Plant assembly

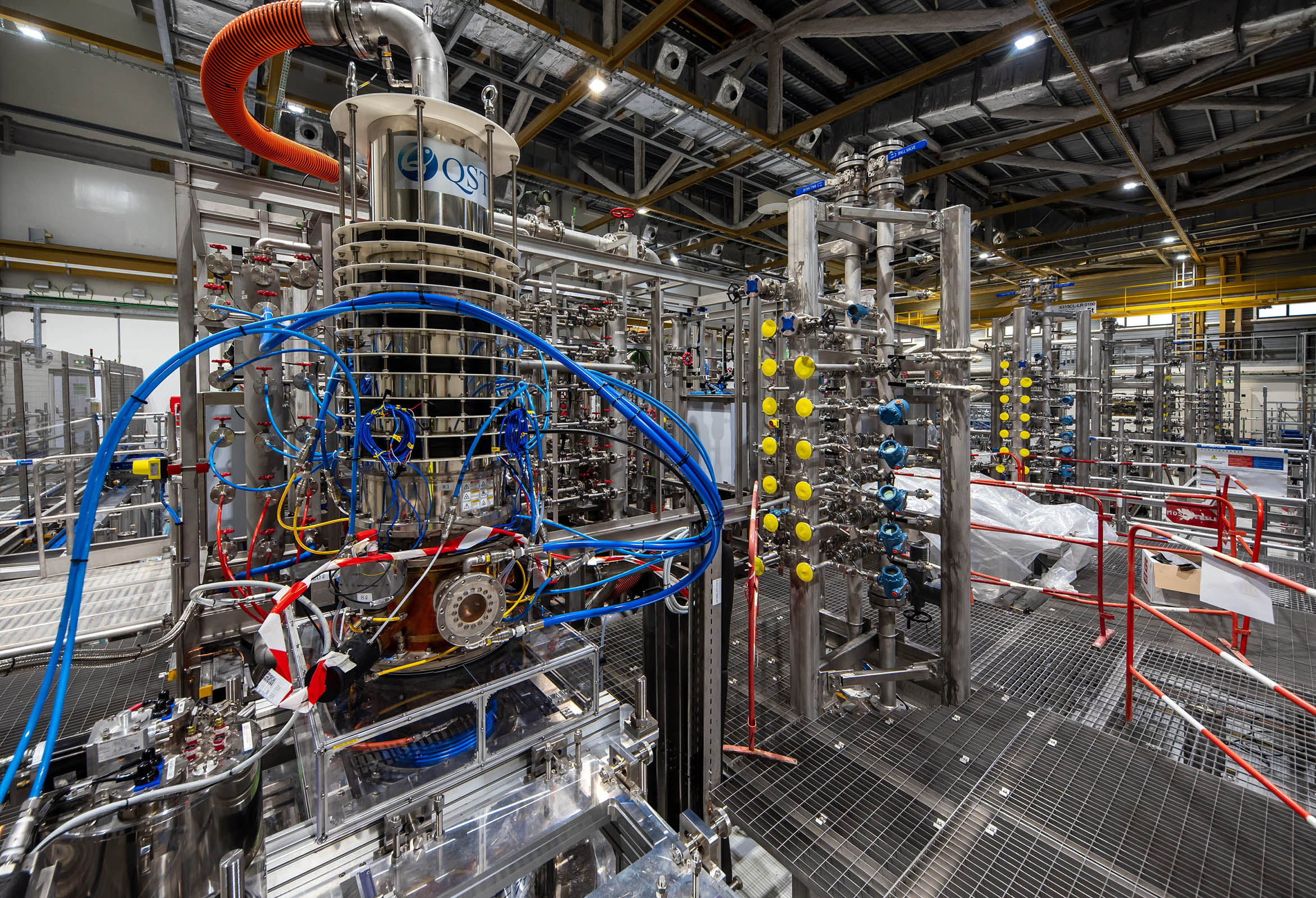

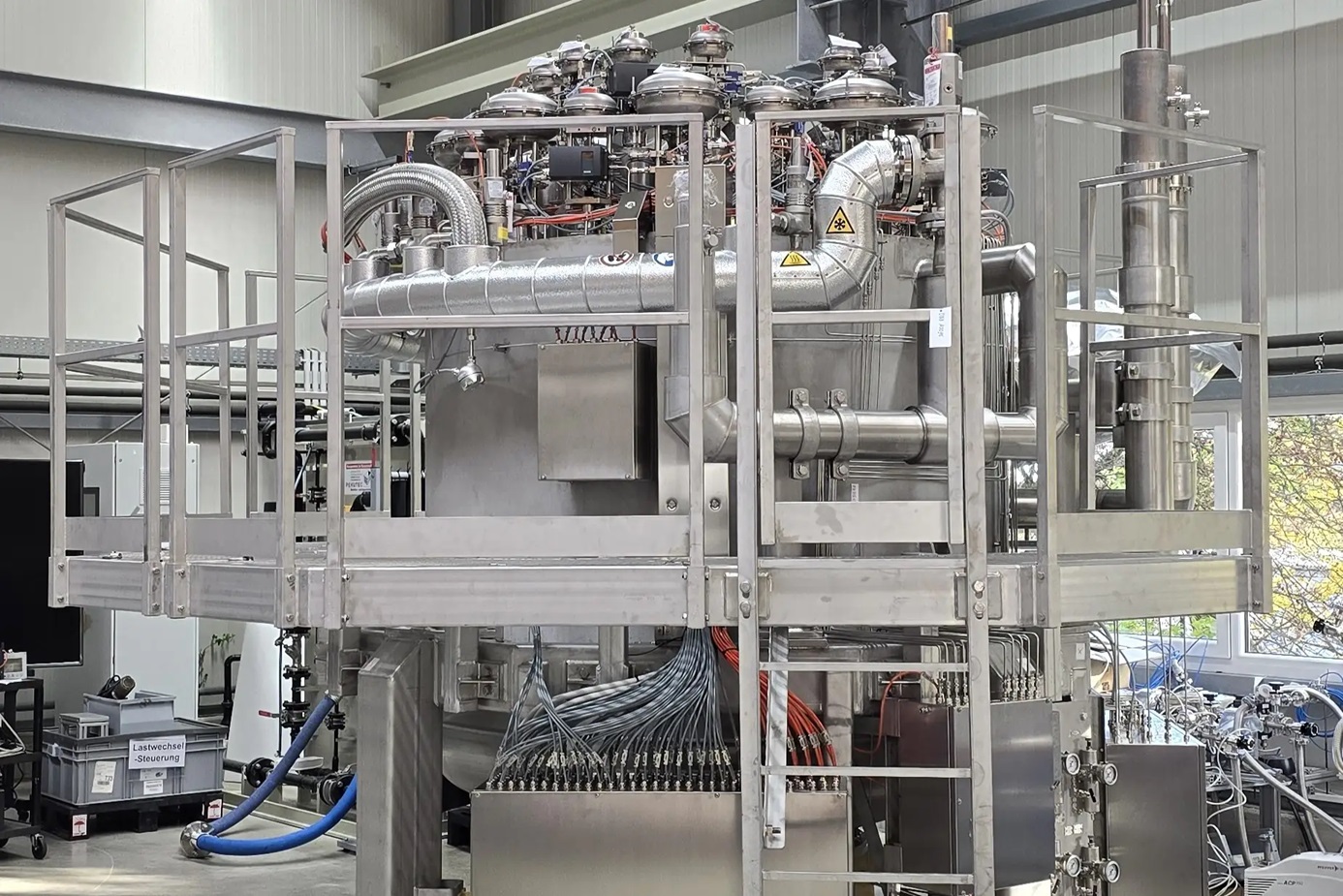

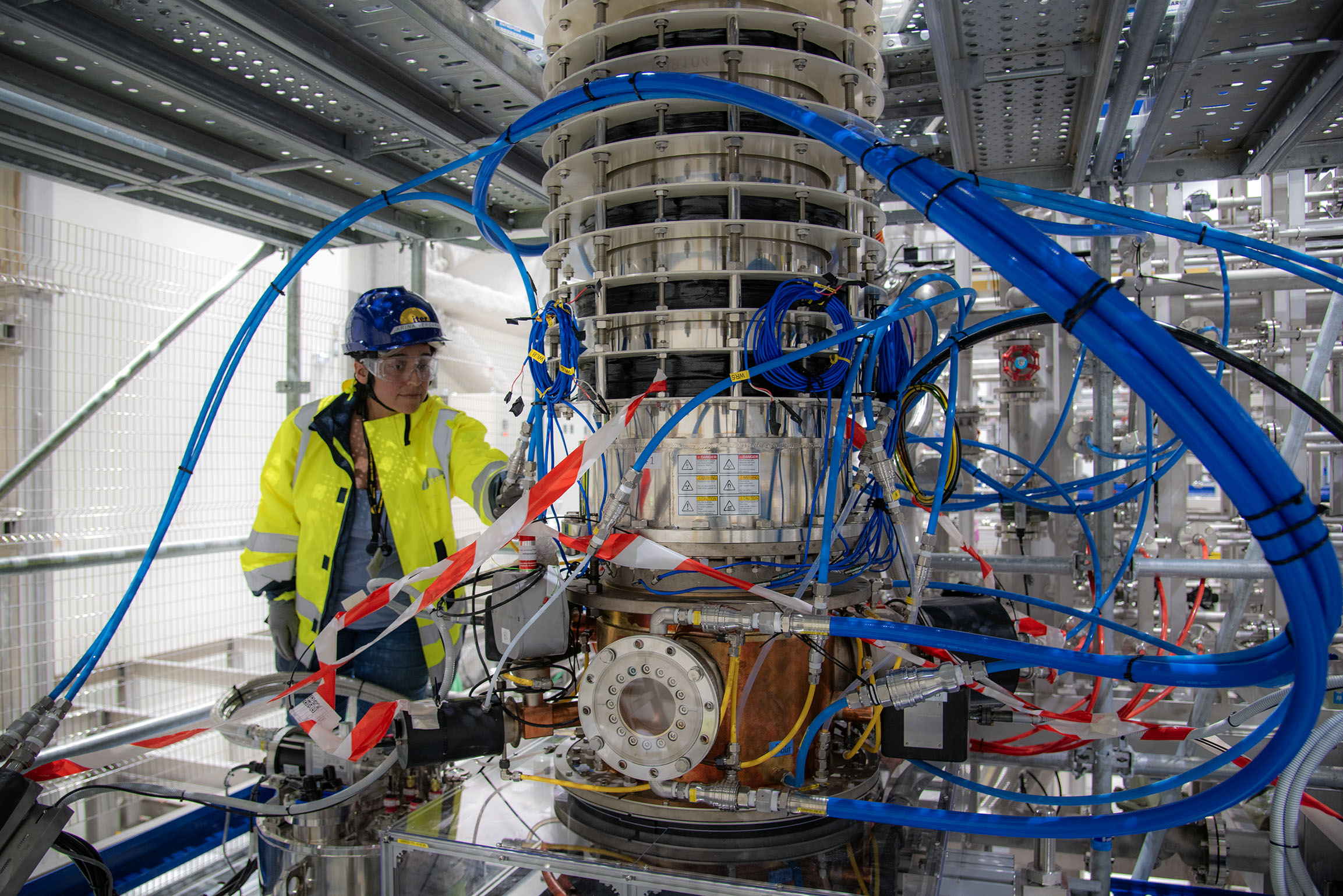

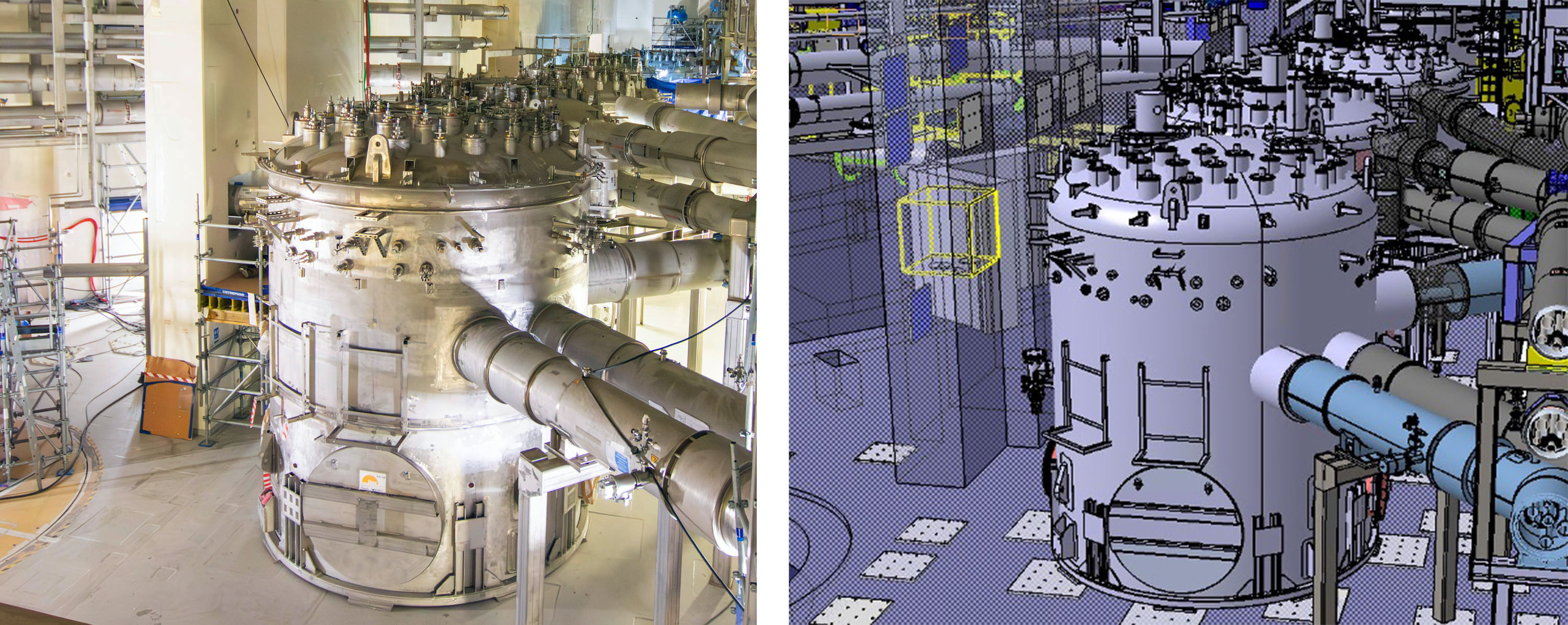

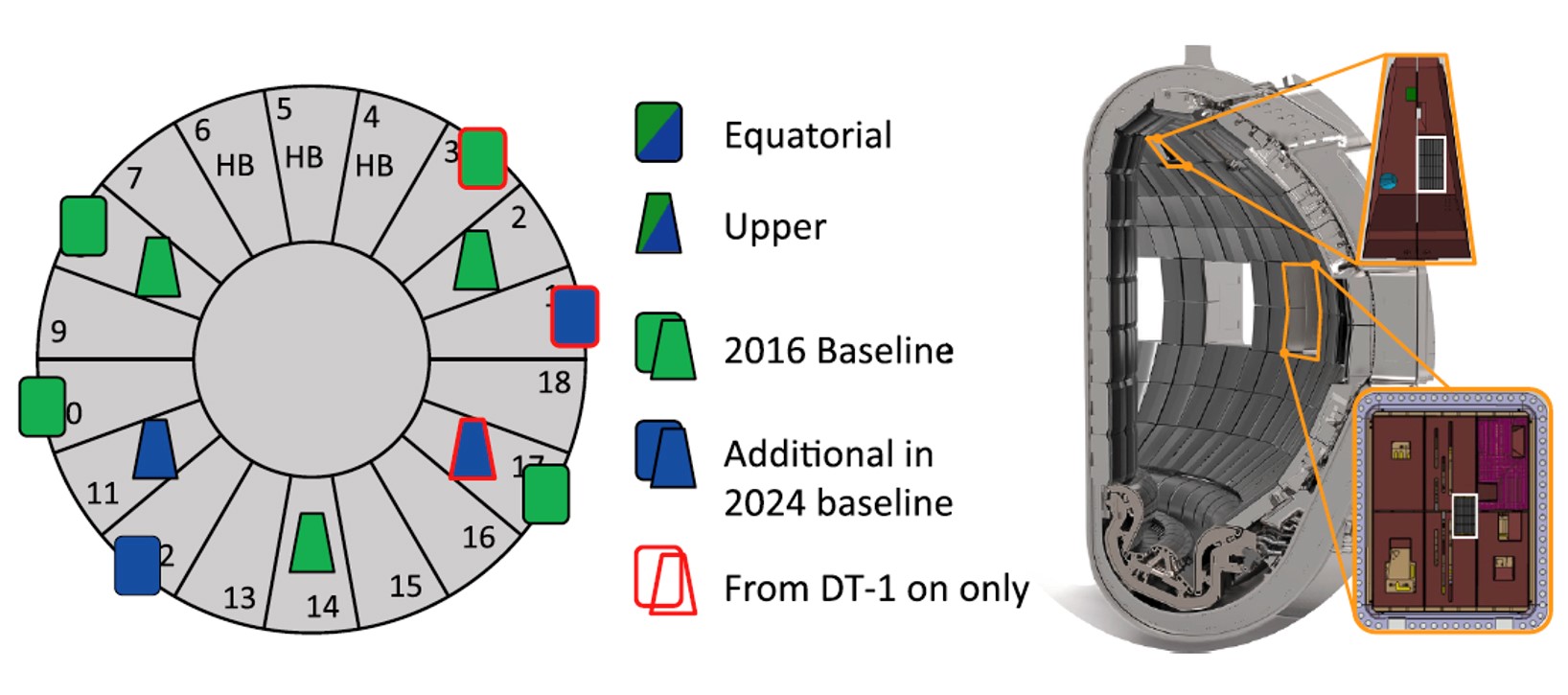

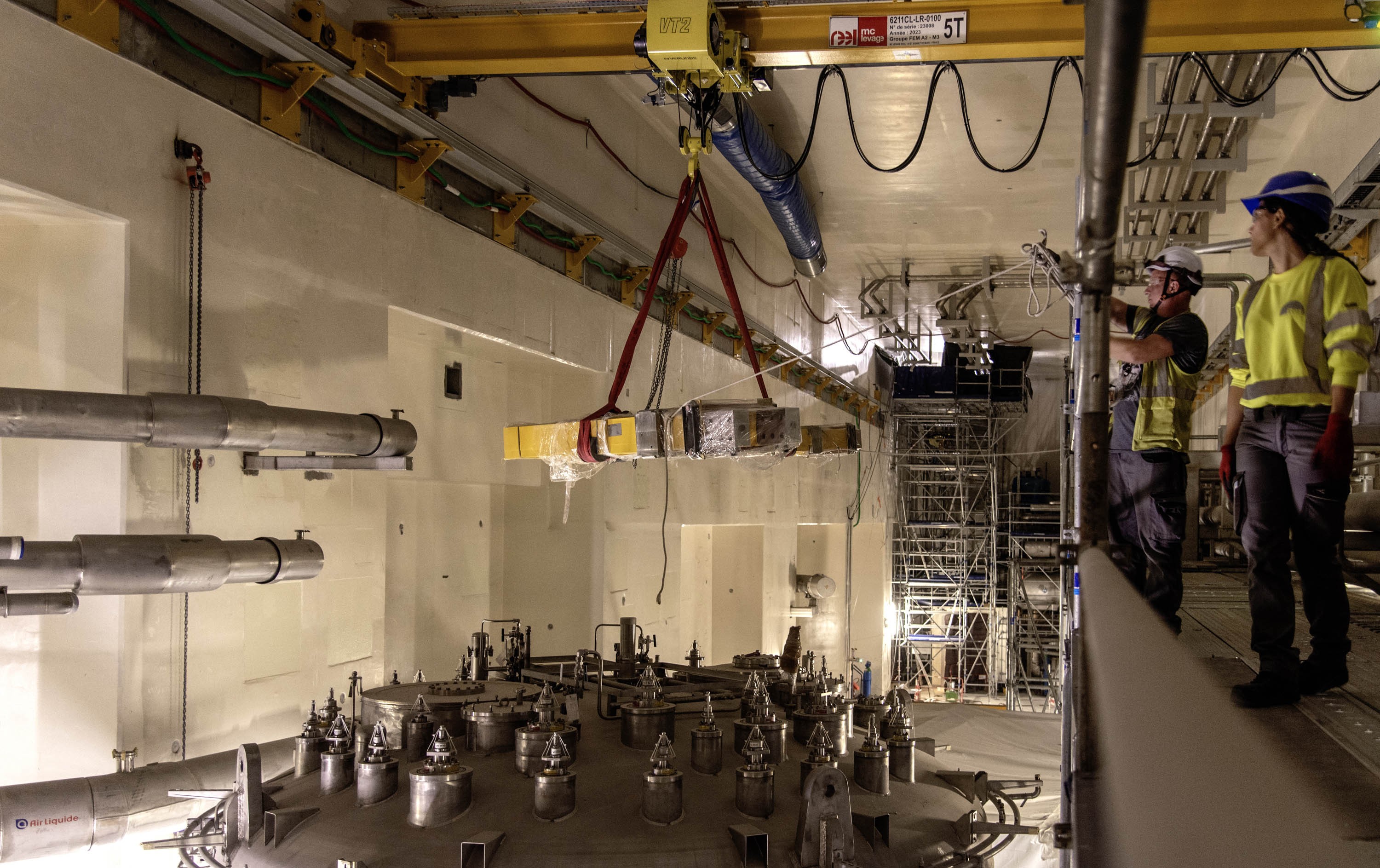

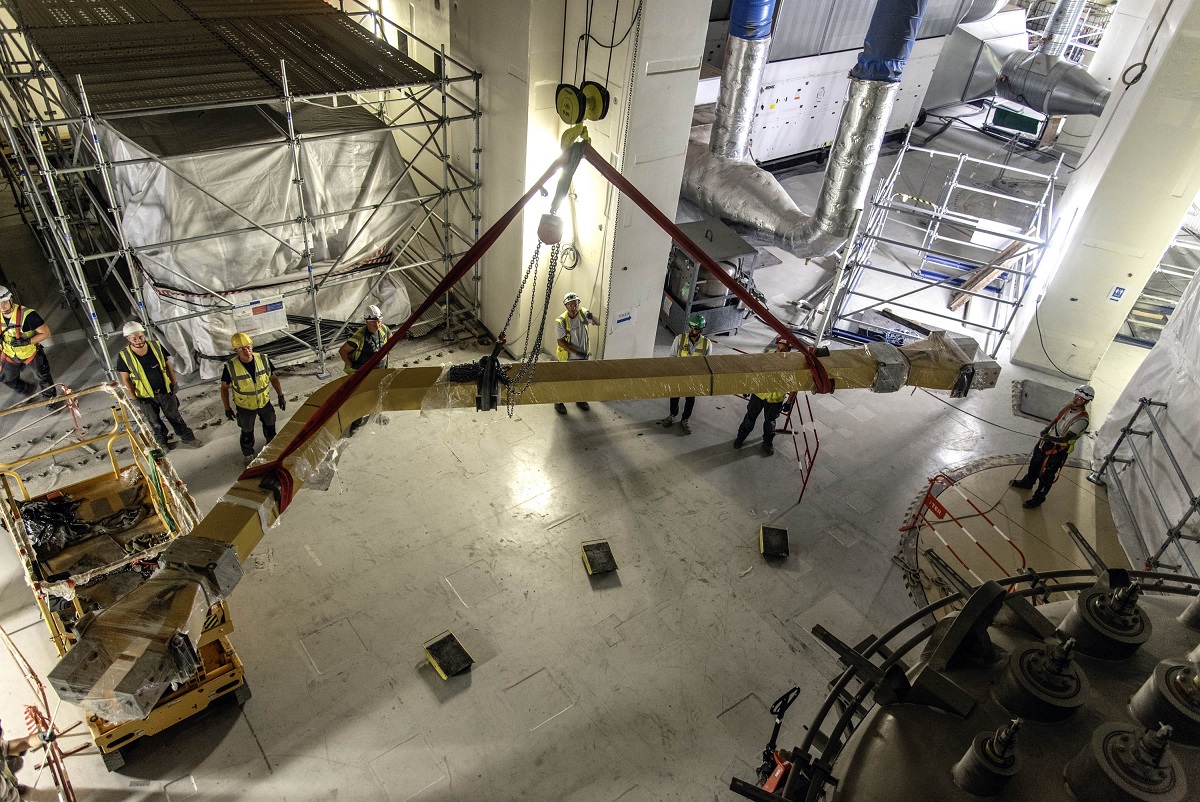

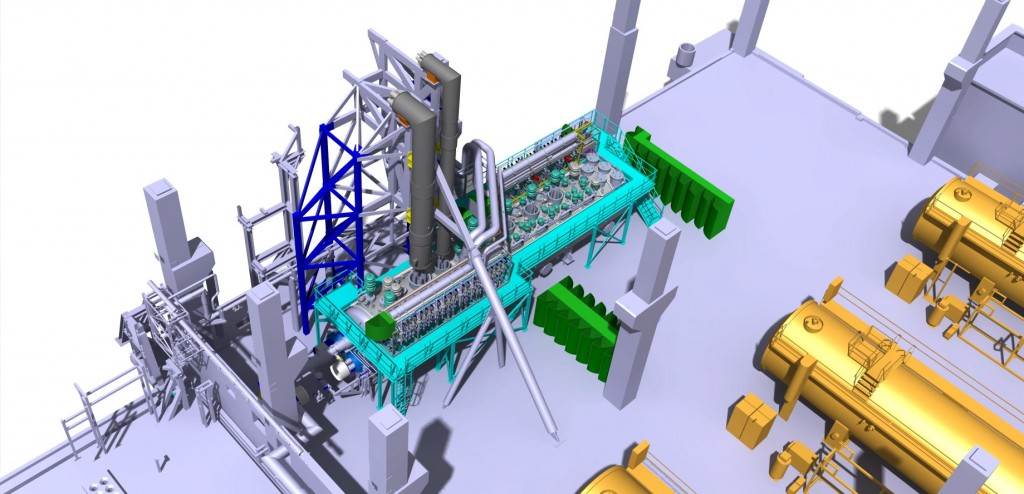

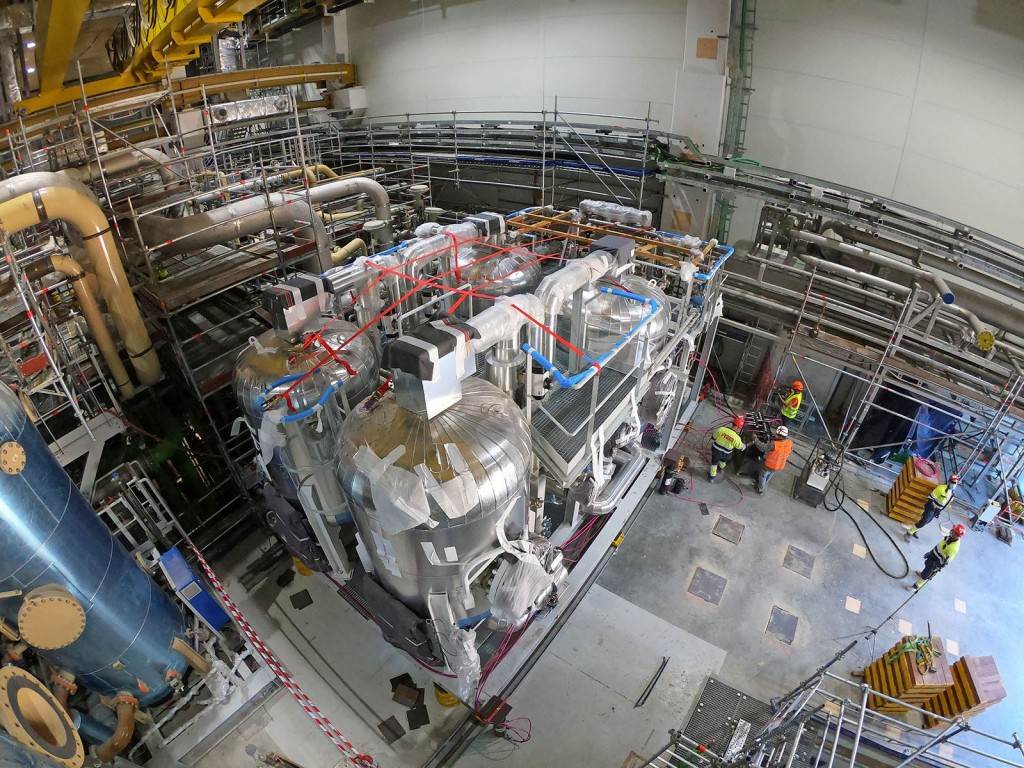

