The Project

- Building ITER

- Projects Underway

- Construction Archives

- Neutral Beam Test Facility

- Assembly Overview

- Tokamak Assembly

- Plant Assembly

- Commissioning

- Assembly Tooling

- Metrology

- Project Milestones

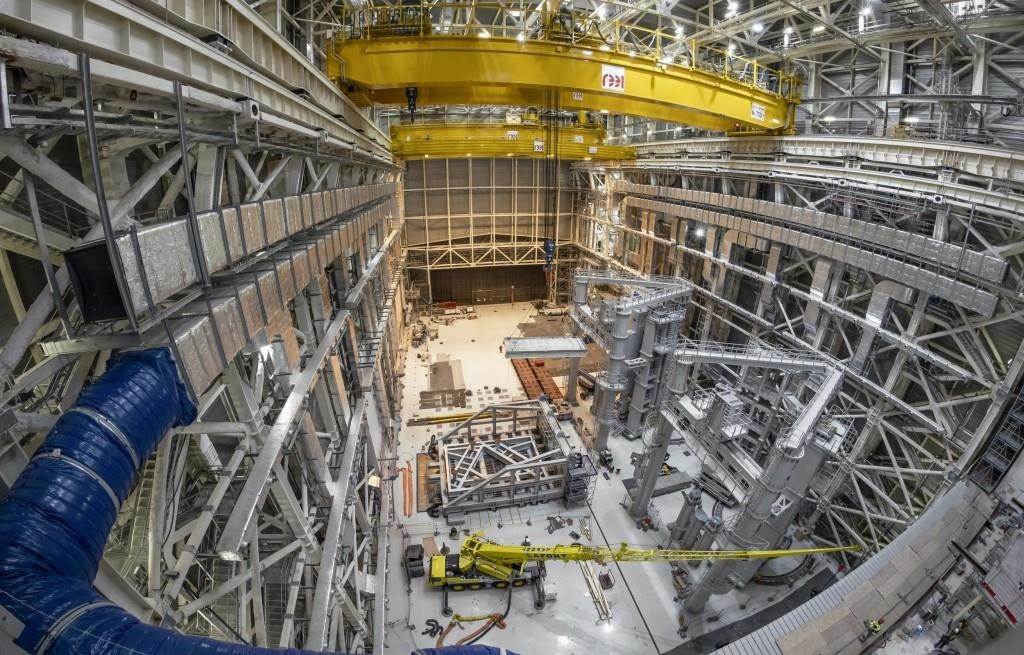

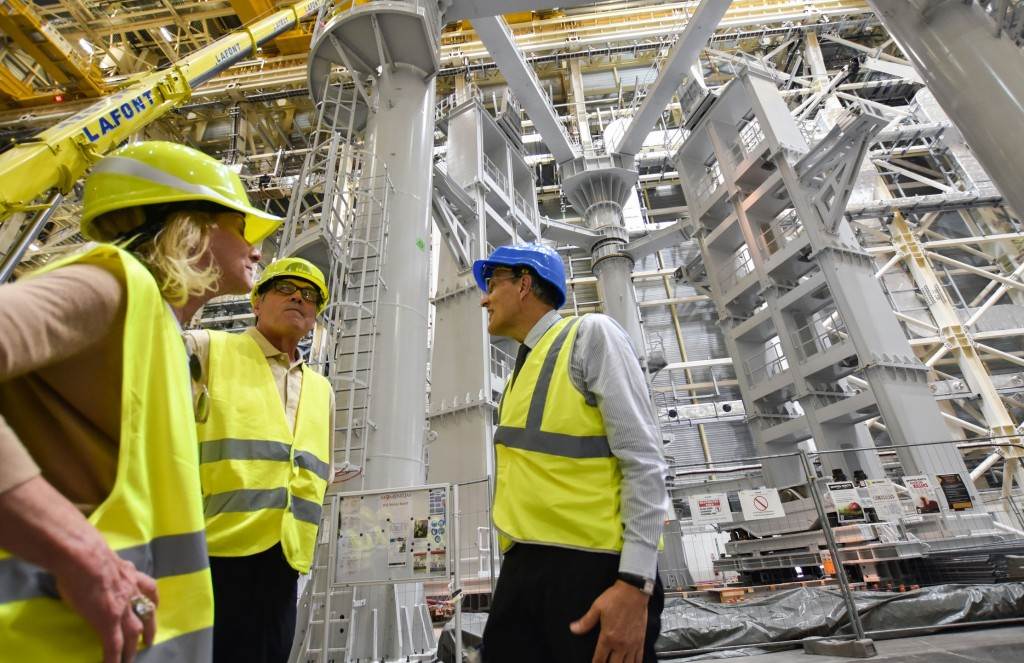

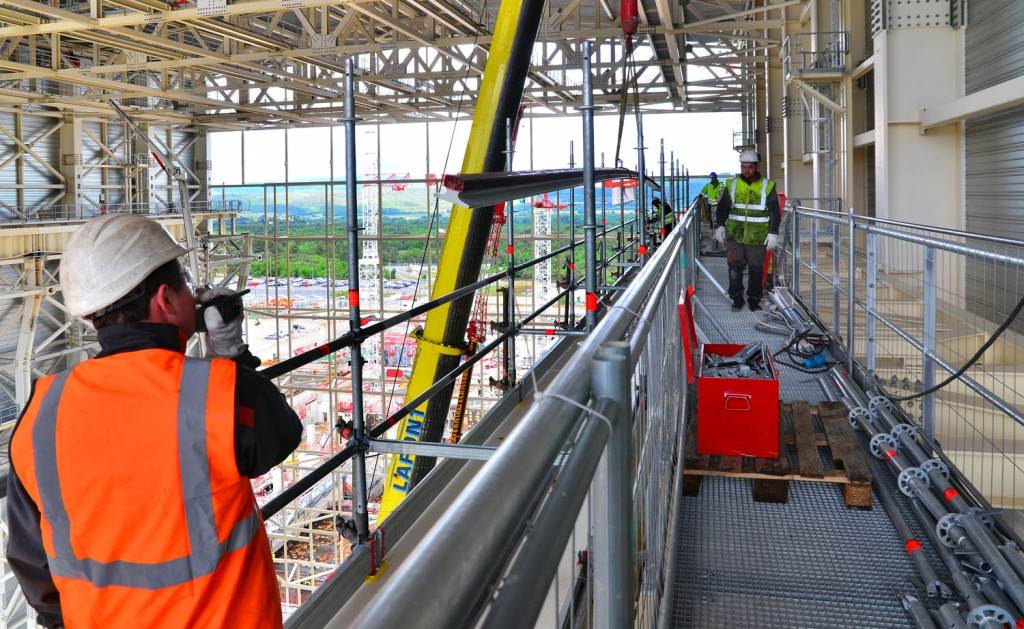

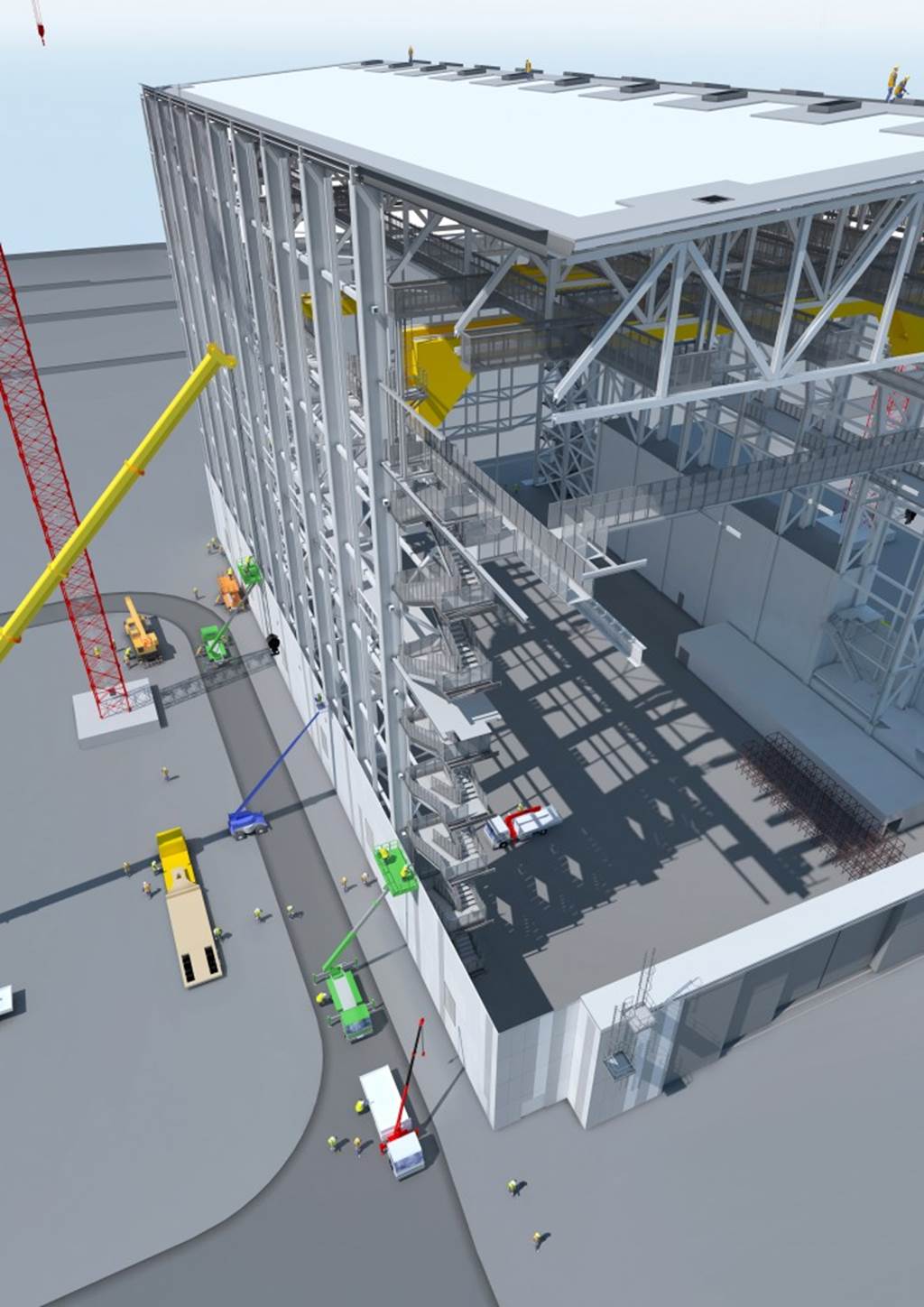

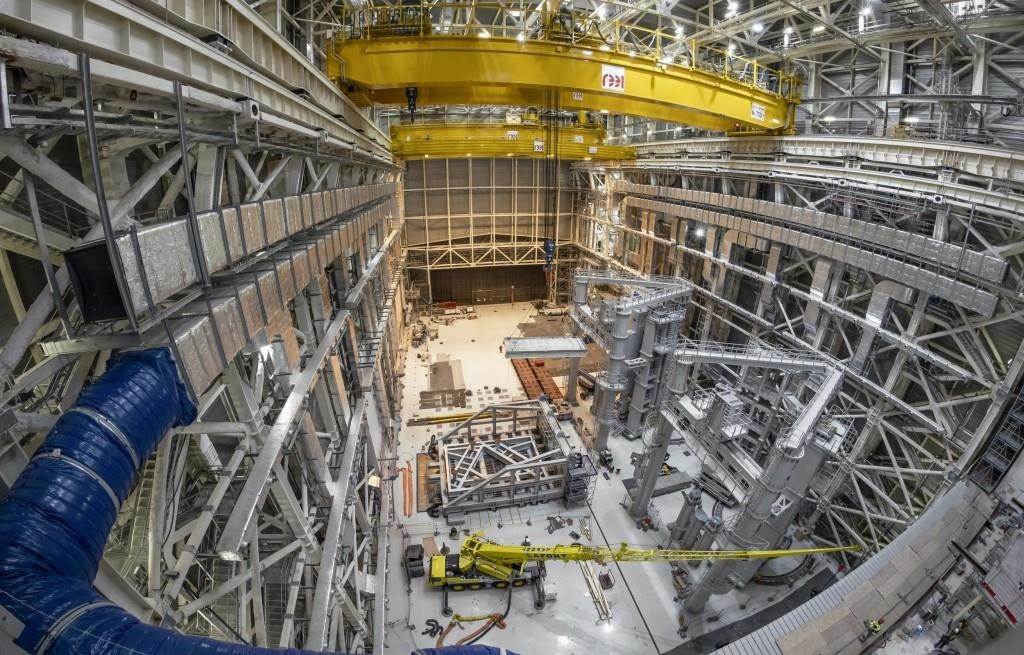

