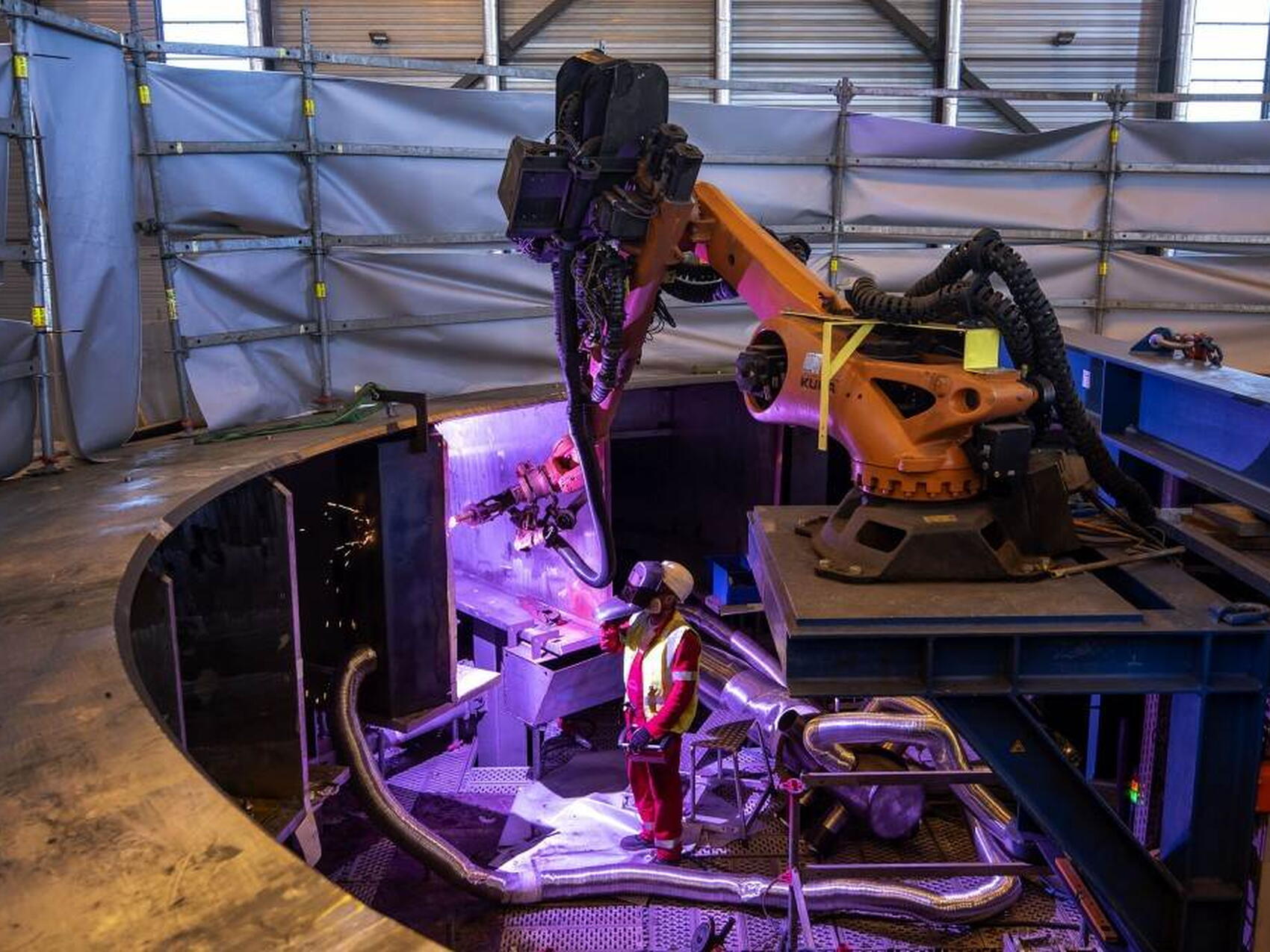

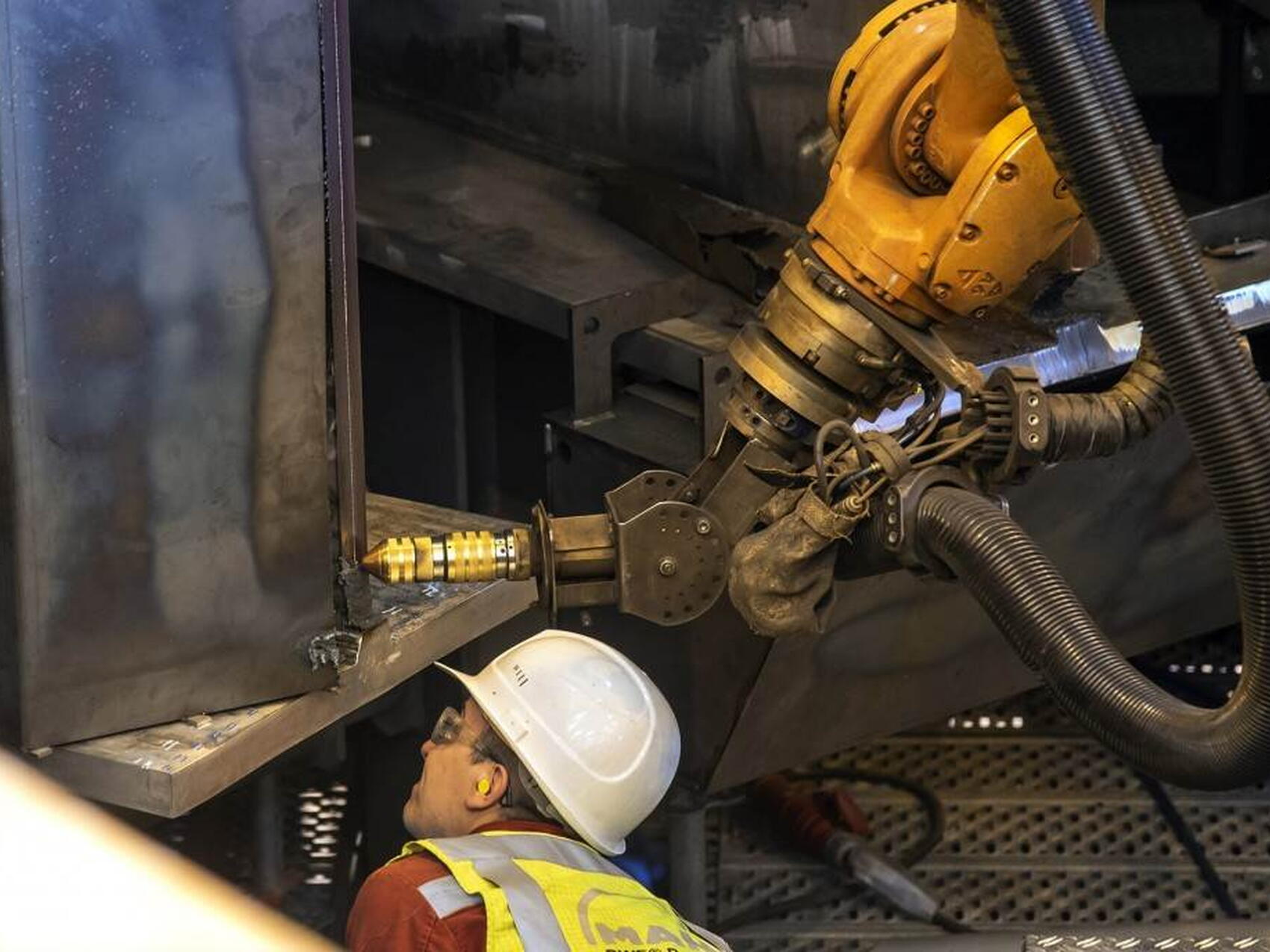

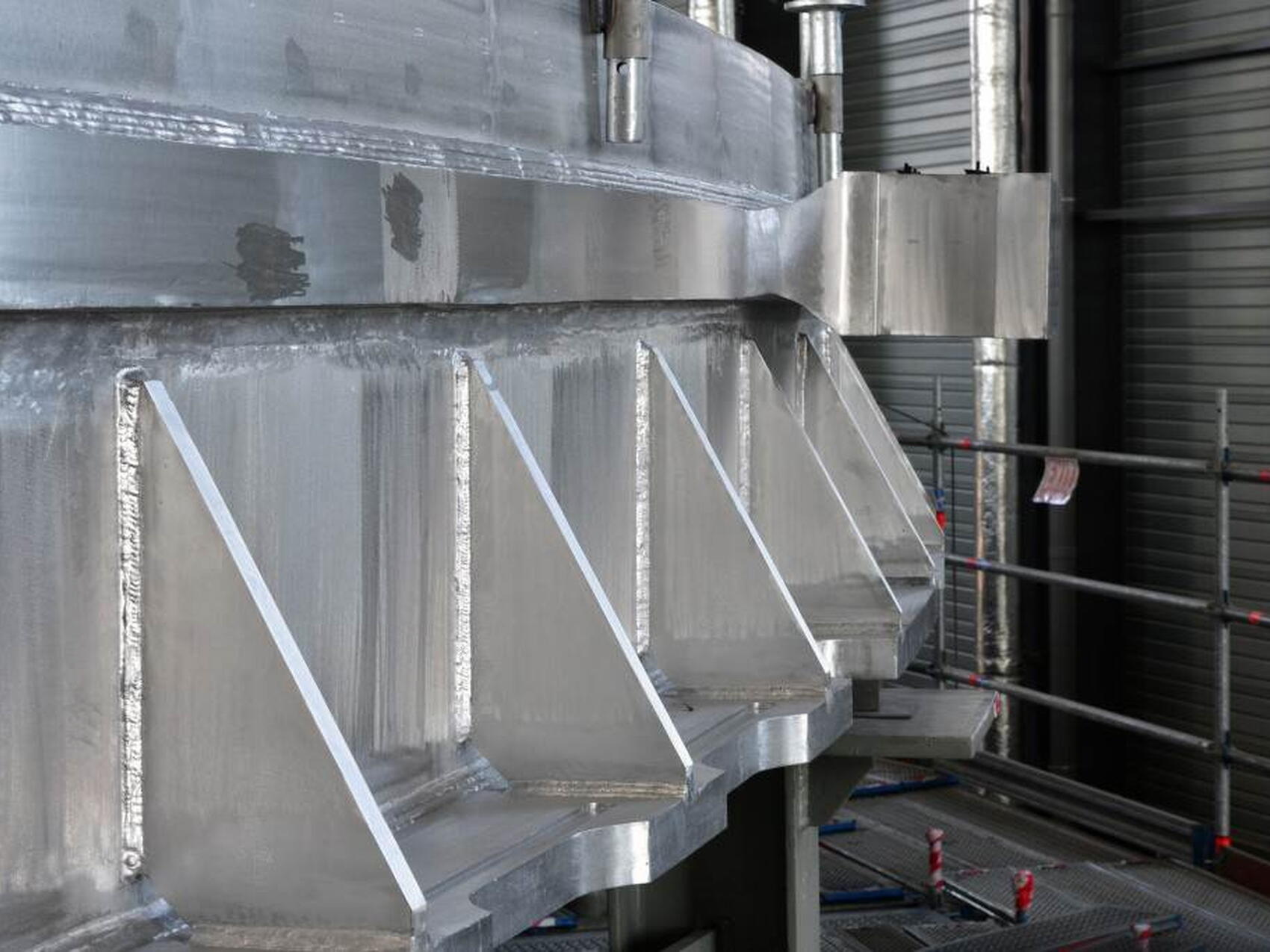

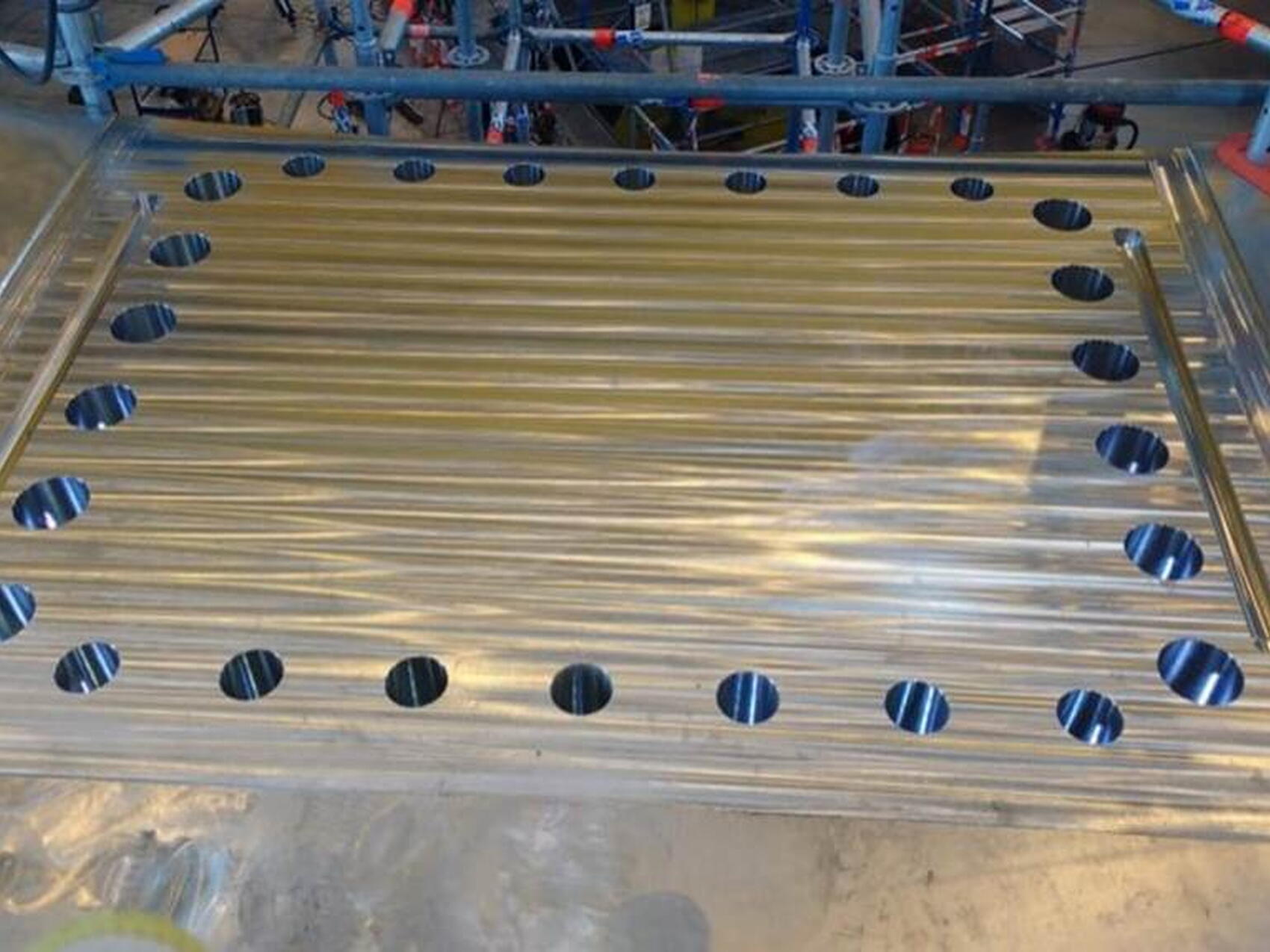

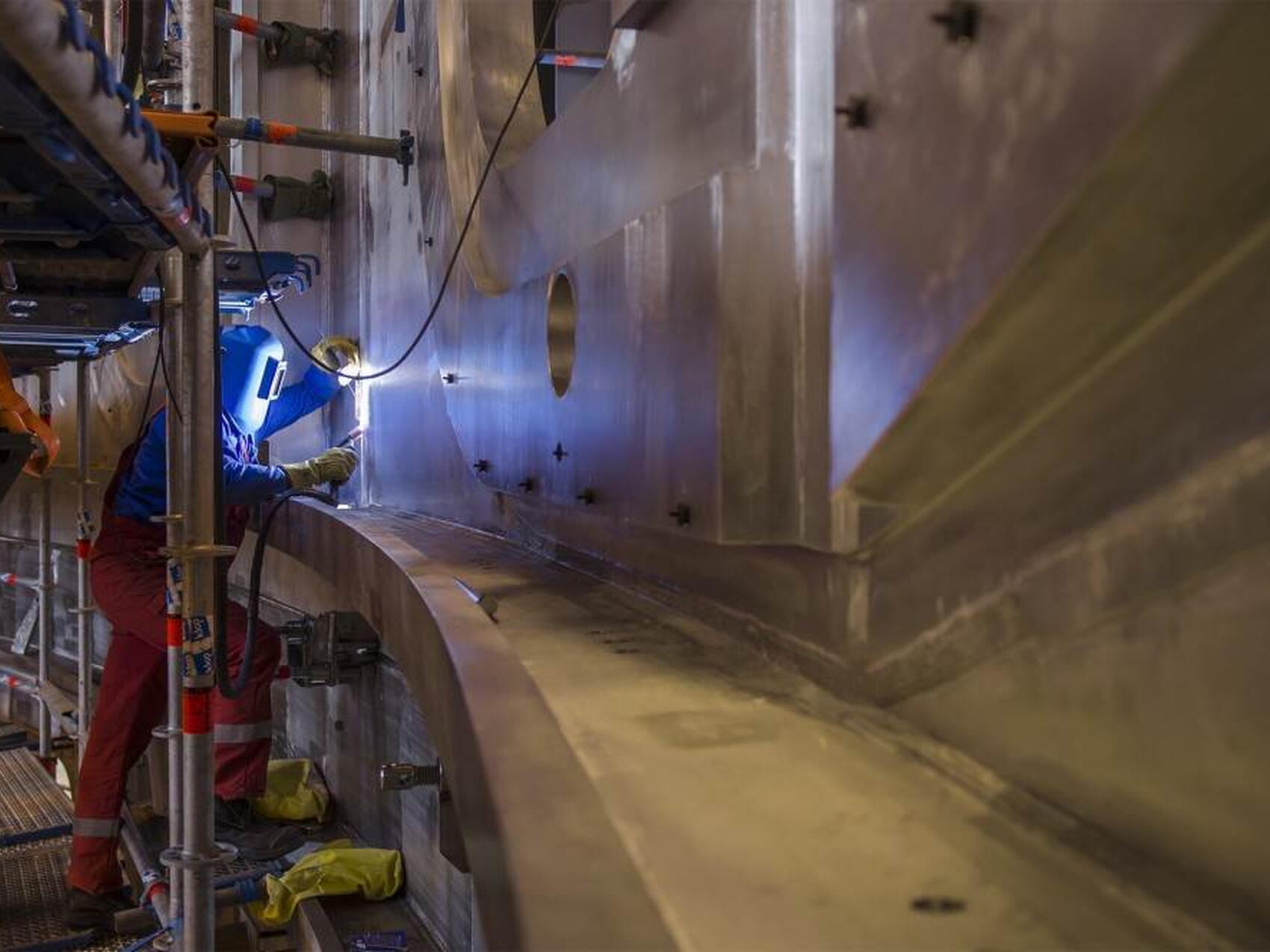