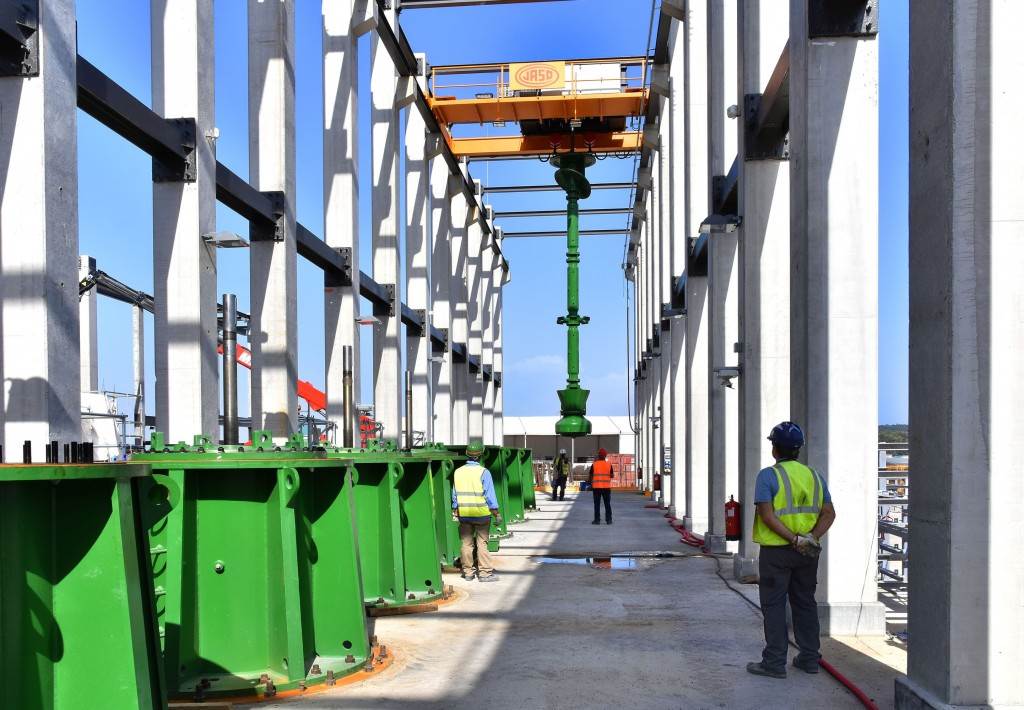

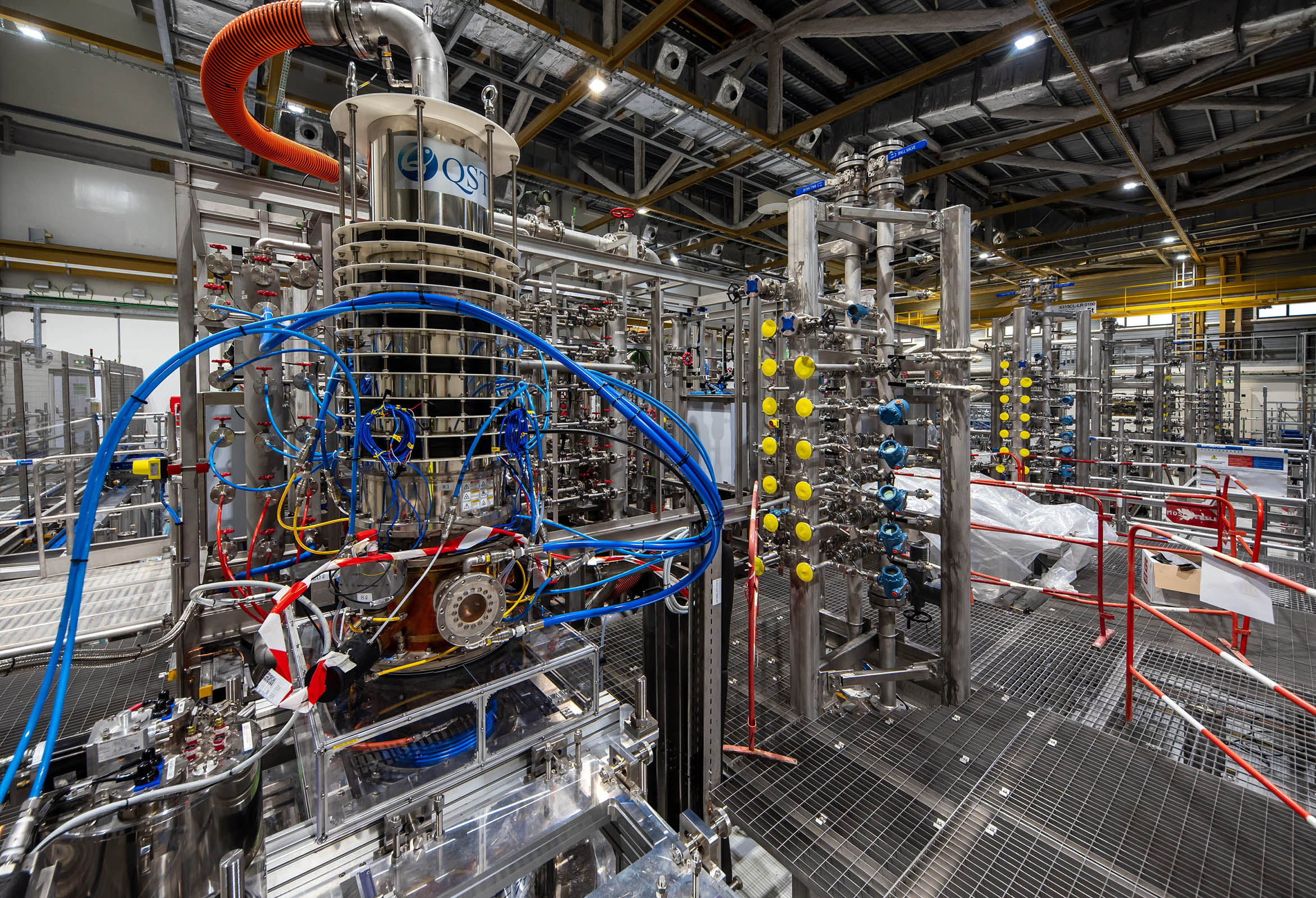

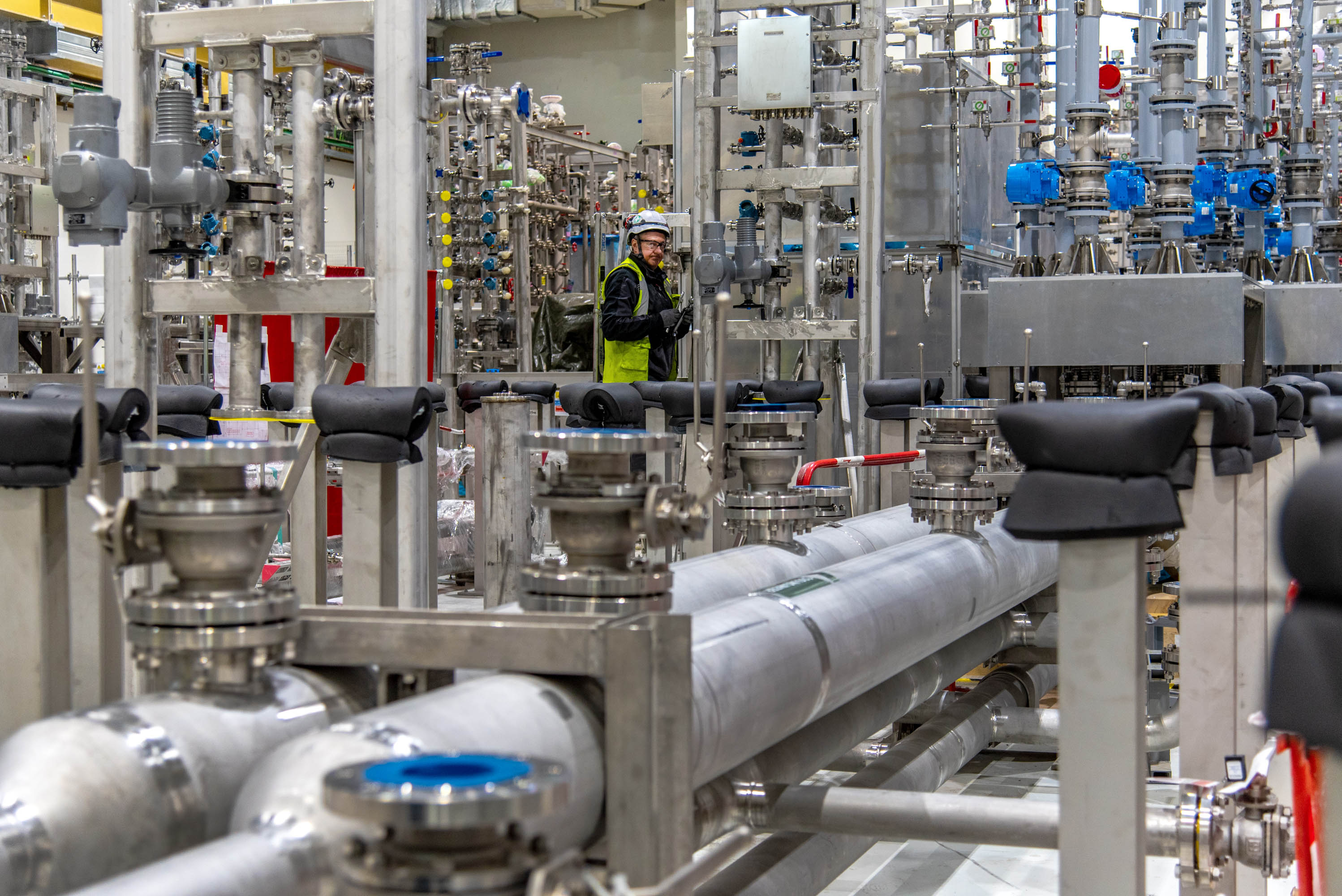

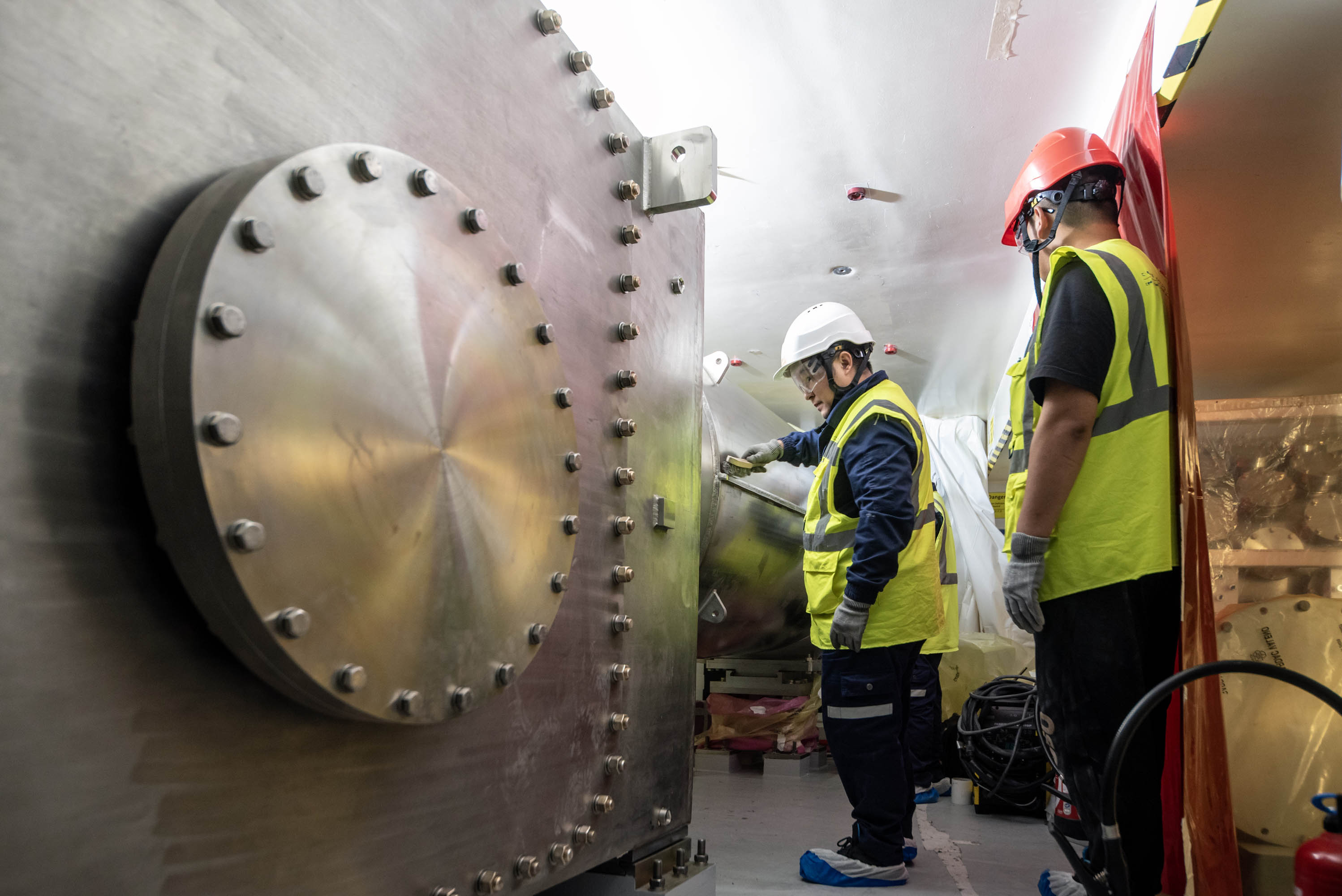

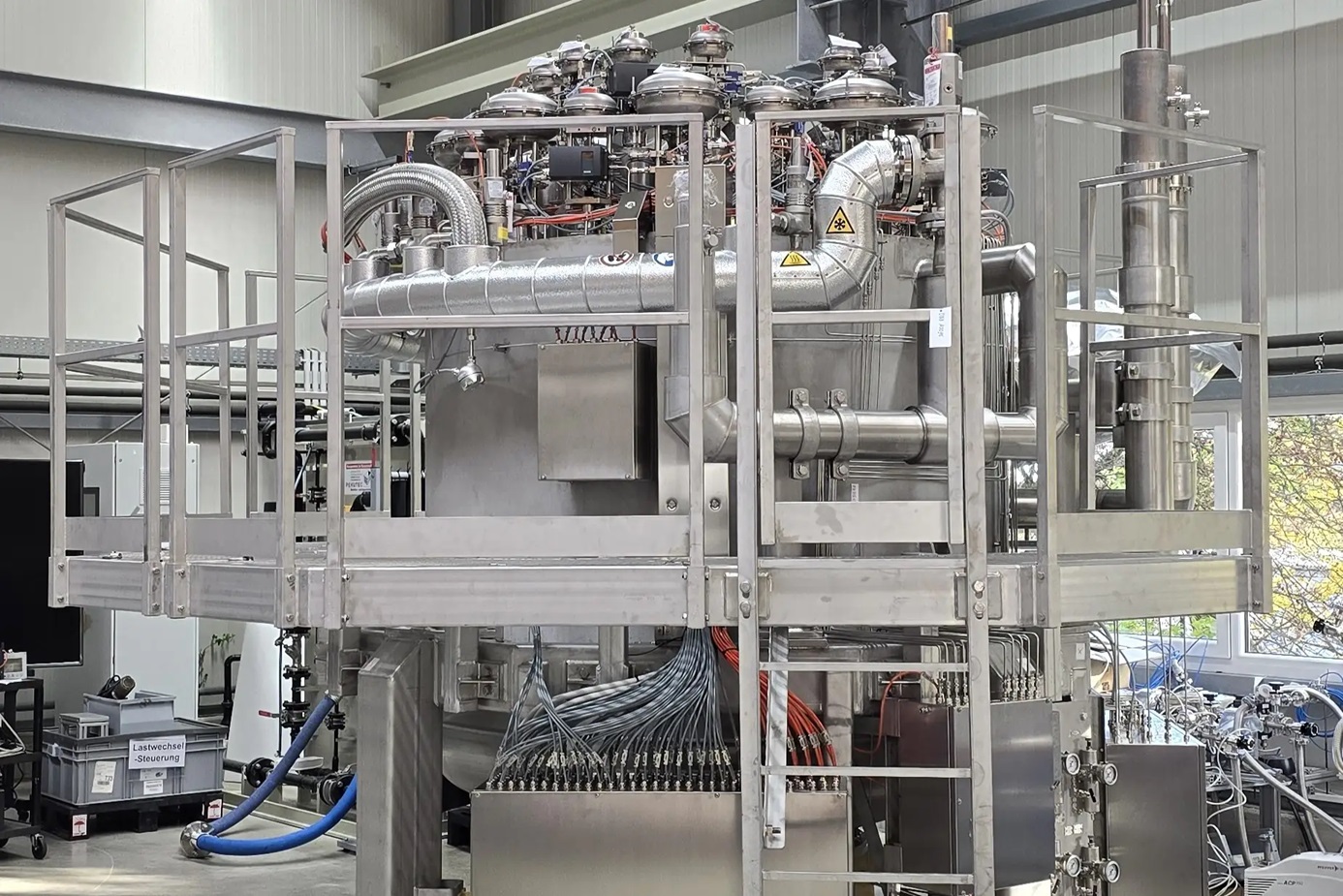

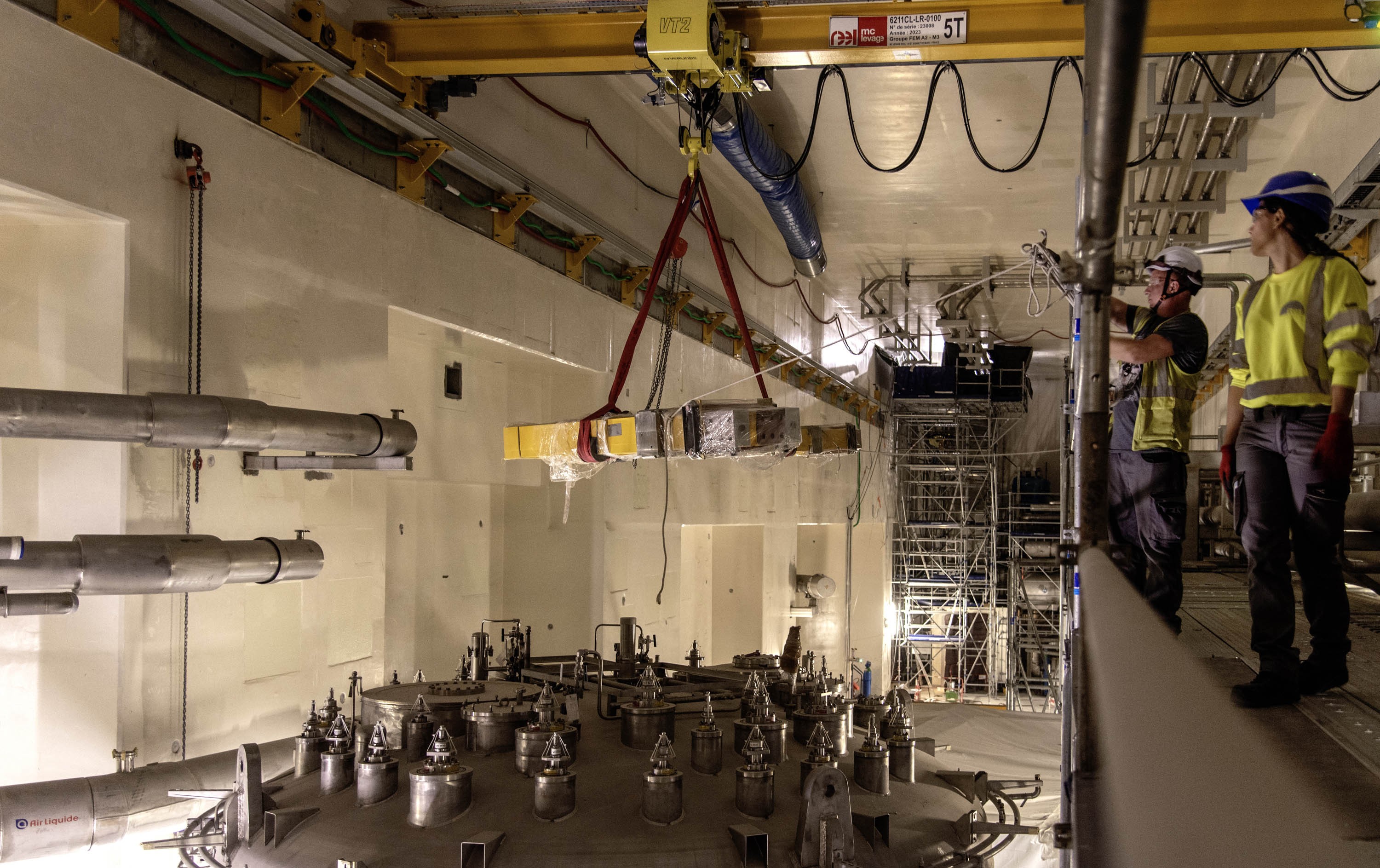

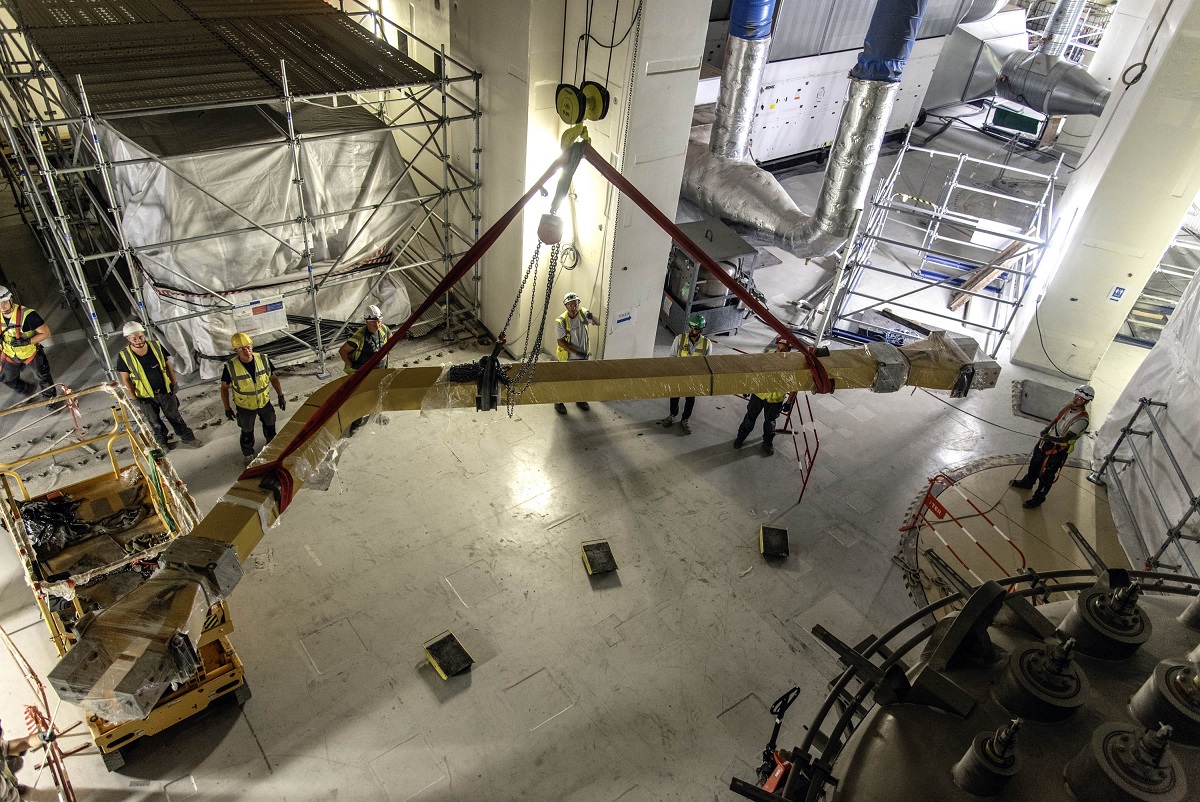

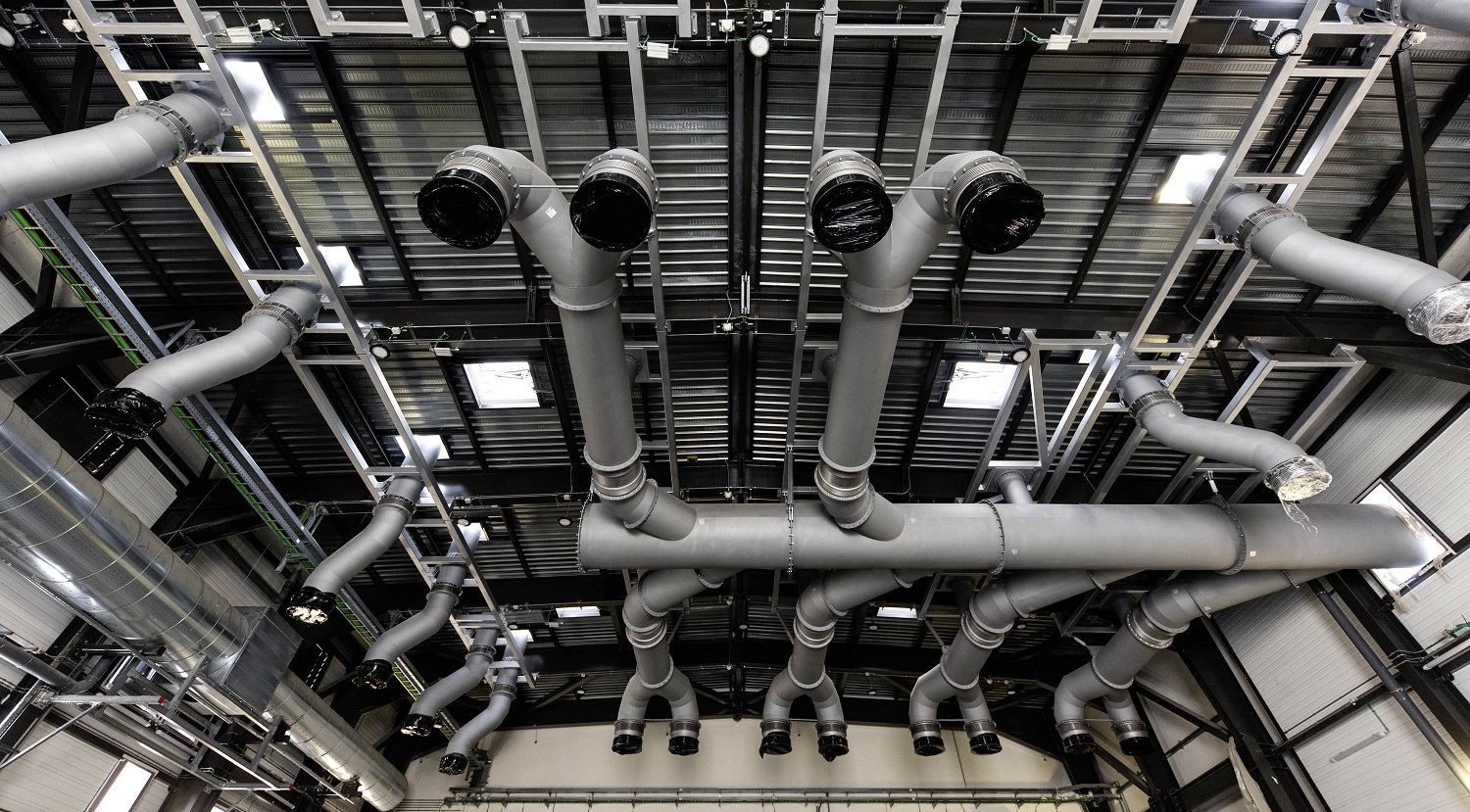

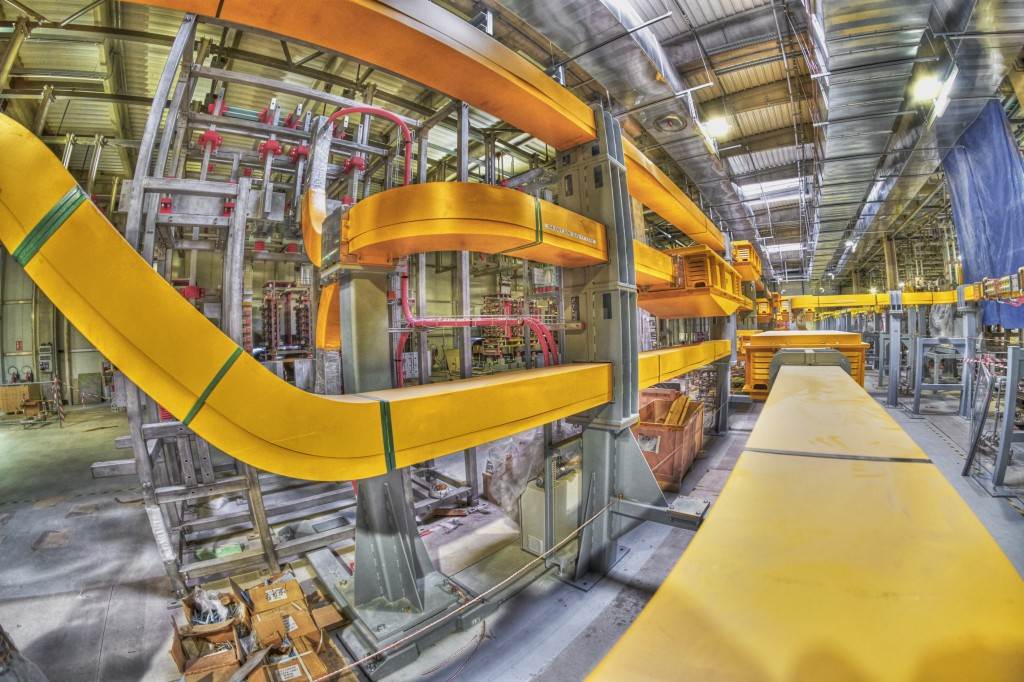

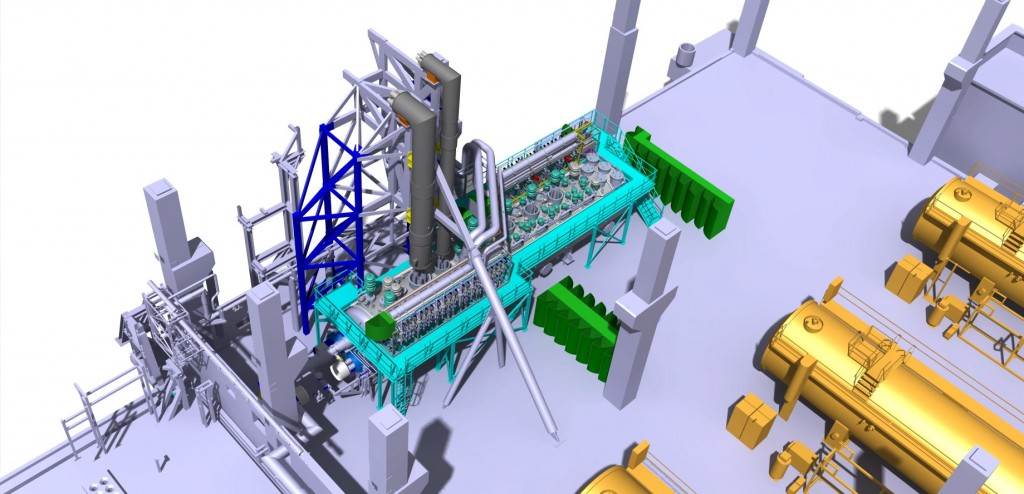