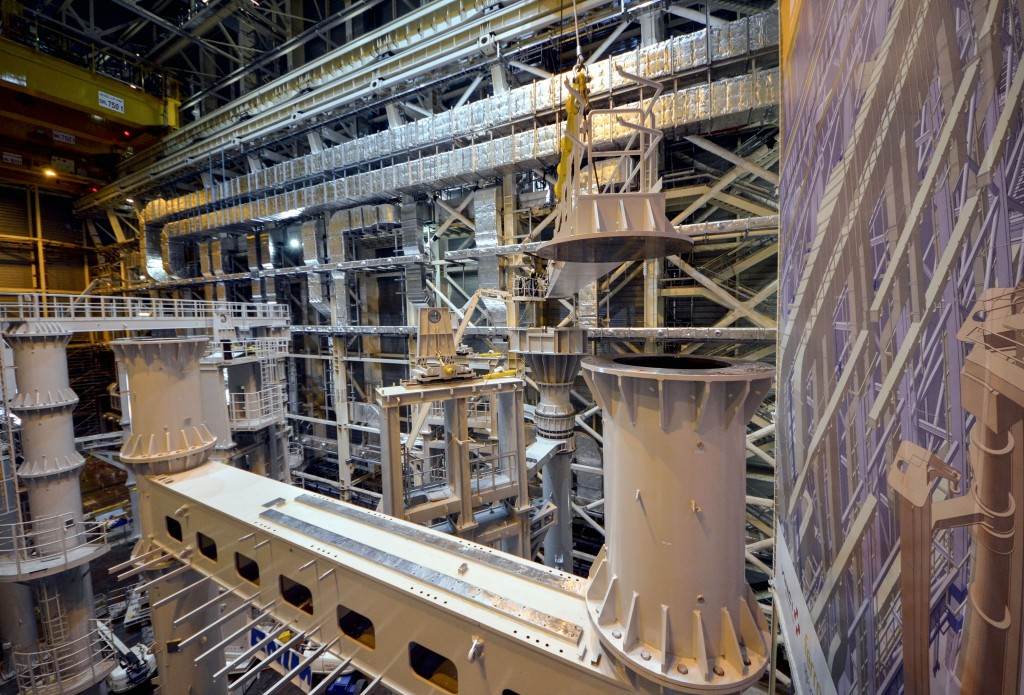

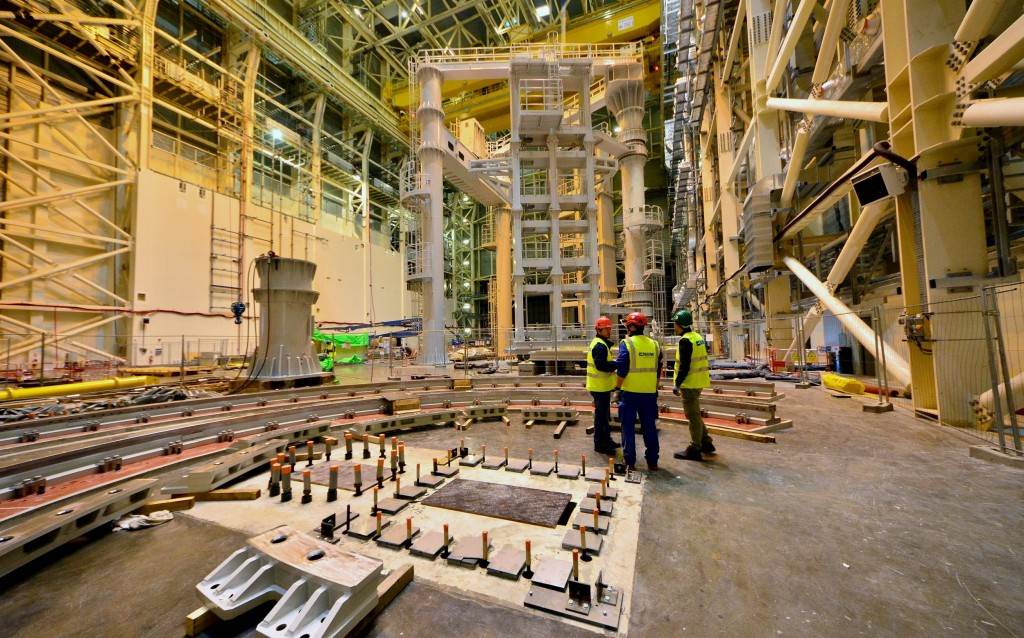

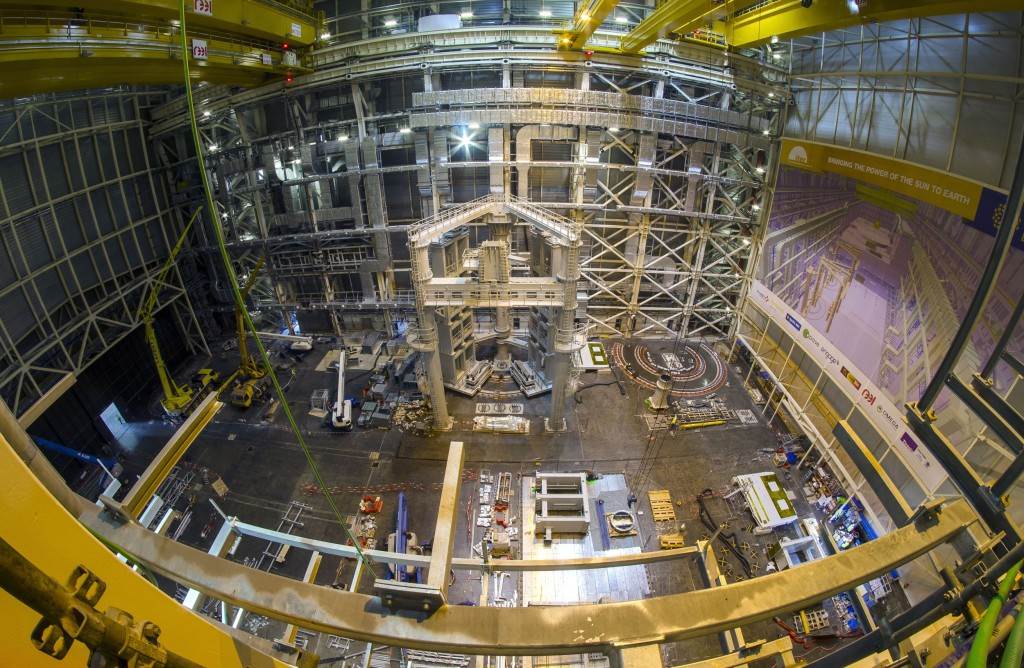

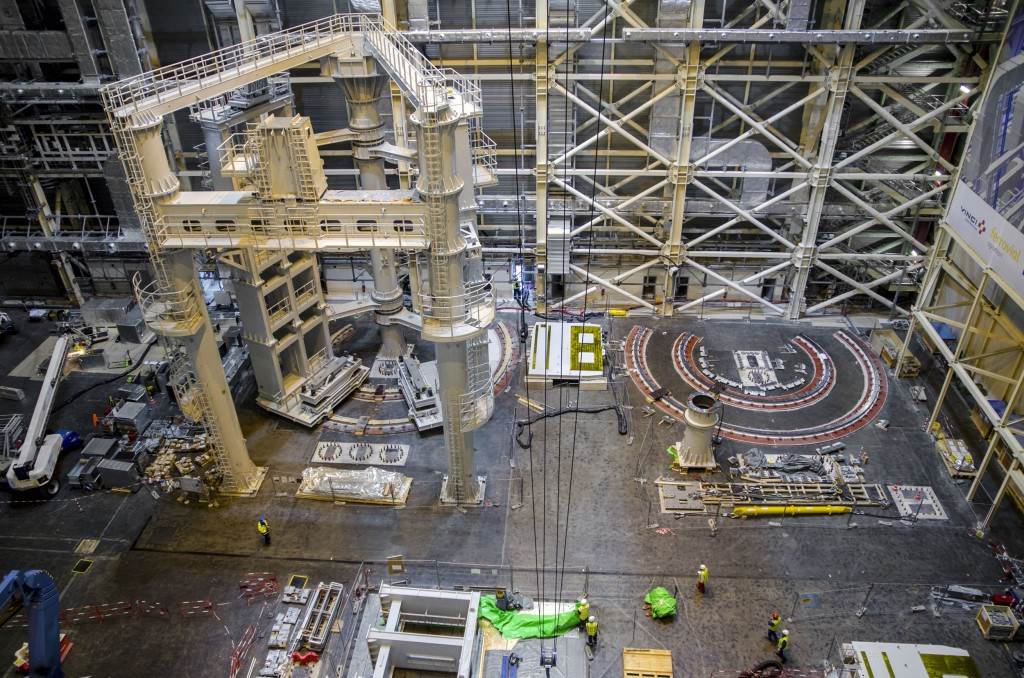

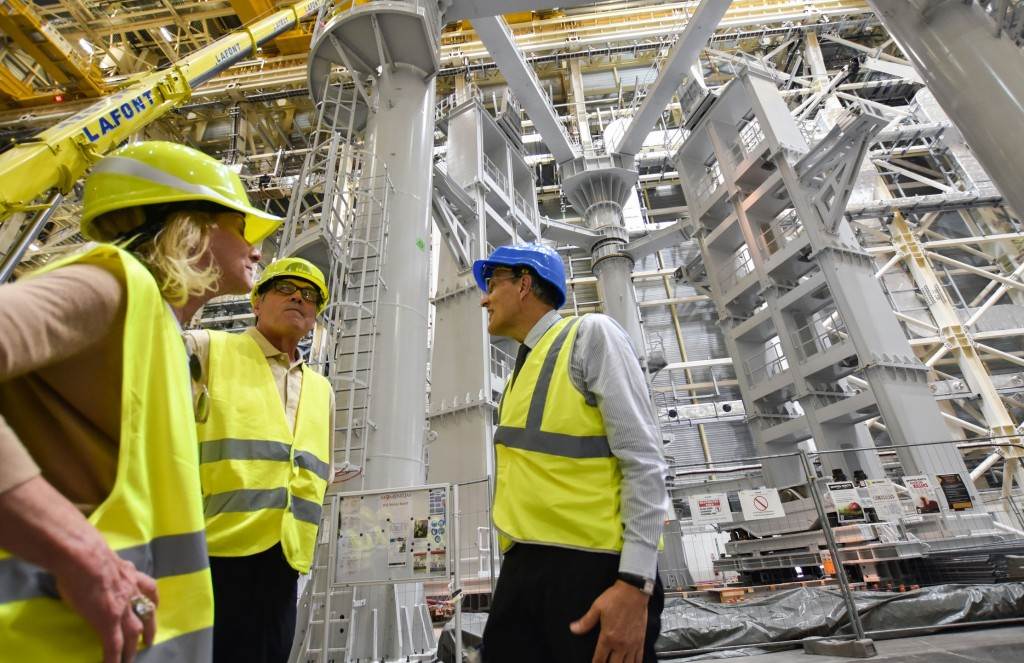

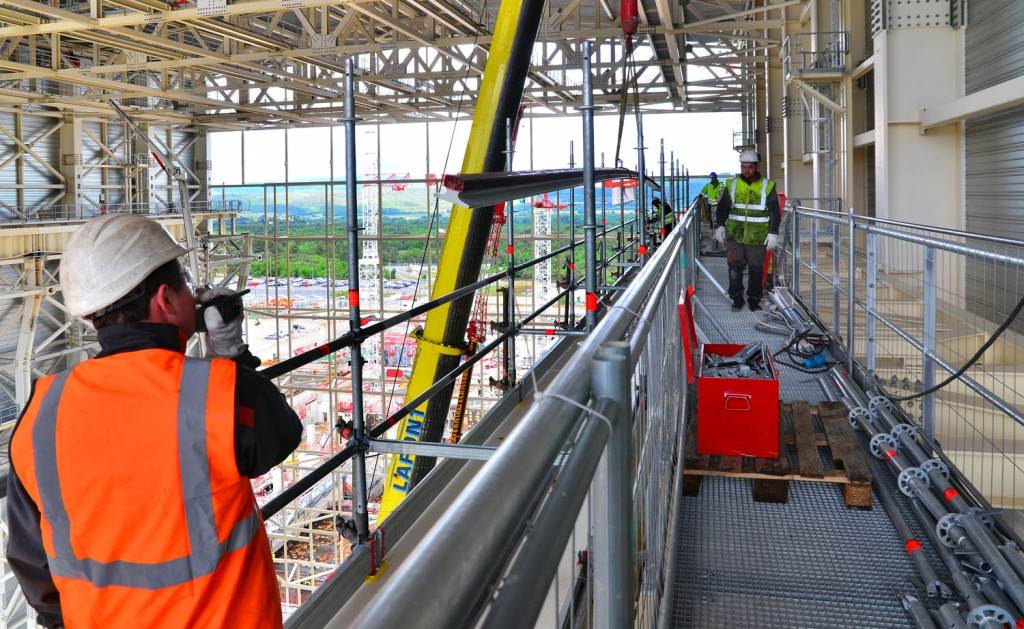

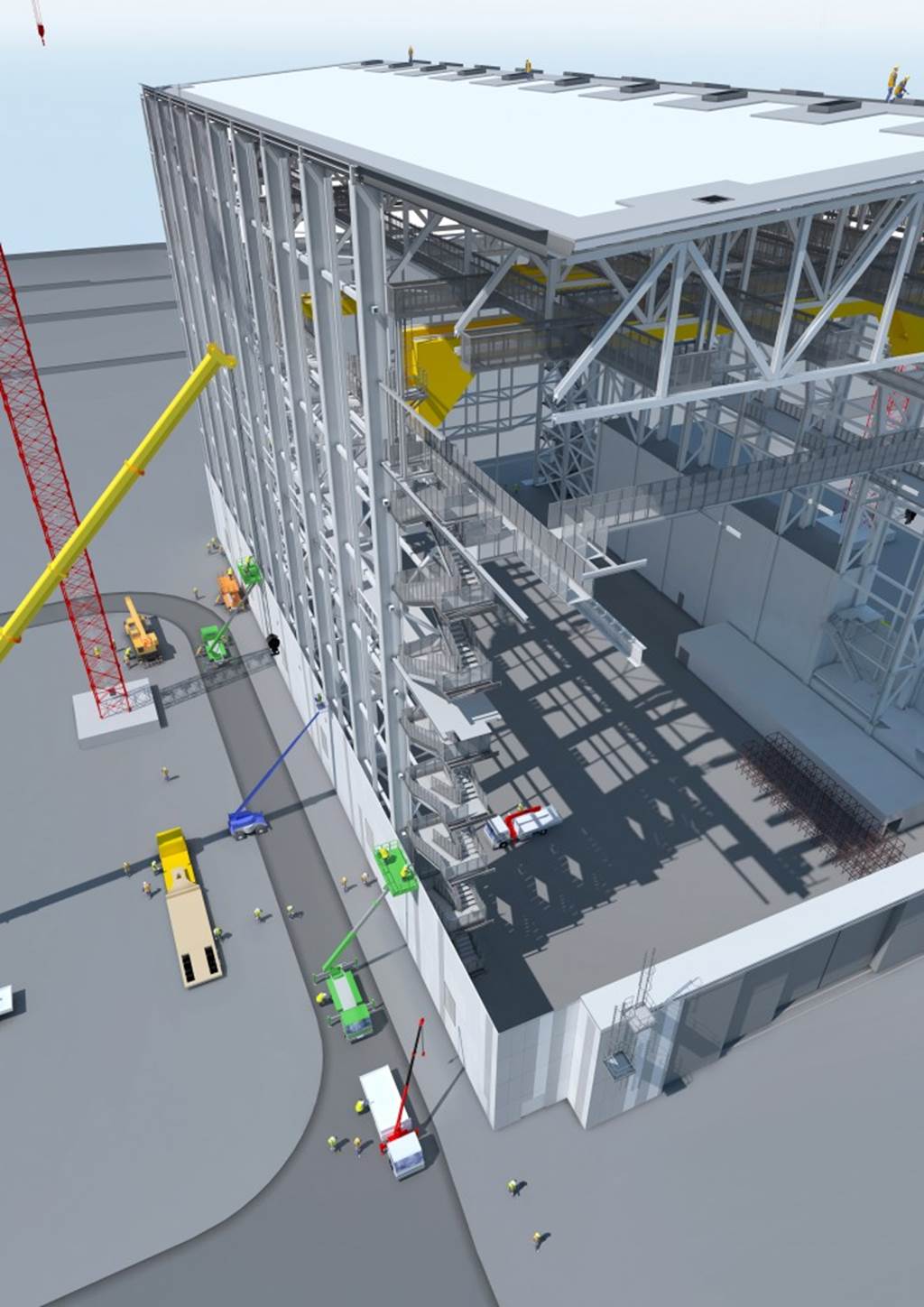

Assembly Hall

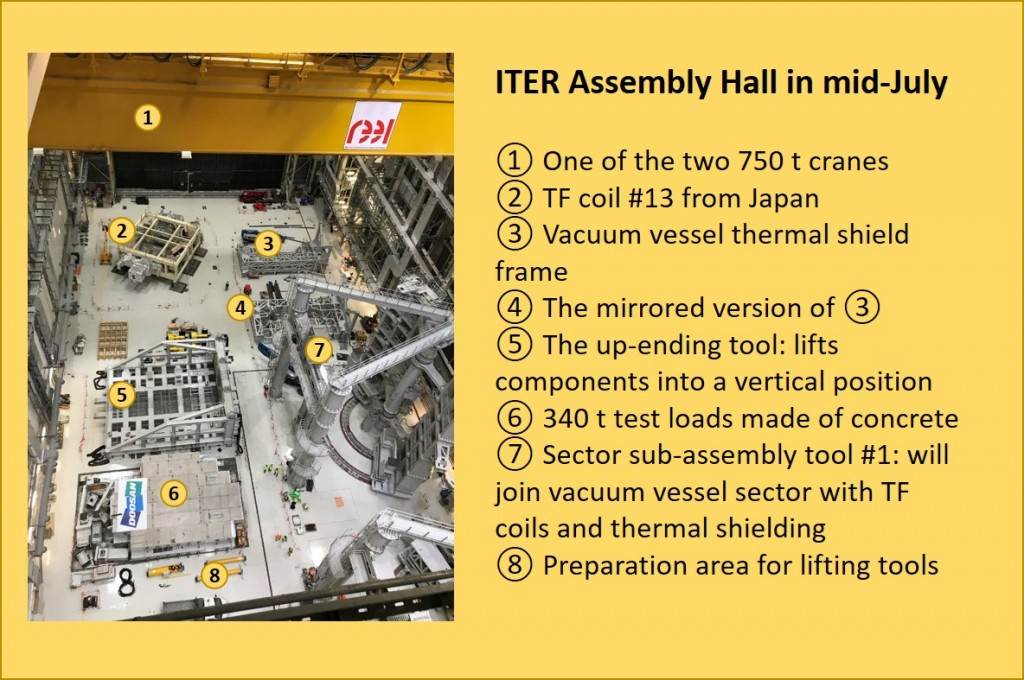

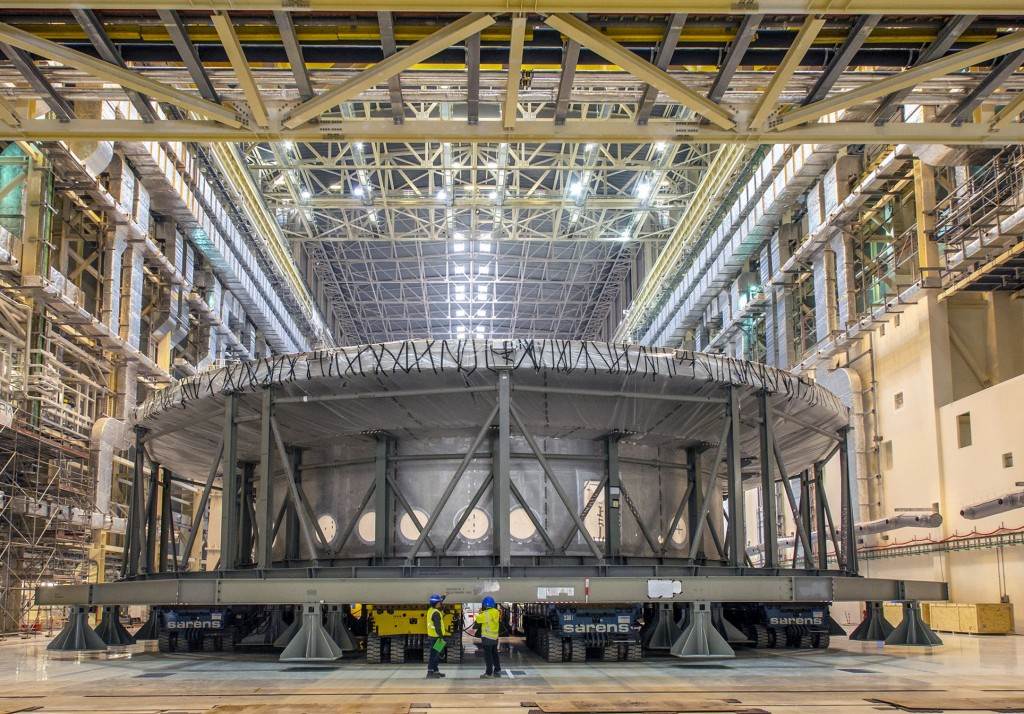

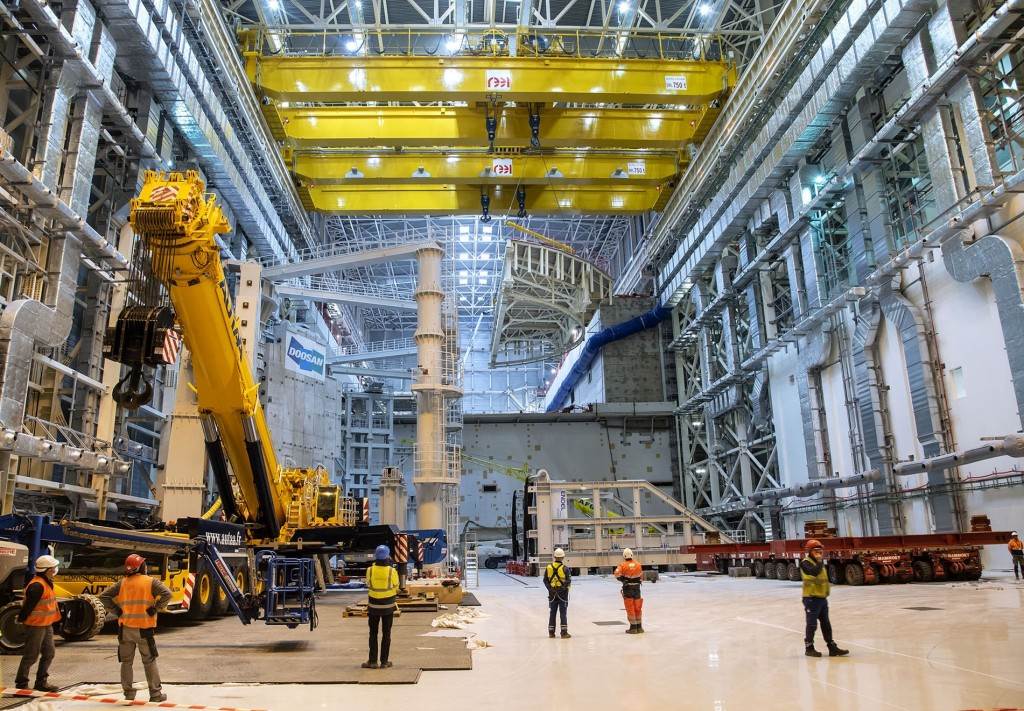