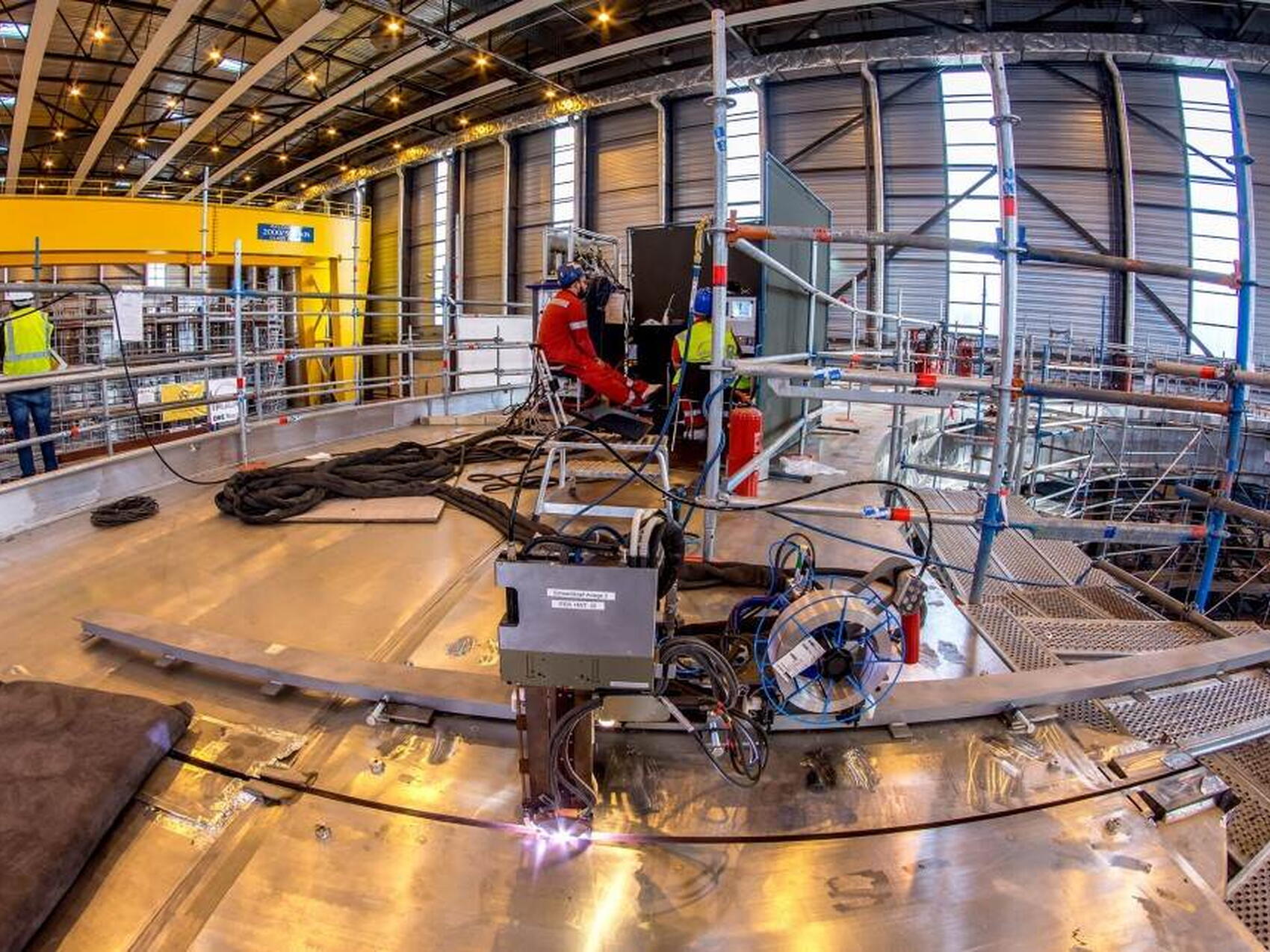

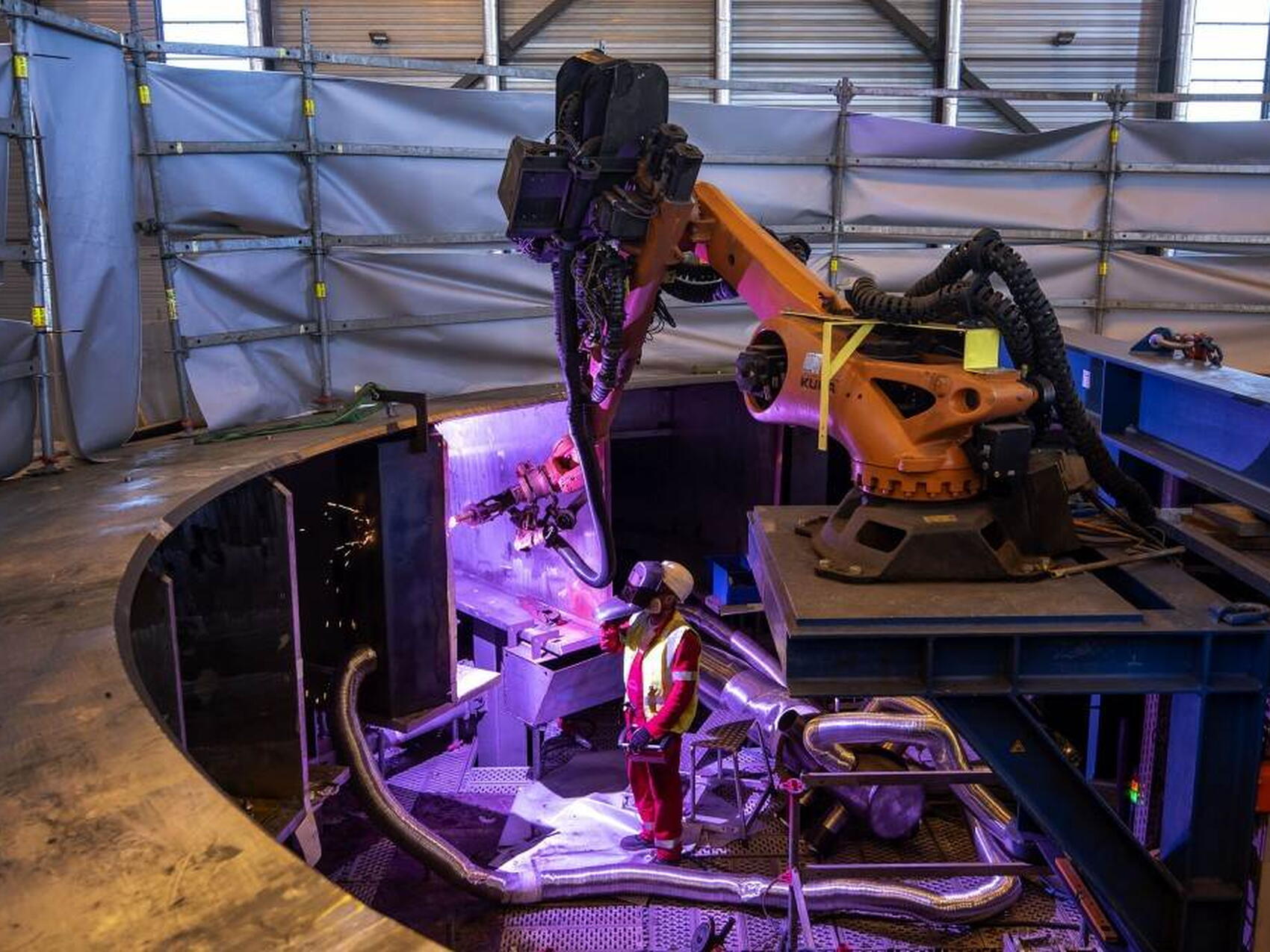

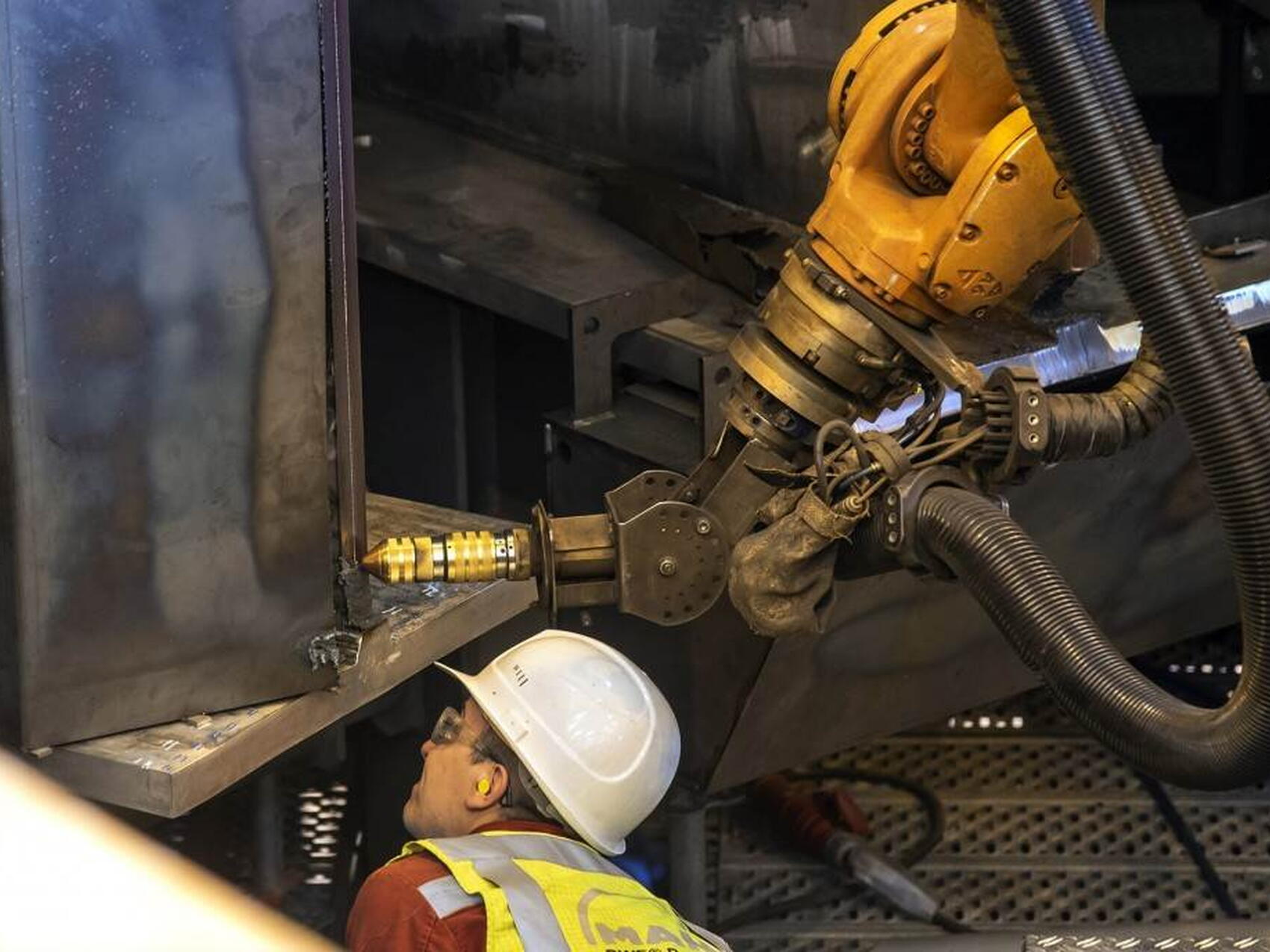

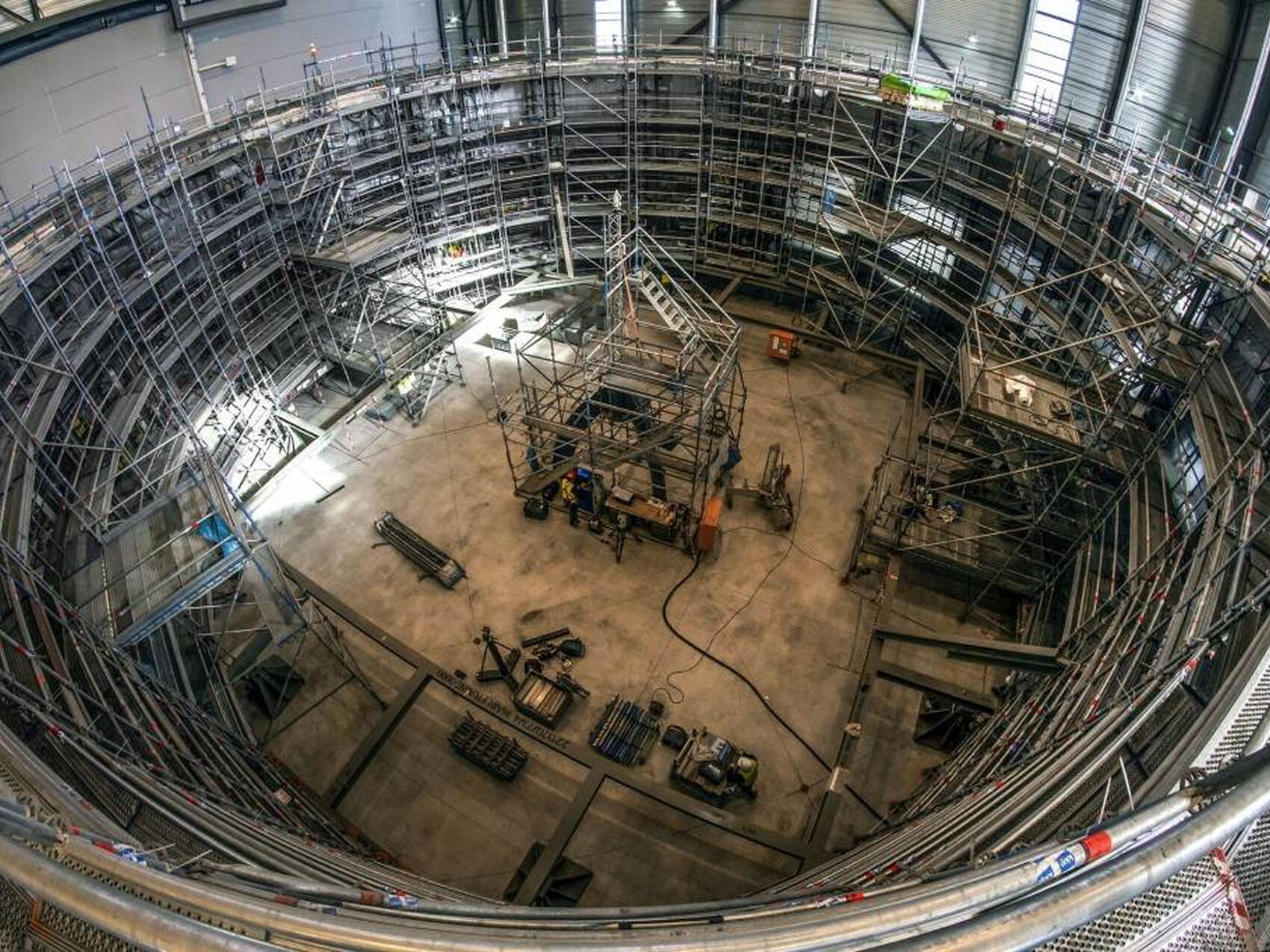

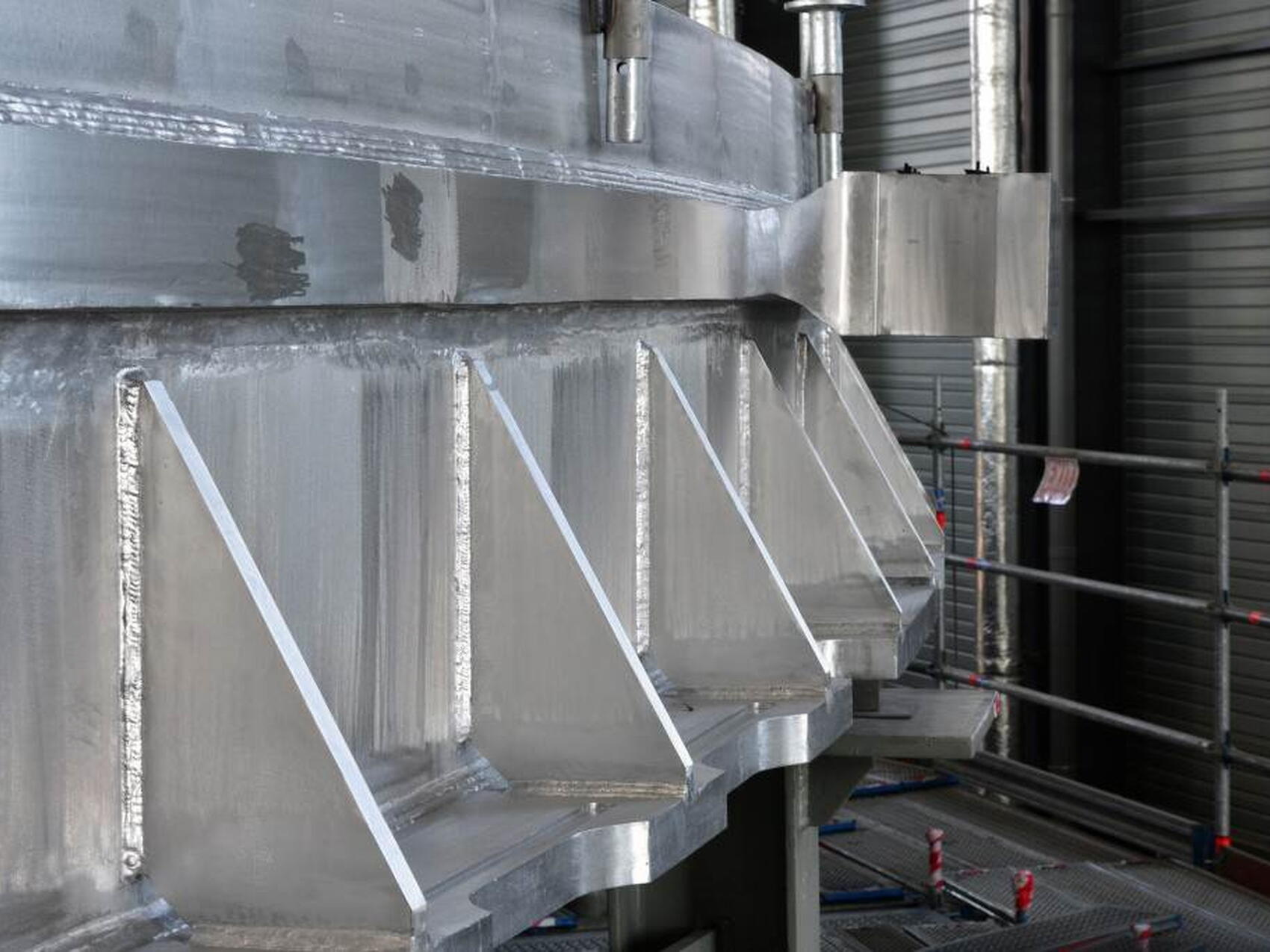

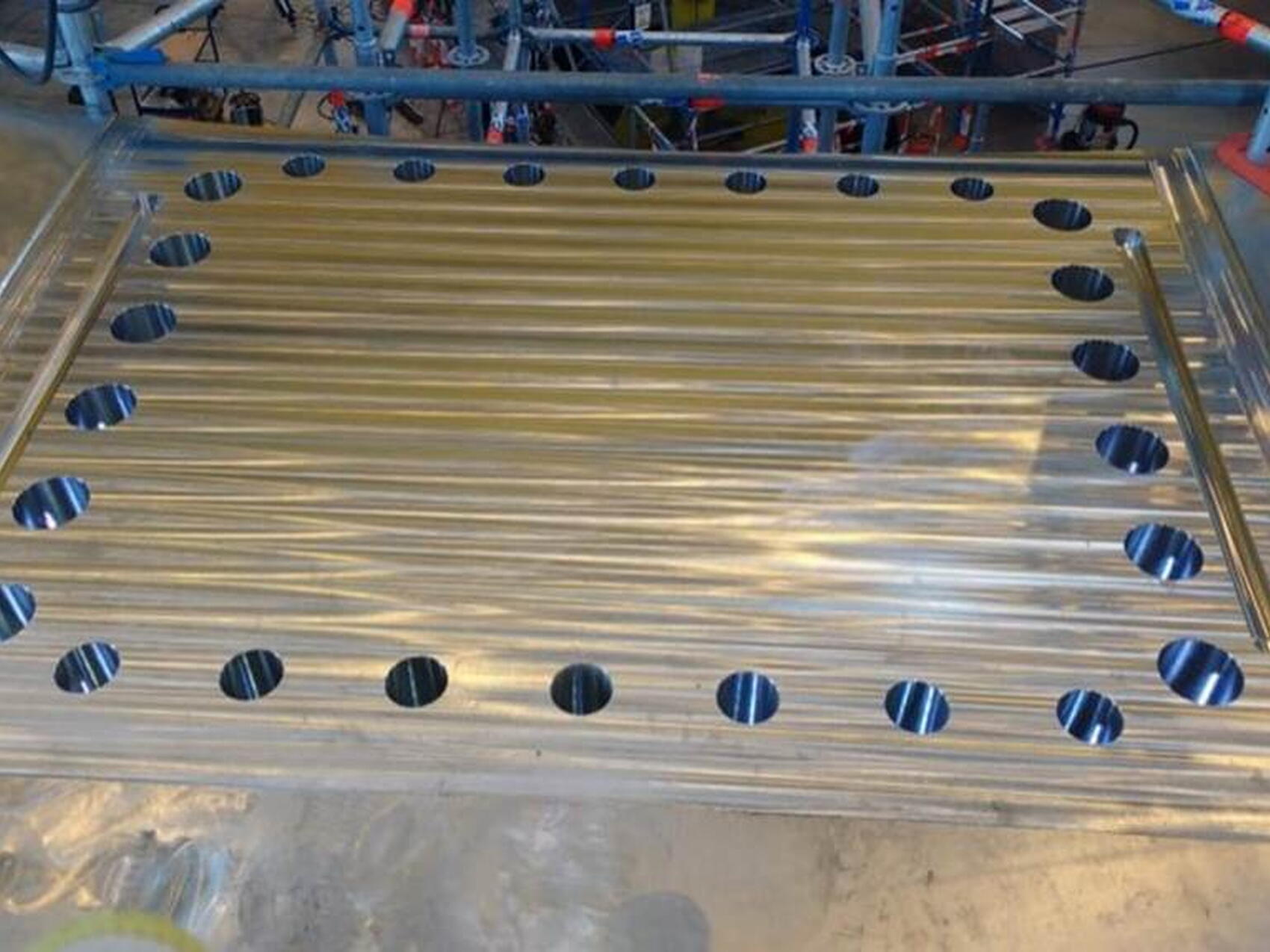