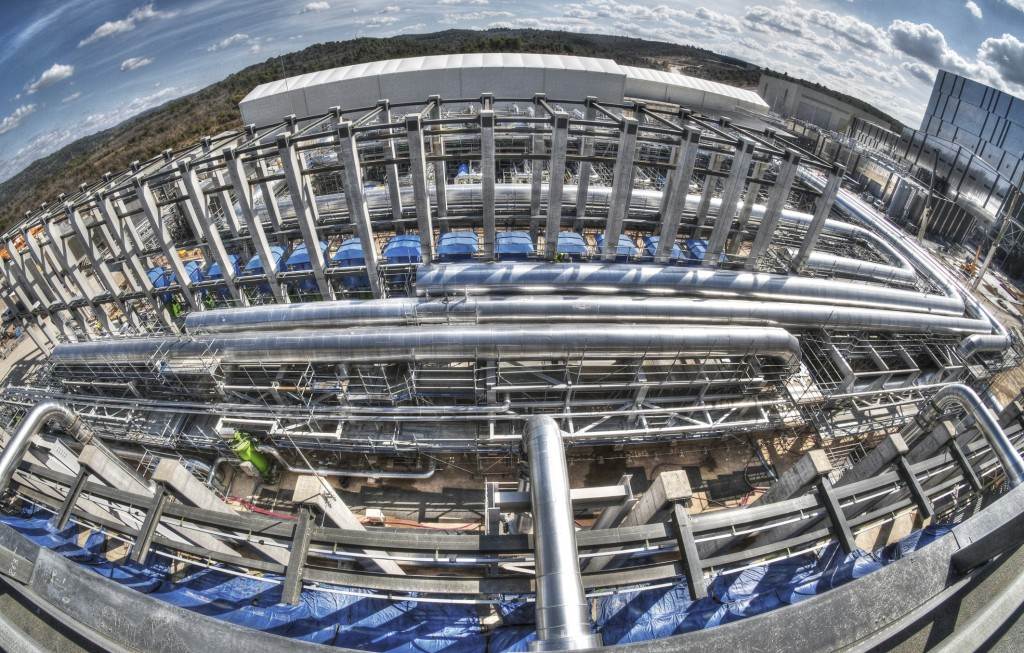

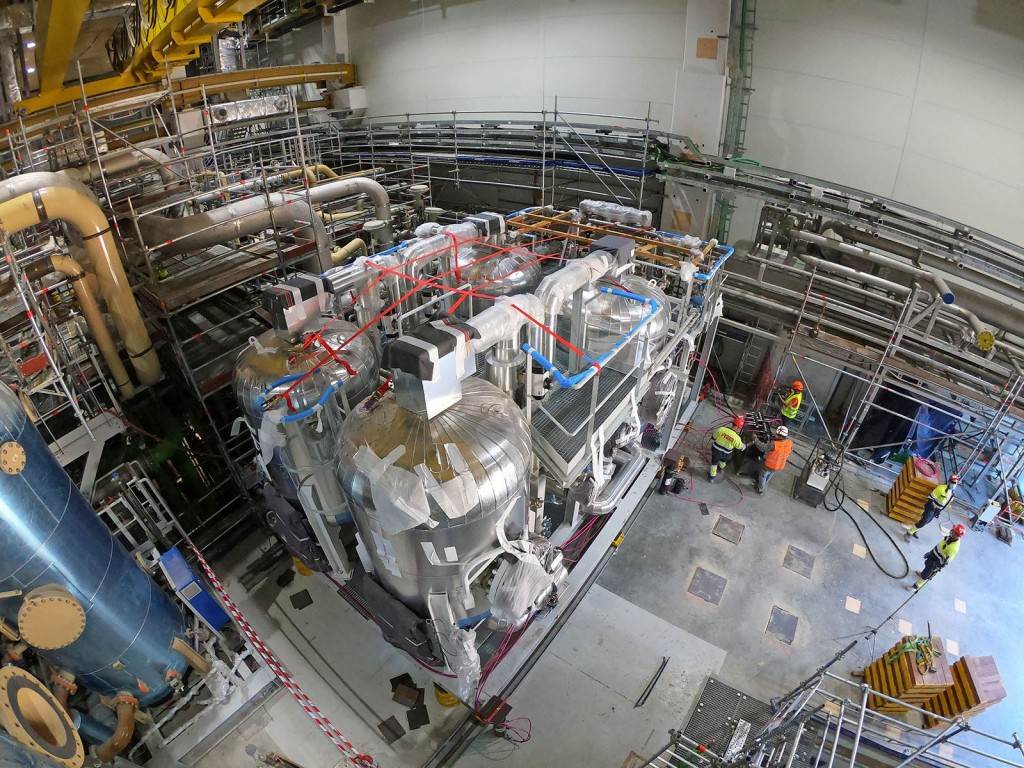

First-phase plant assembly contracts cover the systems needed for the Start of Research Operation. This category includes the cryogenic, cooling water and electrical plants; basic diagnostics; some radio frequency heating, as well as large captive components that must be installed in the buildings early.