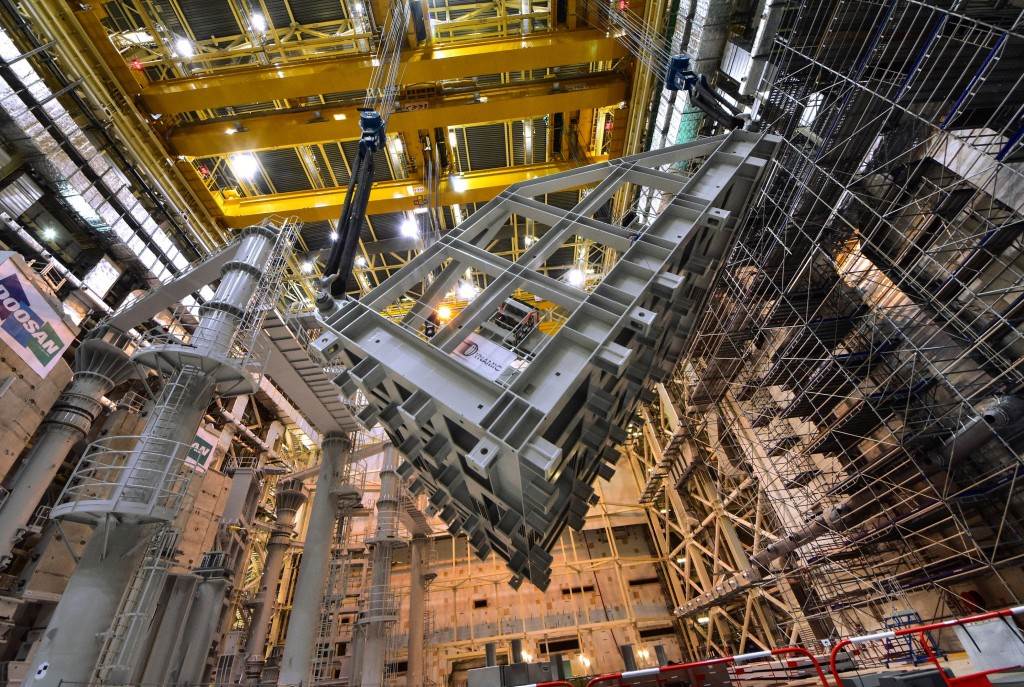

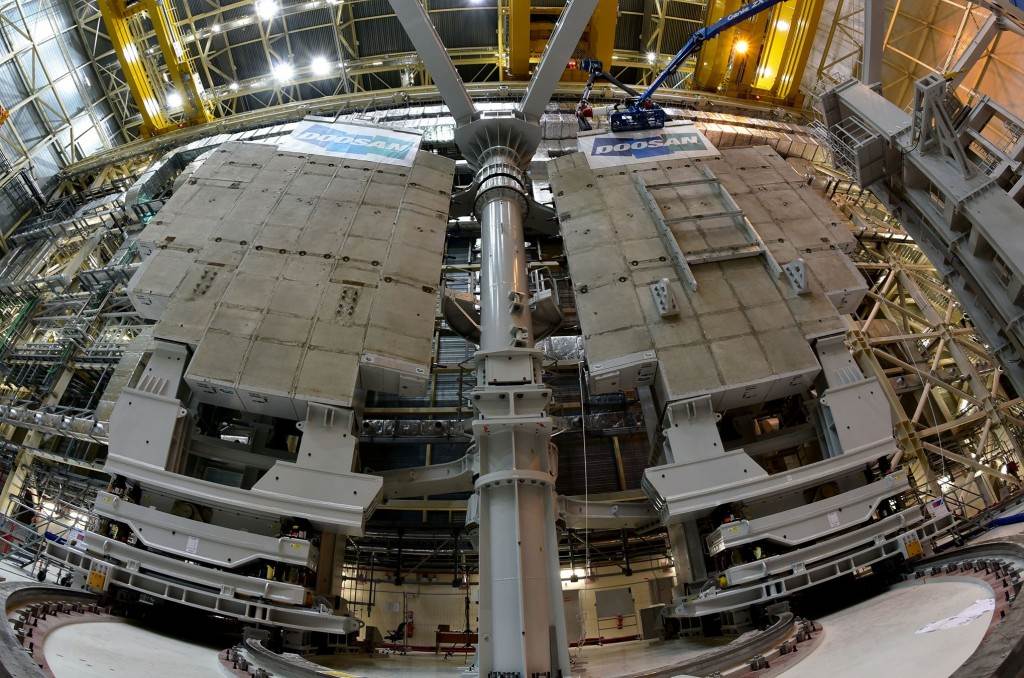

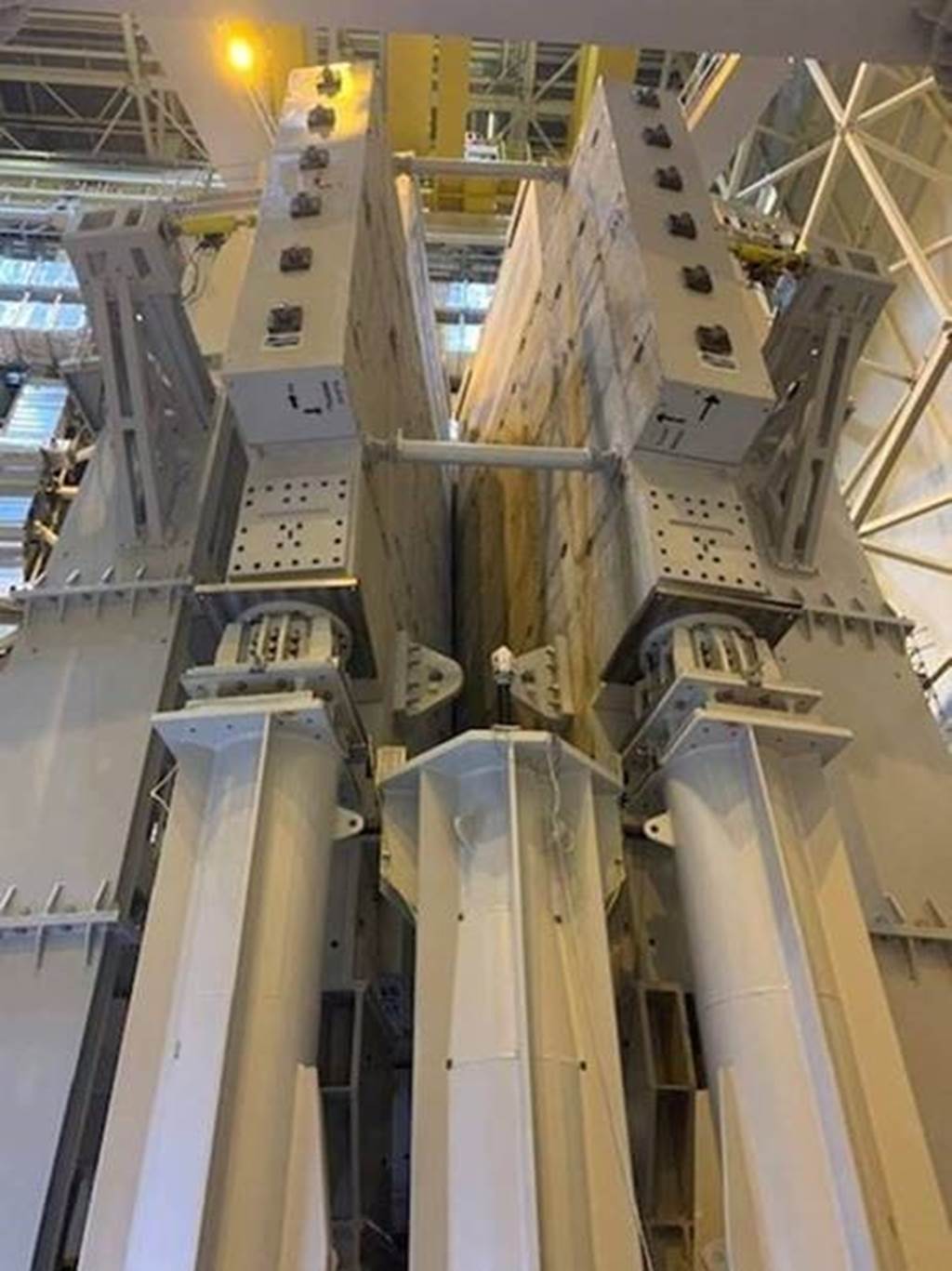

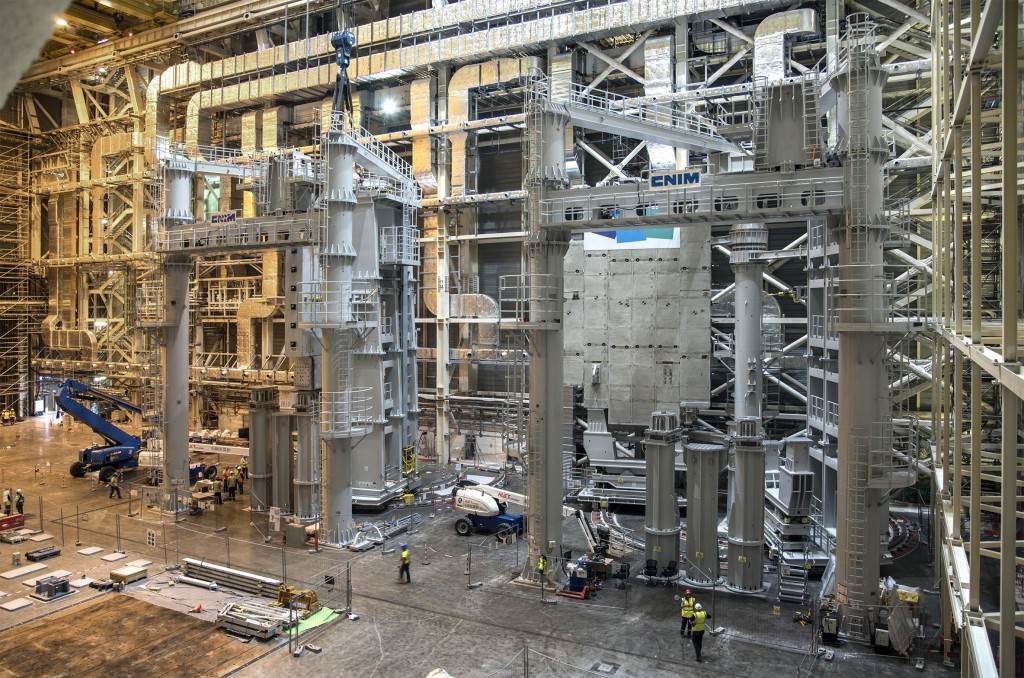

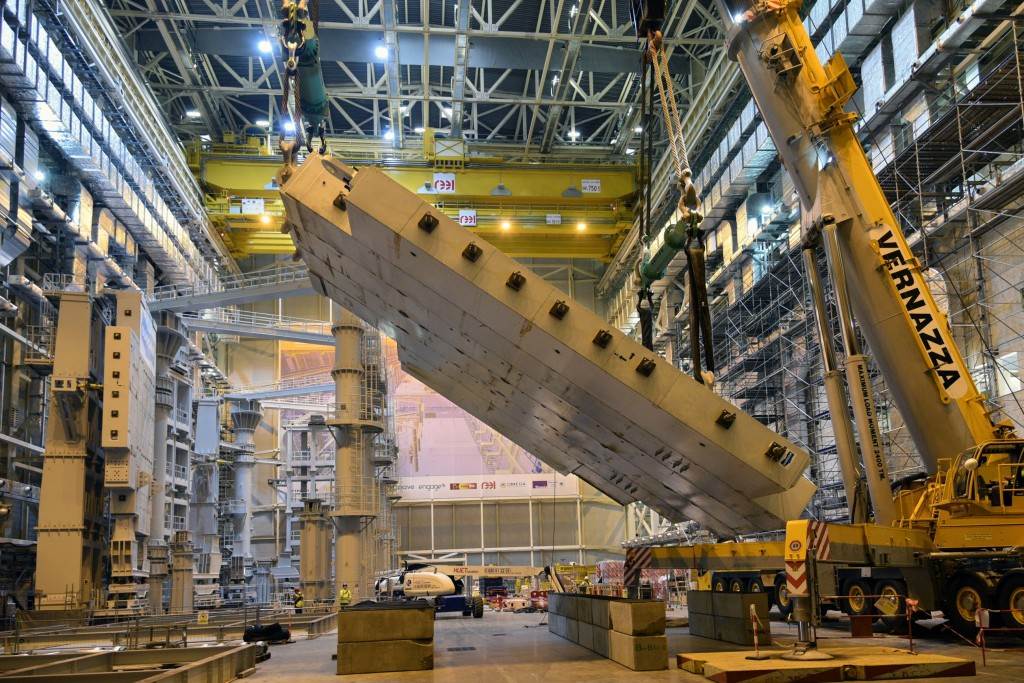

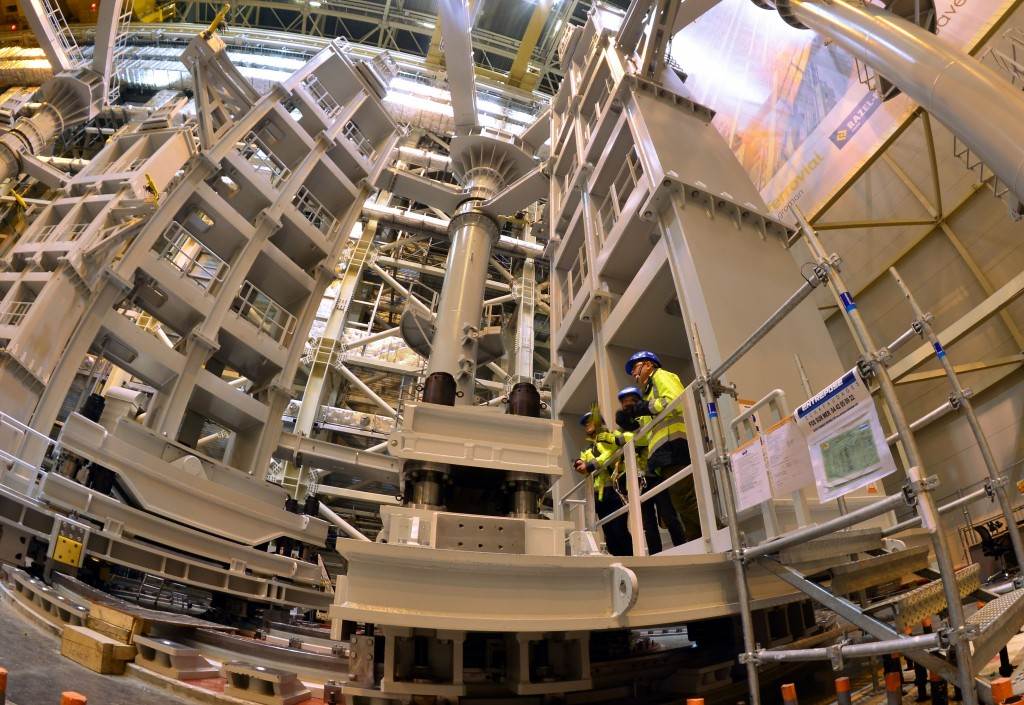

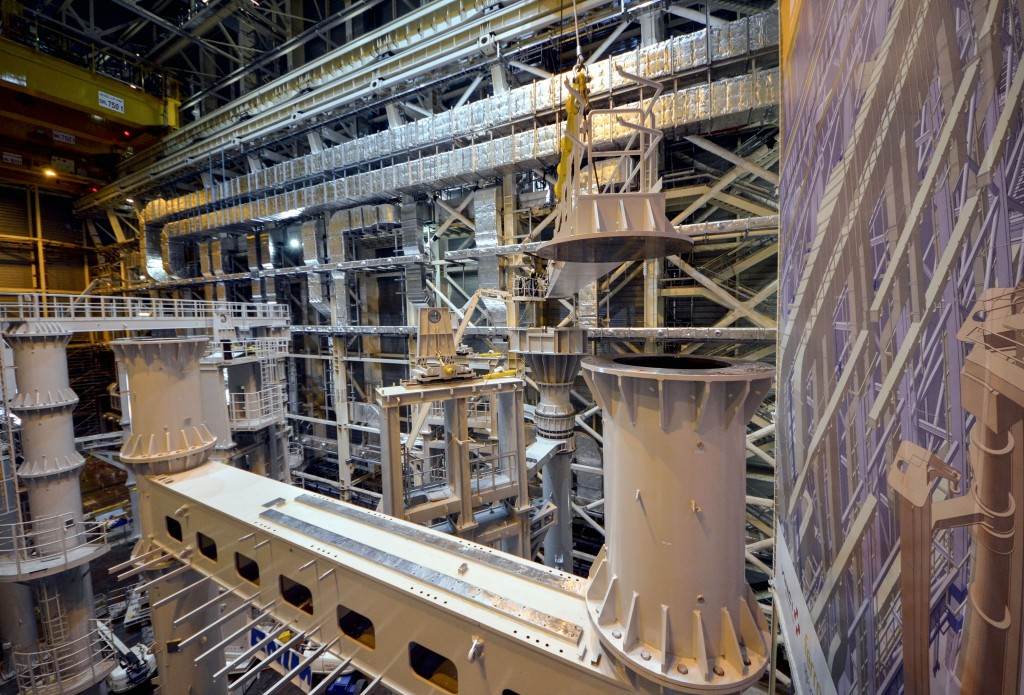

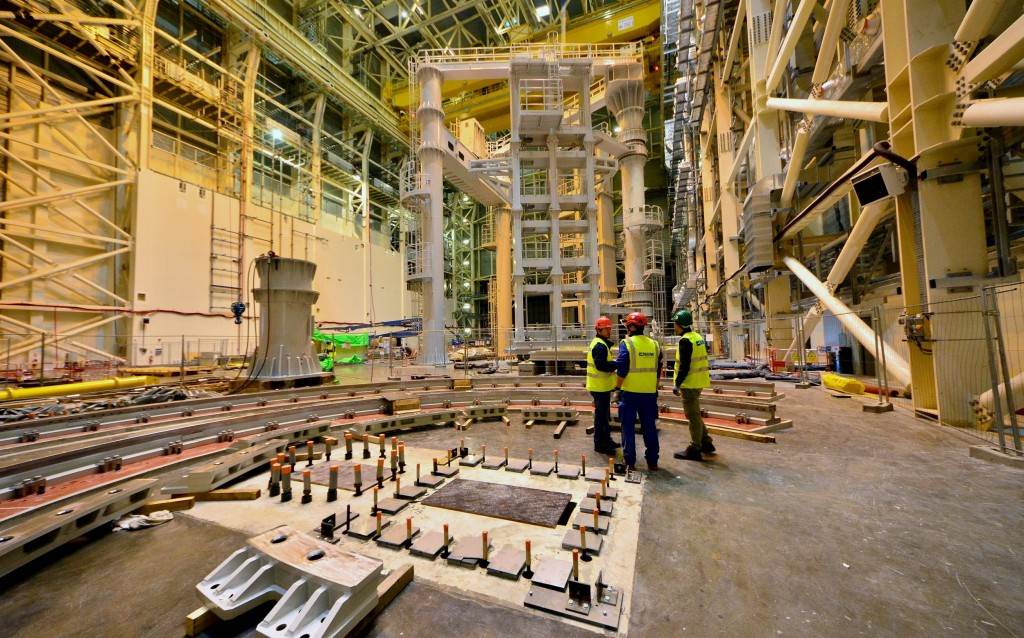

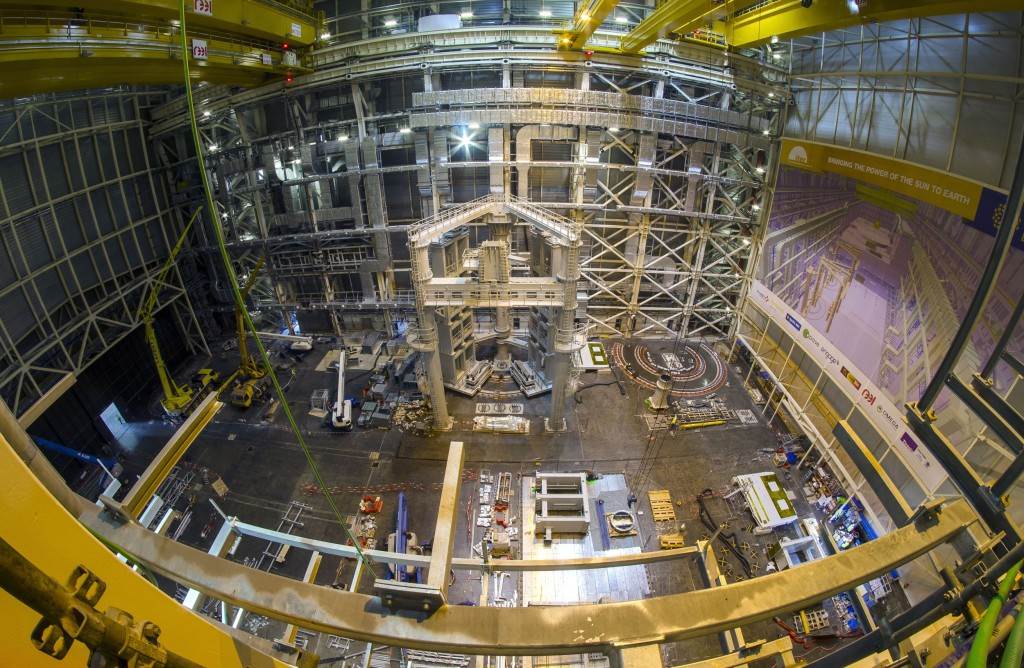

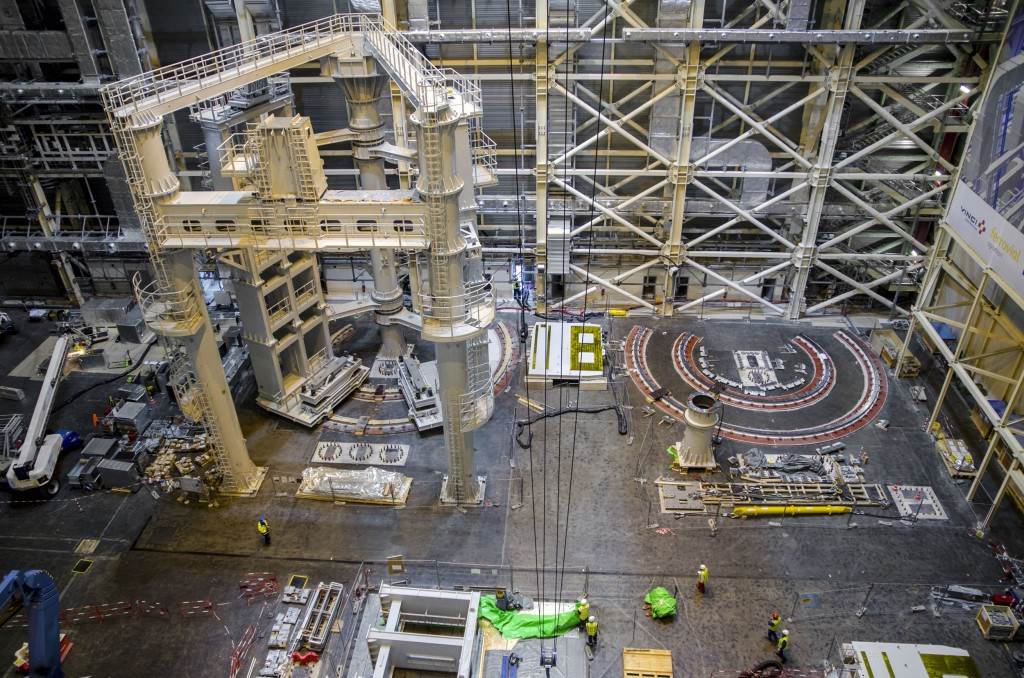

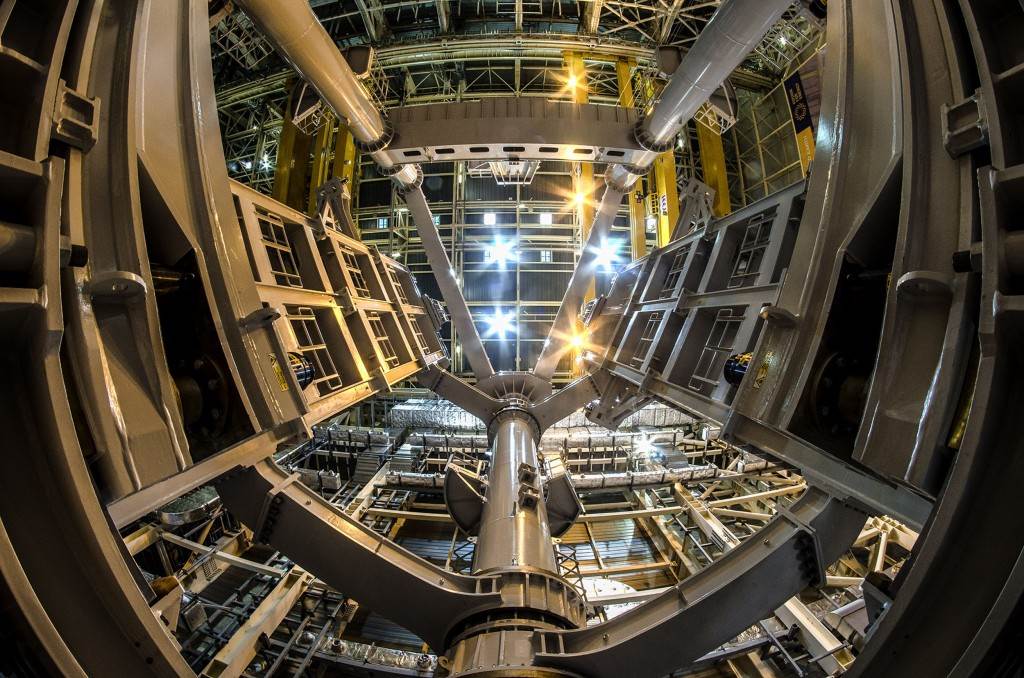