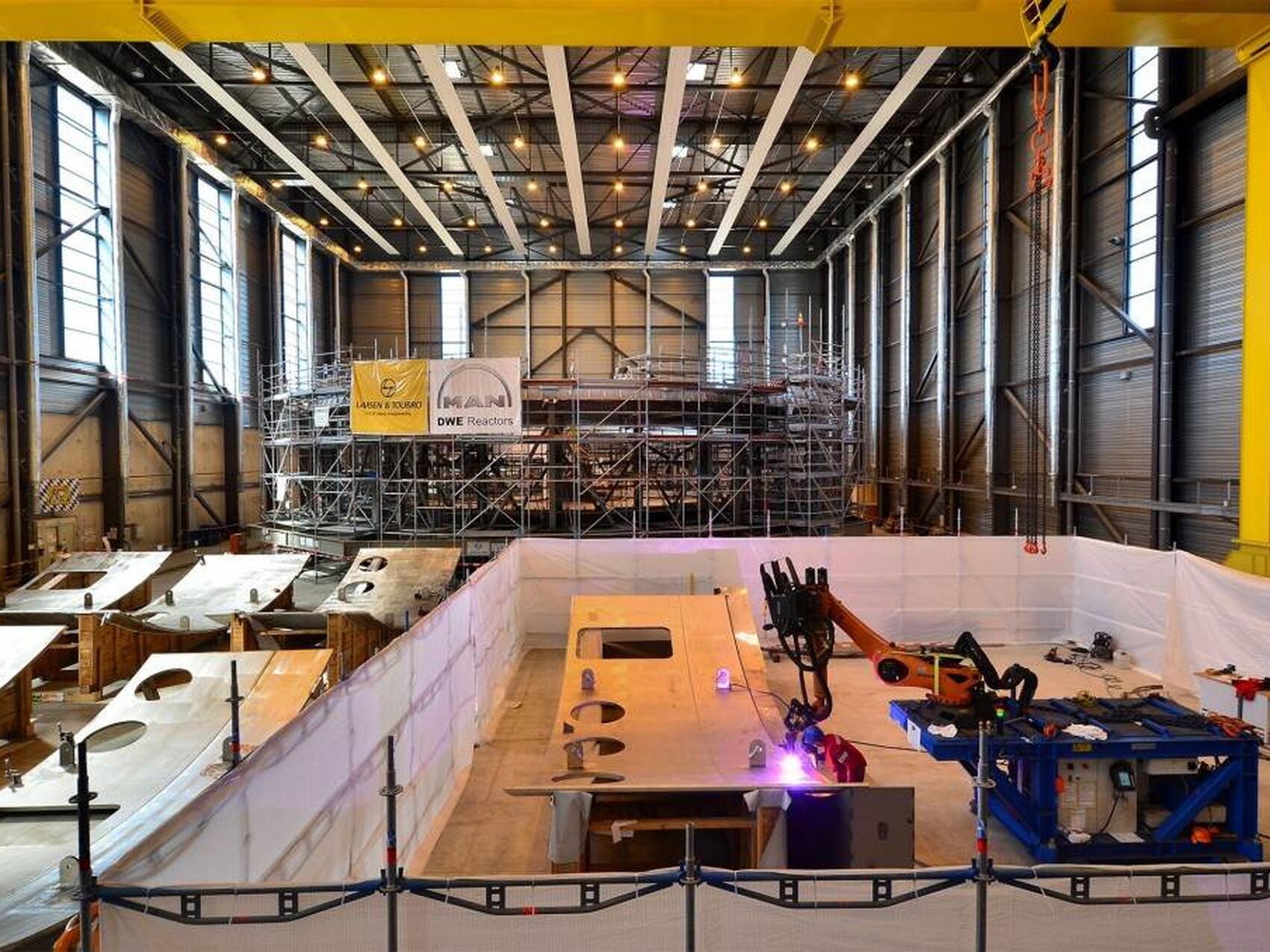

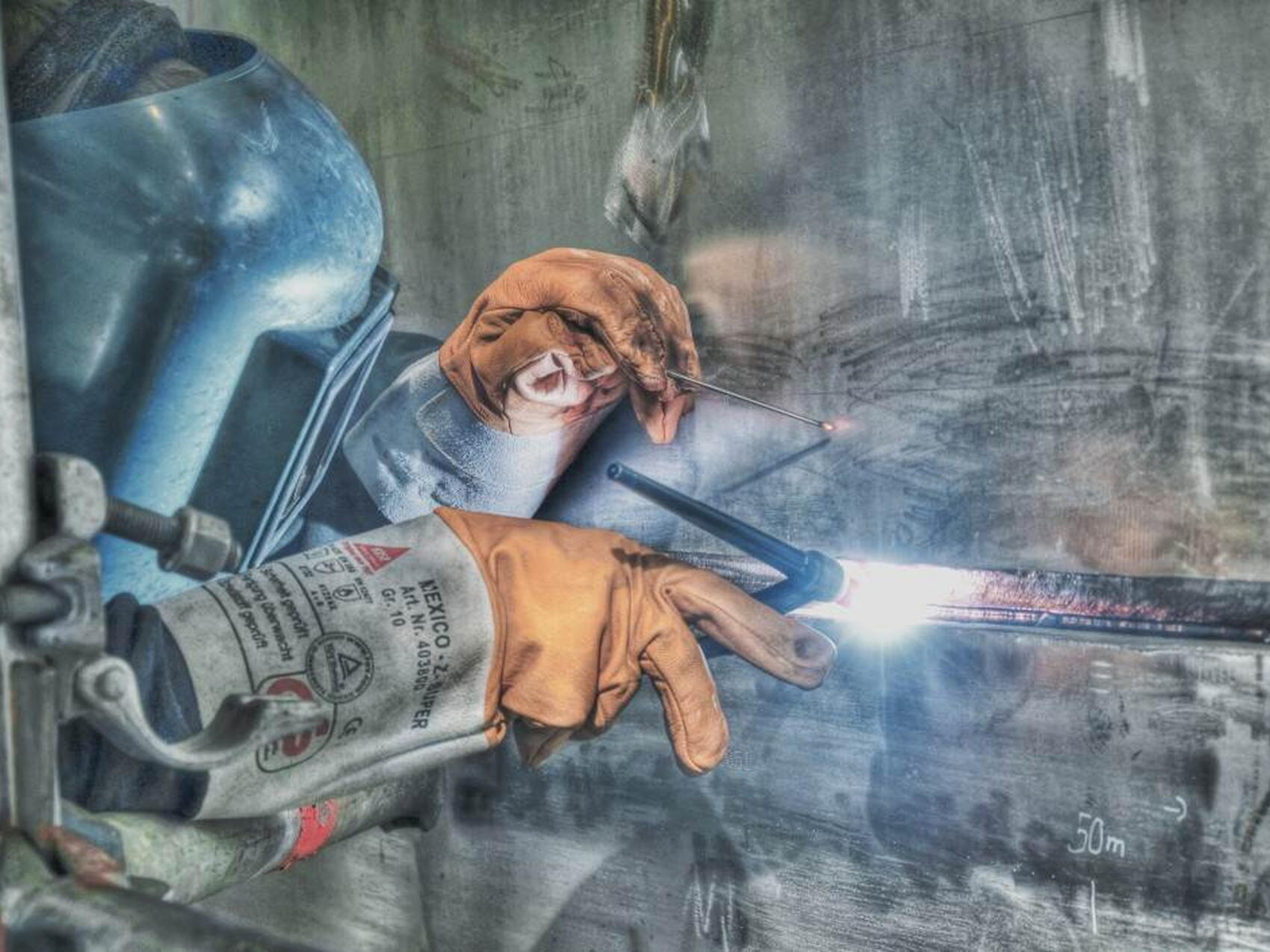

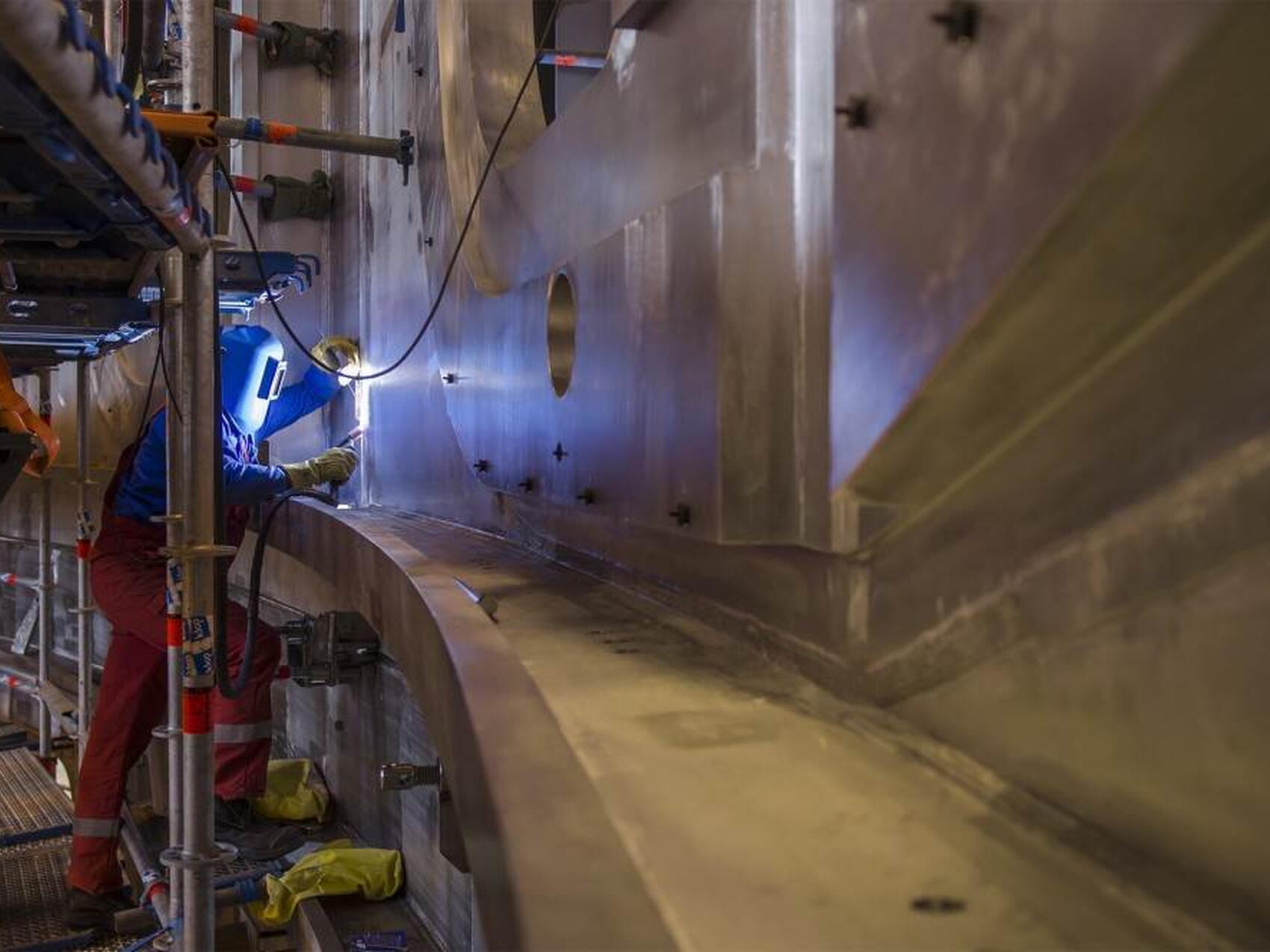

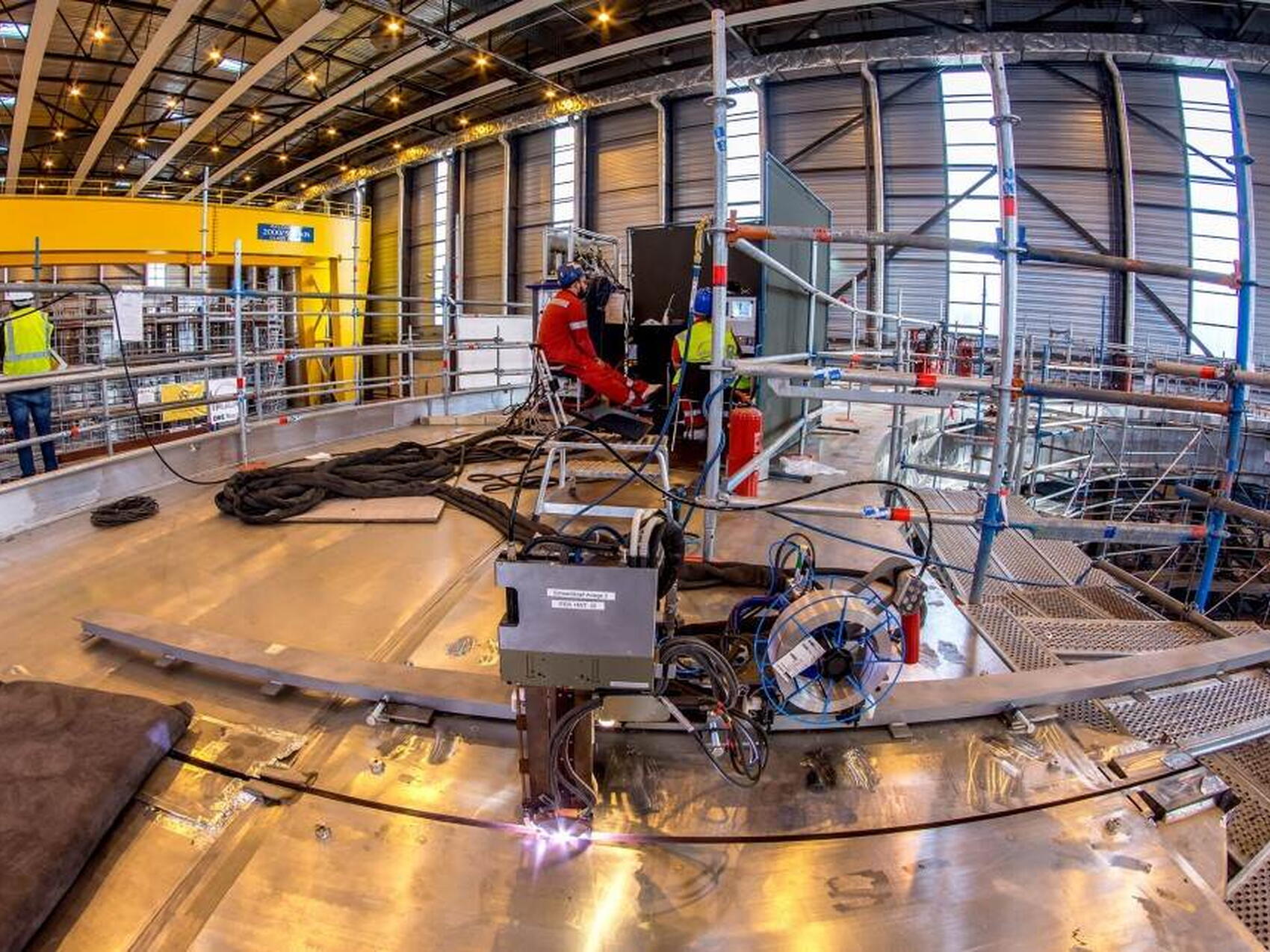

The cryostat is a fully welded single wall stainless steel structure with a flat bottom, a rounded lid and wall thicknesses that range from 25 to 200 millimetres. A number of large openings provide access to vacuum vessel ports at three levels; others allow access for coolant pipework, cryo and current feedlines, and remote handling. Advanced welding techniques such as automated, all-position narrow groove gas tungsten arc welding were specially developed for the fabrication of this challenging component.