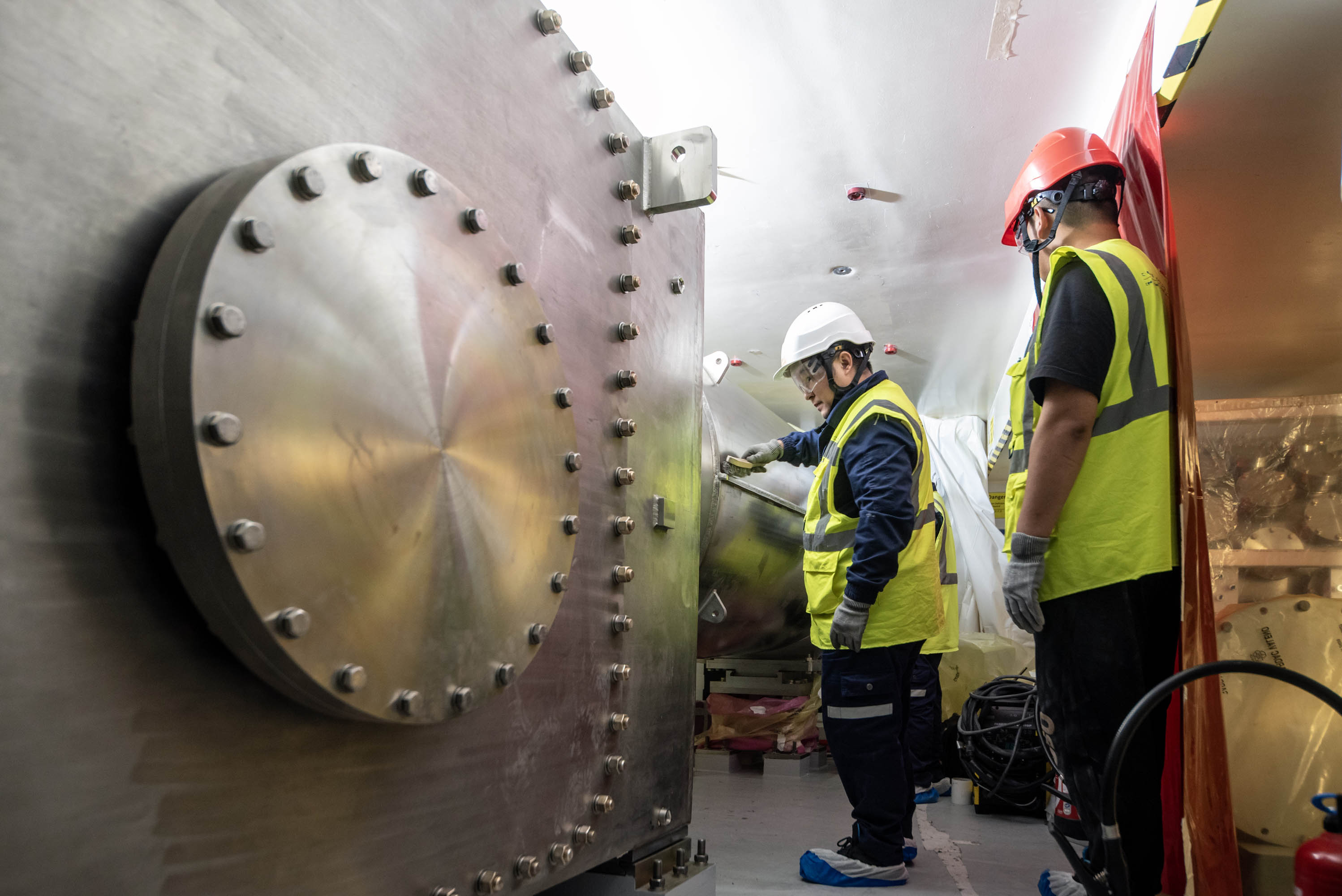

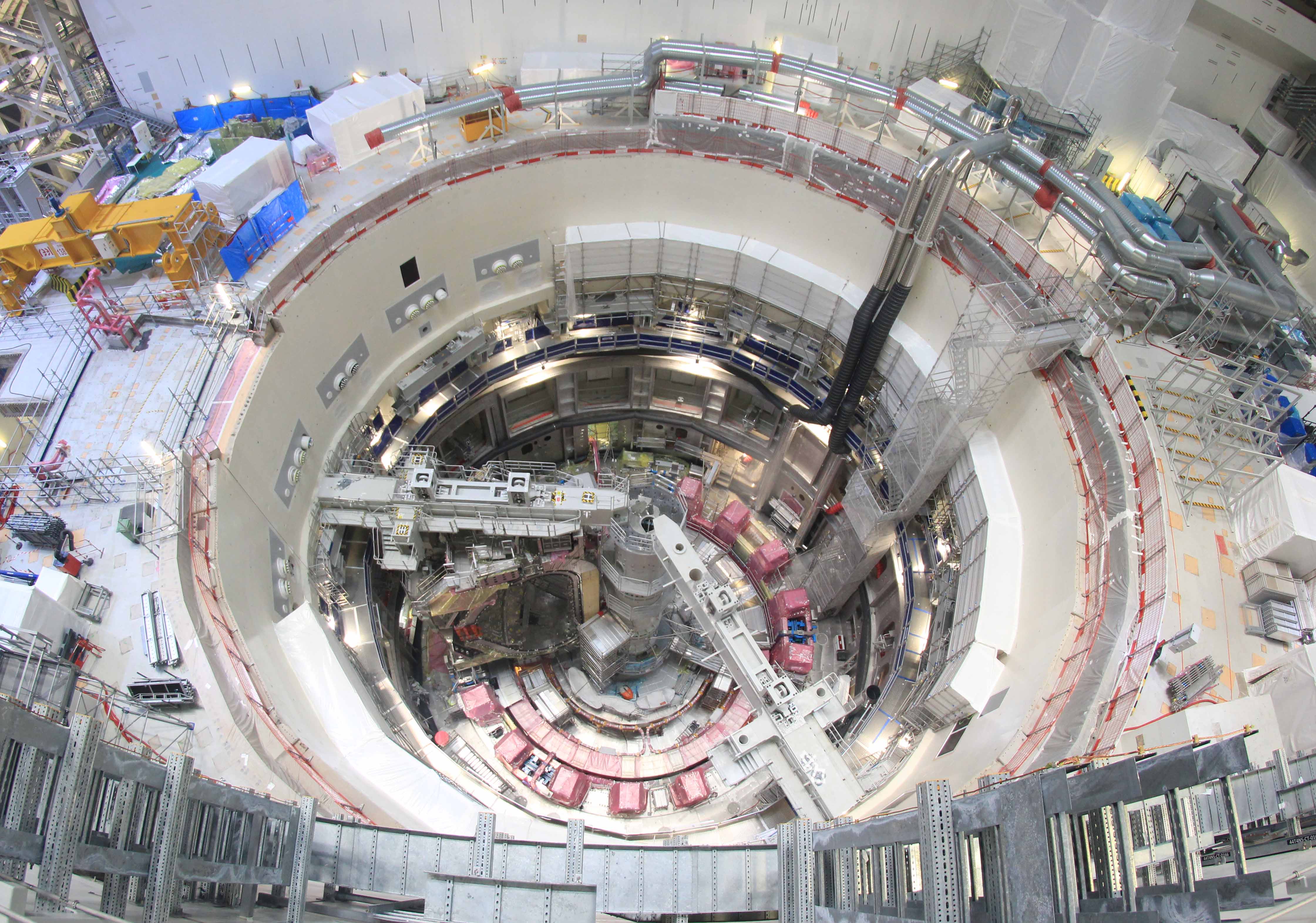

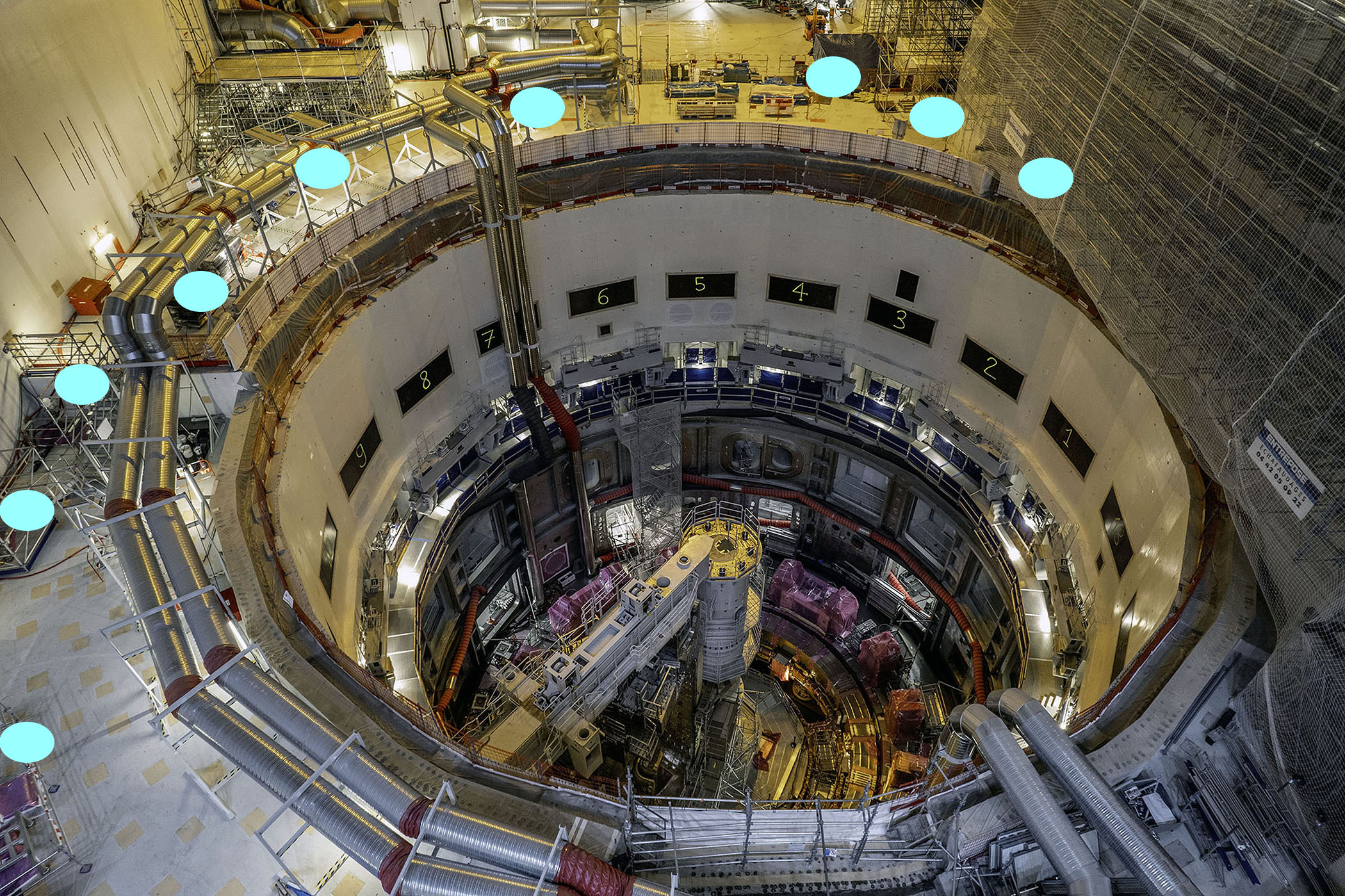

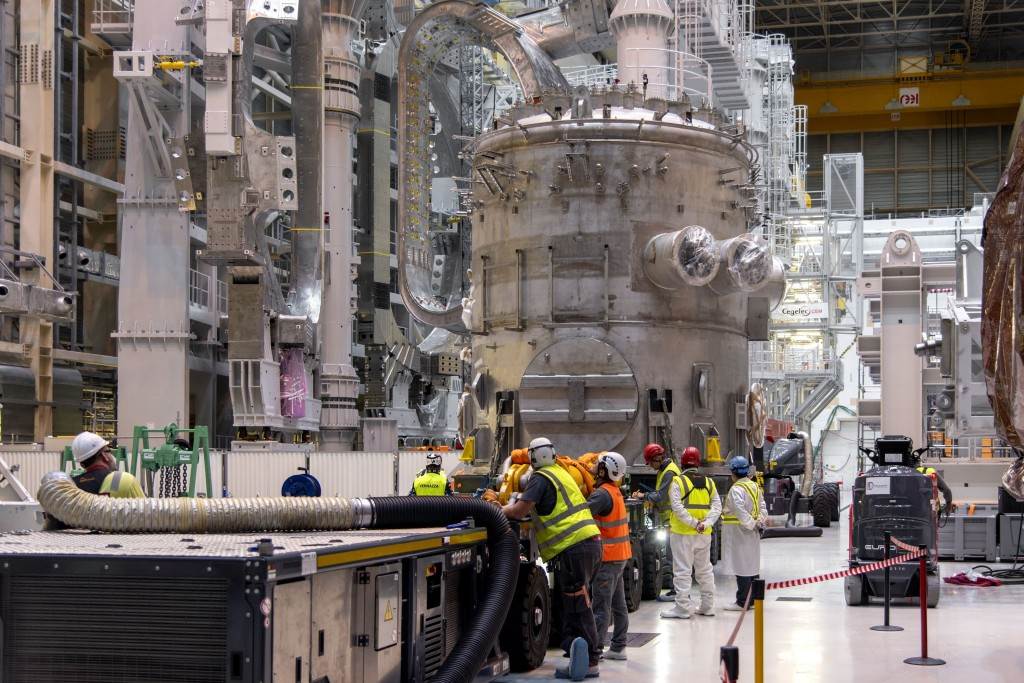

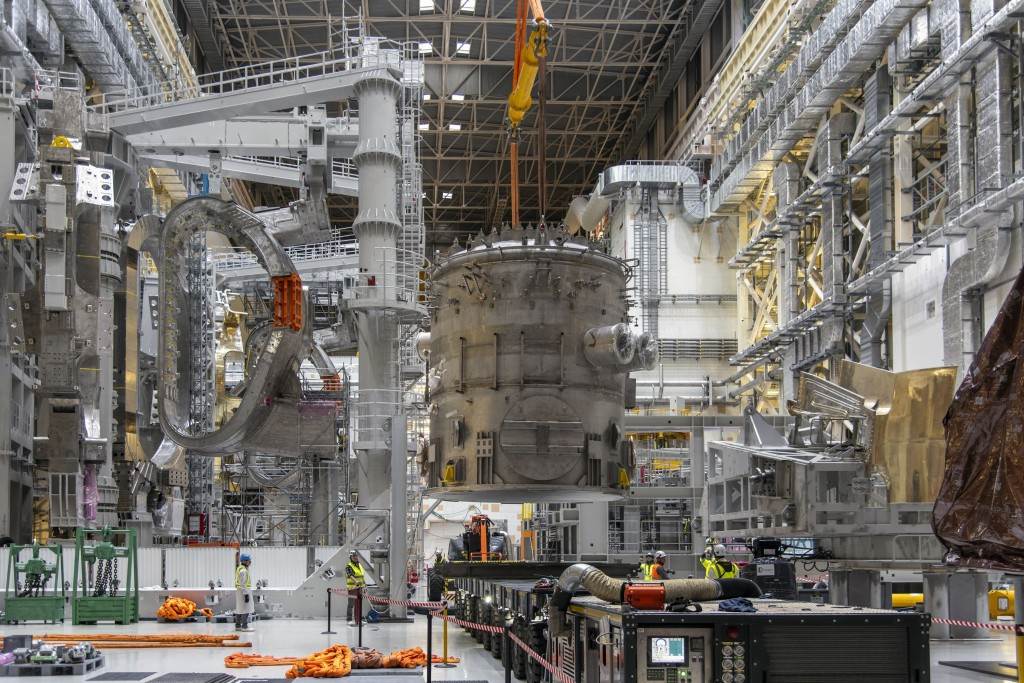

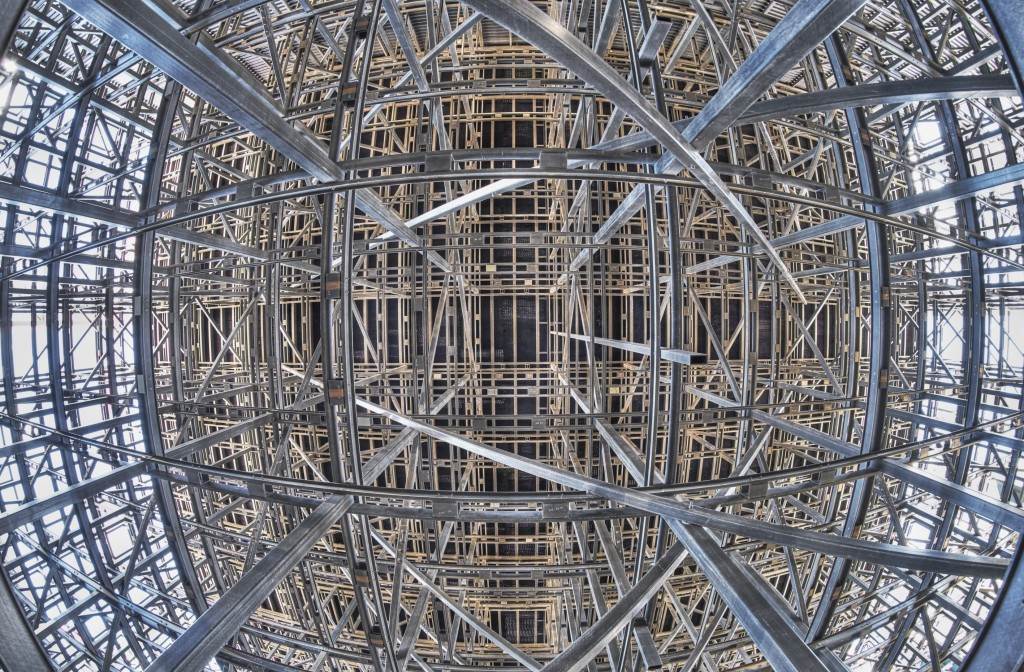

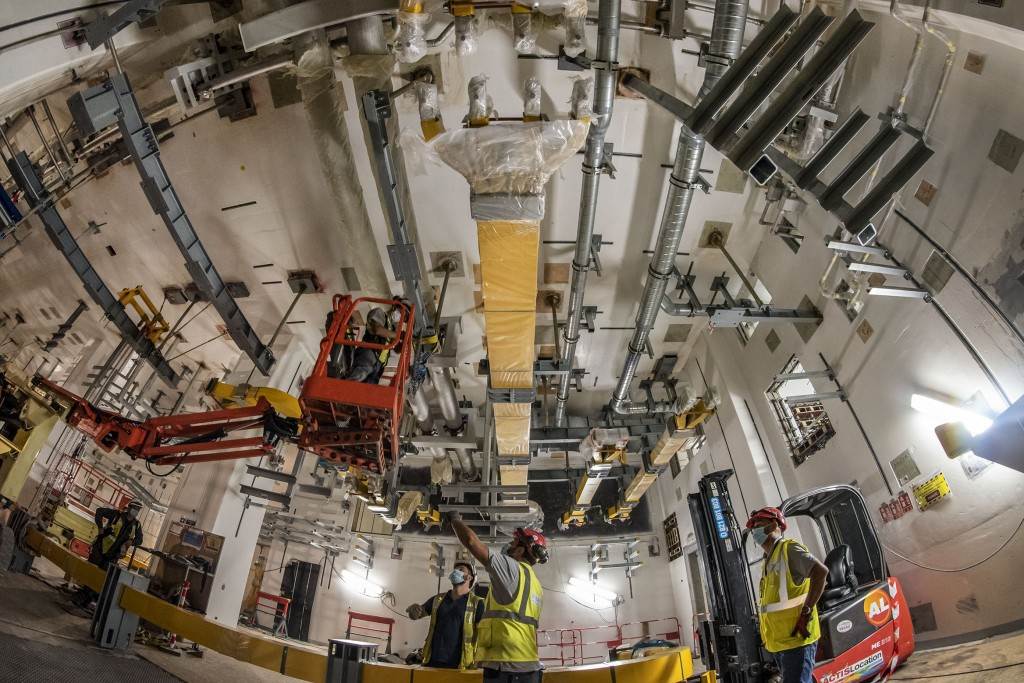

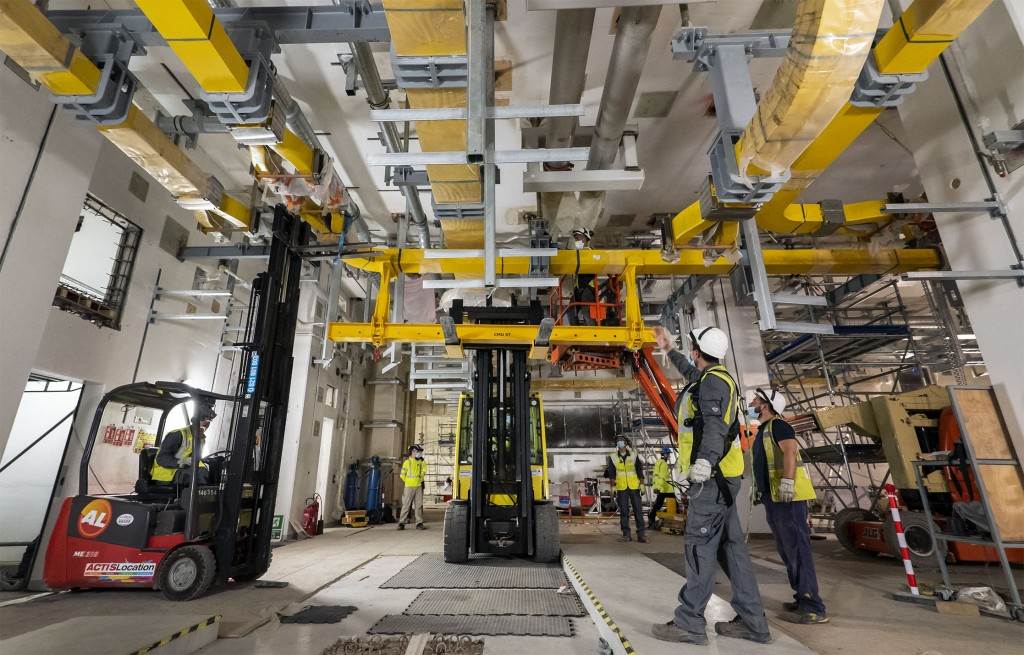

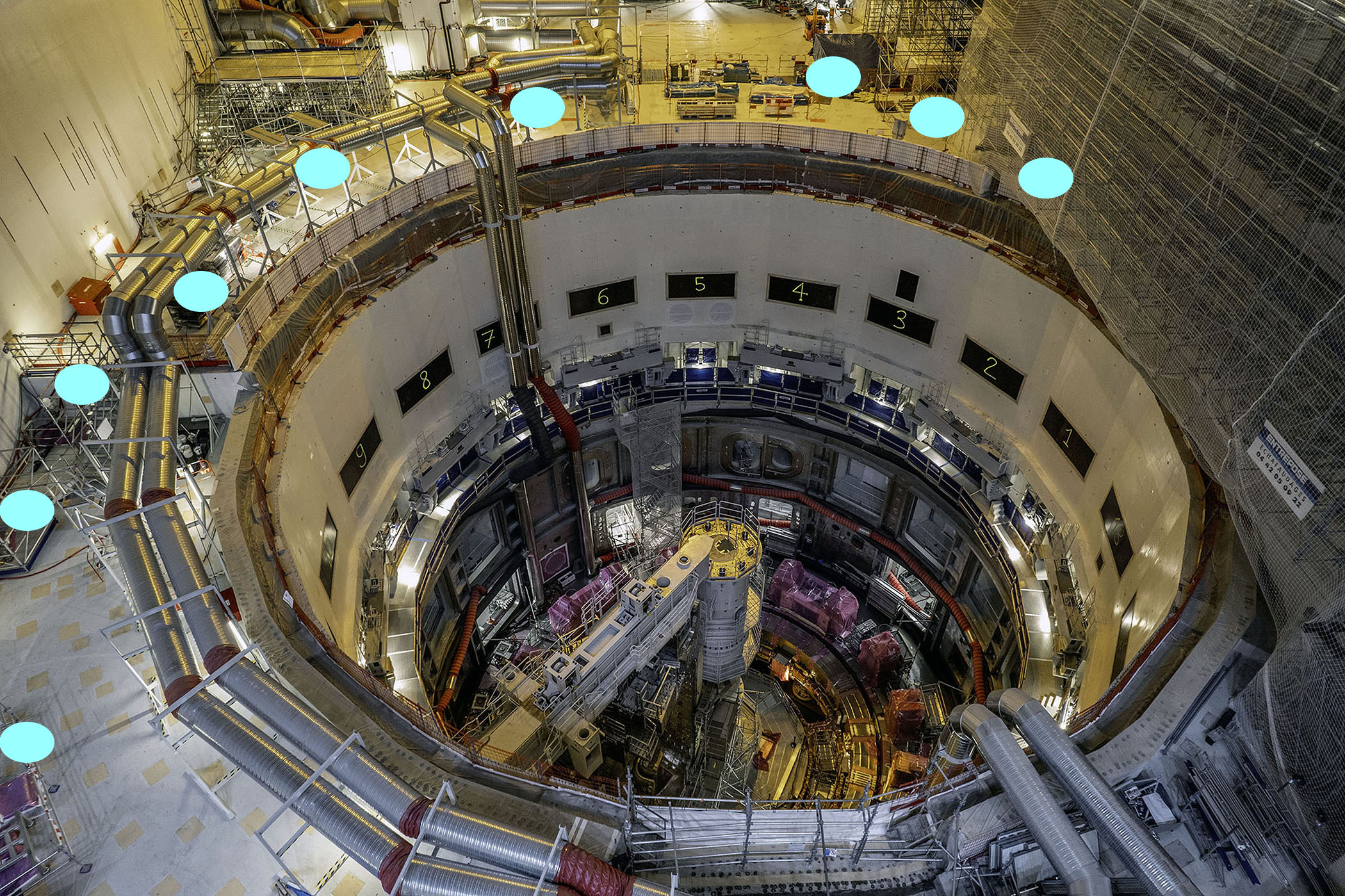

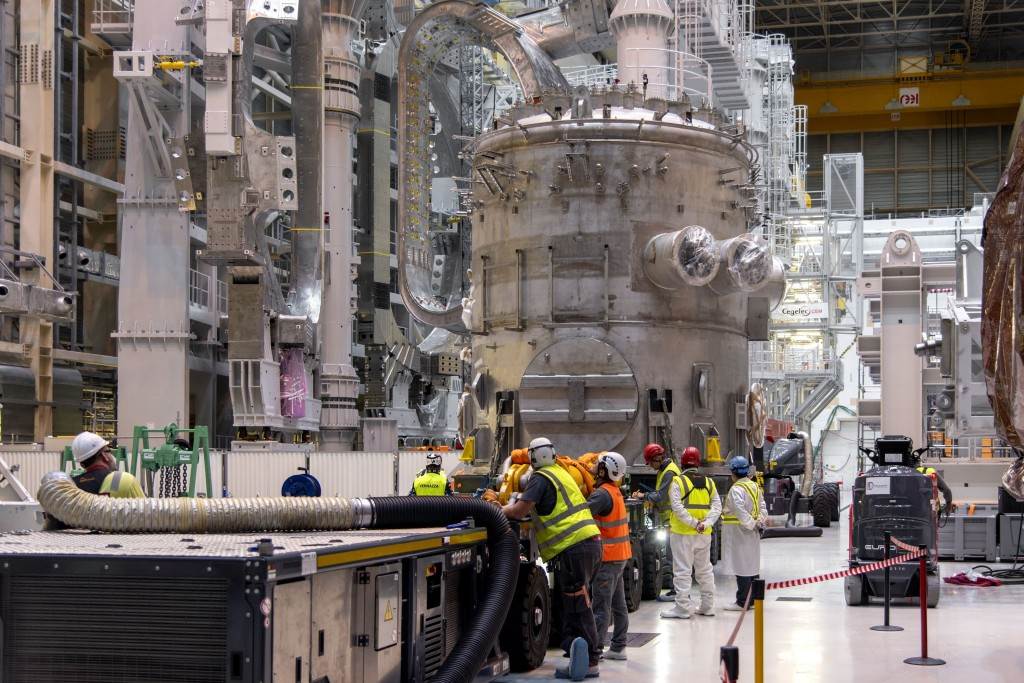

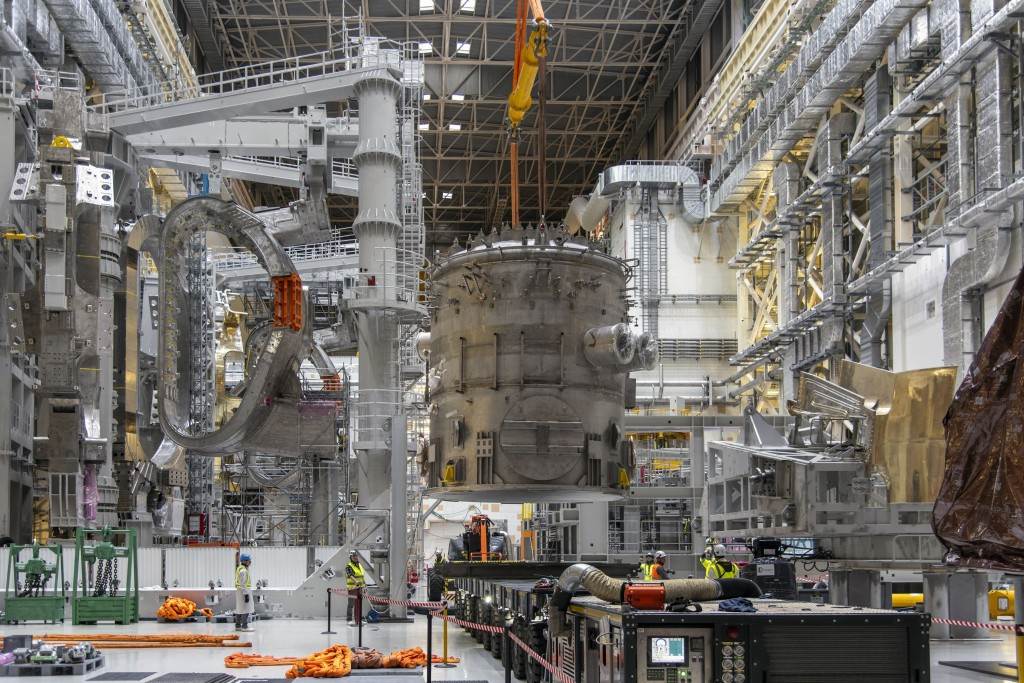