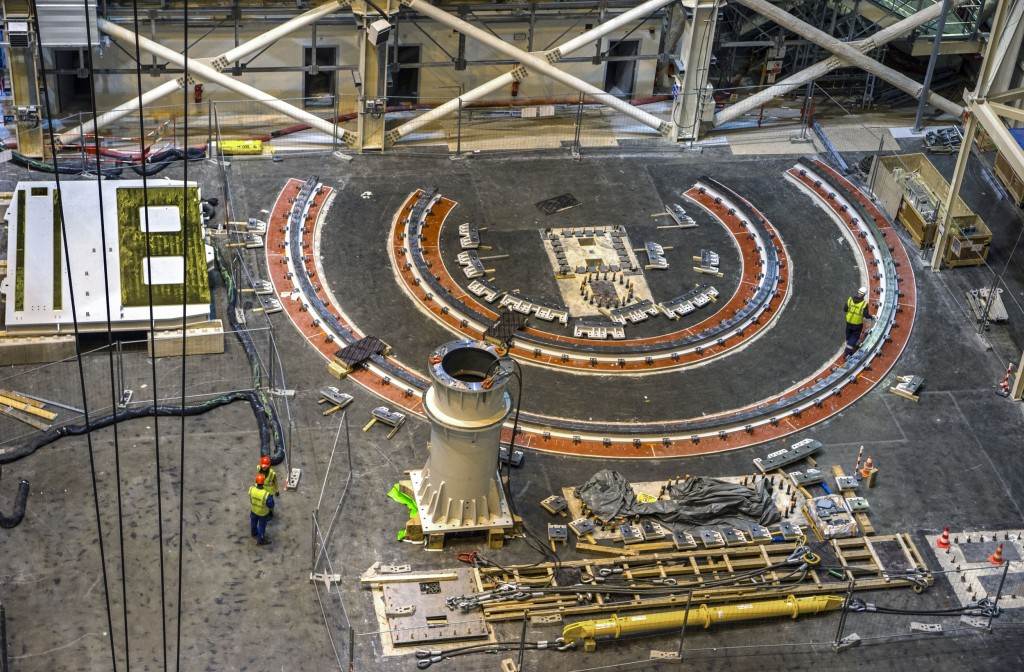

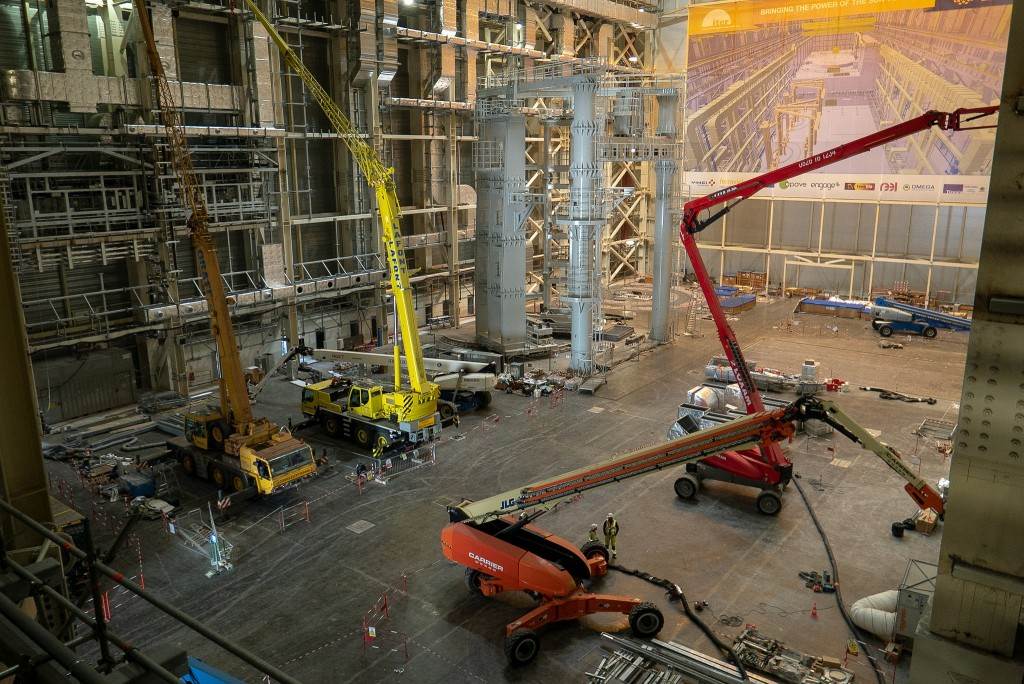

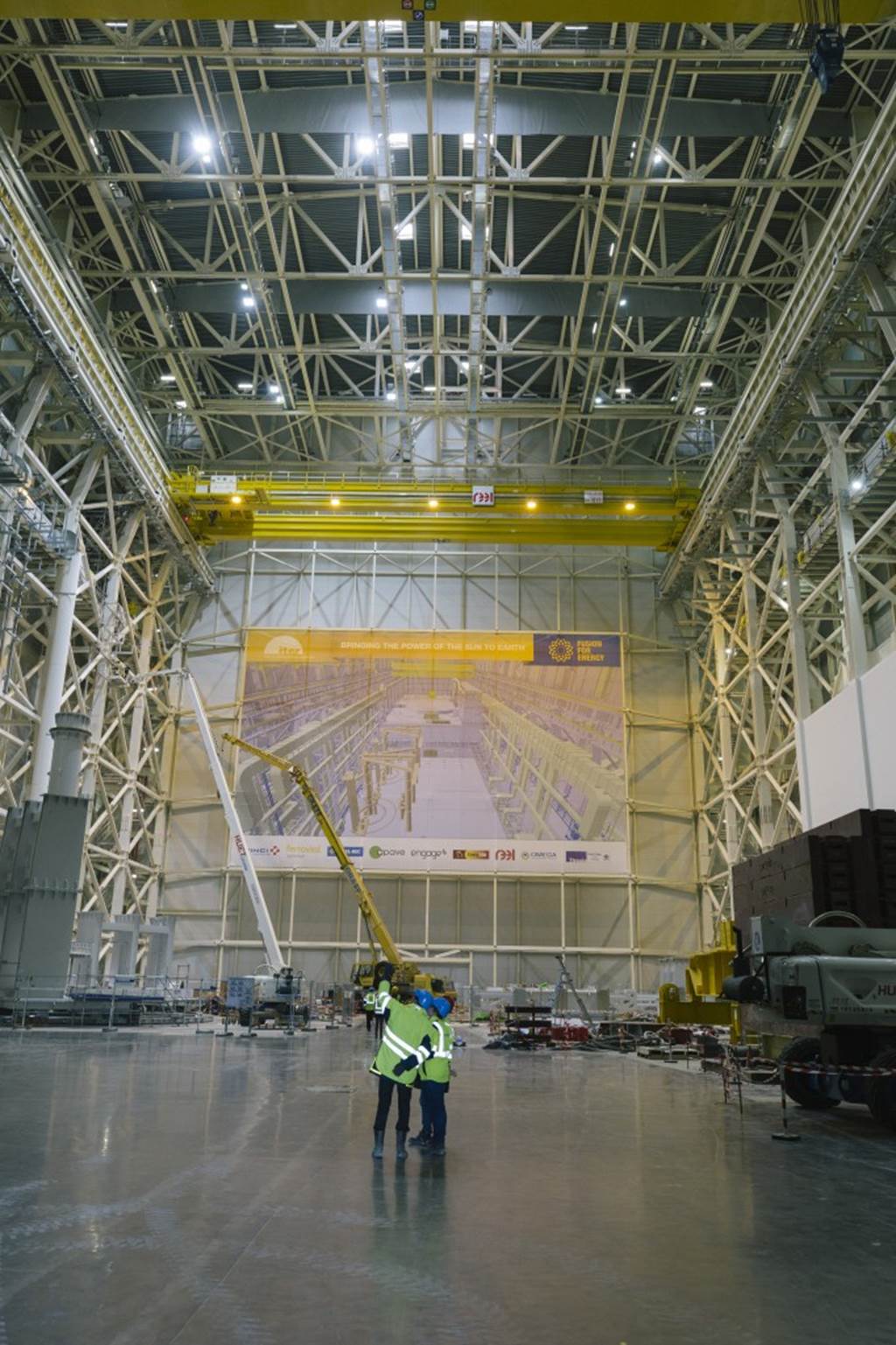

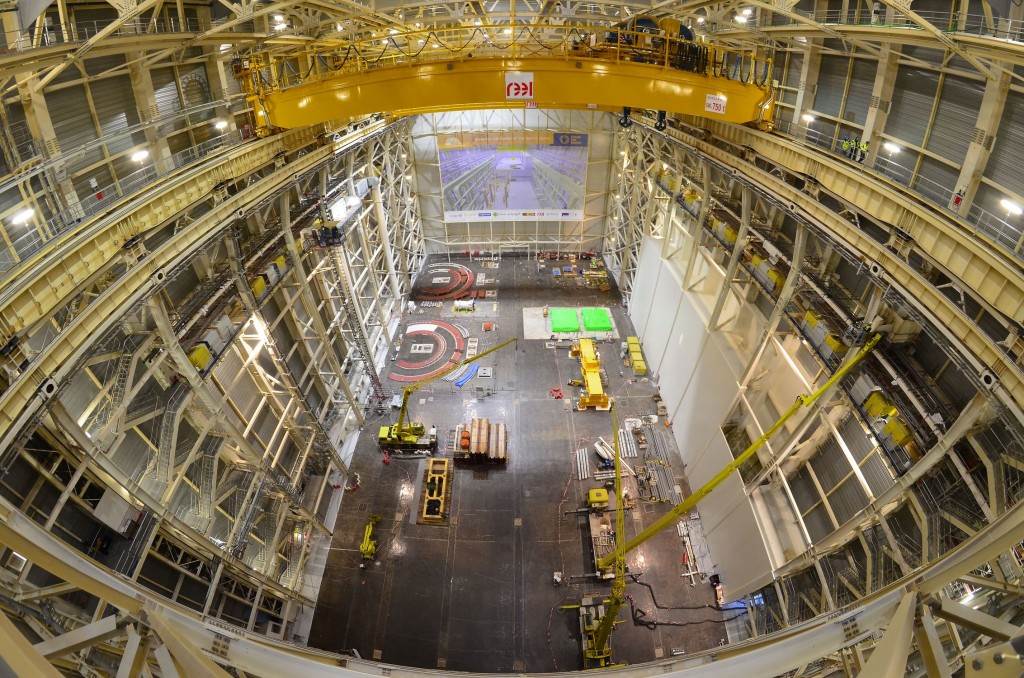

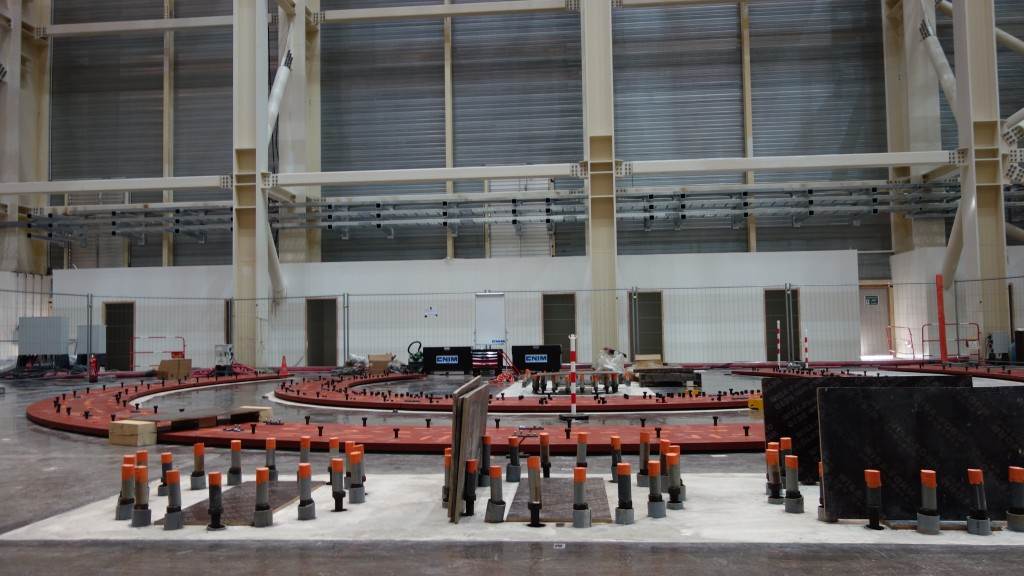

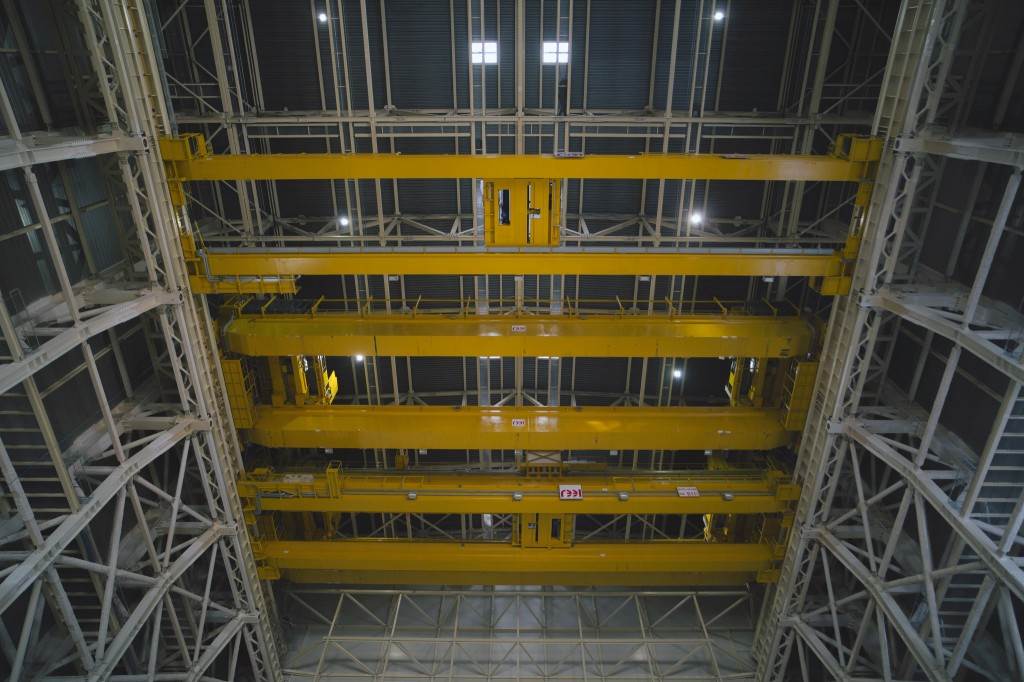

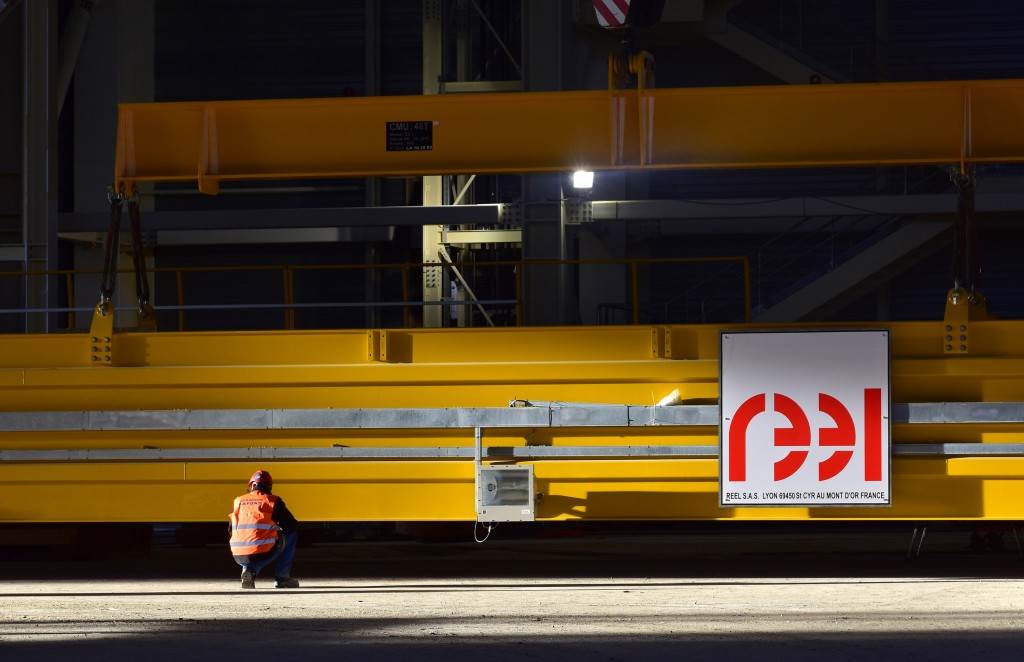

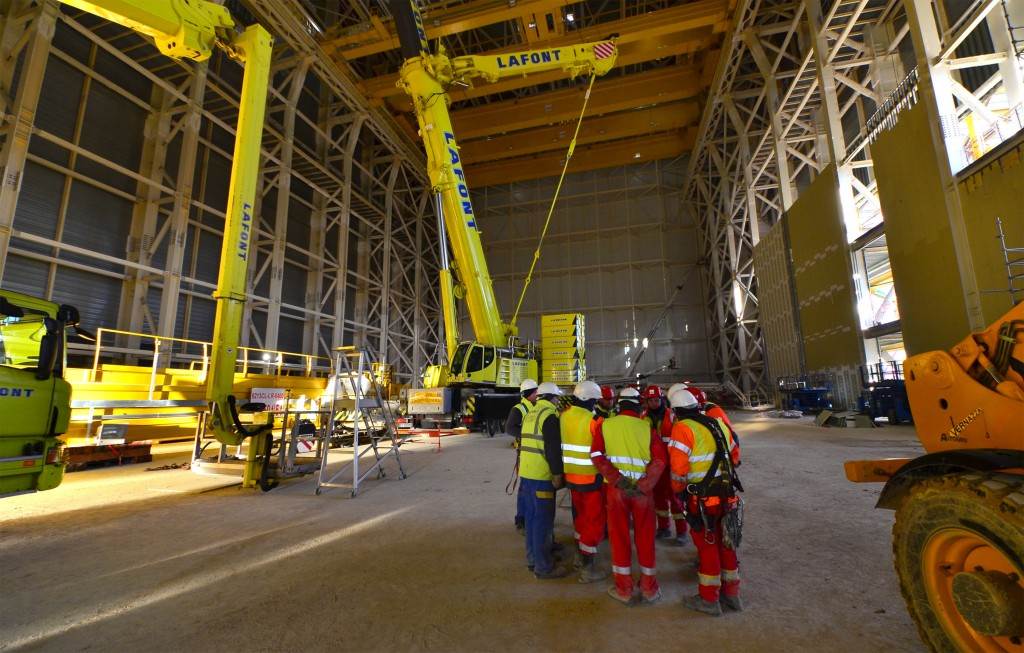

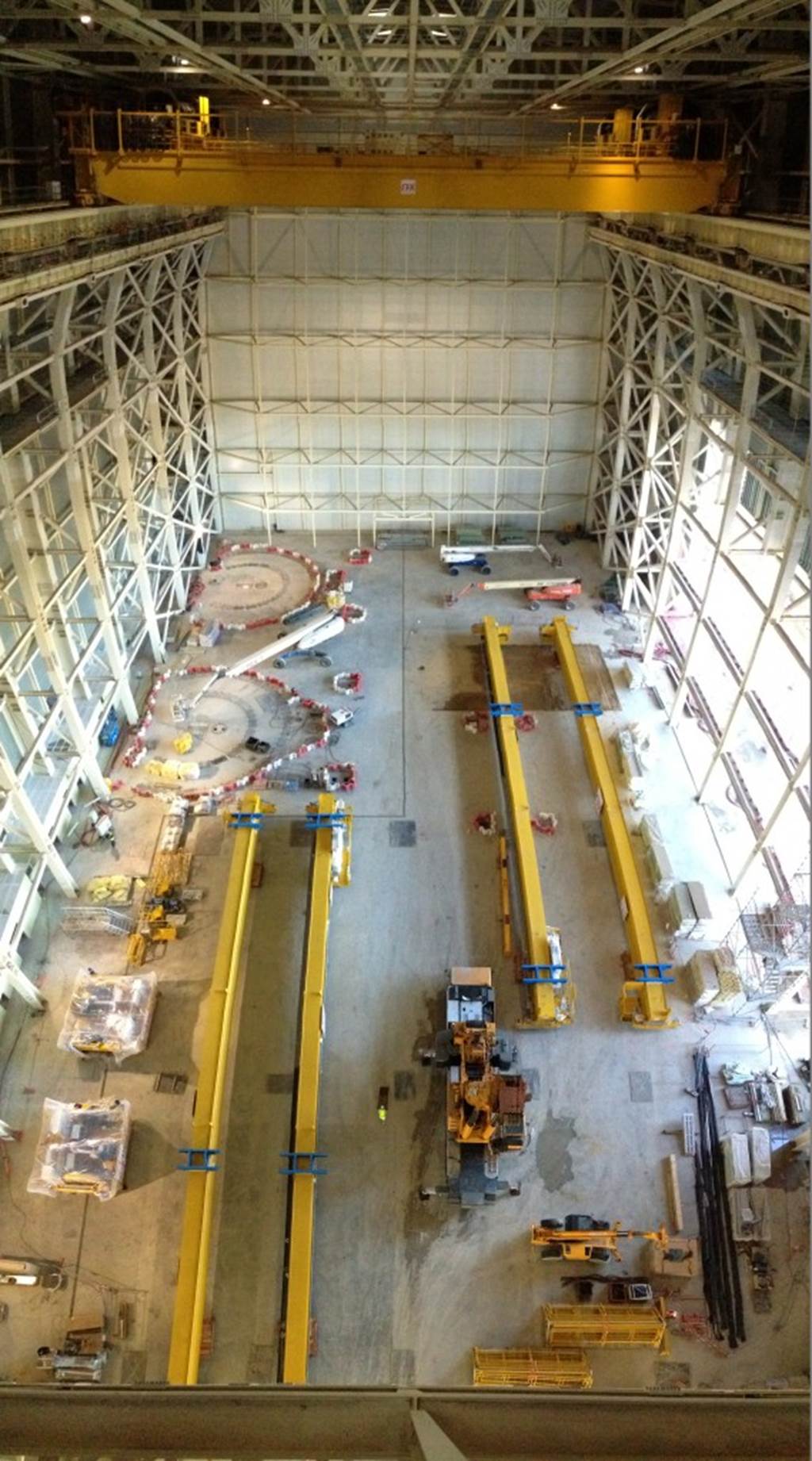

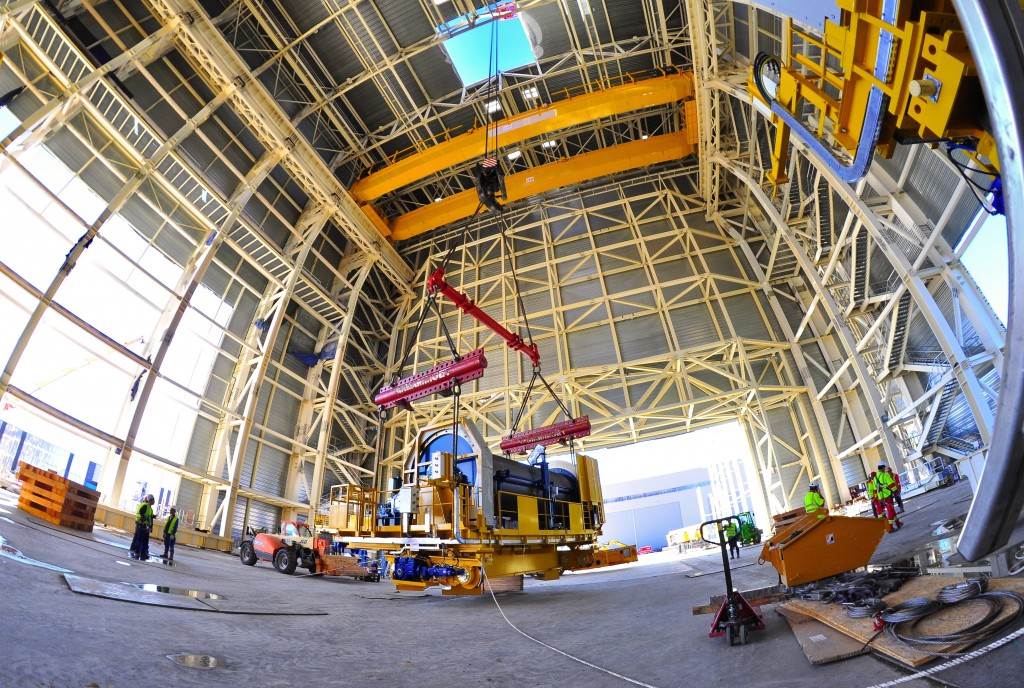