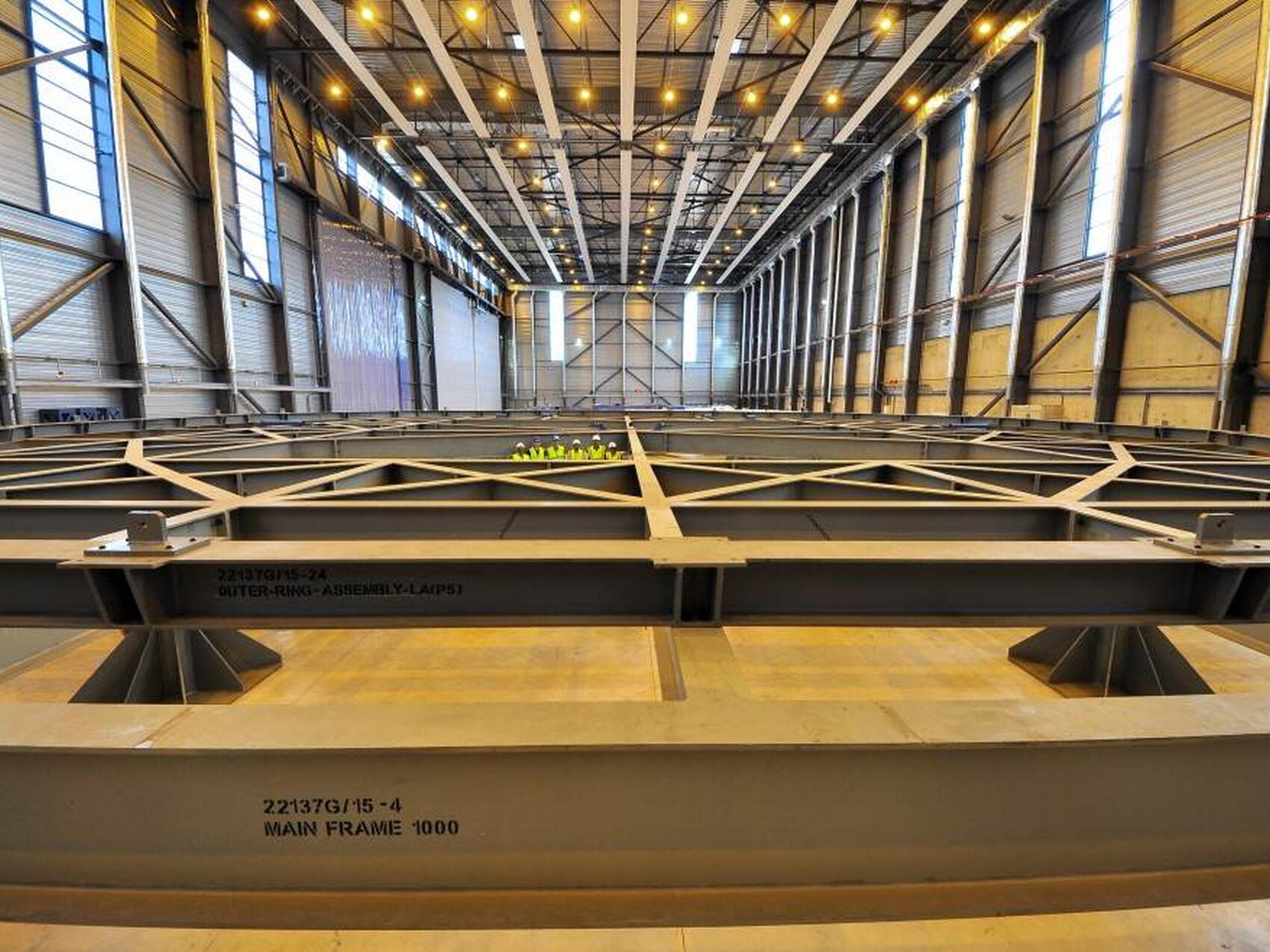

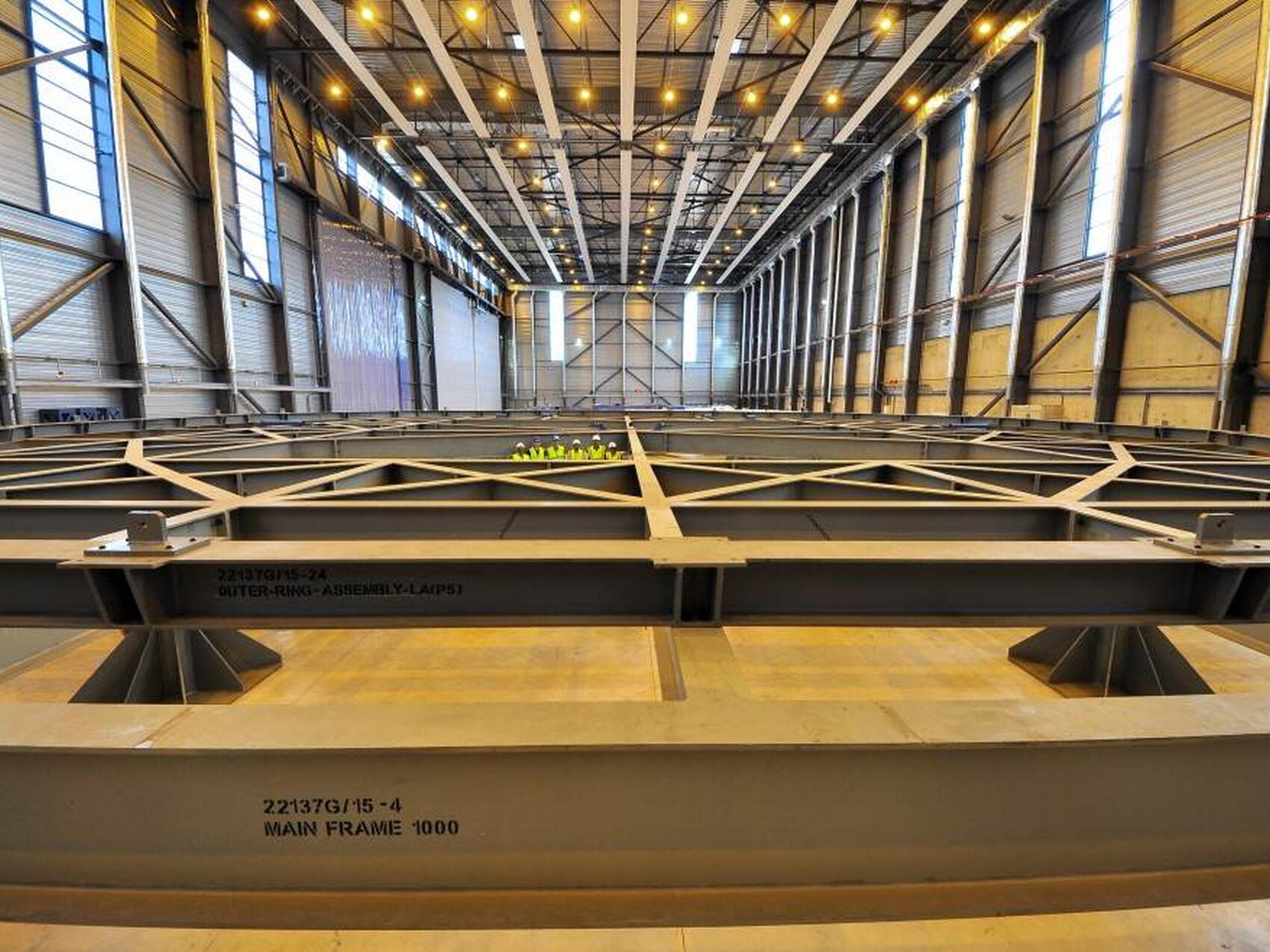

Manufacturing took place in two stages: the fabrication of 54 segments in India, and their subsequent assembly at ITER into four large sections (base, lower cylinder, upper cylinder, top lid). The four sections will finally be installed and welded in the Tokamak Pit.

Assembly at ITER

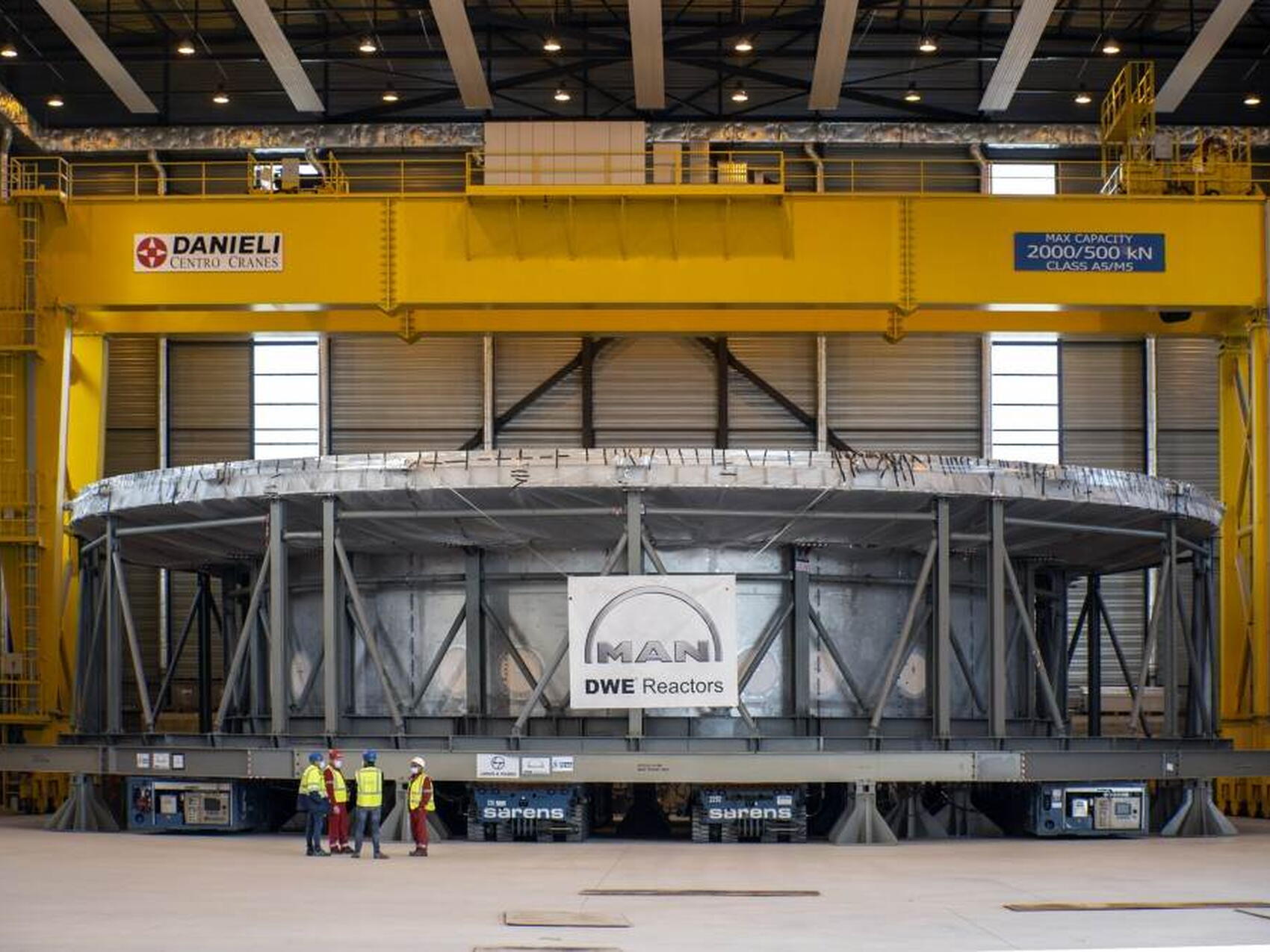

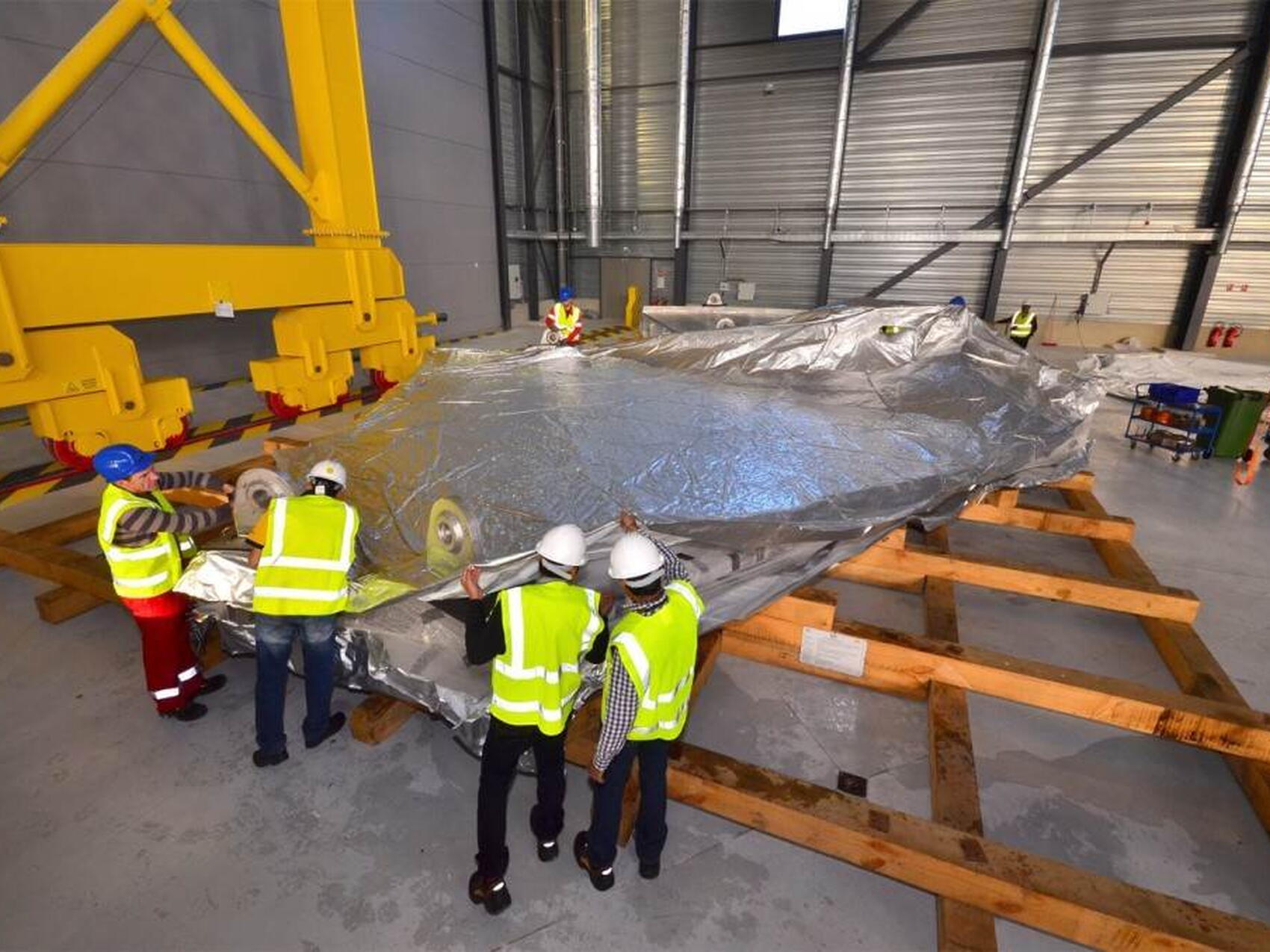

Cryostat segments fabricated in India were progressively shipped between 2015 and 2021 to the Cryostat Workshop on site.