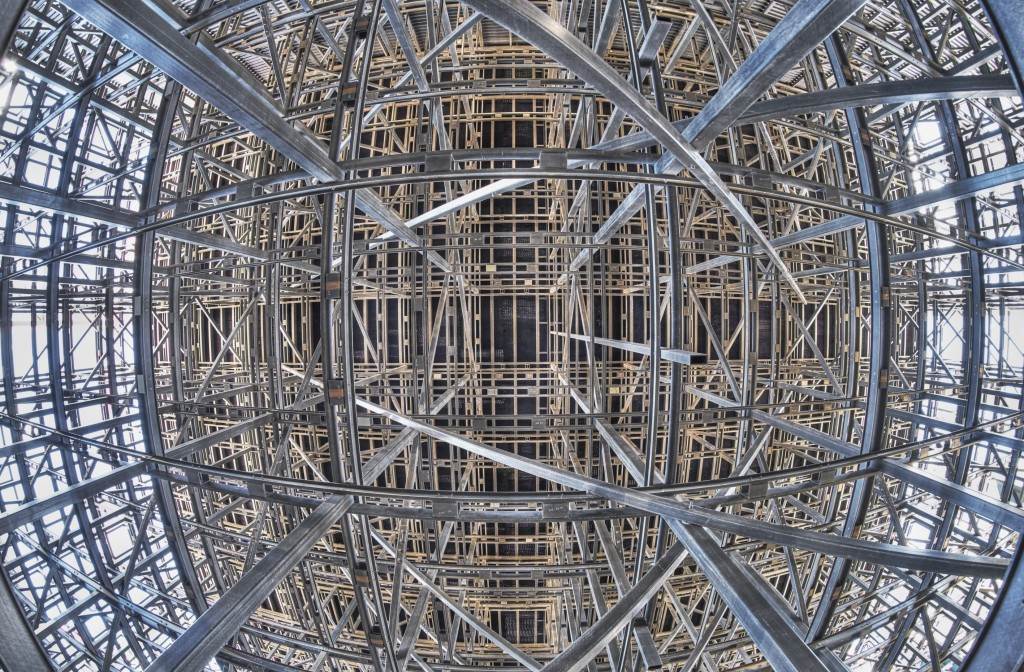

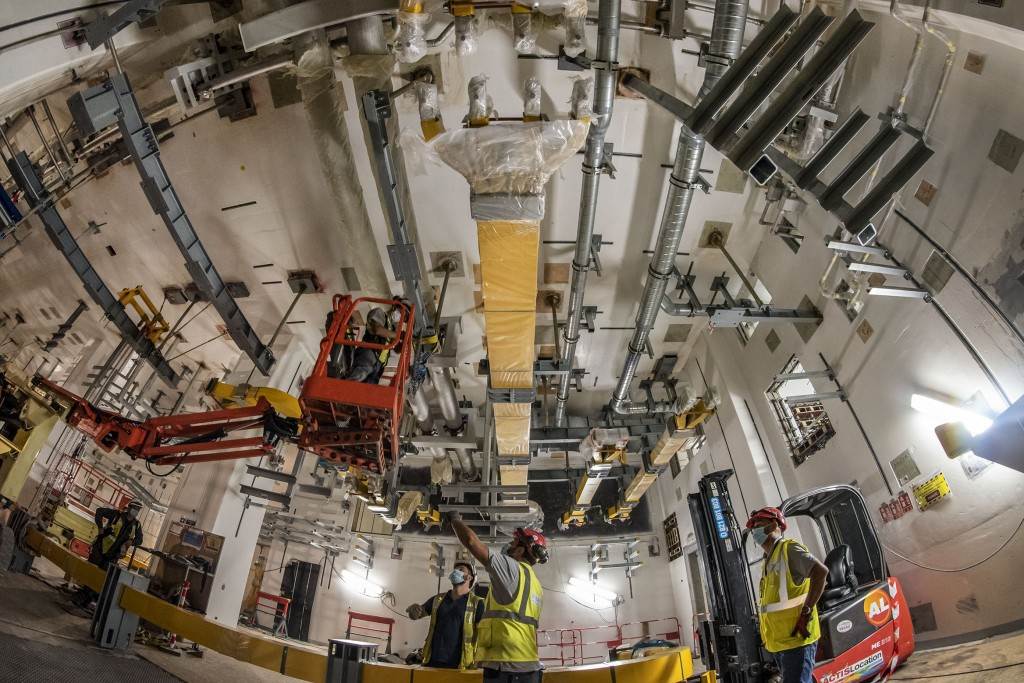

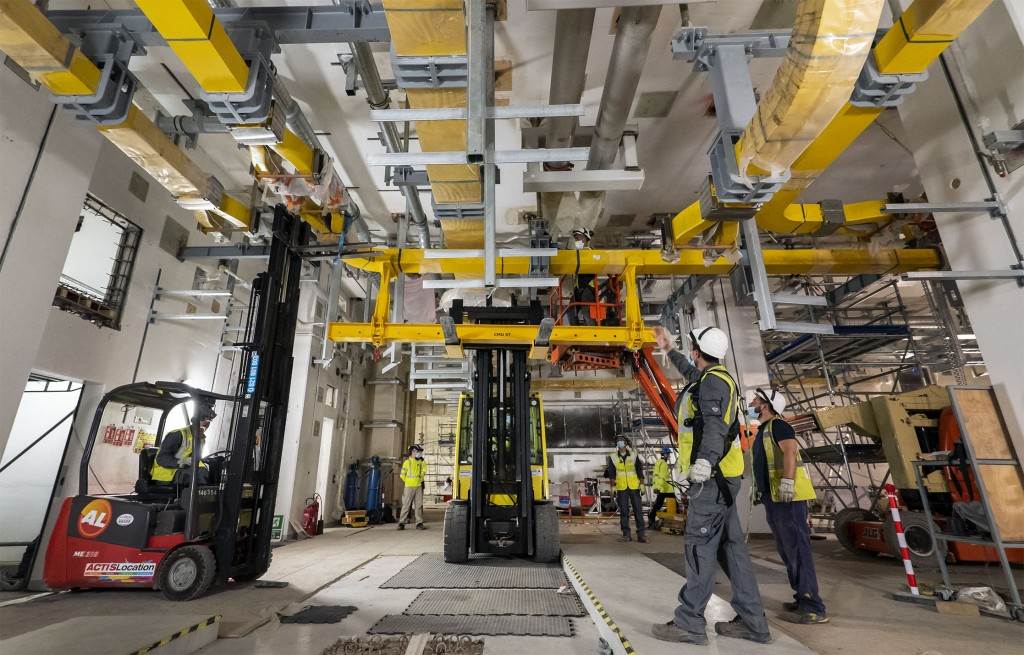

For the most complex and time-sensitive area—the Tokamak Complex—the choice has been made to split the works between two contractors, and to organize the division of scope by system, location and sequence (see detail below). Although the two assembly contractors for the Tokamak Complex work in distinct areas, their work scope contains many common elements.