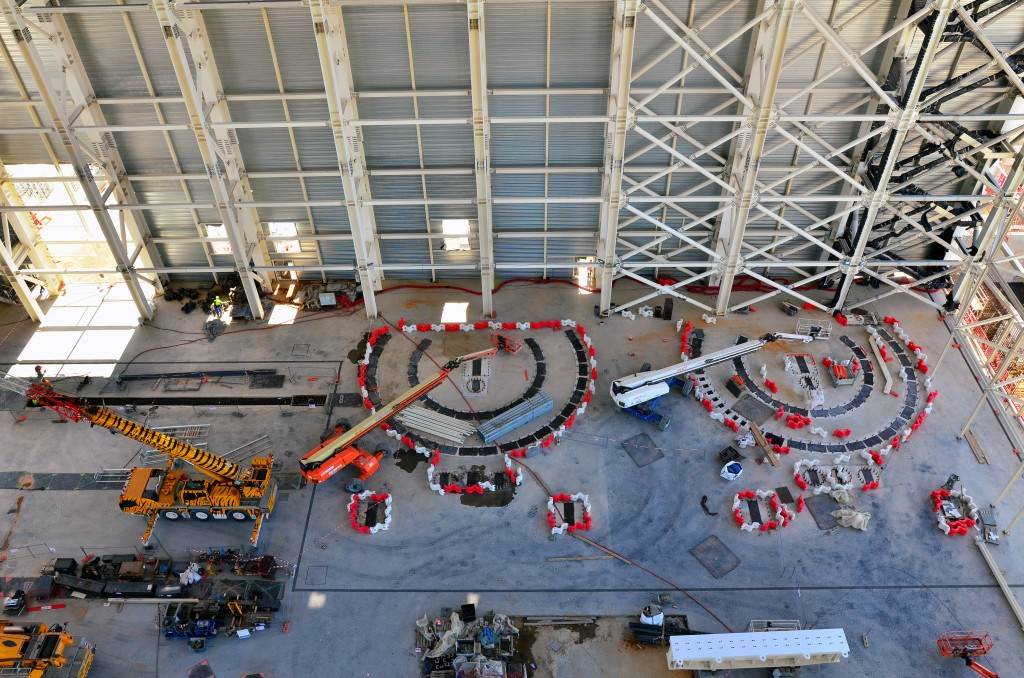

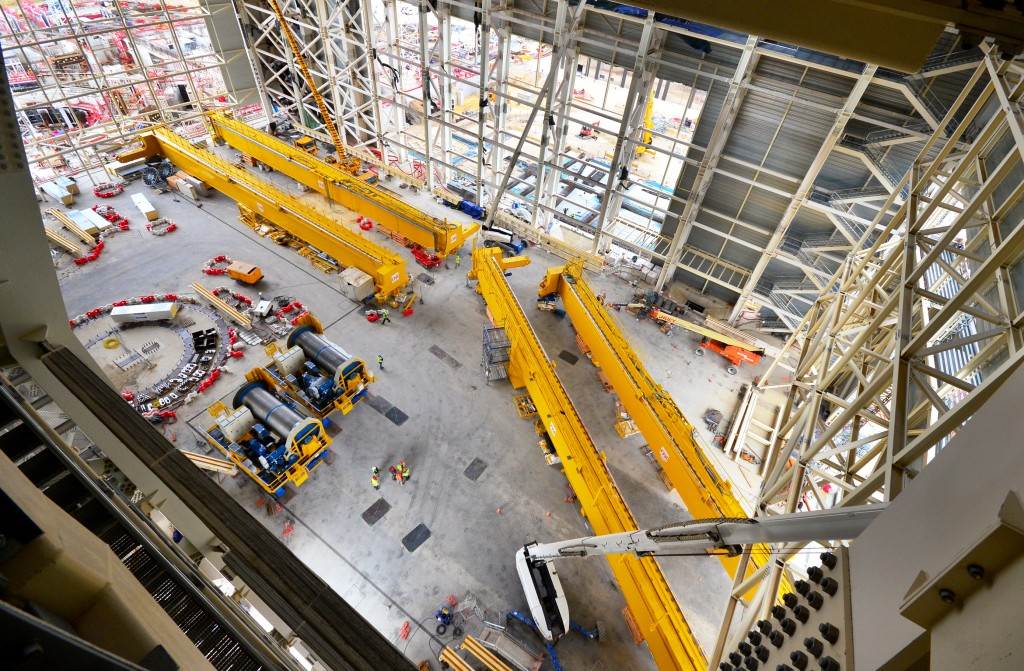

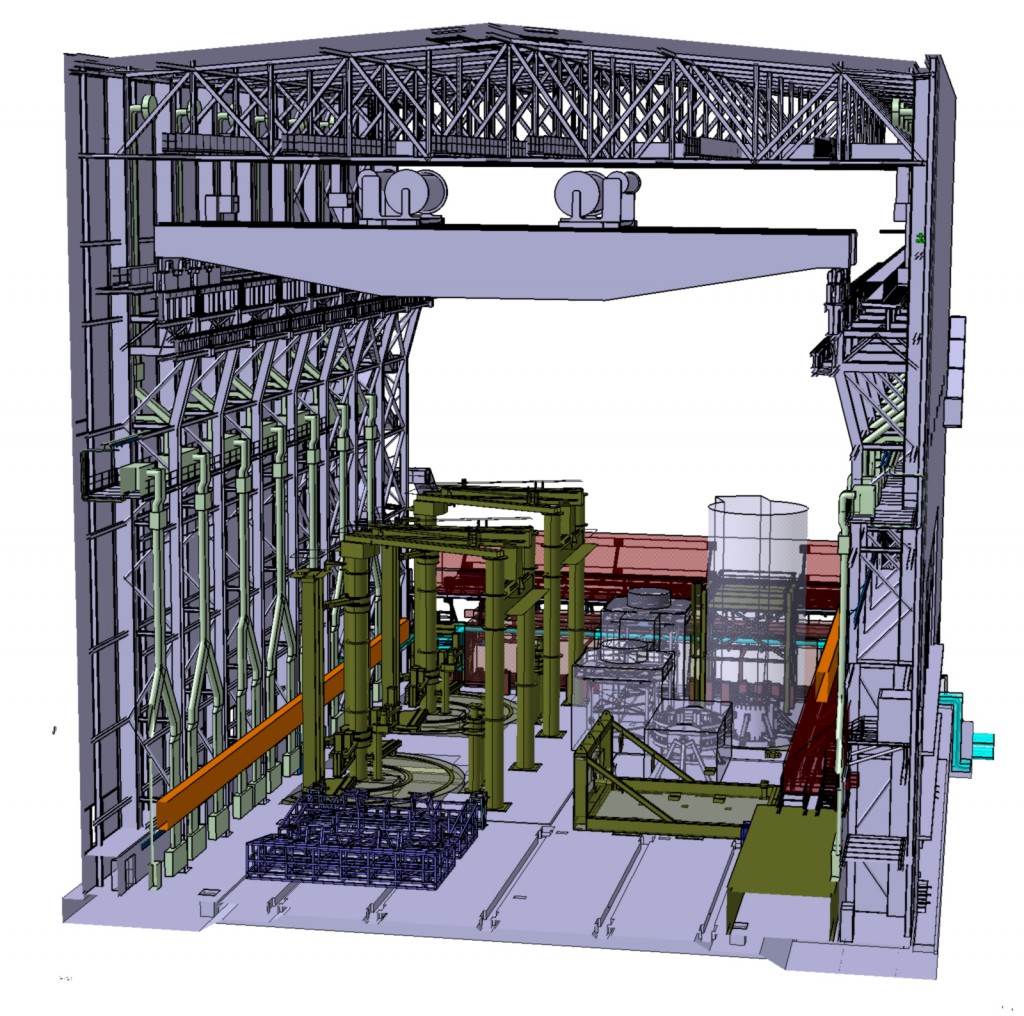

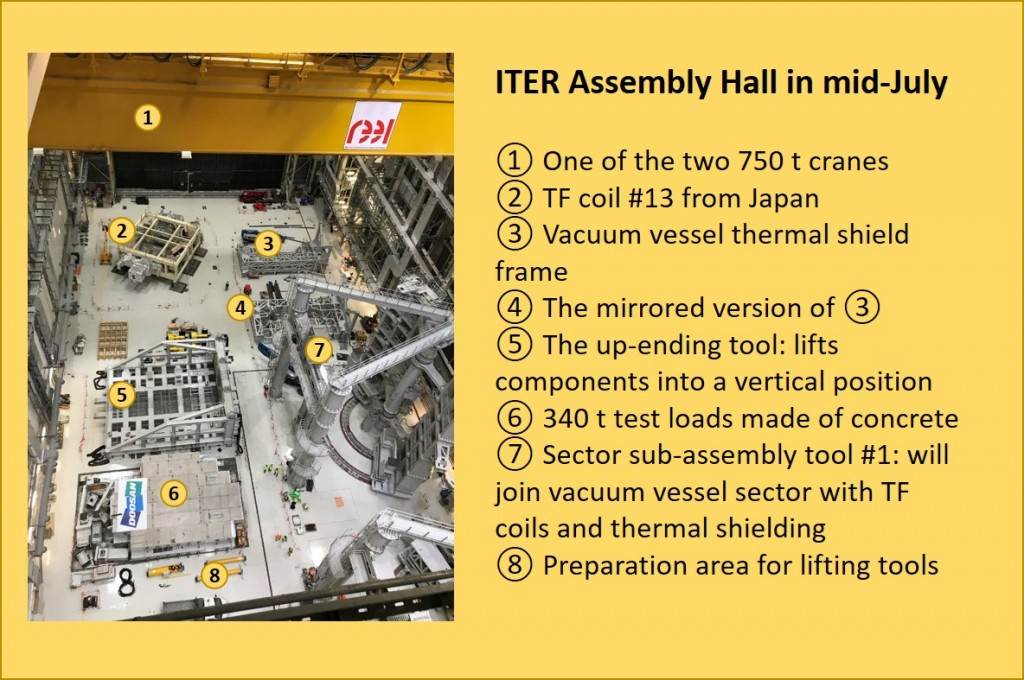

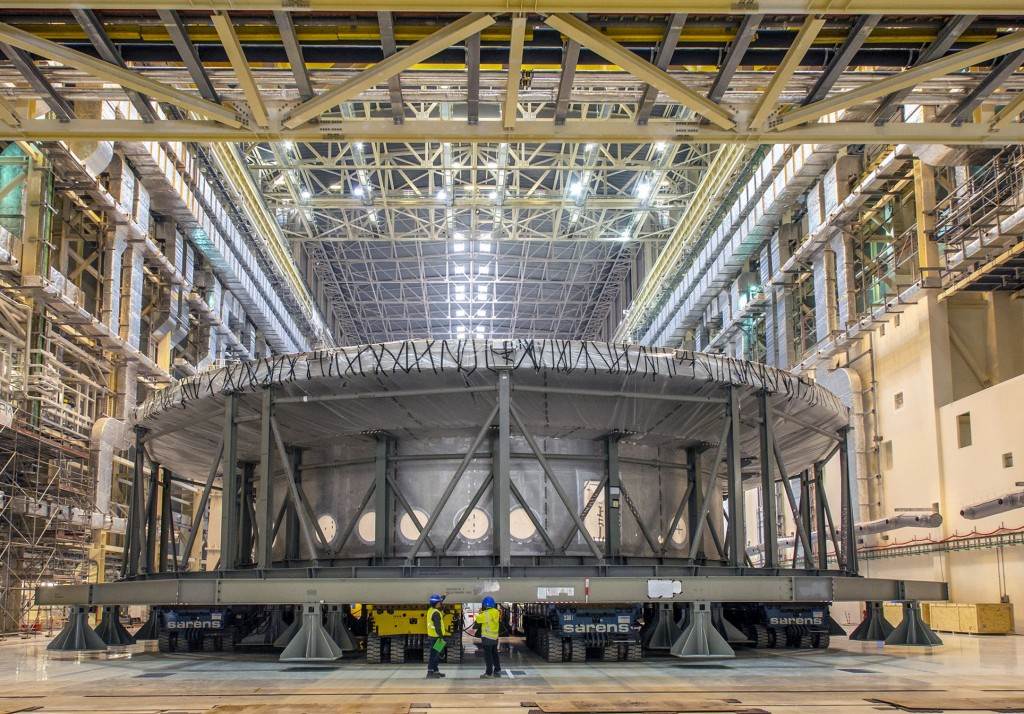

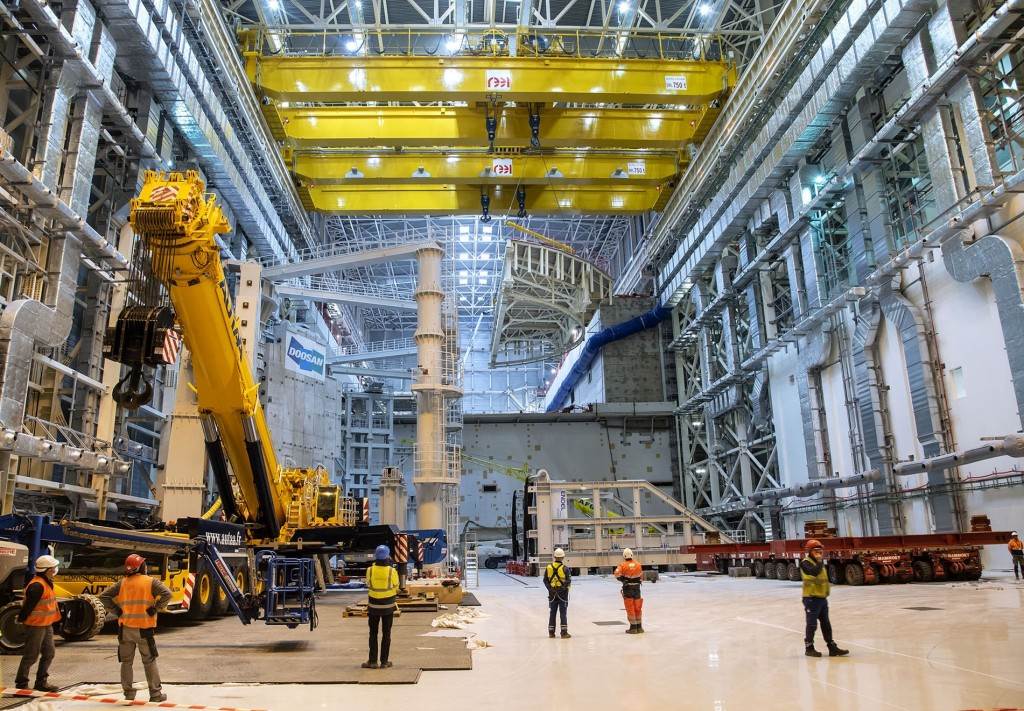

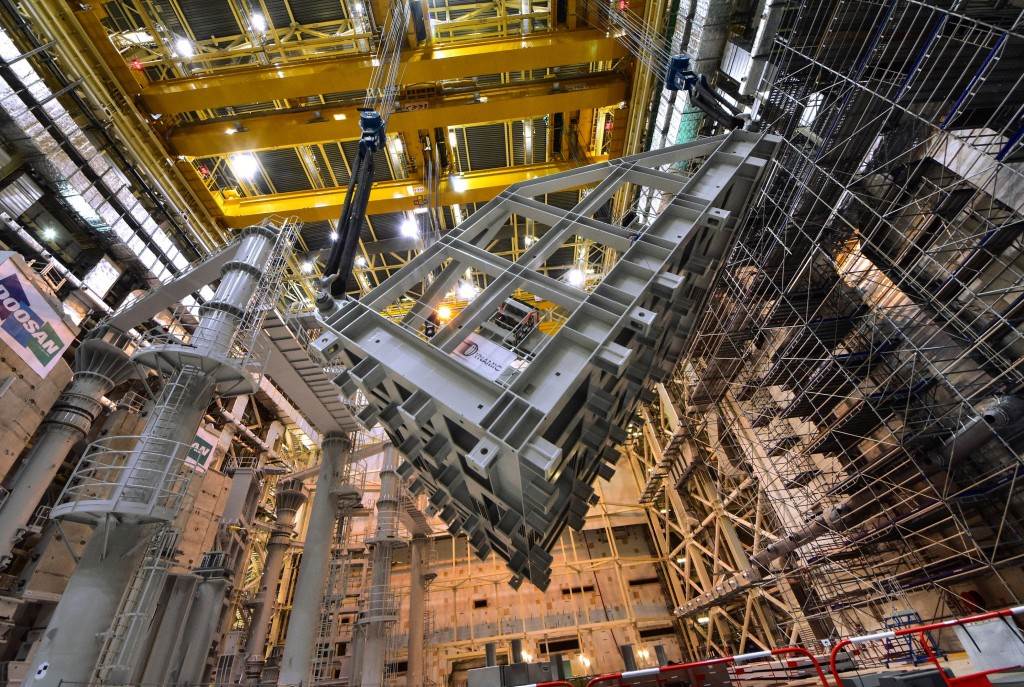

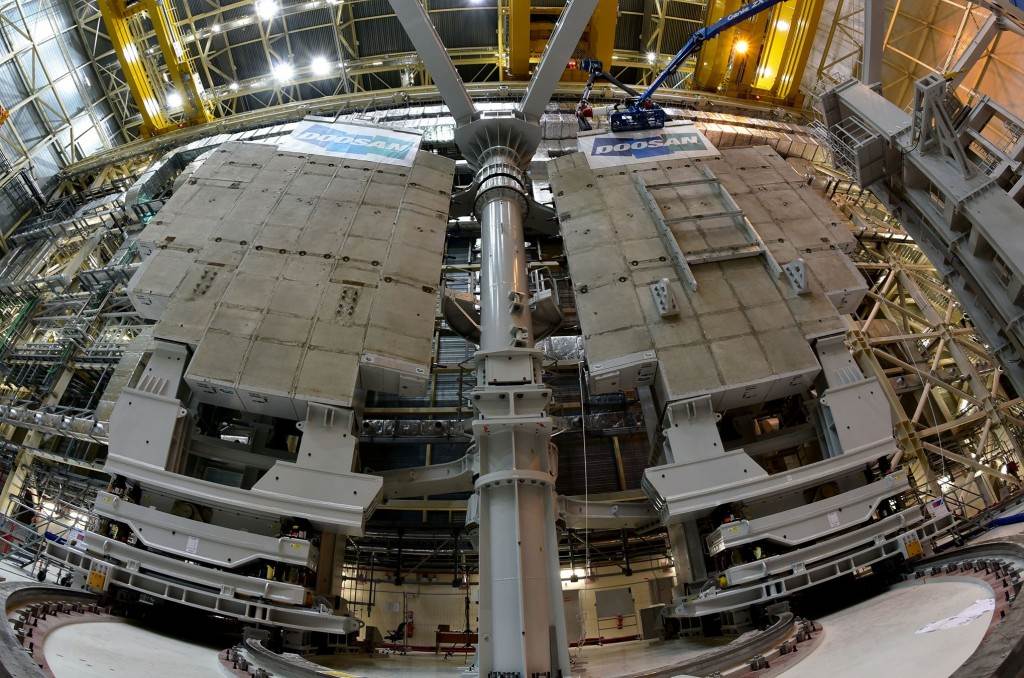

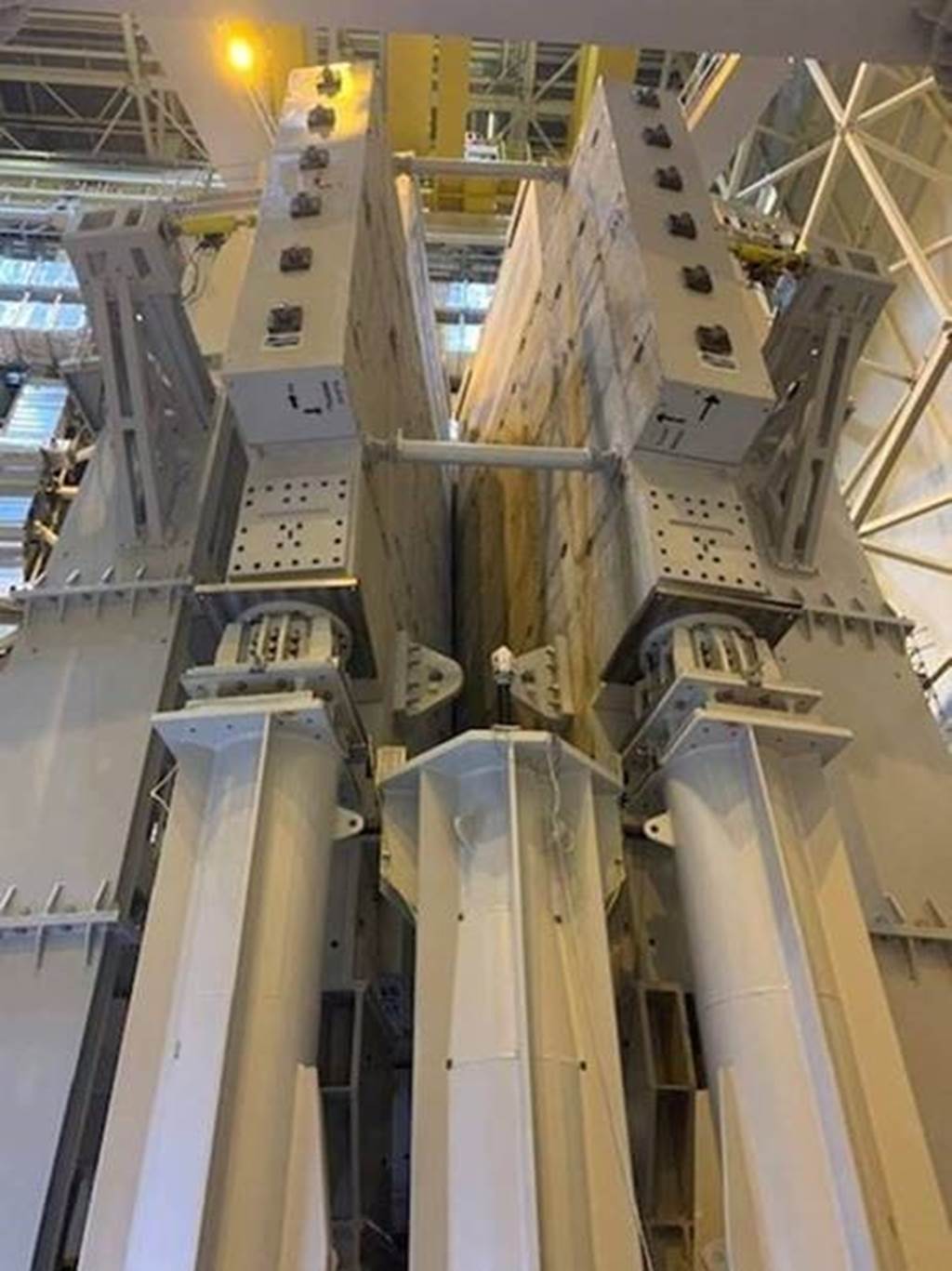

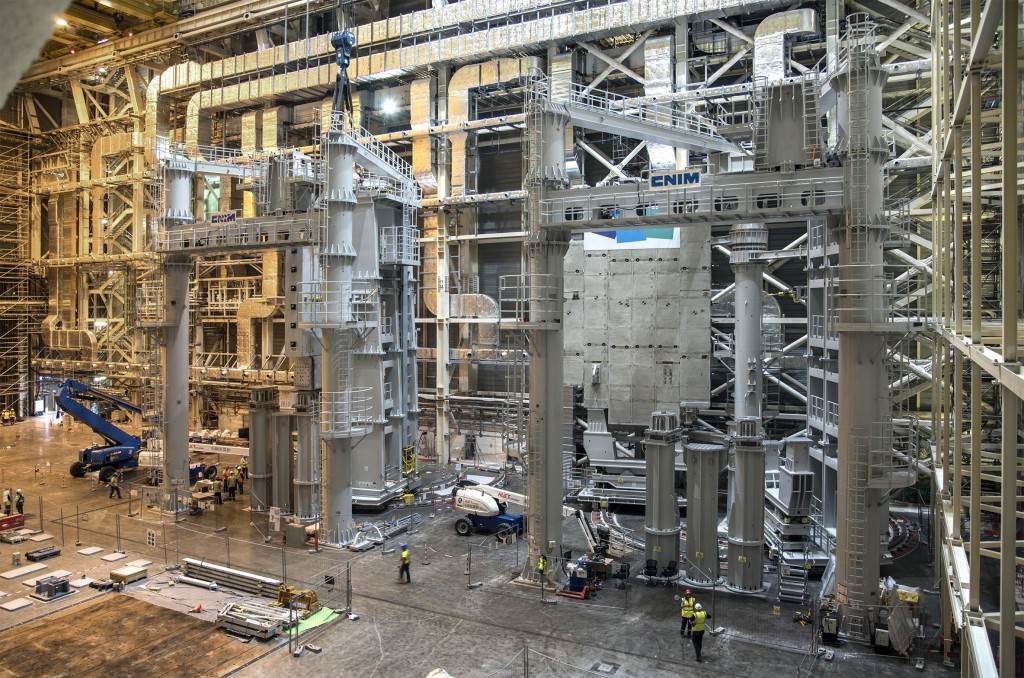

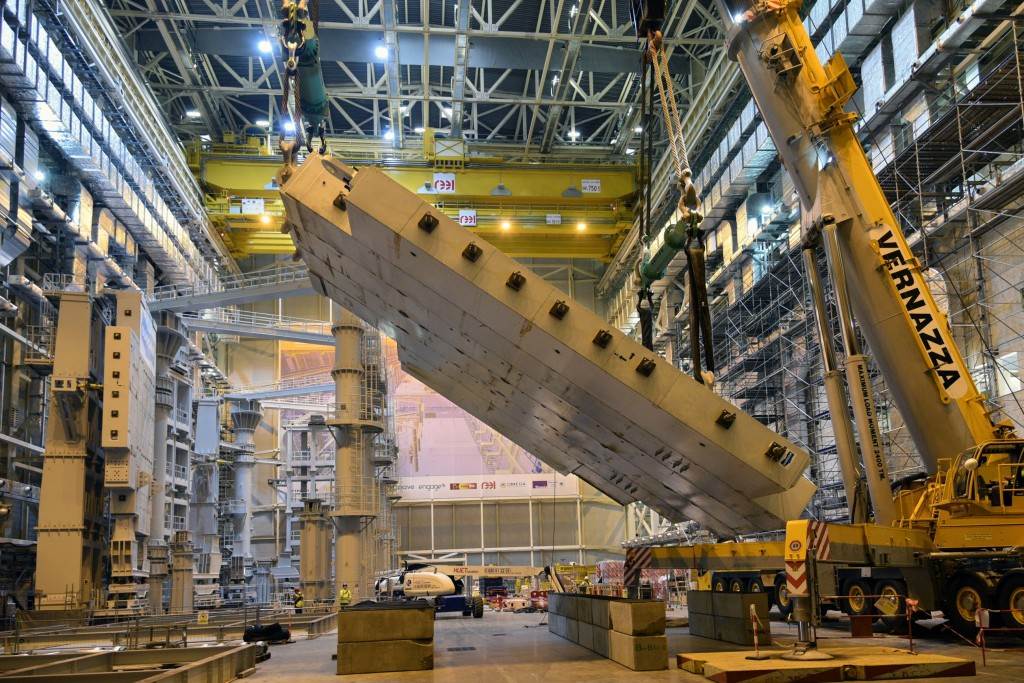