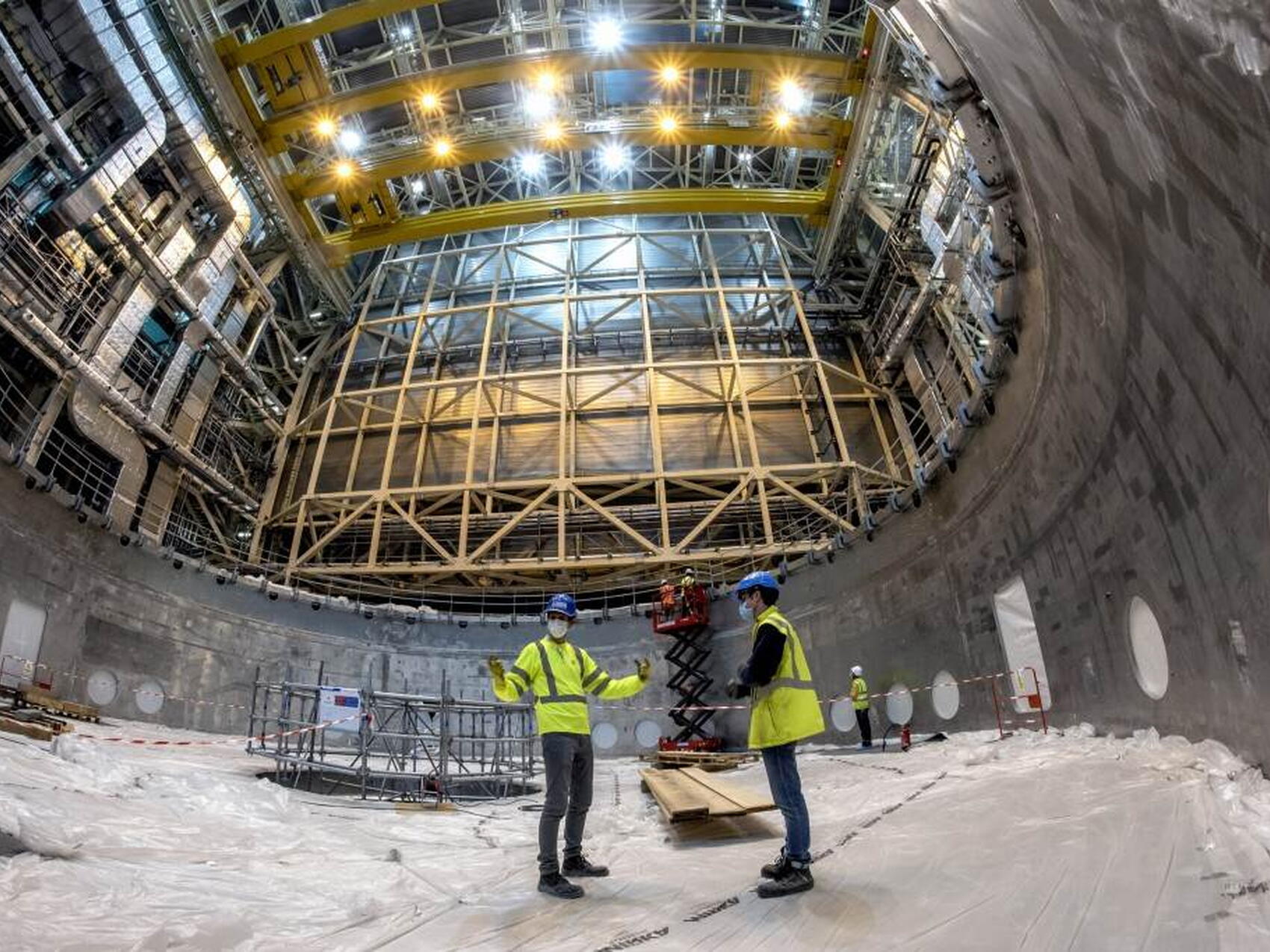

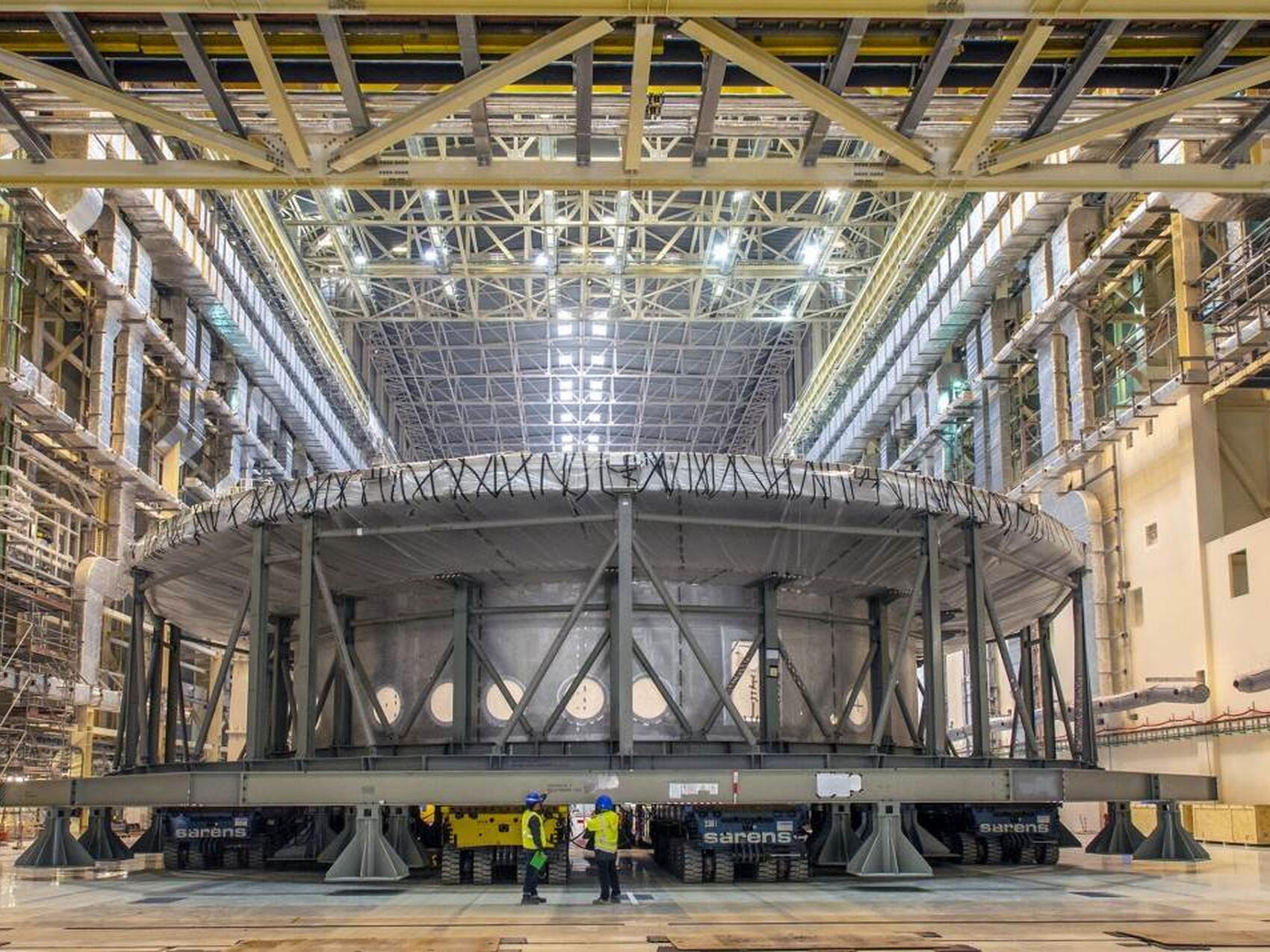

Beginning with the cryostat base—the first cryostat section needed in the Tokamak assembly sequence—and ending with the cryostat lid, the sections were assembled and welded on large assembly frames. These frames acted both as support platforms during the welding activities and as support fixtures that interface with the transport vehicles when the time came to move the completed components out of the workshop.