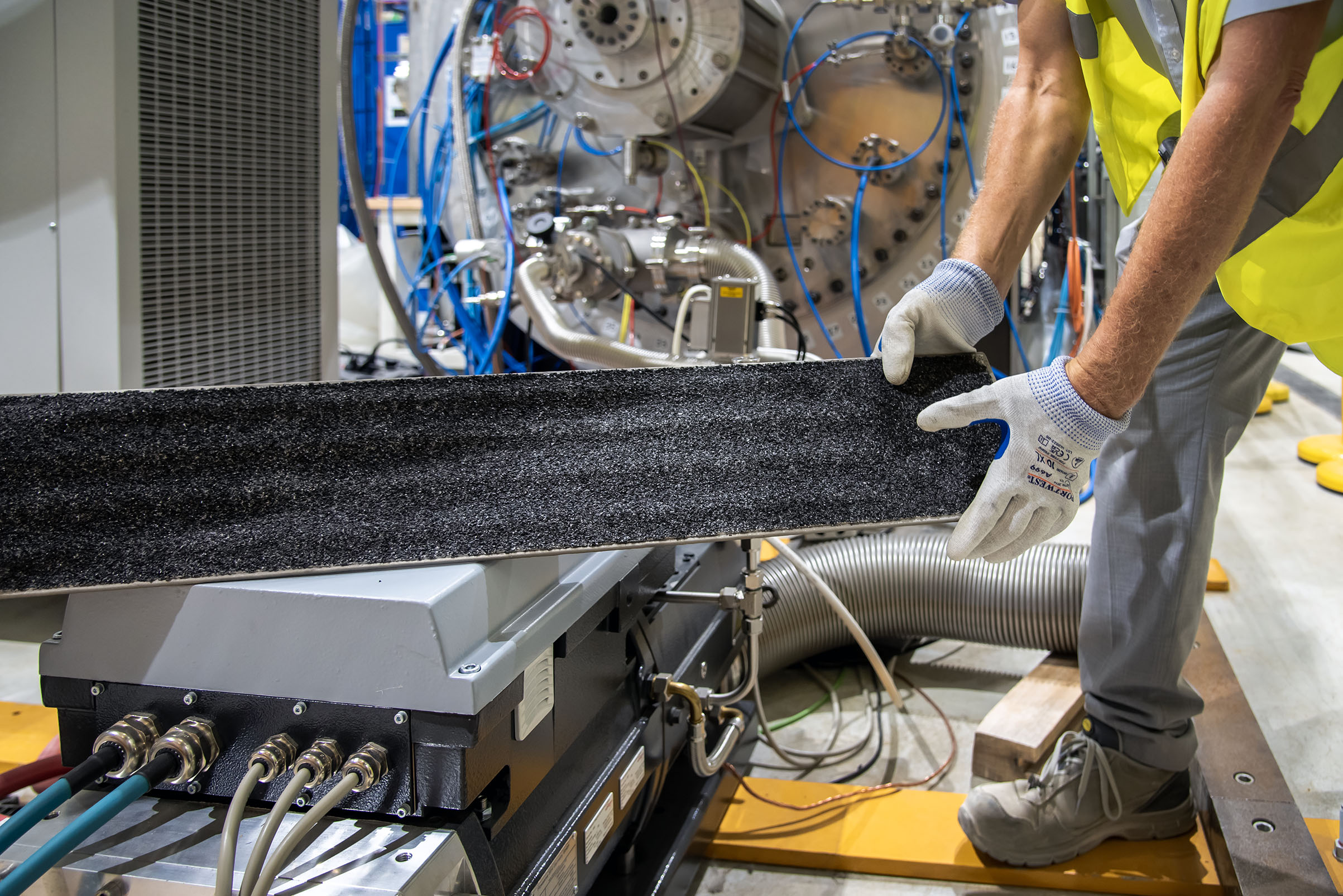

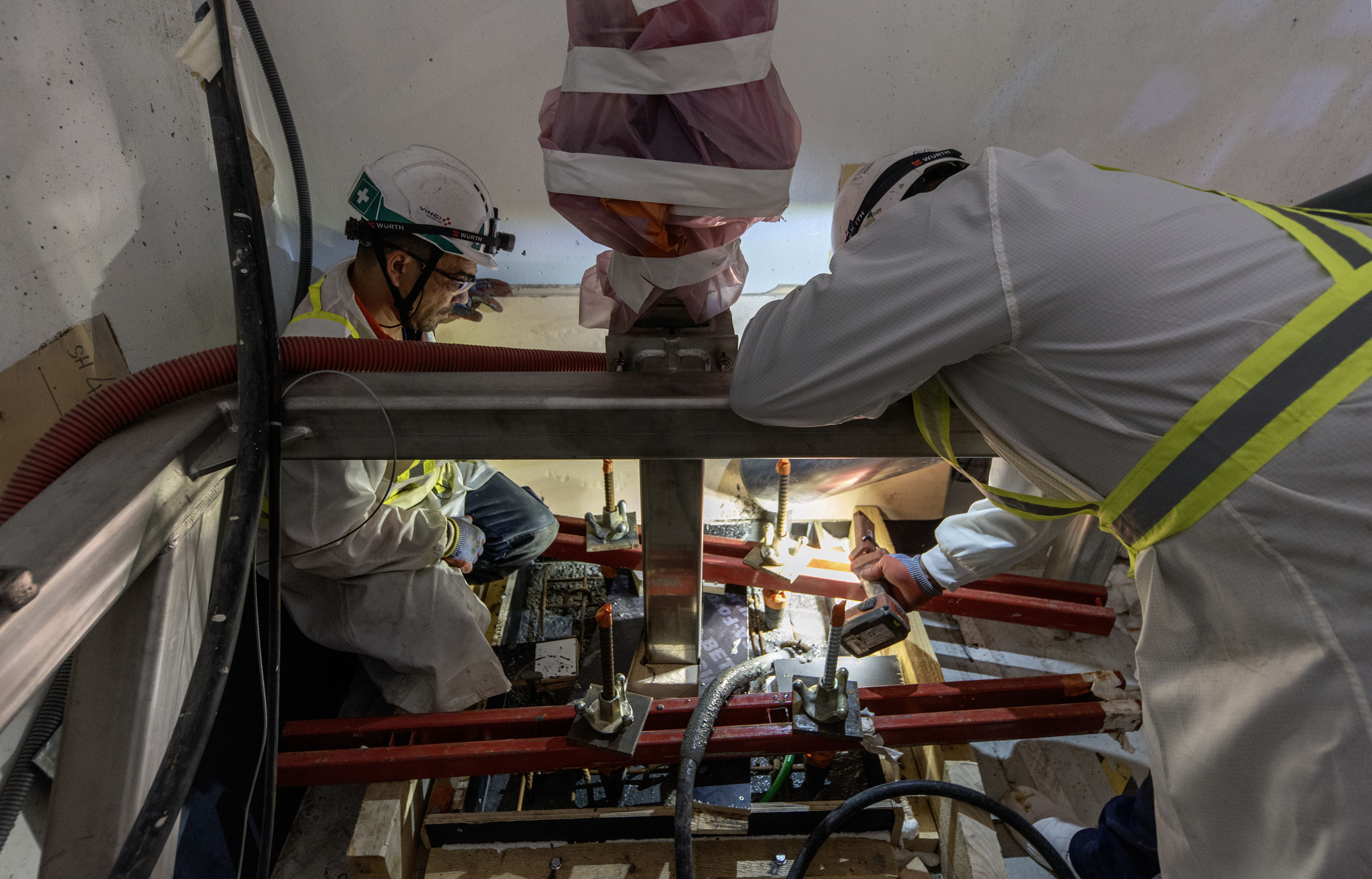

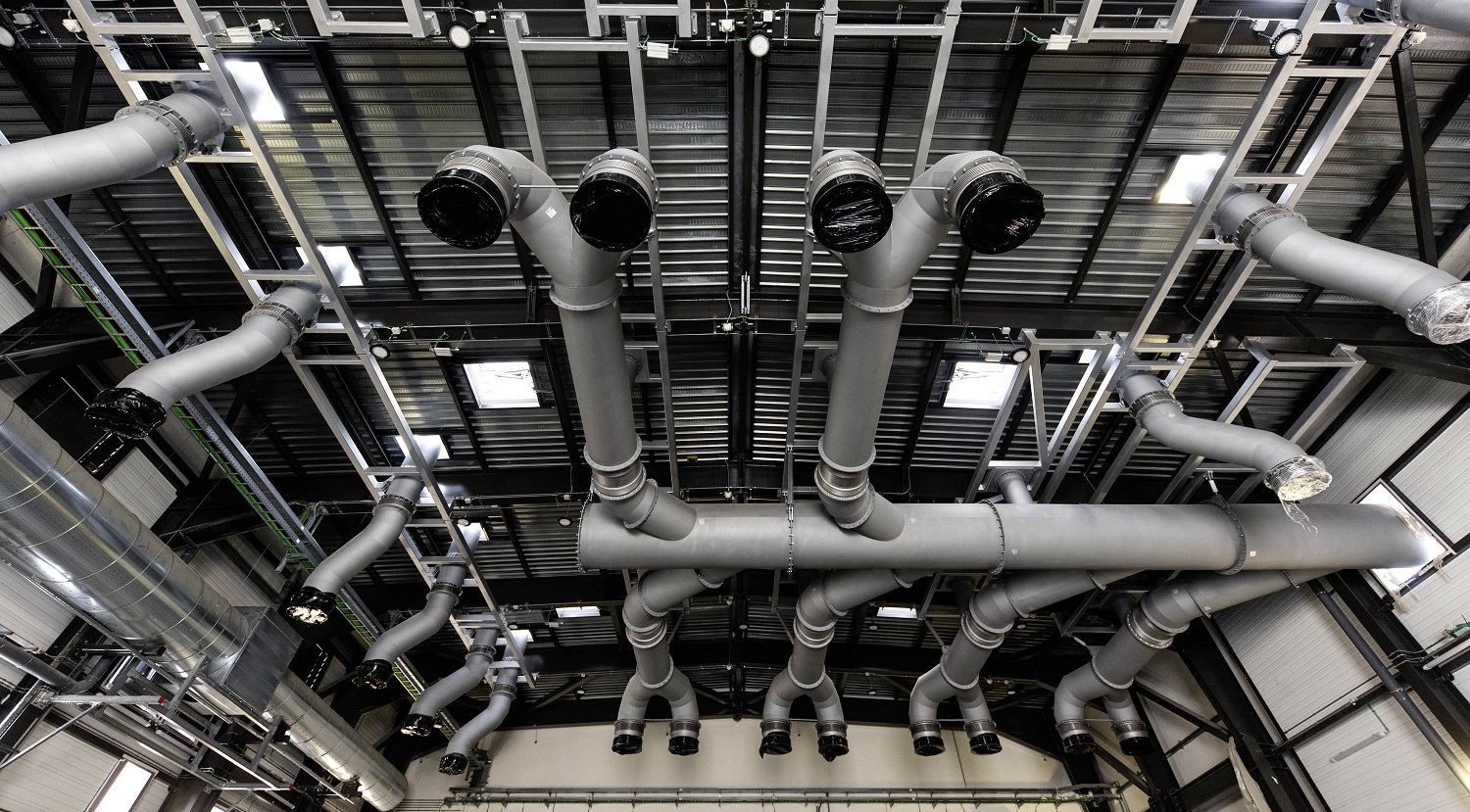

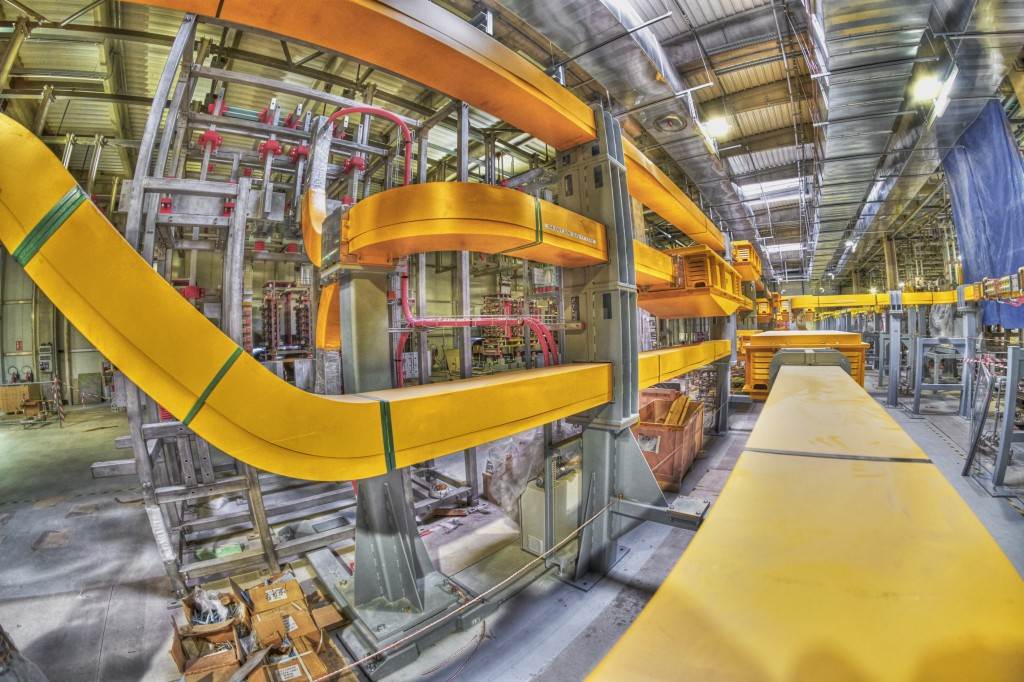

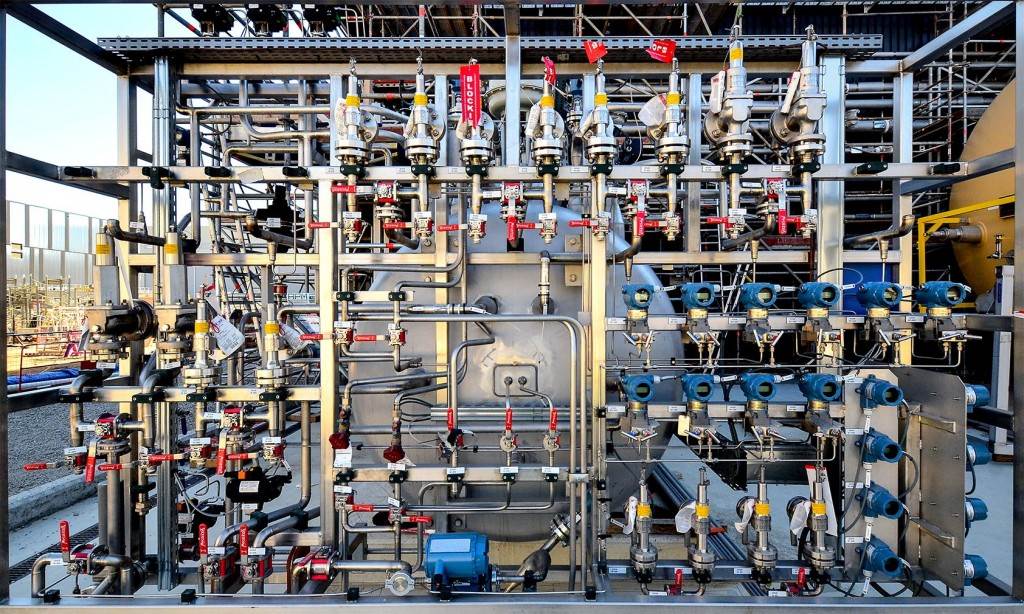

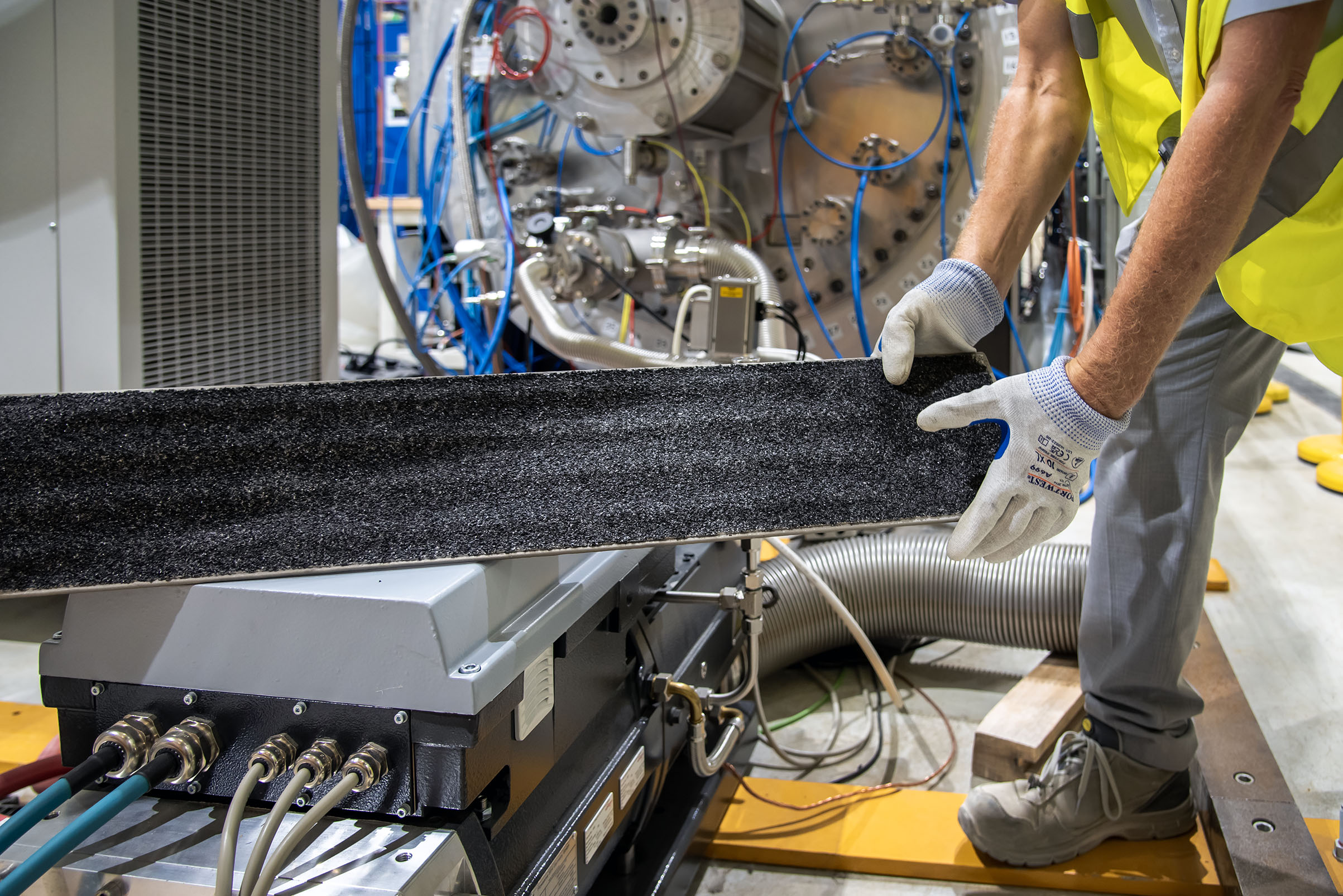

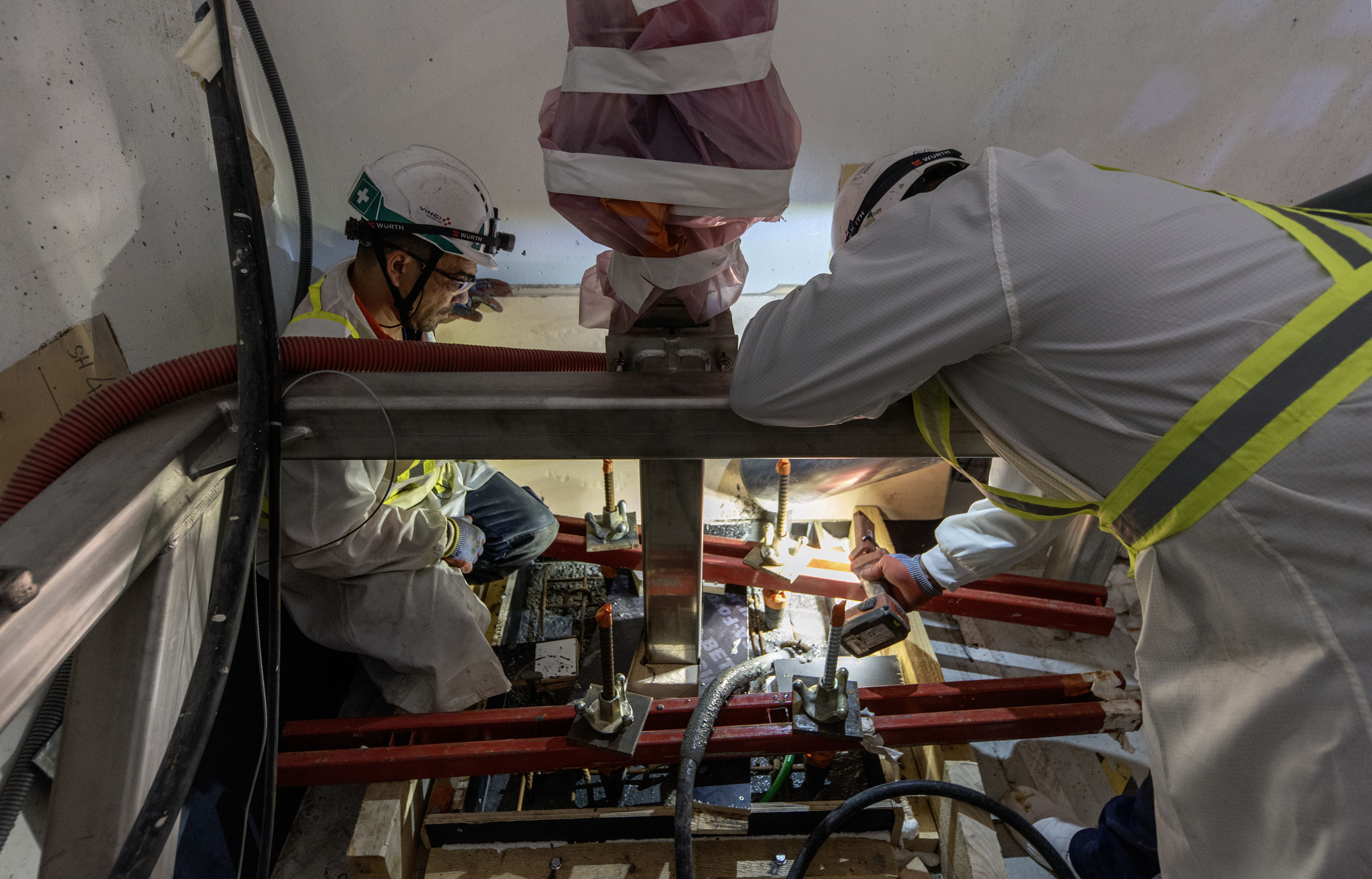

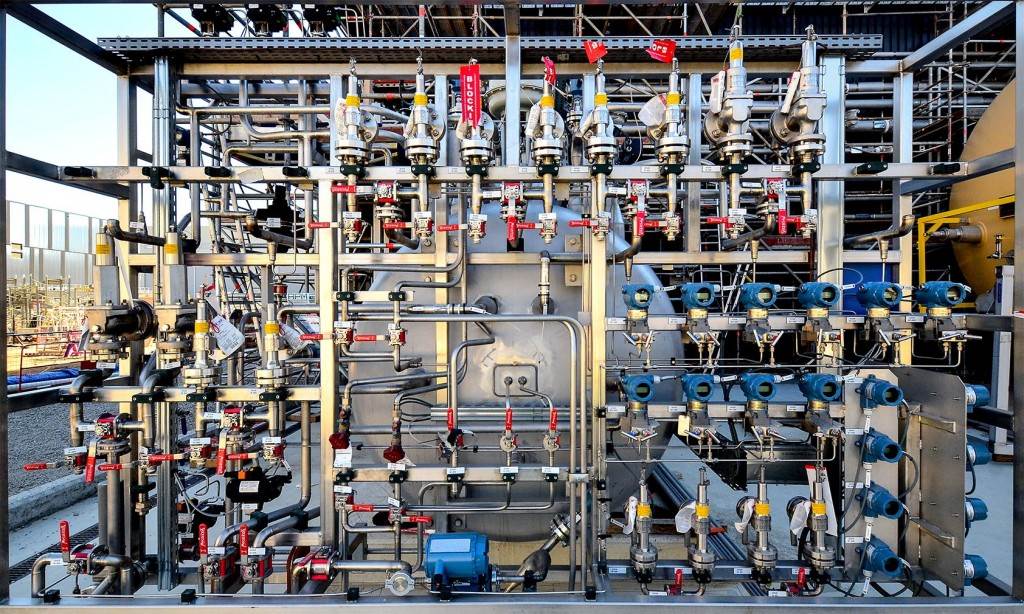

Mechanical and piping works: vessels, piping systems, heat exchangers, pumps, motors; cable trays and cable pulling; wave guides; piping thermal installation; pressure tests, flushing. Electrical, instrumentation and control: DC busbars, switching equipment, power cables, I&C cables and cabinets.