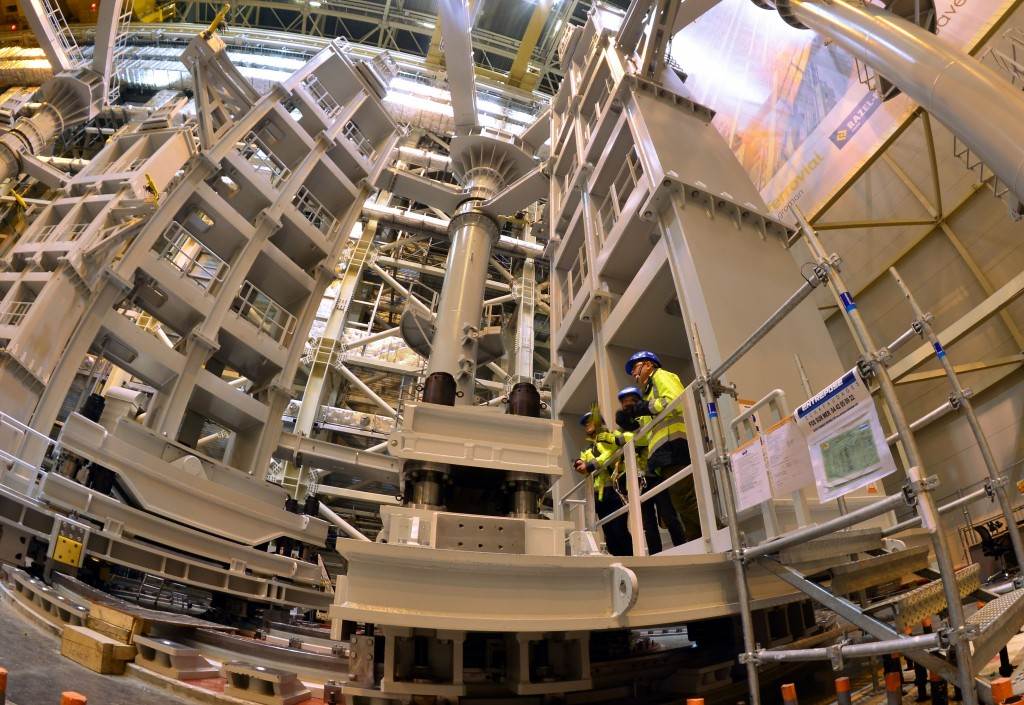

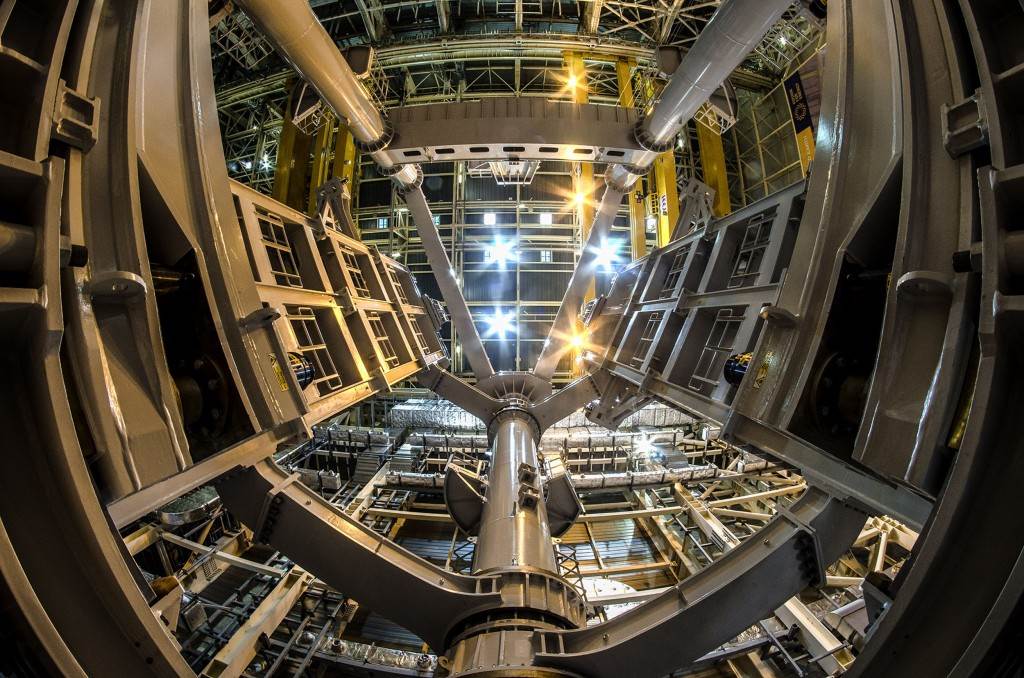

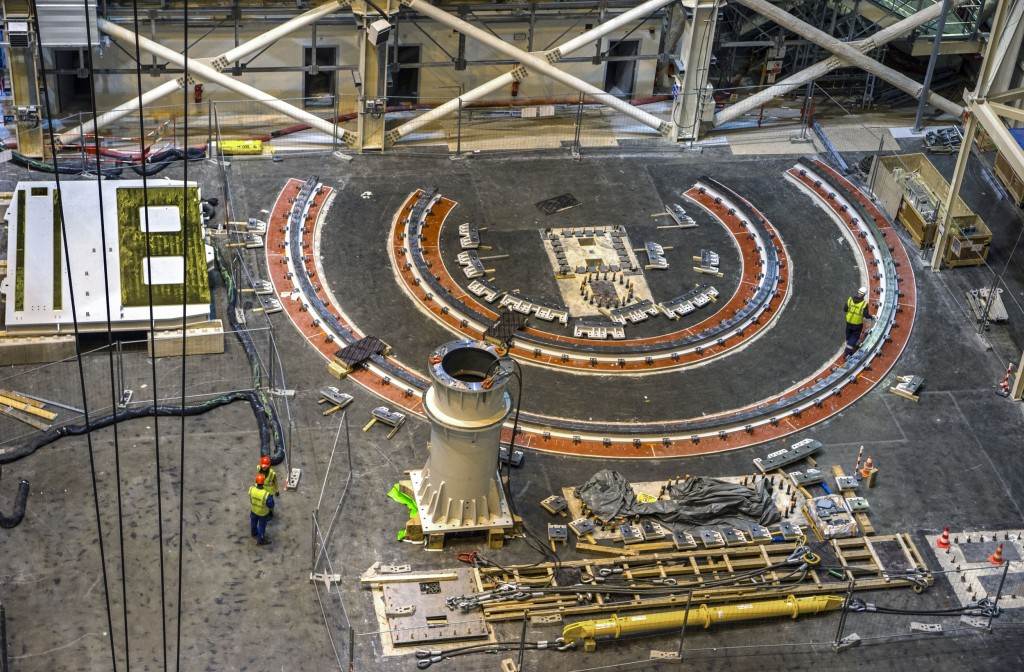

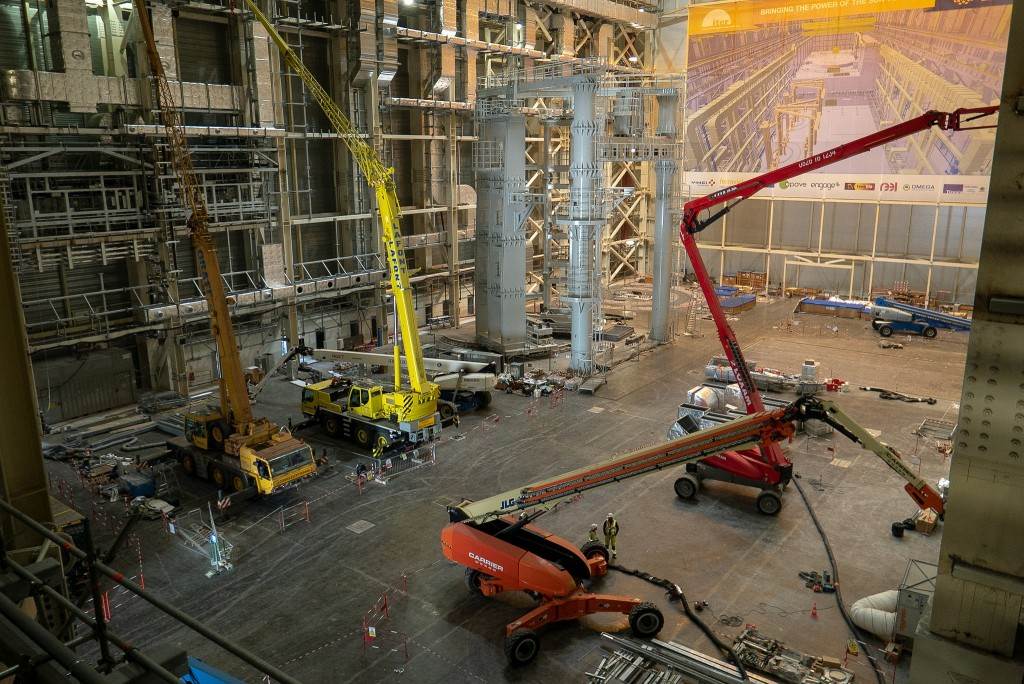

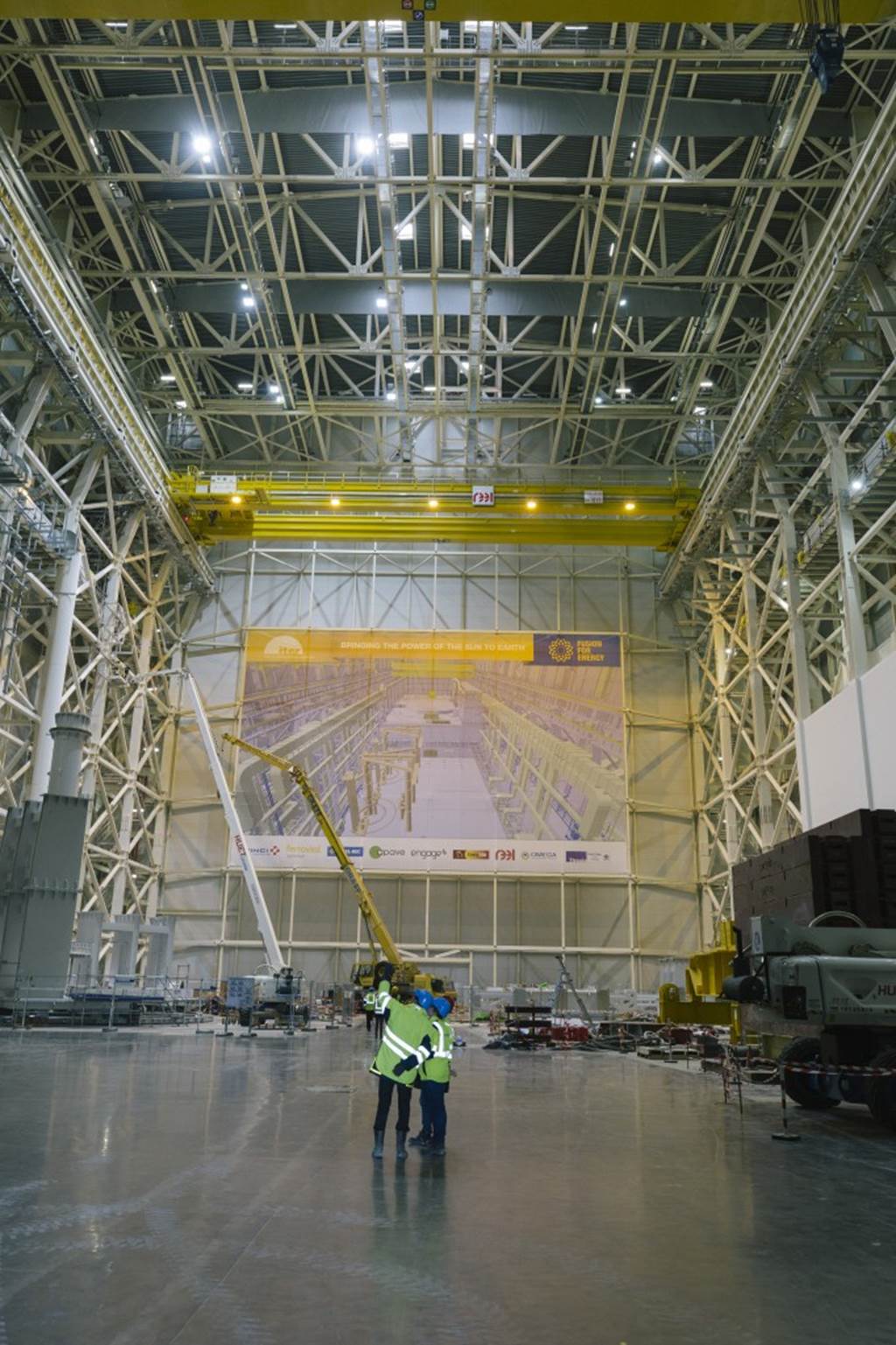

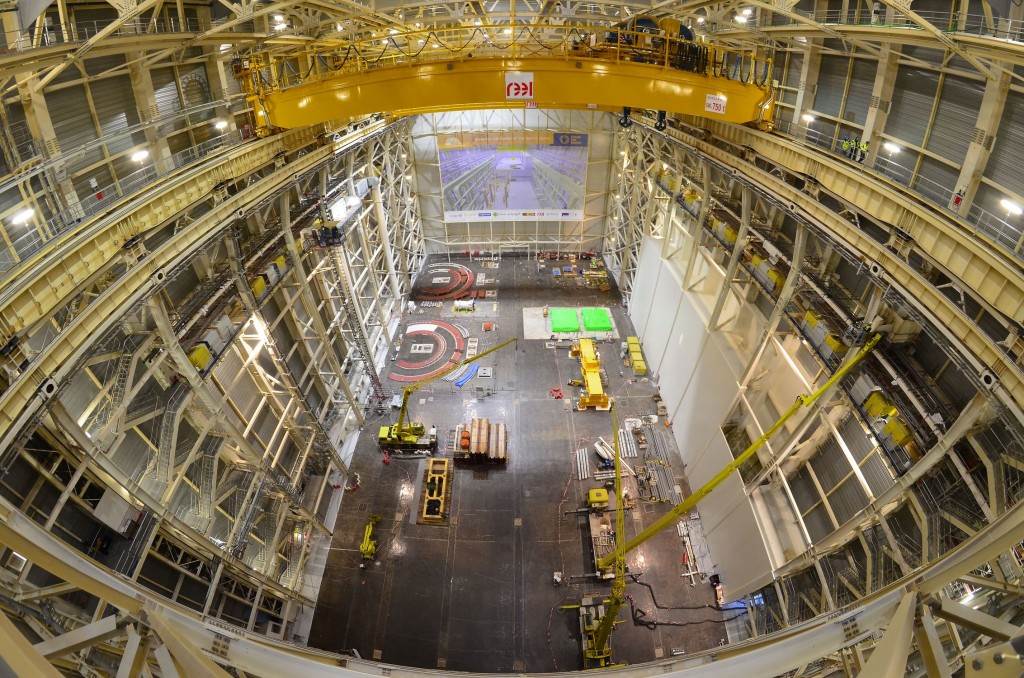

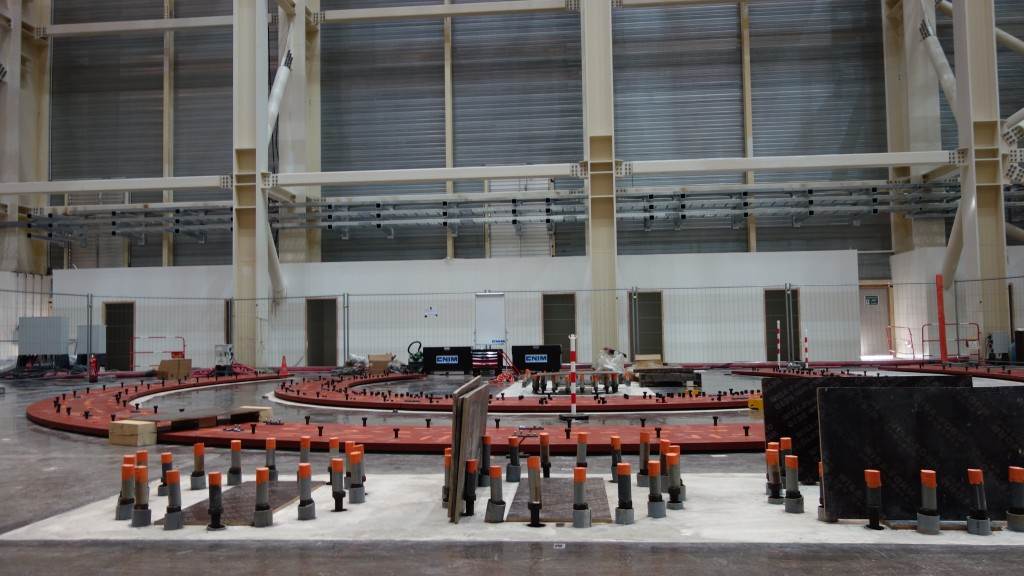

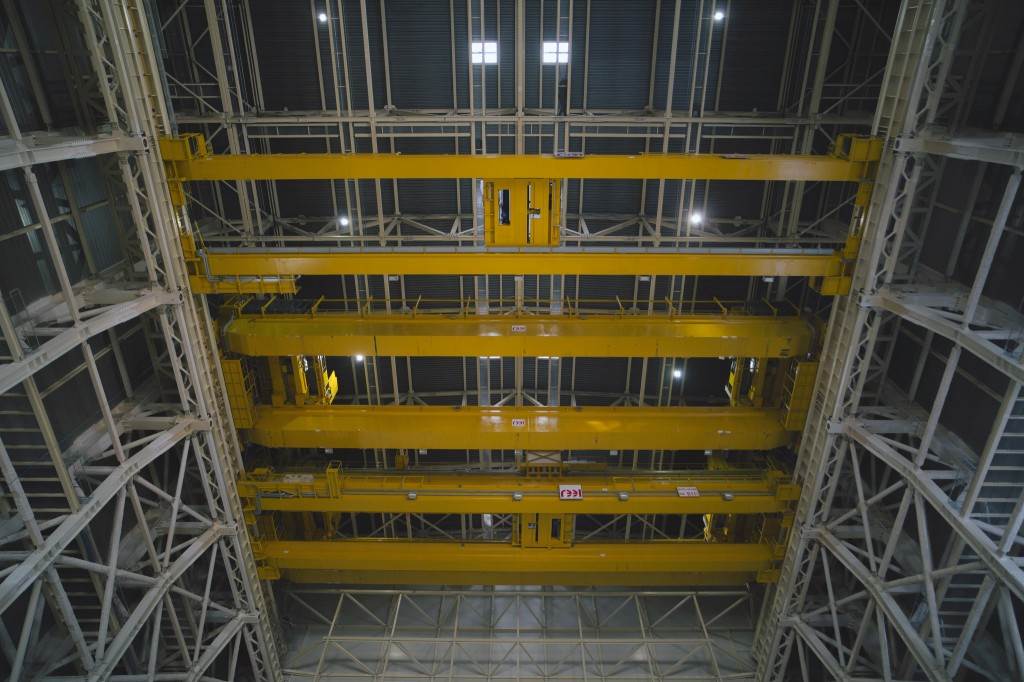

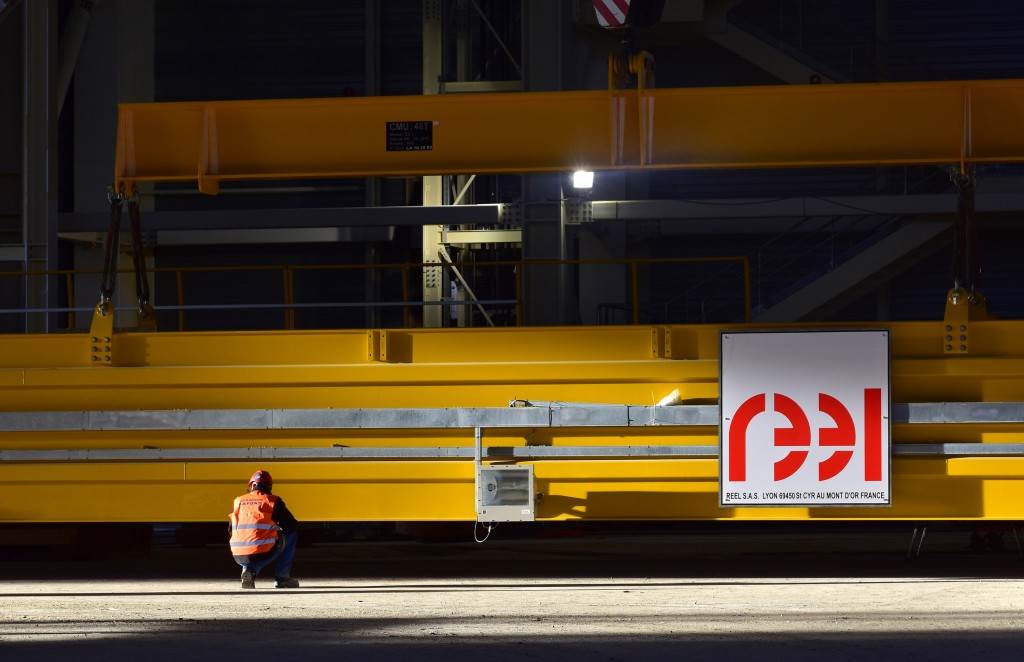

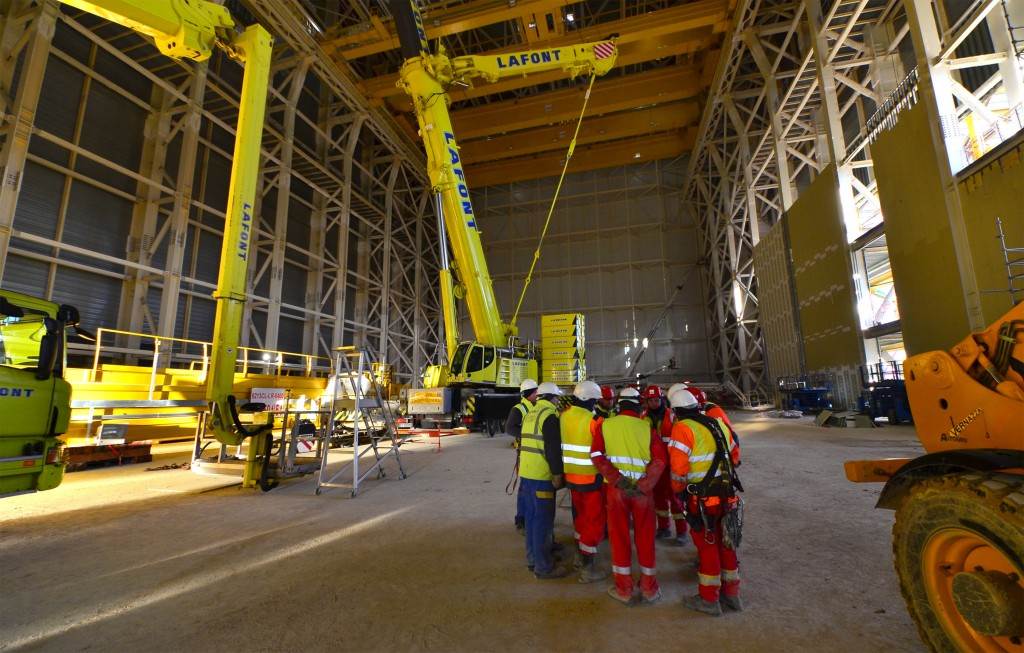

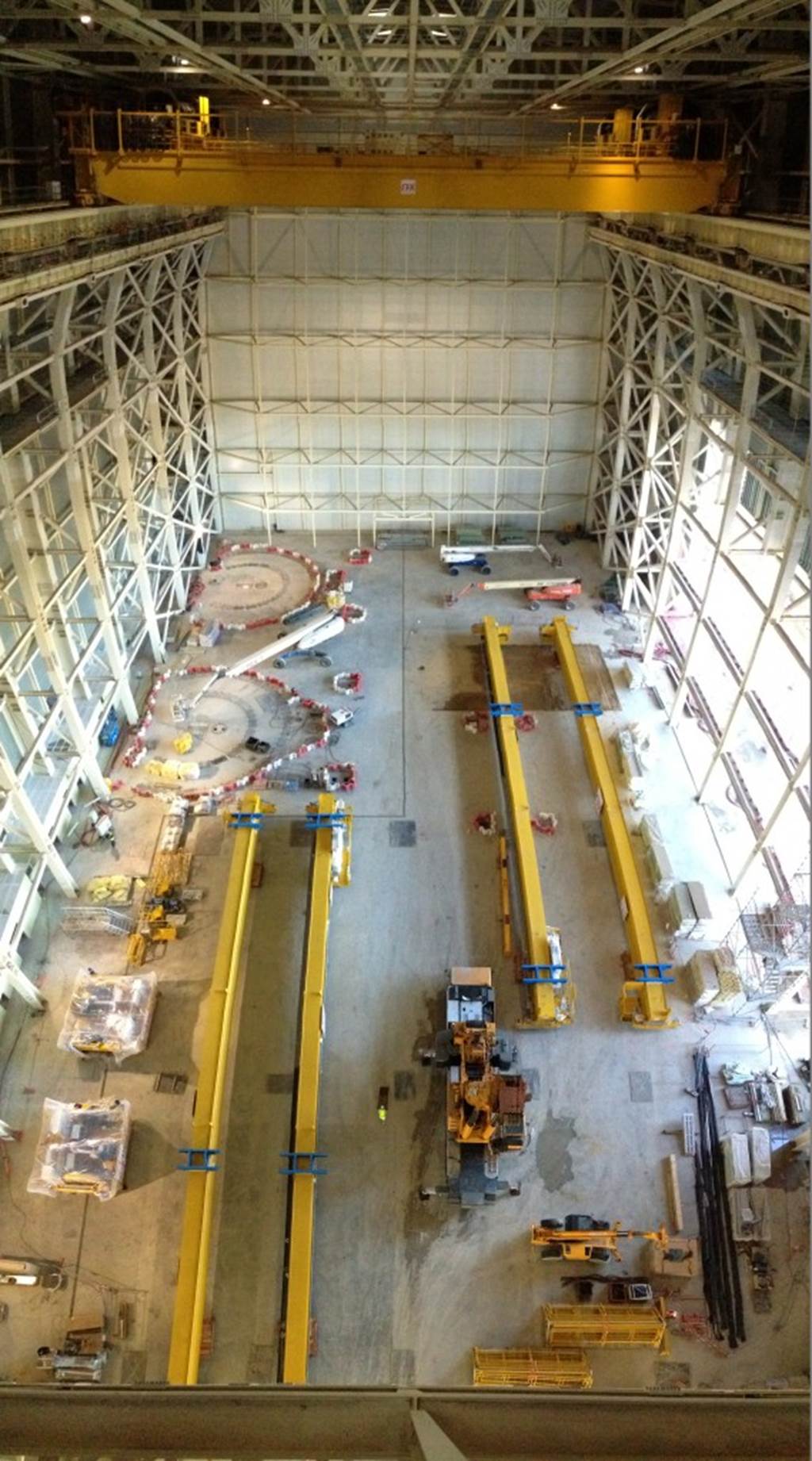