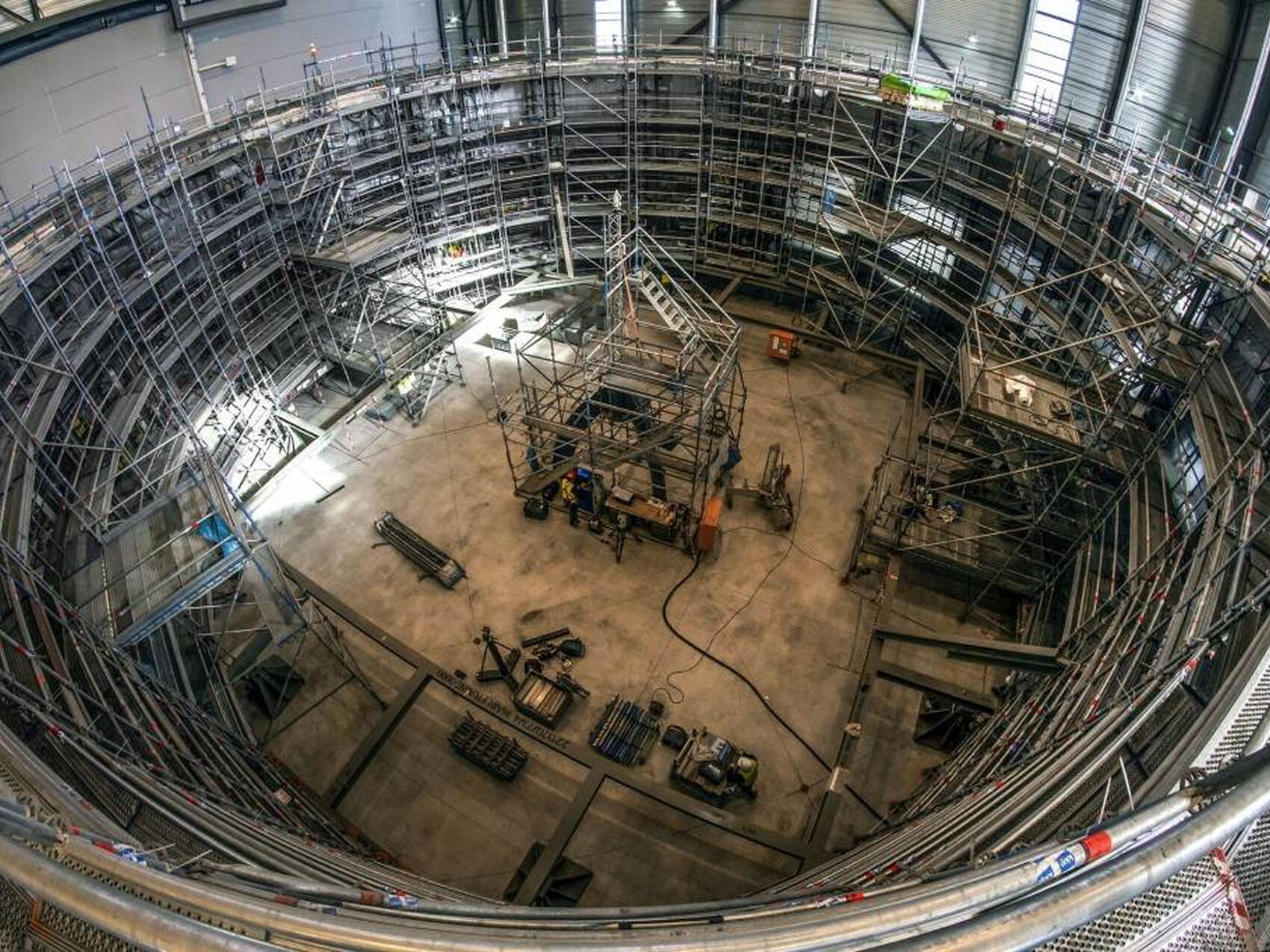

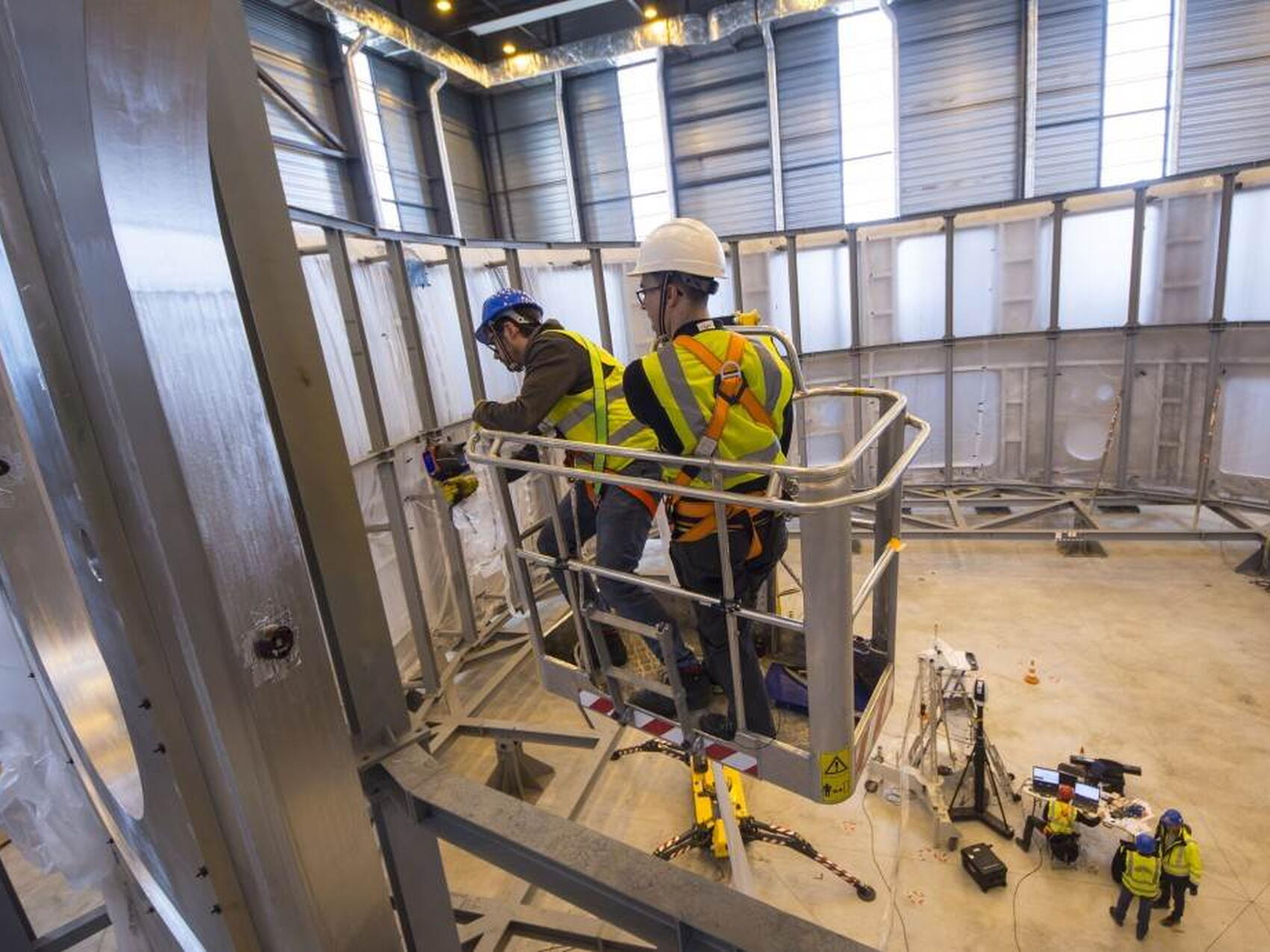

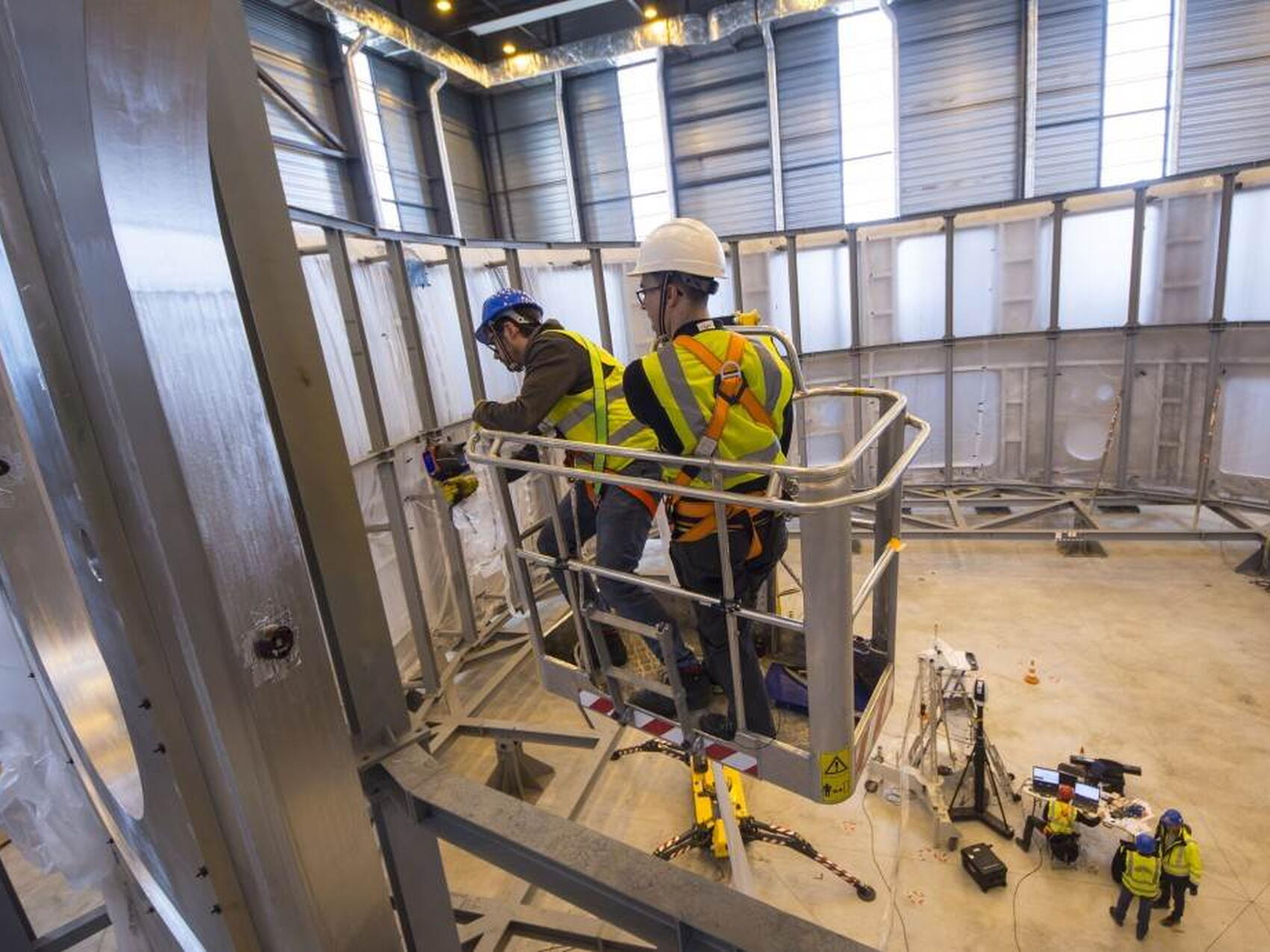

Using optical metrology techniques and strict dimensional control, operators carefully aligned the segments to be welded. A small team of highly specialized technicians—working singly or in teams (one above, one below)—filled the gaps between each segment with weld material. Given the importance of high vacuum in the cryostat, each weld was verified through a variety of leak detection techniques.

In helium leak detection, one-metre sections of the weld to be verified were "enclosed" within leak-tight boxes positioned on opposite surfaces. Helium injected on one side of the weld is detected—if it has filtered through a crack—by a mass spectrometer on the other side, thereby signalling a leak that must be repaired by grinding out the faulty weld and replacing it.

Three other quality assurance techniques were used: radiographic and ultrasonic testing to detect the presence of flaws that could challenge the structural integrity of the welds, and liquid penetrant testing (LPT) for surface checks.

In total, the Indian Domestic Agency estimates that one kilometre of full penetration weld joints were carried out to exacting standards for the sub-assemblies in the site workshop, to be followed by several hundred metres of weld joints to assemble the cryostat sections in the Tokamak pit.

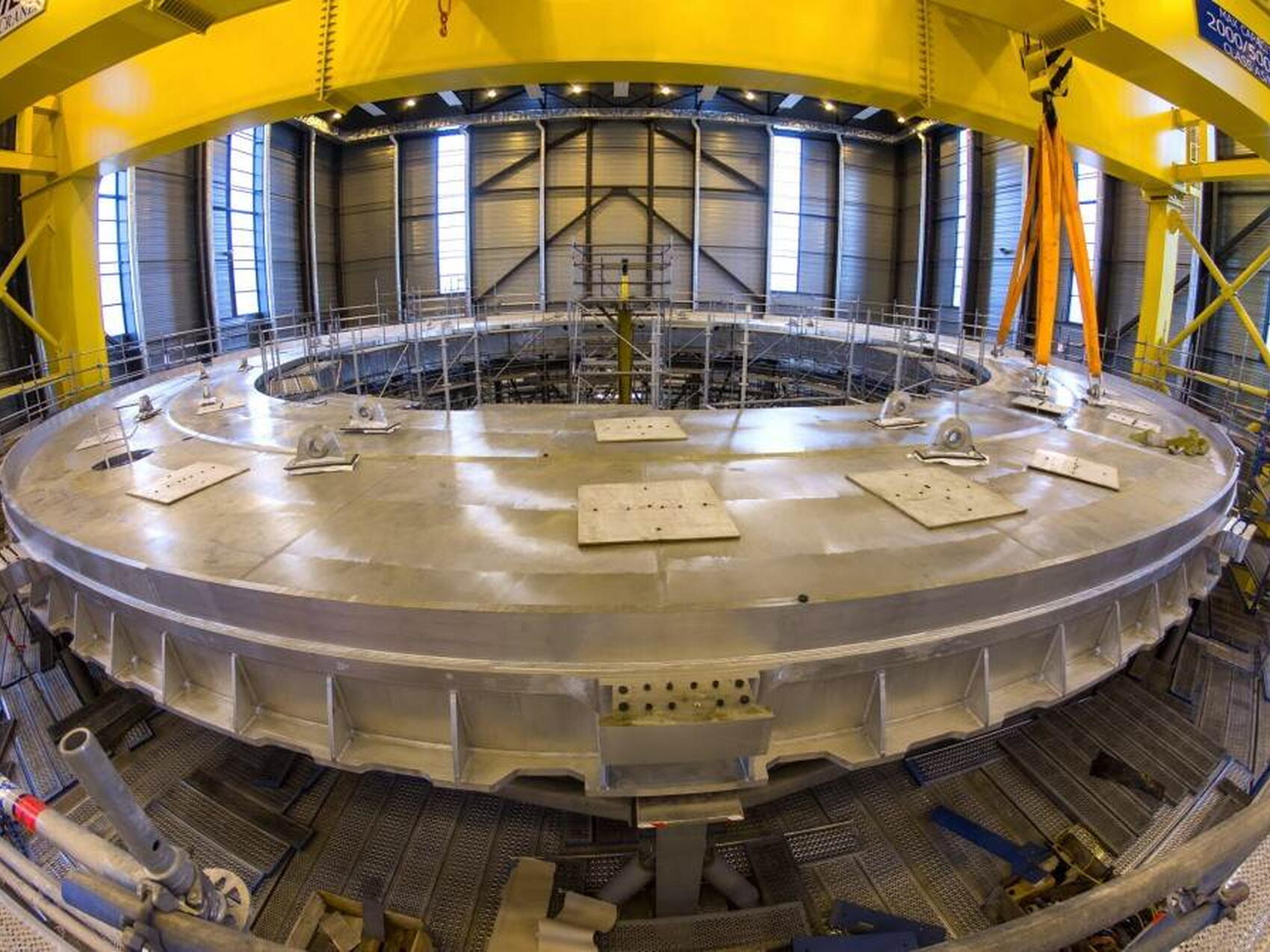

It took approximately three years (2016 to 2019) to finalize the on-site assembly and welding operations for the cryostat base—a 1,250-tonne component formed from a tier 1 "disk" and a tier 2 vertical ring and pedestal.

The less-complex lower cylinder (375 tonnes) was assembled in two years, and completed in 2019, while the upper cylinder and top lid were completed in 2020 and 2022 respectively. The top lid is considered the most complex of the sections because of its 3D profile.

In May 2020, the 1,250-tonne cryostat base was transferred to the Assembly Hall, lifted by overhead crane, and inserted into the bottom of the Tokamak assembly pit. The lower cryostat went next, in August 2020. The two bottom cryostat sections were fully welded together by Indian Domestic Agency contractors operating directly inside of the pit. The upper cylinder and top lid will remain in storage until they are needed in the assembly sequence.

Cryostat Assembly facts:

- Section assembly: 2016-2022

- Number of segments fabricated in India: 54

- Sections assembled on site: cryostat base, lower cylinder, upper cylinder, top lid

- Length of weld joints for in-workshop assembly (four sections): ~ 1,015 m

- Length of weld lines (passages): 50 km

- Welding wire: 1,500 km (17 tonnes)

- Length of weld joints for in-pit assembly: ~ 390 m

- Diameter of sections: 30 metres

- Weight of each section: base: 1,250 tonnes; lower cylinder: 375 tonnes; upper cylinder: 430 tonnes; lid: 665 tonnes

- Completed sections: lower cylinder, March 2019; cryostat base, June 2019; cryostat upper cylinder, March 2020; cryostat lid, March 2022

- Installed in Tokamak pit: cryostat base, May 2020; cryostat lower cylinder, August 2020

- Procurement responsibility: India

Photo Gallery