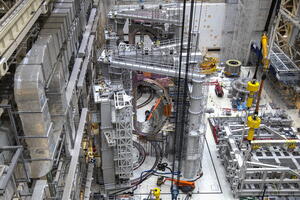

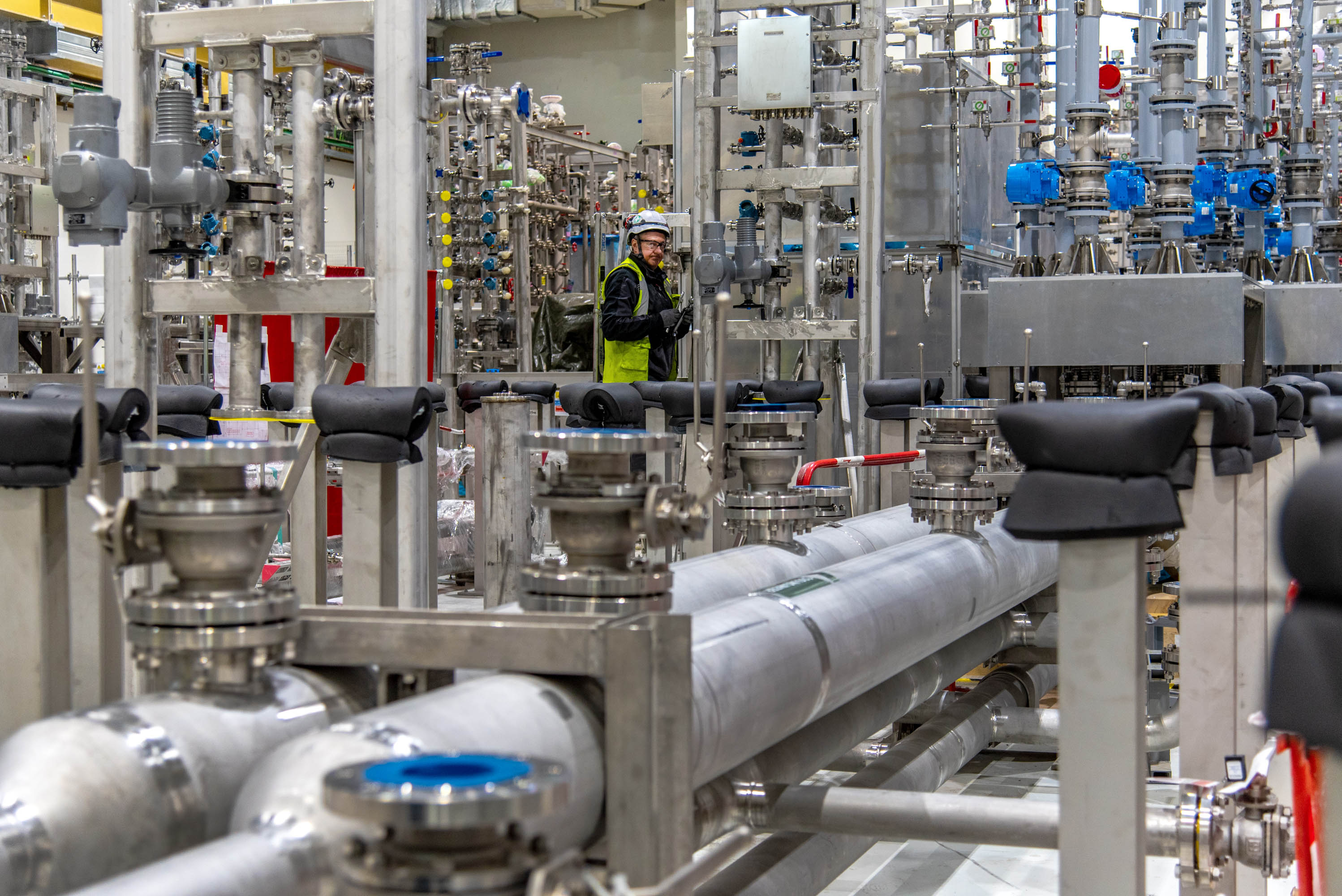

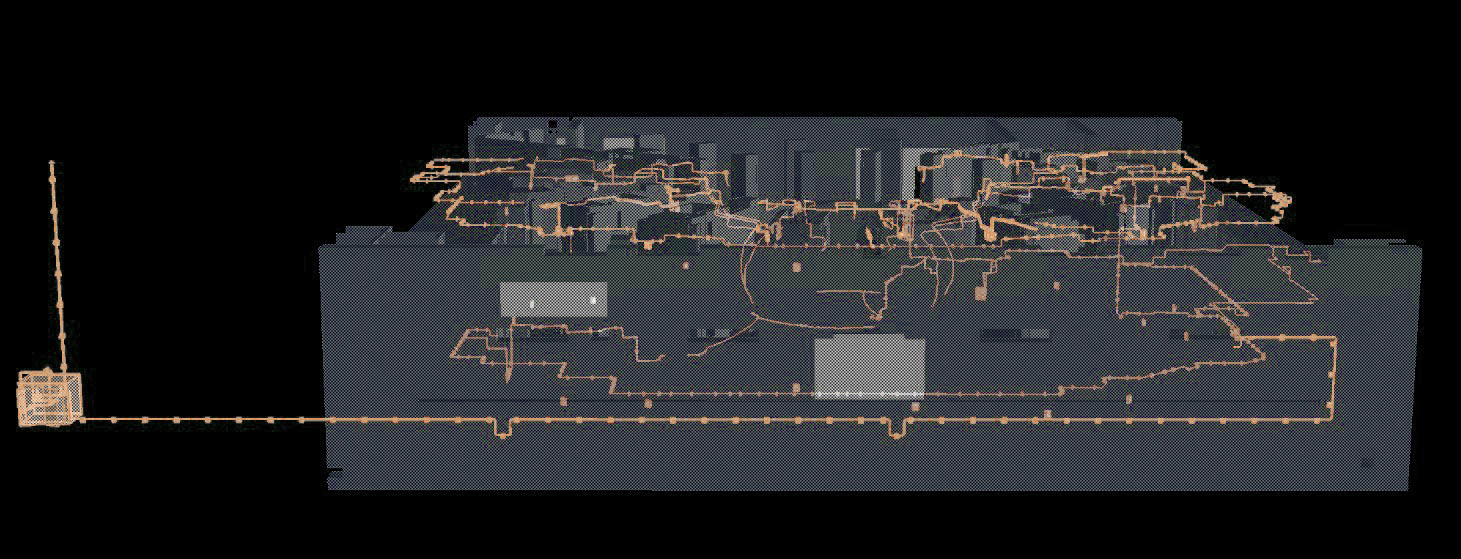

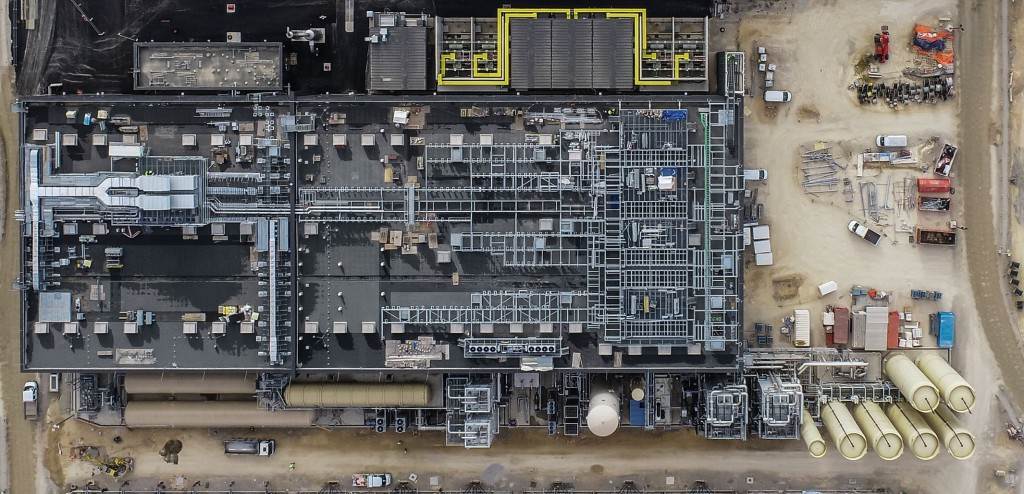

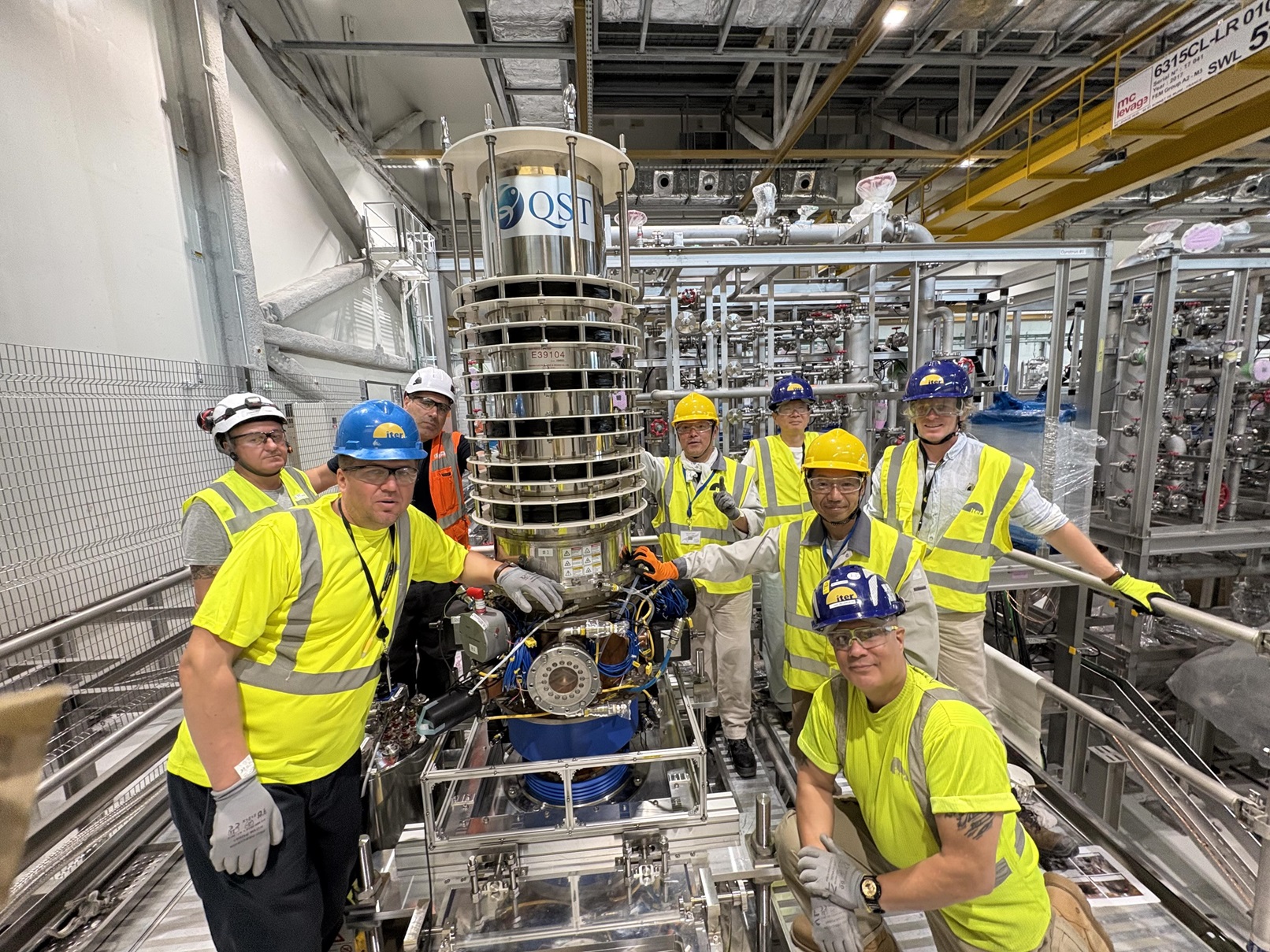

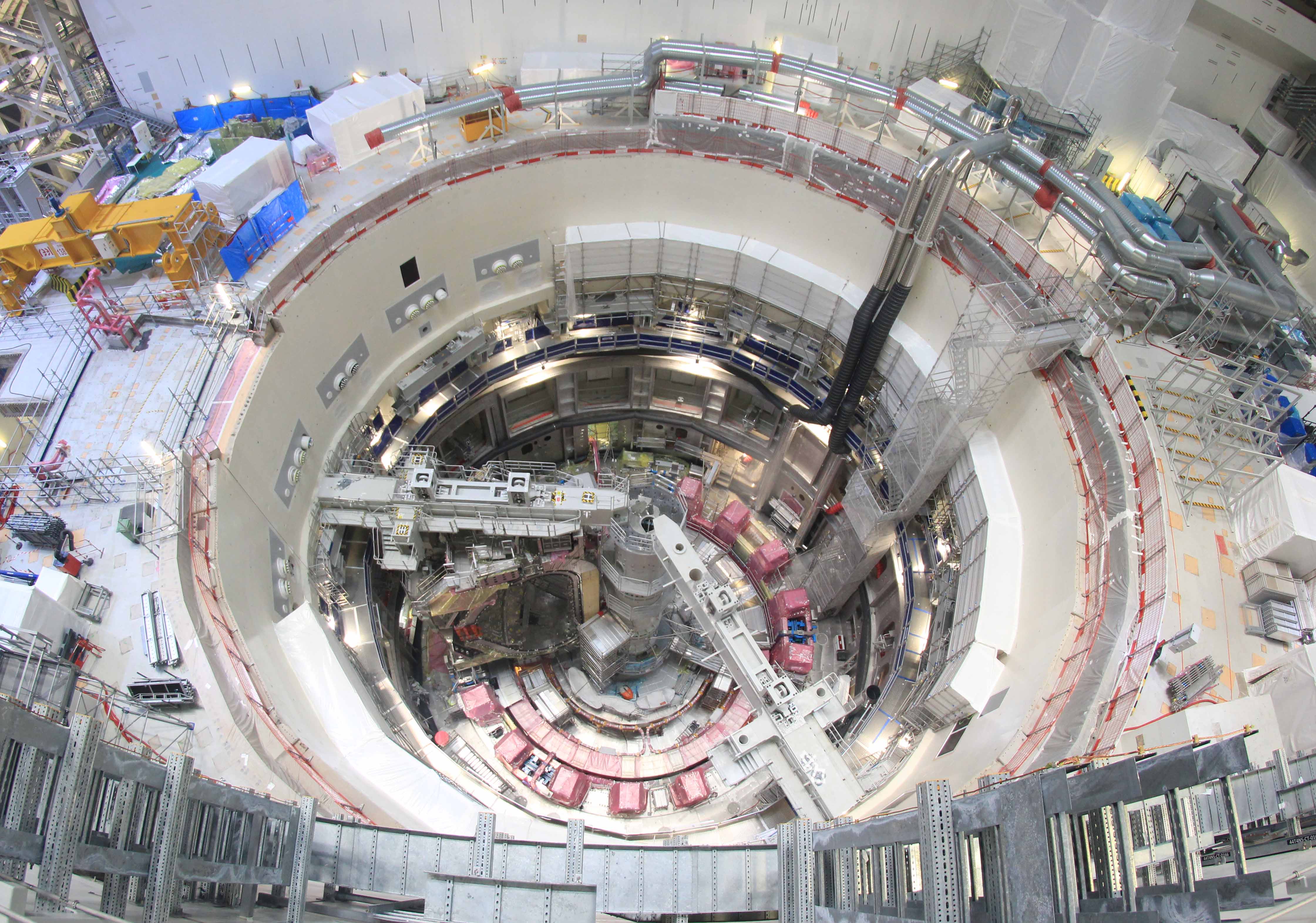

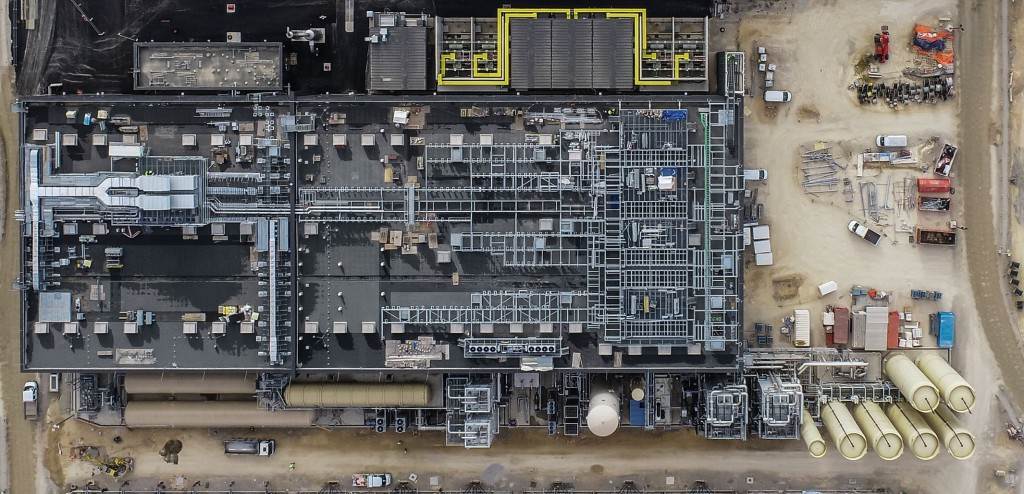

The installation of equipment is progressing in the Tokamak Complex. Work to install systems is also underway in plant buildings across the ITER platform; others have been fully equipped and turned over to the ITER Organization for commissioning.

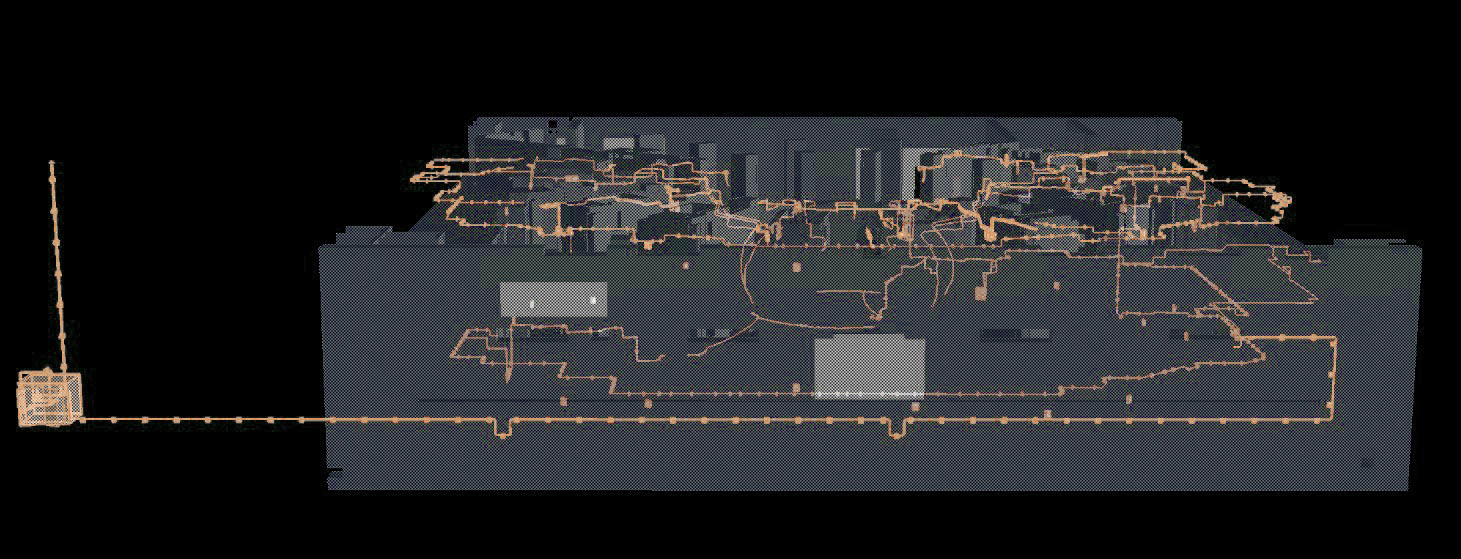

5

km cryolines

5000

km cables

40

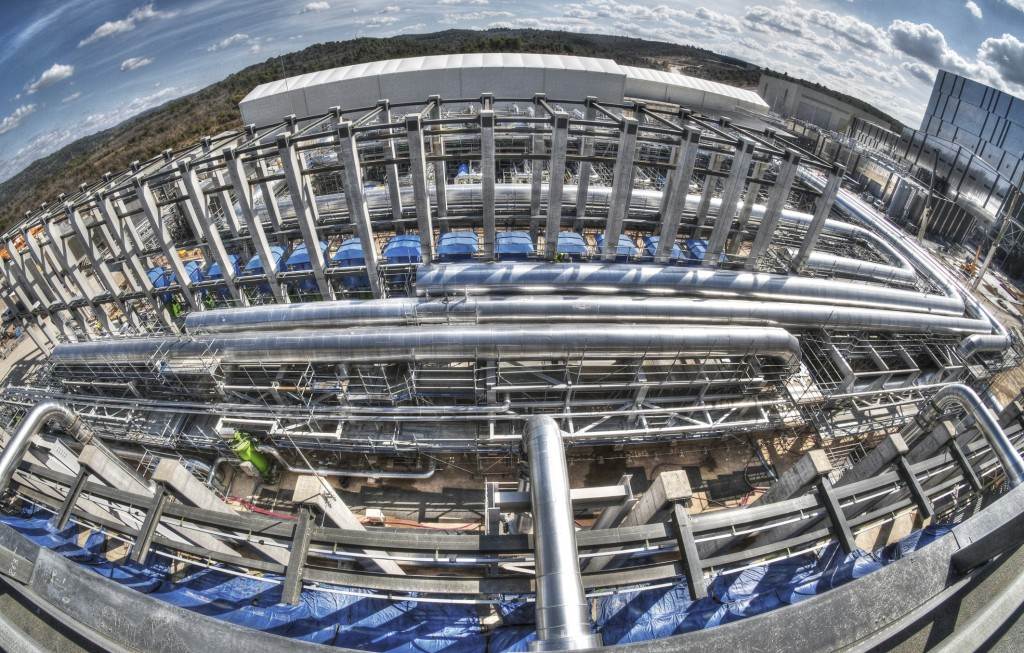

km cooling water piping

170

local control systems

ITER by drone - May 2025 (subtitle version)

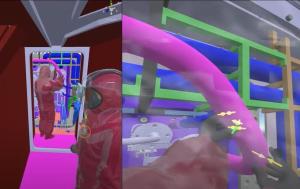

Augmented reality and plant installation (video)