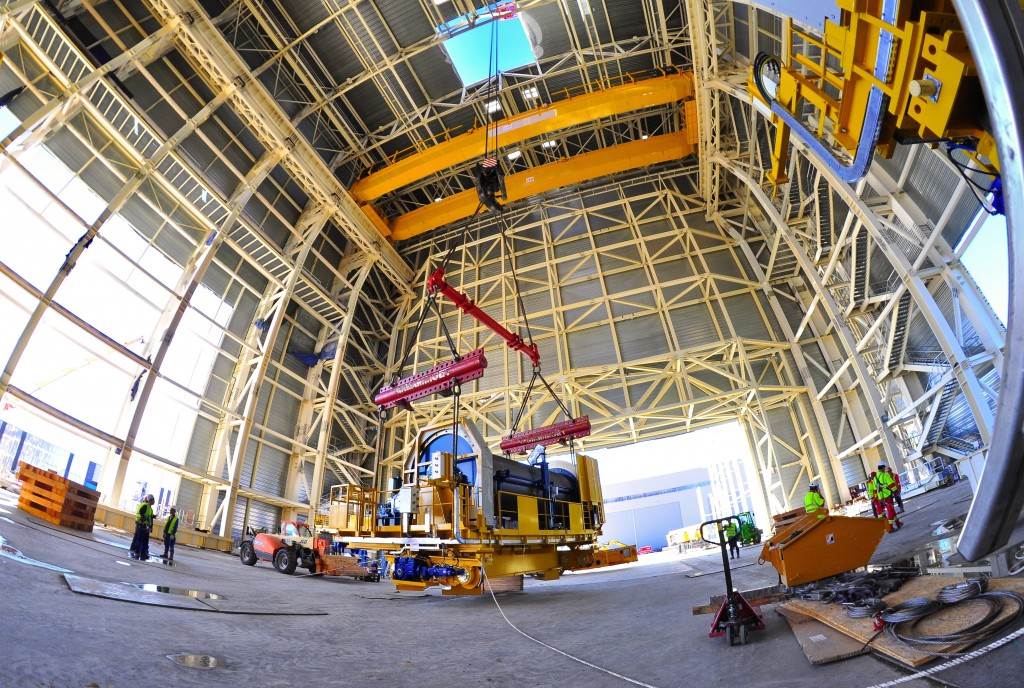

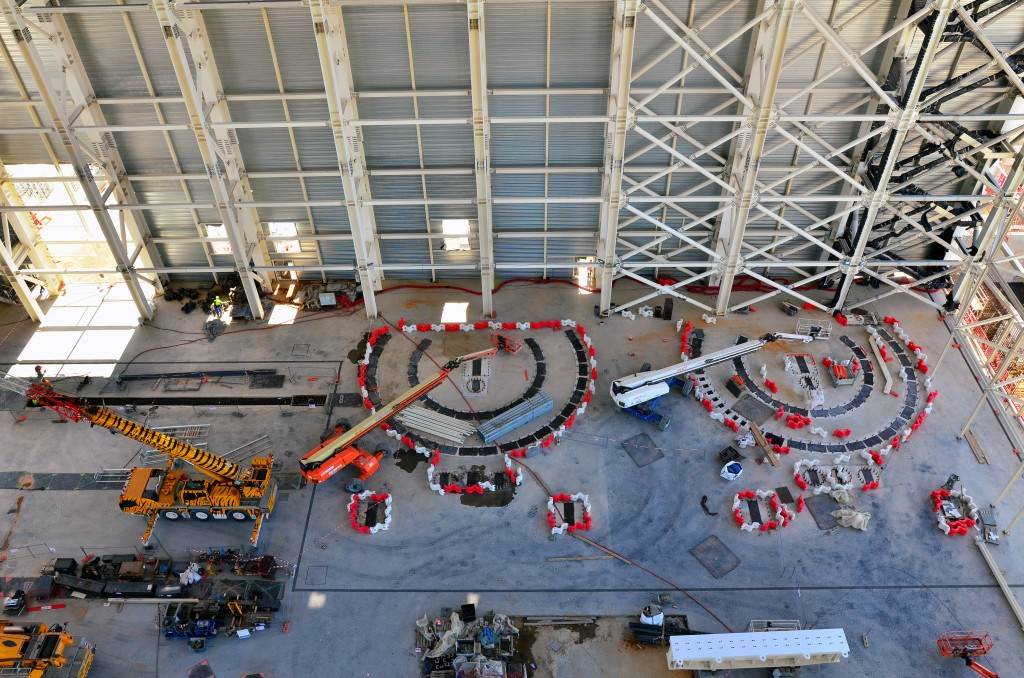

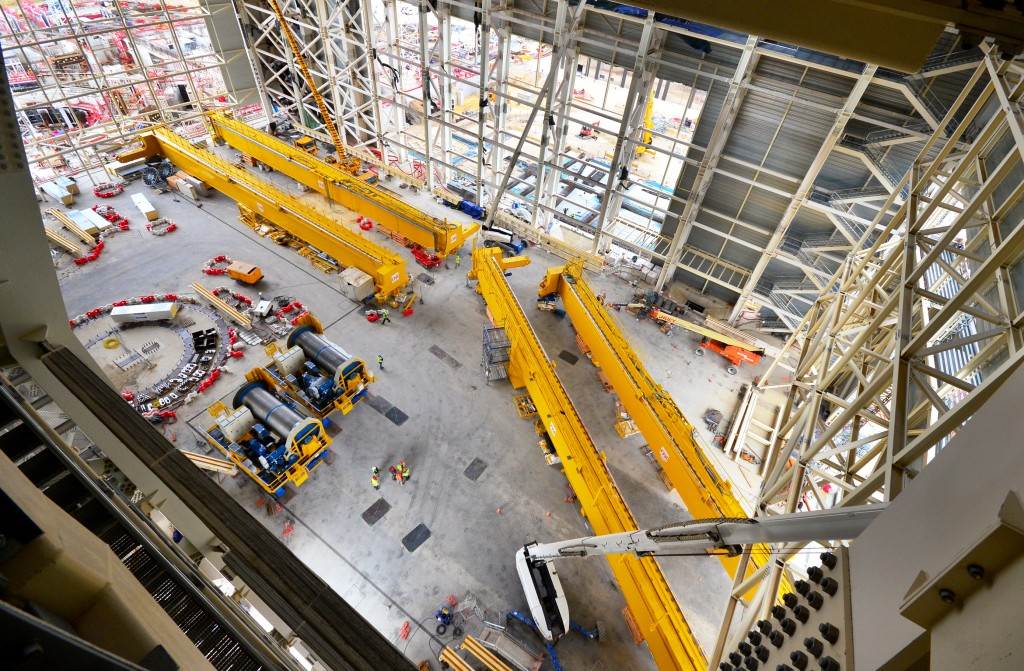

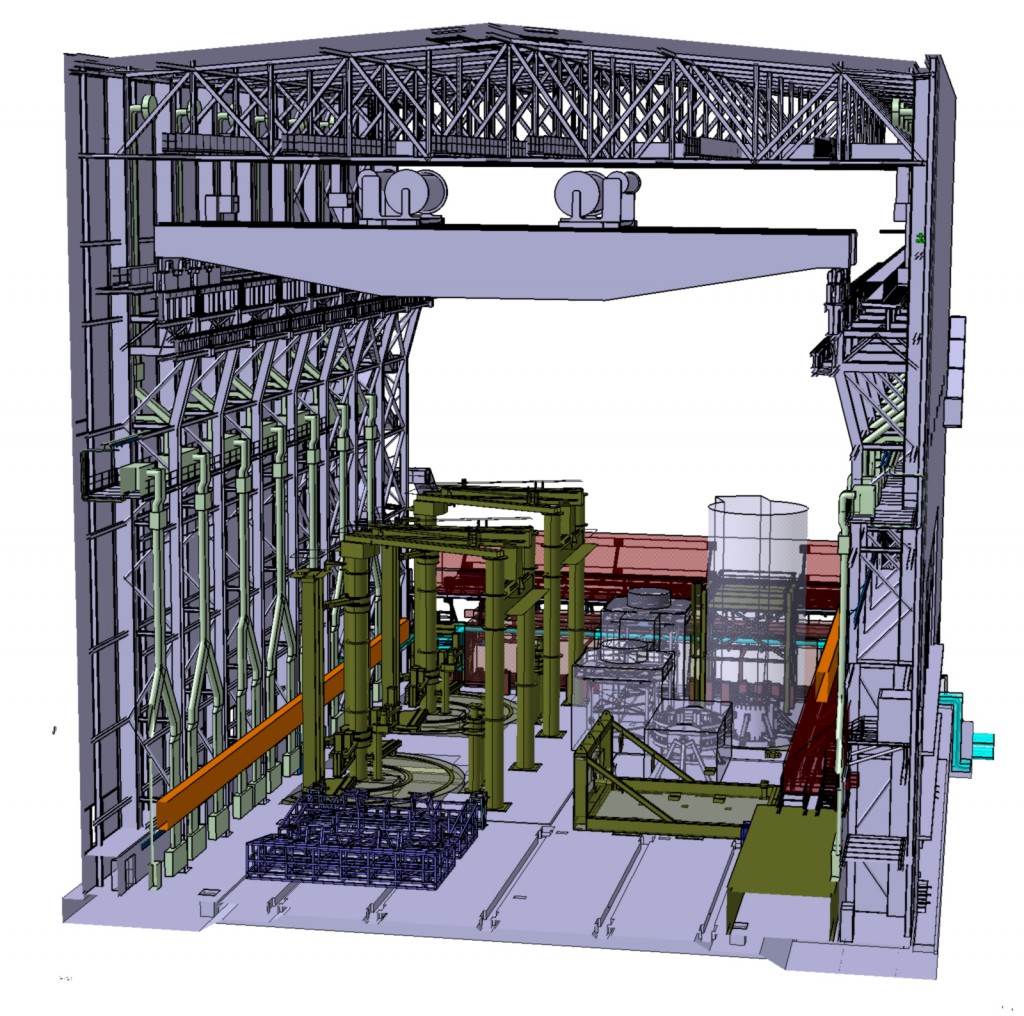

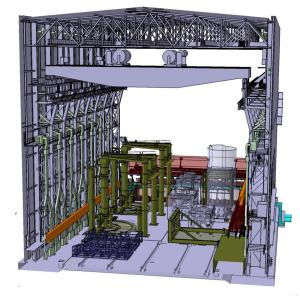

The main hoists of the Assembly Building, capable of handling loads of up to 1,500 tonnes. On the shop floor, some of the specialized tooling required to assemble, lift and finally manoeuver ITER's supersized components.