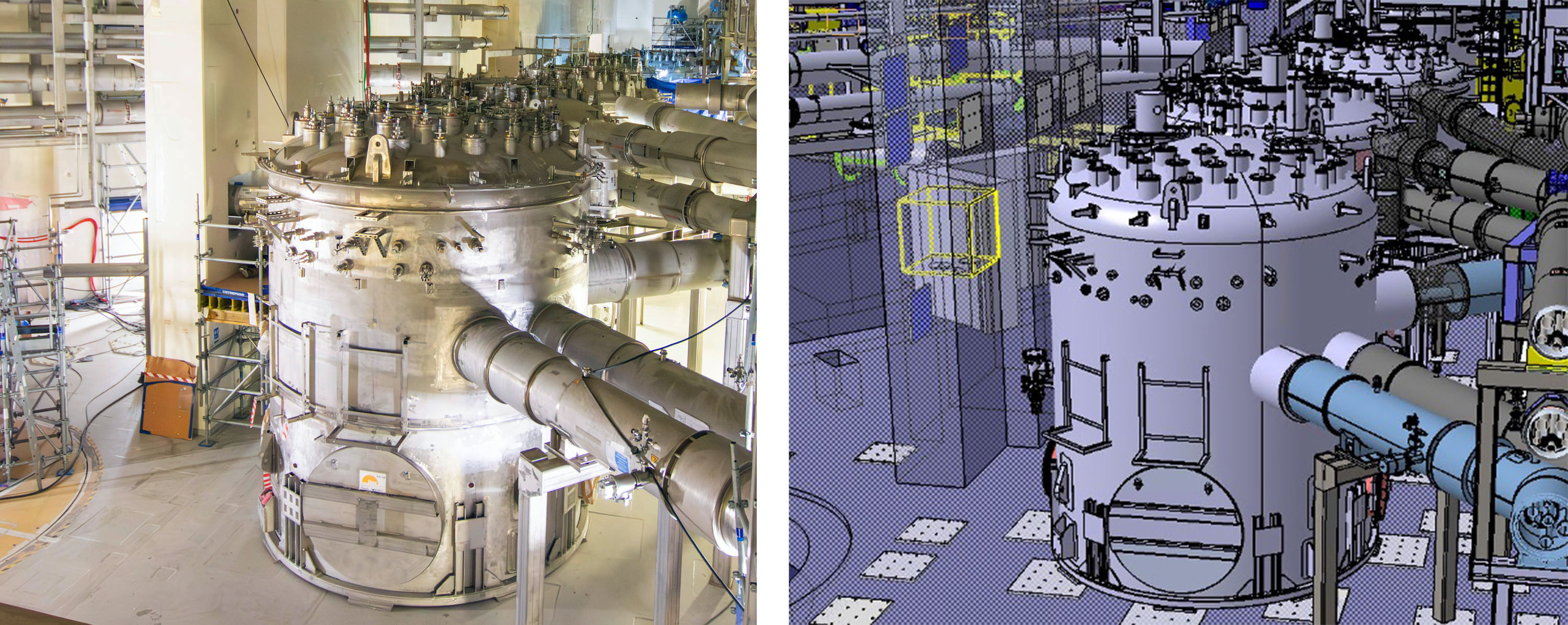

Going deeper and deeper into virtual reality

ITER's cryogenic system (Air Liquide)

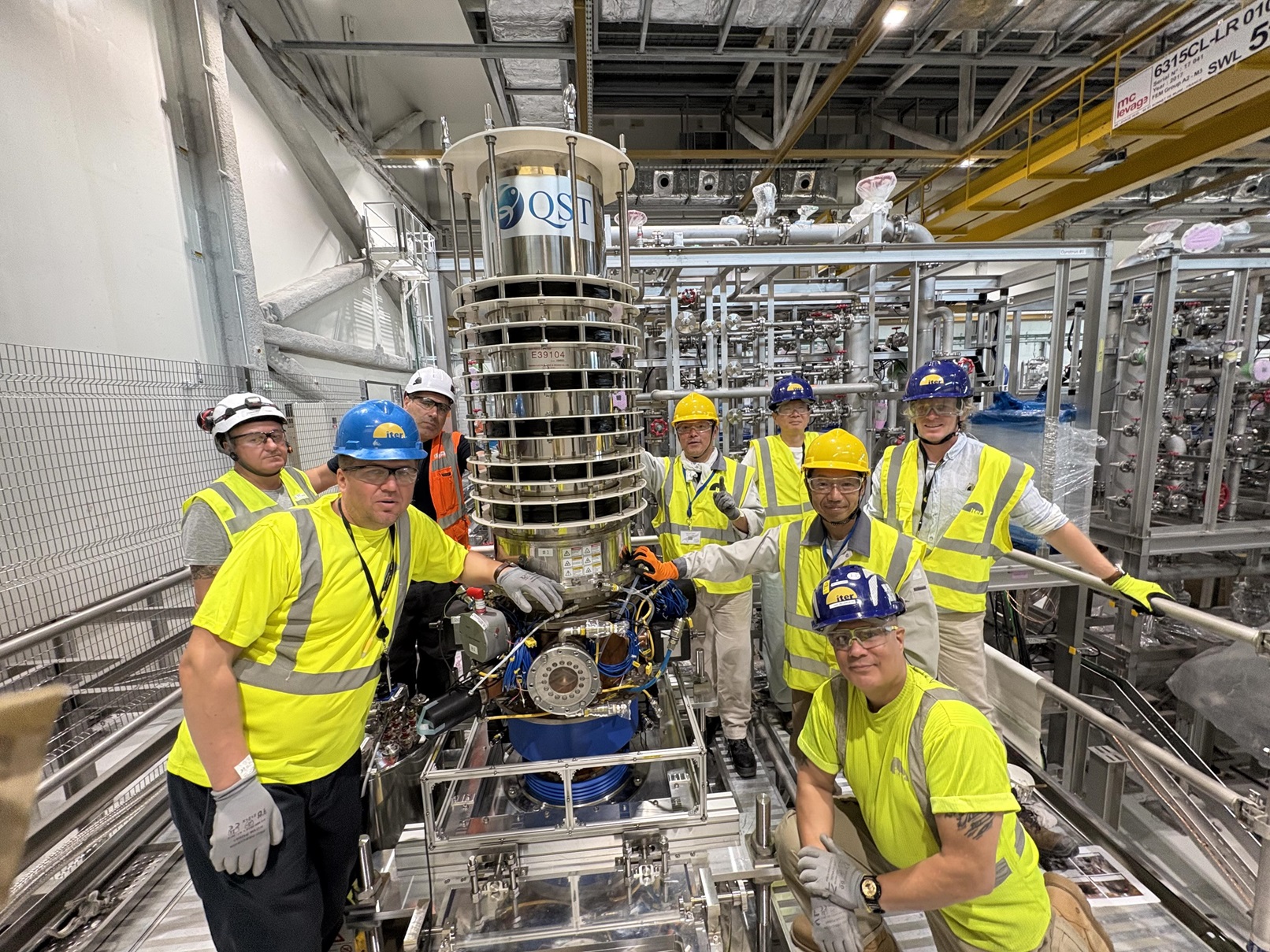

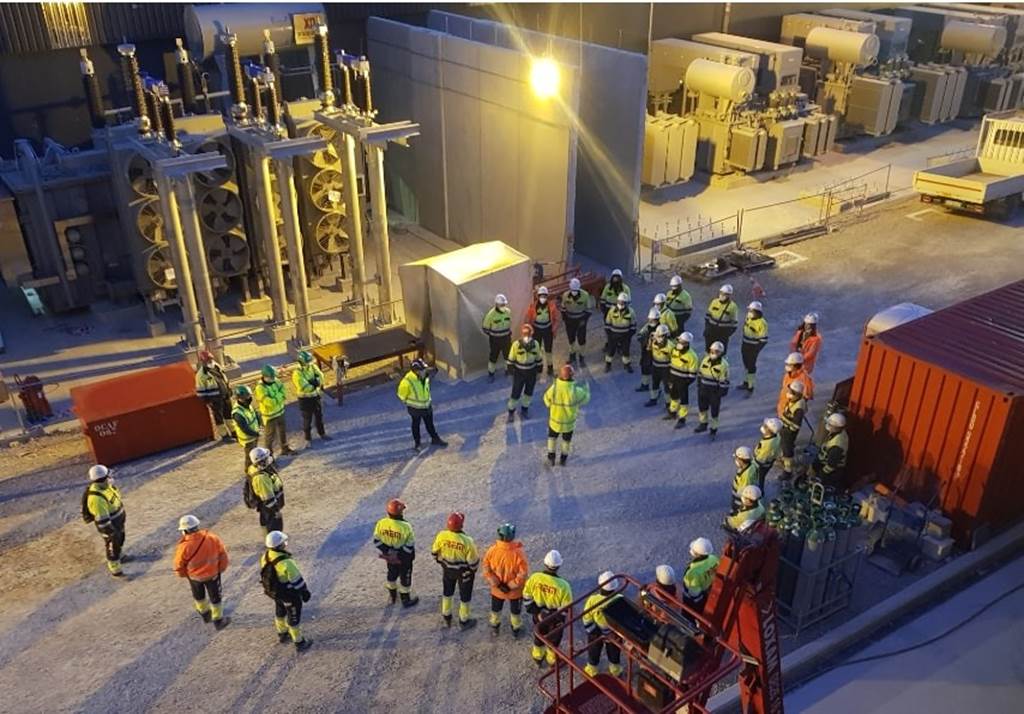

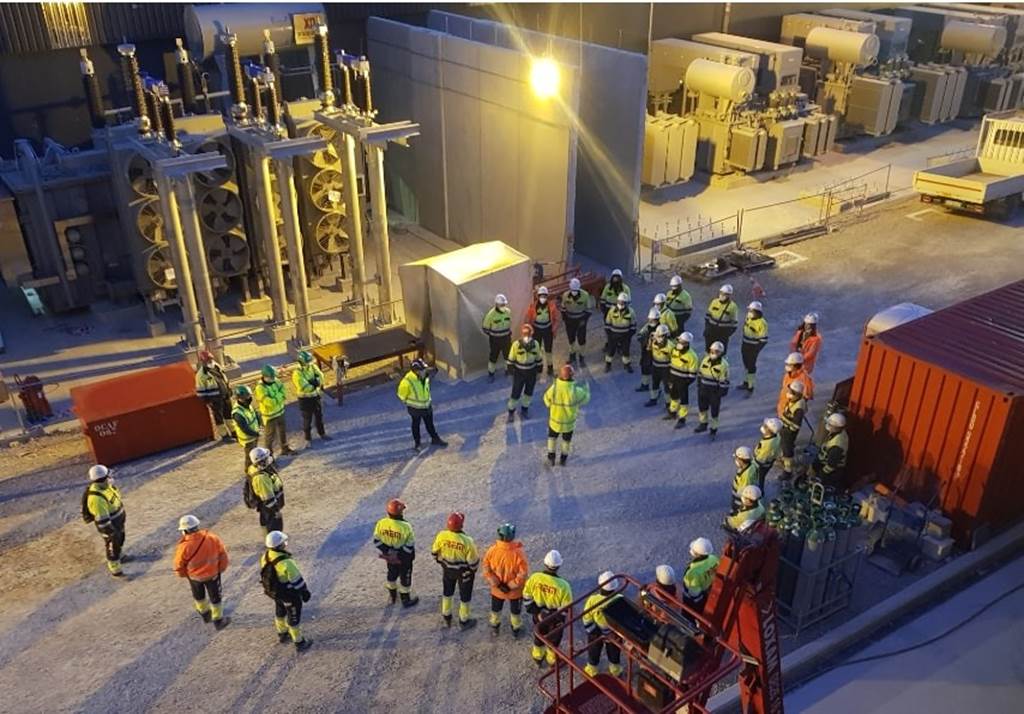

Contractors carrying out the day-to-day work under the oversight of the ITER Organization:

TCC/1

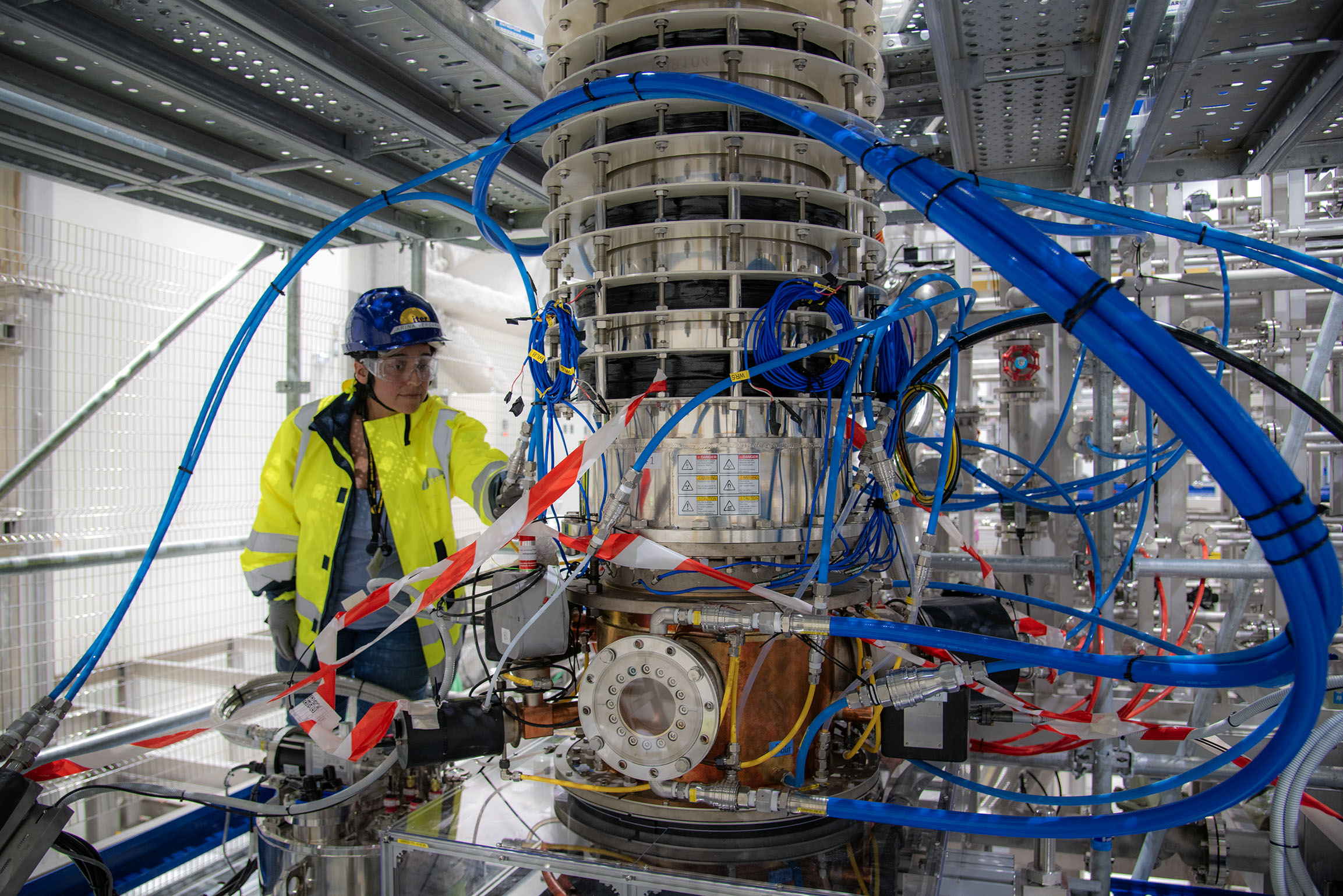

Tokamak Complex Contract 1: Fincantieri Consortium (Fincantieri S.p.A., Fincantieri SI S.p.A., Delta-ti Impianti S.p.A., Comes S.p.A.) For the installation of heating and current drive, diagnostics, fuelling, secondary cooling, and vacuum components.

TCC/2

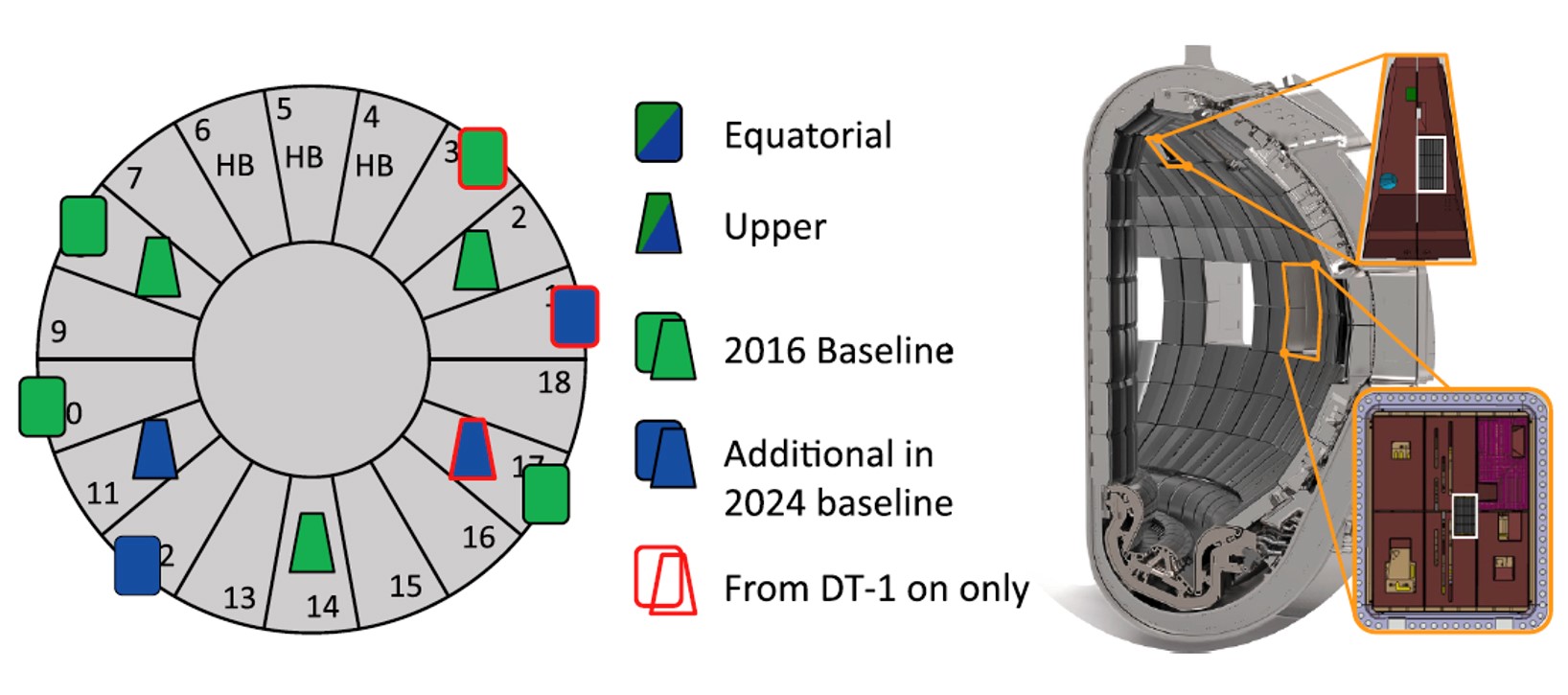

Tokamak Complex Contract 2: META SNC (Cobra Instalaciones y Servicios SA, and Empresarios Agrupados Internacional SA.) For the installation of primary machine cooling water, test blanket module equipment, some vacuum pipework, vacuum vessel pressure suppression.

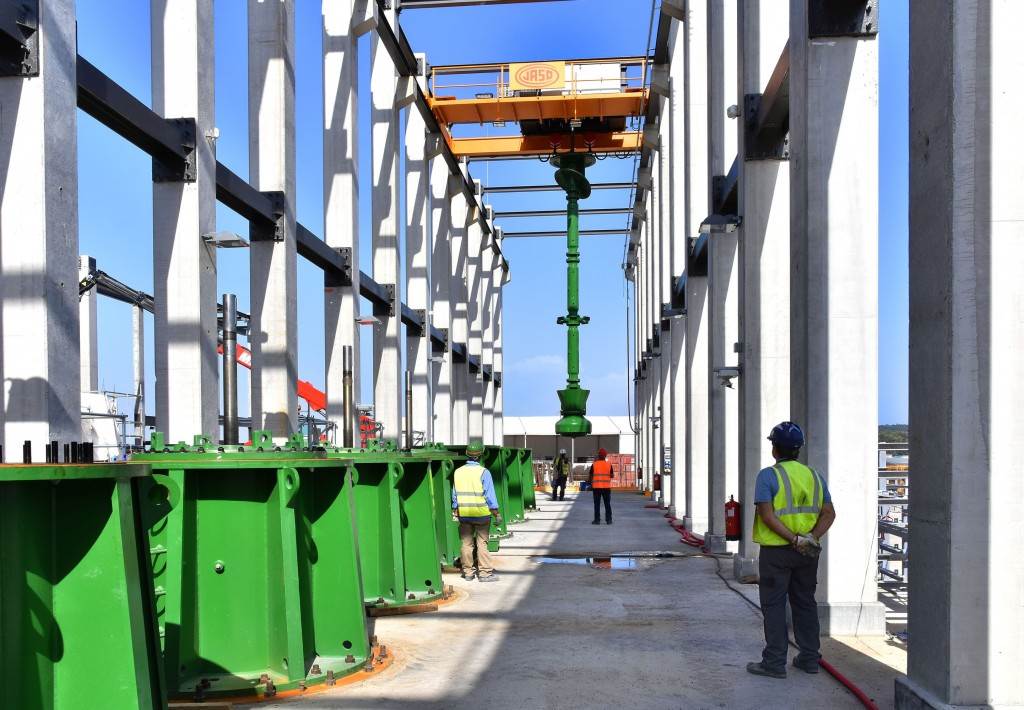

BALANCE OF PLANT

Work on the platform has been divided into these contracts: Group 1 - equipment installation in the Magnet Power Conversion buildings; Group 2 - installation of cooling water plant; Group 3 - electrical distribution; Group 4 - installation of multi-process lines; Group 5 - installation of DC busbars, switching networks and fast discharge units; Group 6 - installation of converters, transformers, reactive power compensation units, and harmonic filters.