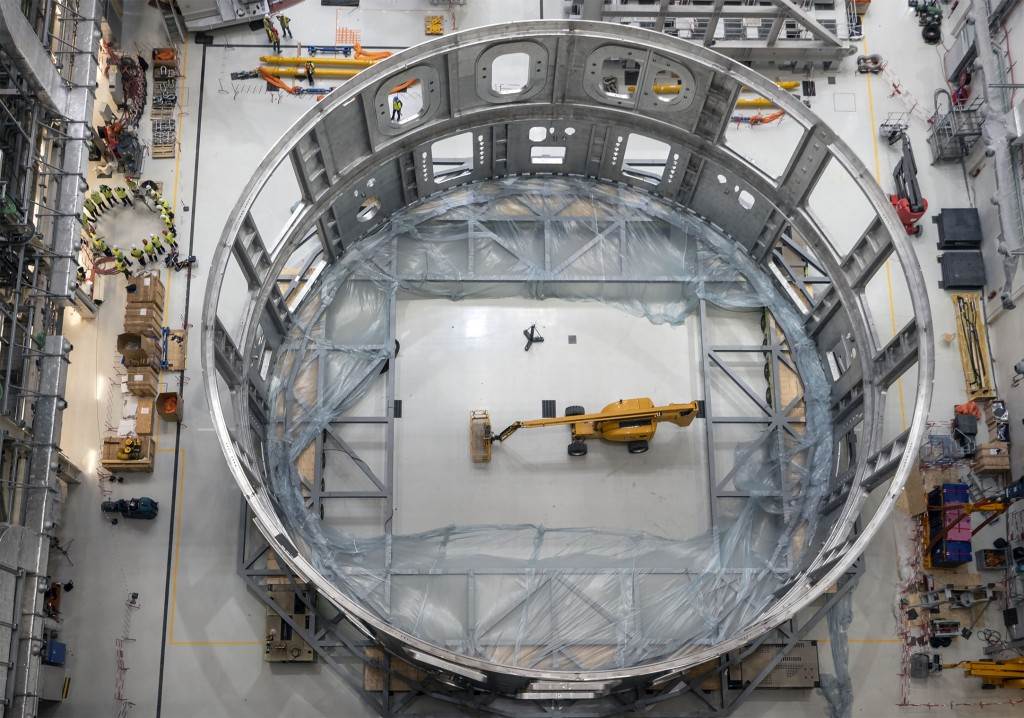

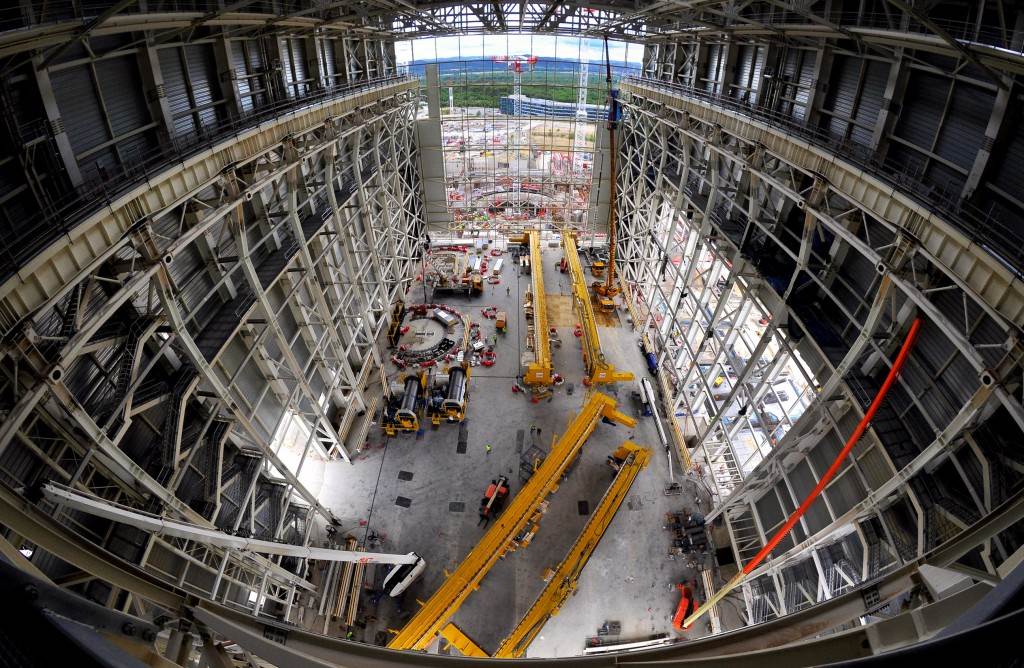

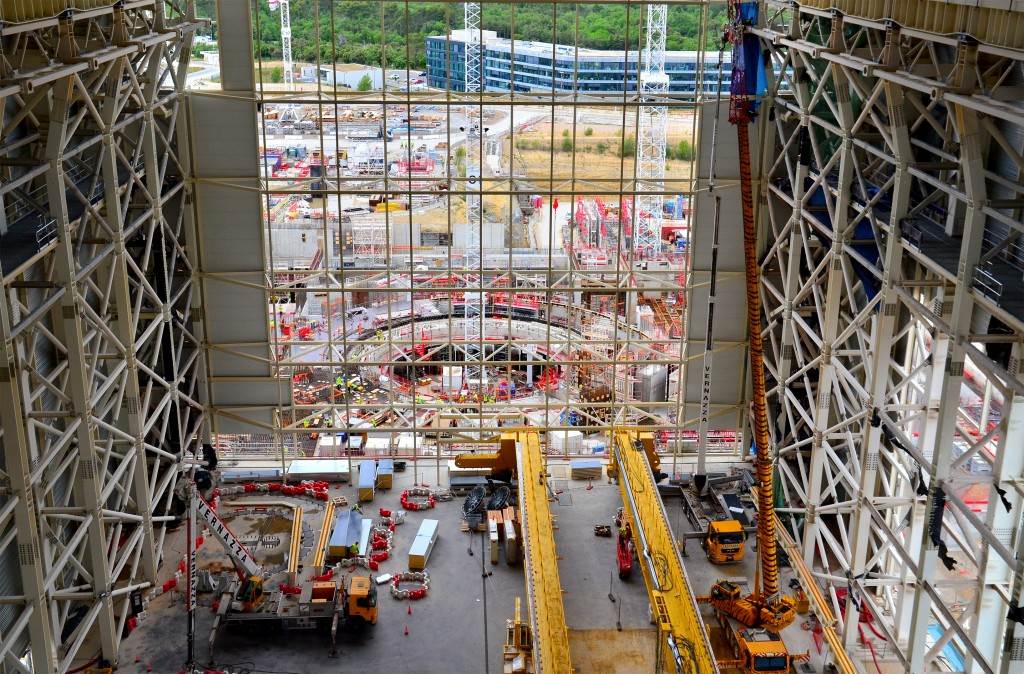

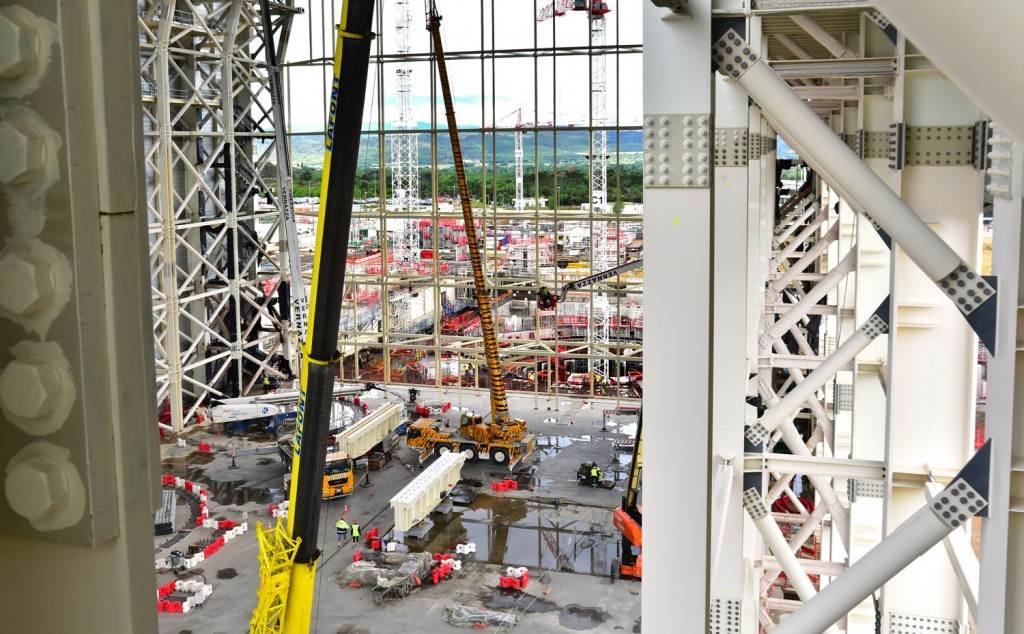

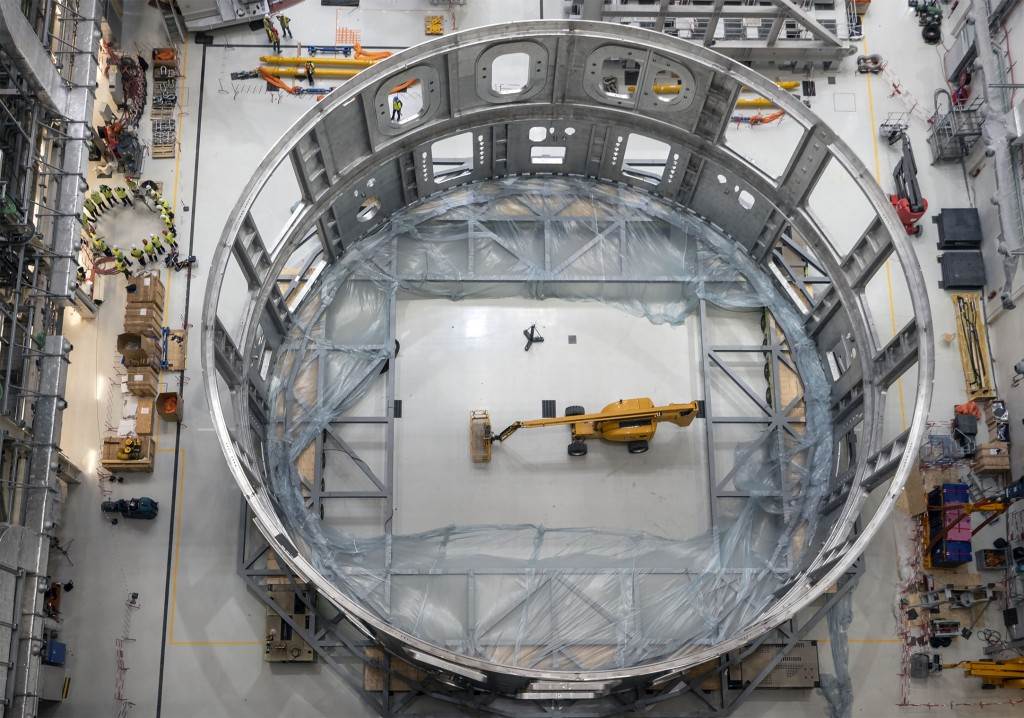

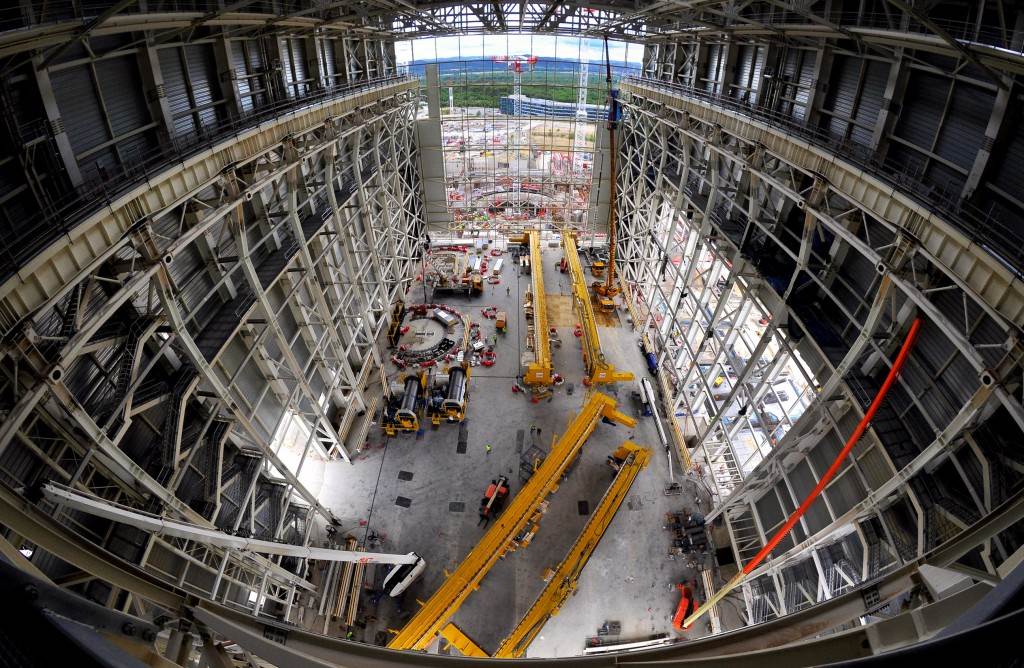

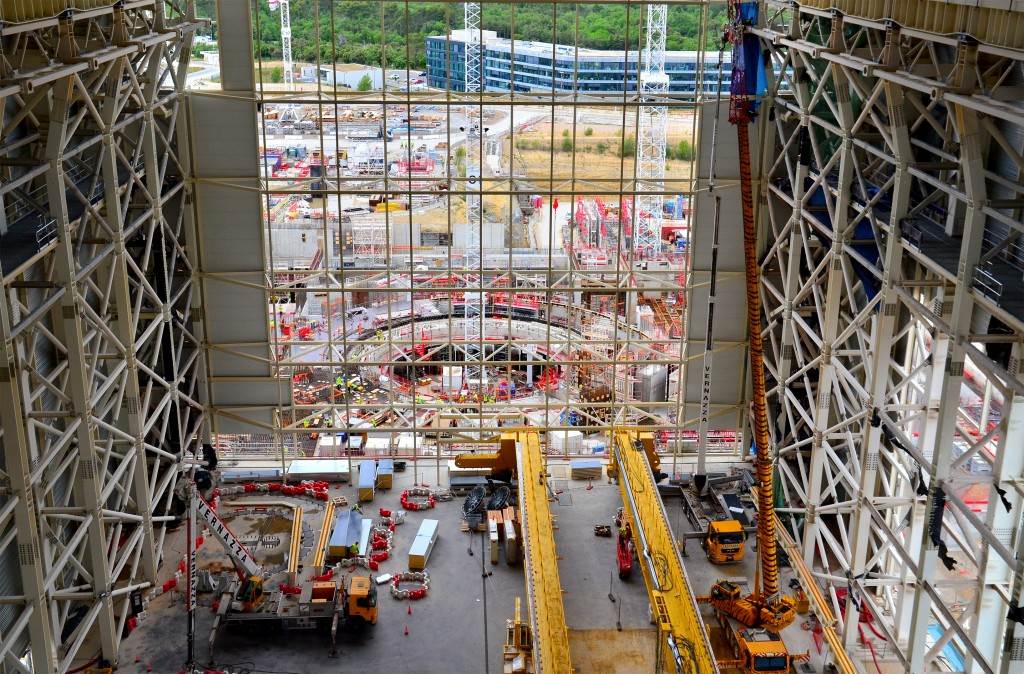

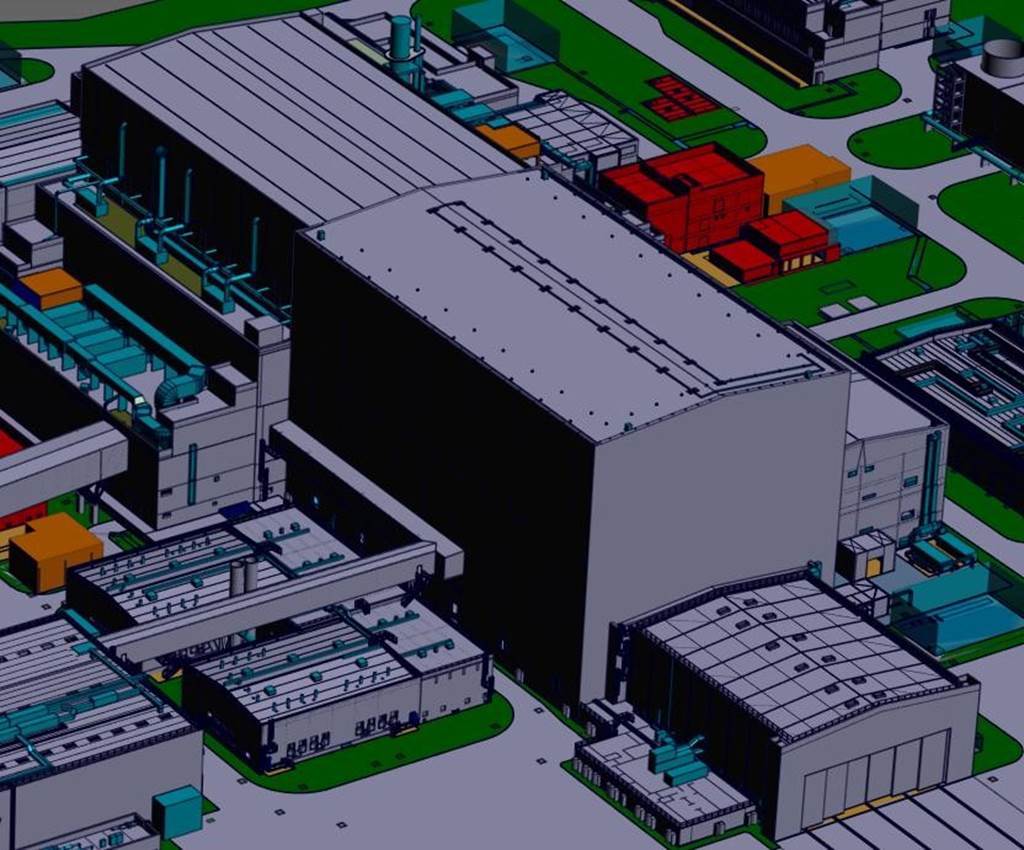

Connected directly to the Tokamak Building, the Assembly Hall is the location for pre-assembly activities on the massive components of the ITER device before they are transported to the Tokamak Pit for installation. This vast workshop hosts custom-made tools as well as two 750-tonne cranes that travel the length of the Assembly and Tokamak buildings.

Here, for example, each of the nine steel sectors of the ITER vacuum vessel will be sub-assembled with thermal shielding and a pair of toroidal field coils before being lifted and positioned inside the machine. Here also, the six modules of the central solenoid will be stacked and consolidated within a support structure.

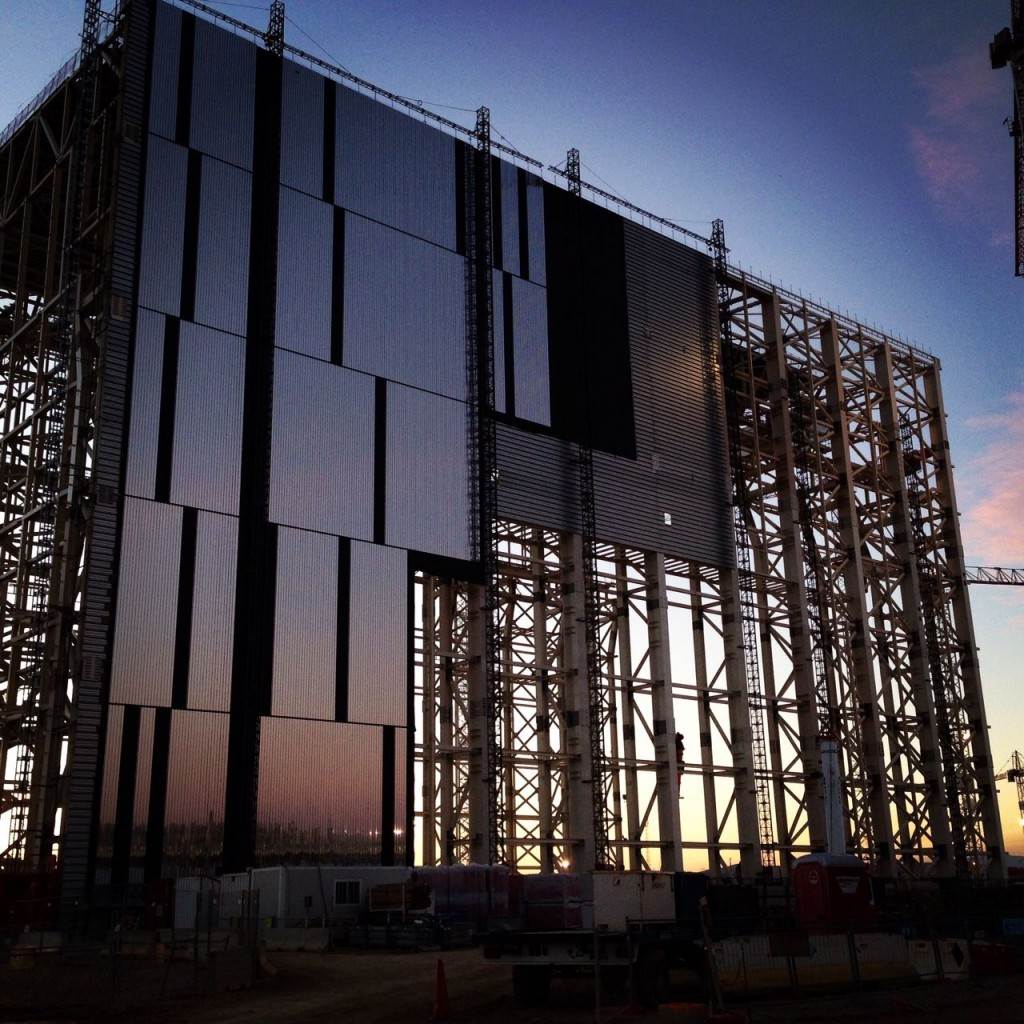

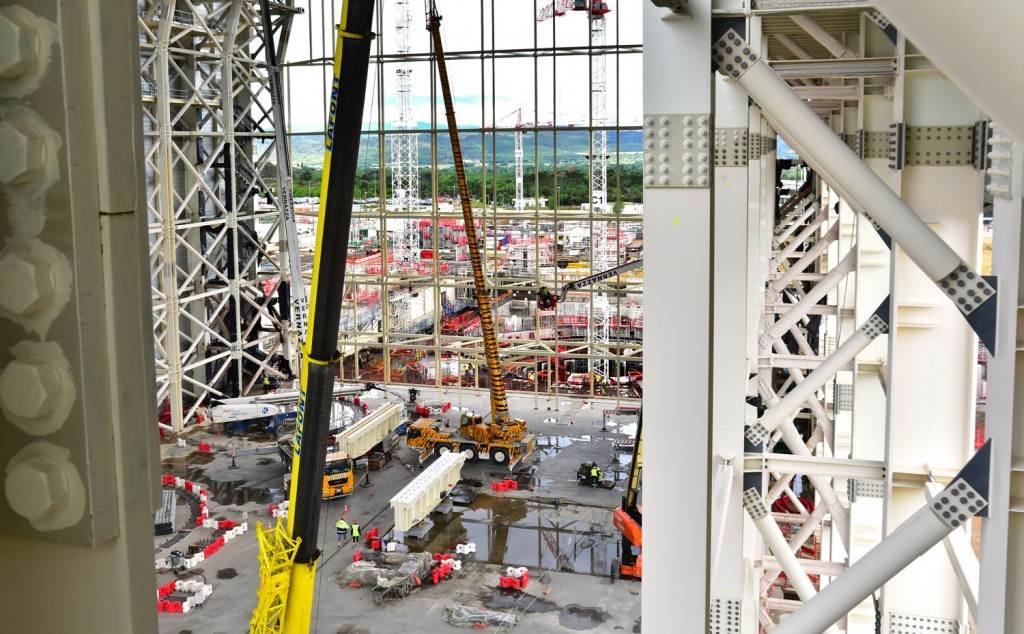

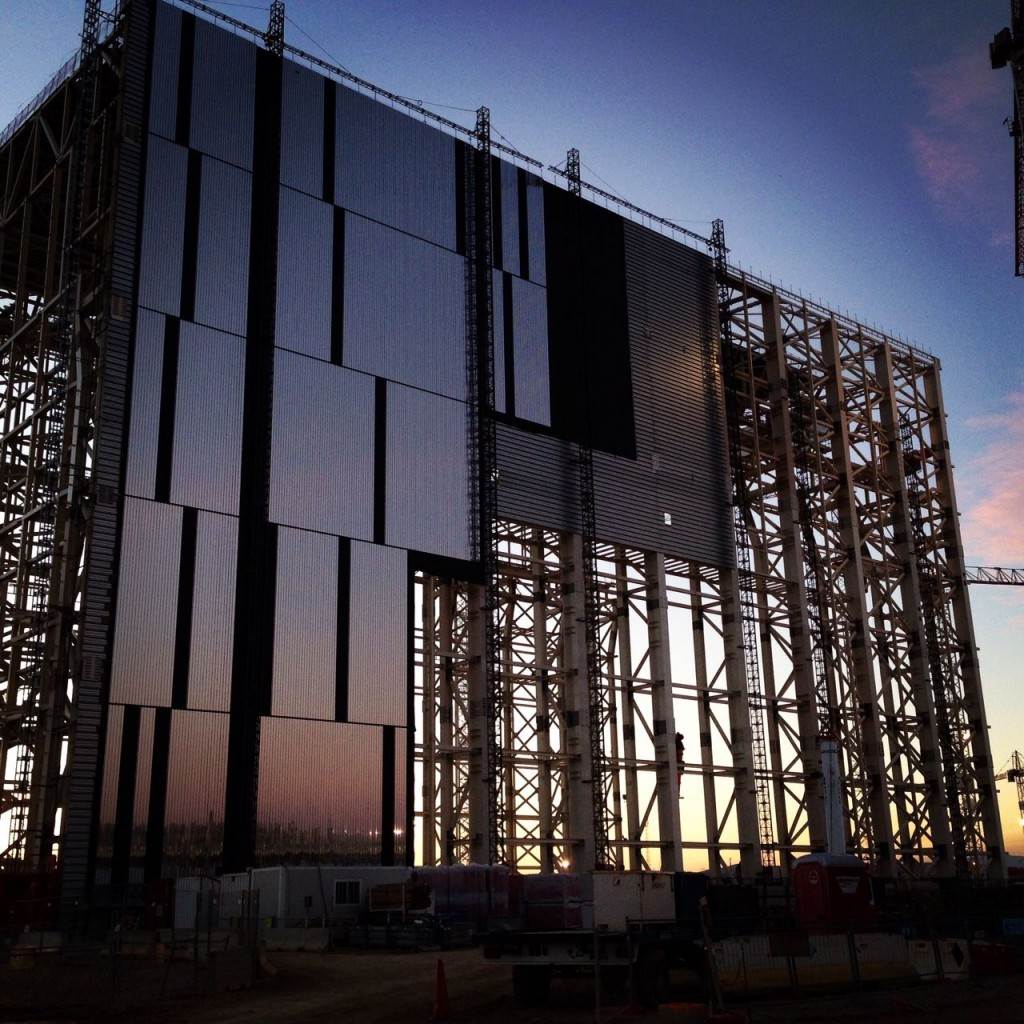

Work on the Assembly Hall began in June 2012 and was completed in September 2015 with the lifting of the massive 730-tonne roof structure. Two 750-tonne overhead cranes and two 50-tonne auxiliary cranes were installed and commissioned; tools for major assembly tasks were also put in place. In March 2020, the temporary wall separating the Assembly Hall from the Tokamak Building was removed, and the crane rails were extended over the Tokamak assembly pit to allow for the start of machine assembly.

To follow ITER machine assembly, please visit these pages.

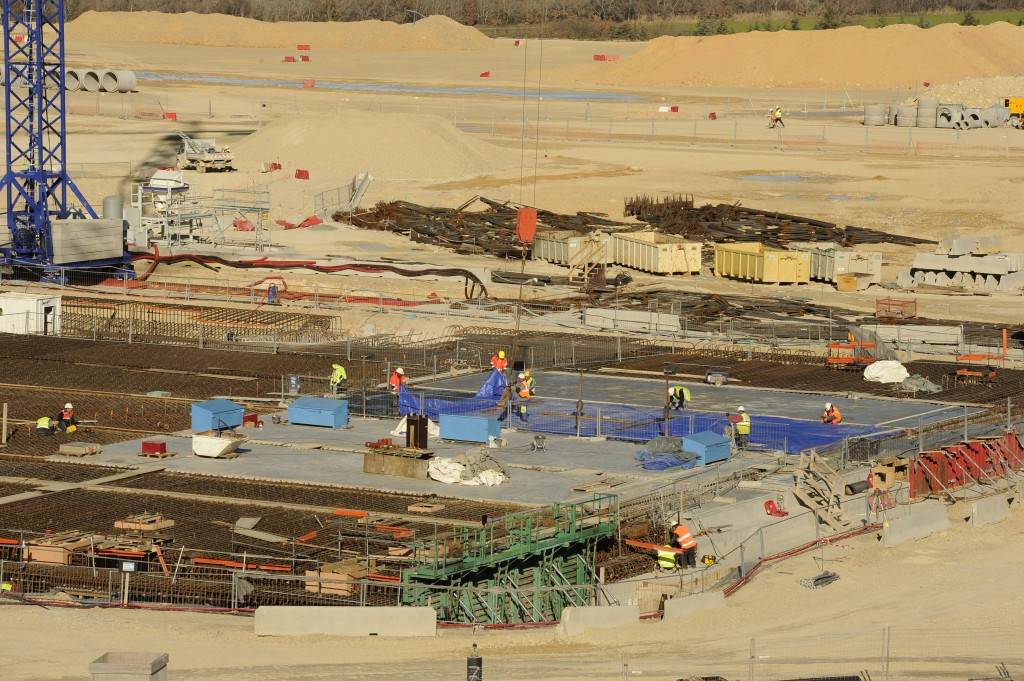

Assembly Building facts:

- Construction 2012-2015

- Building dimensions: Height: 60 metres; Length: 97 metres; Width: 60 metres

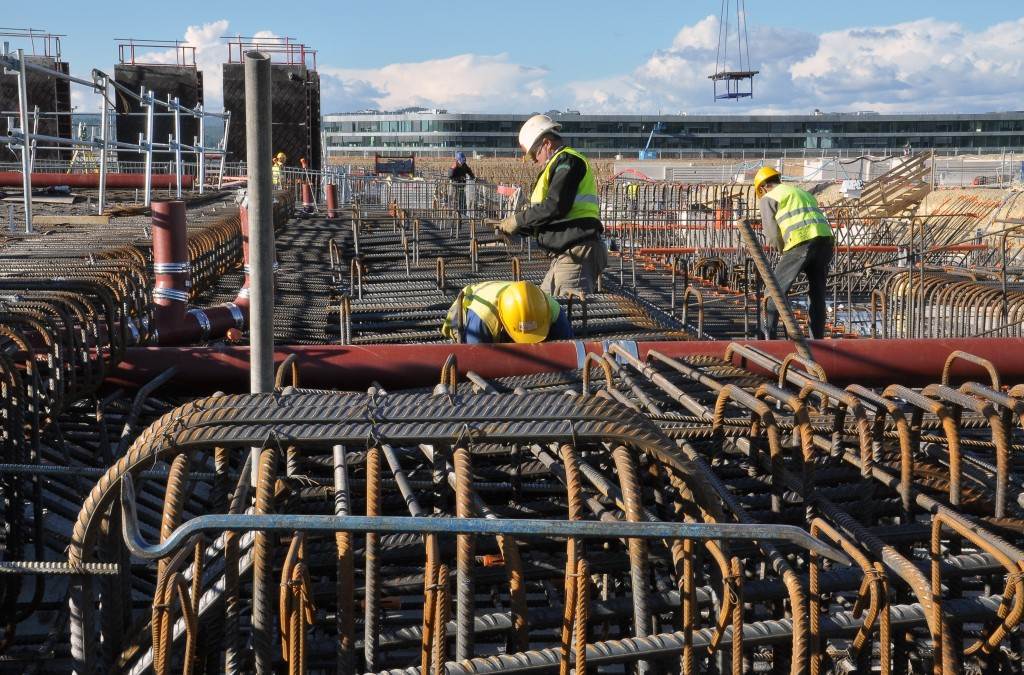

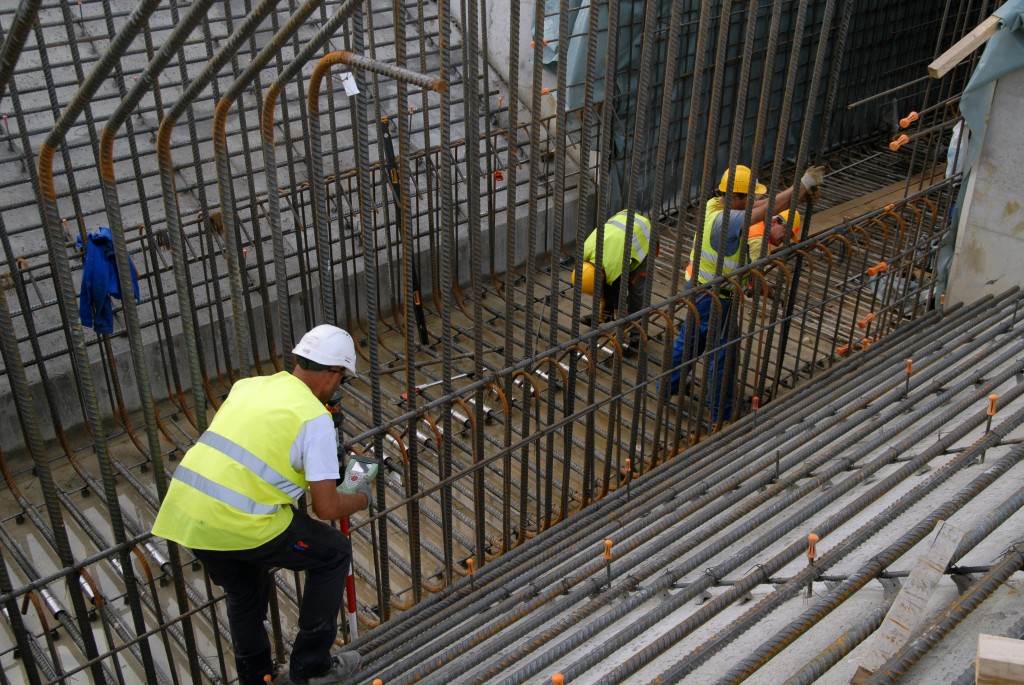

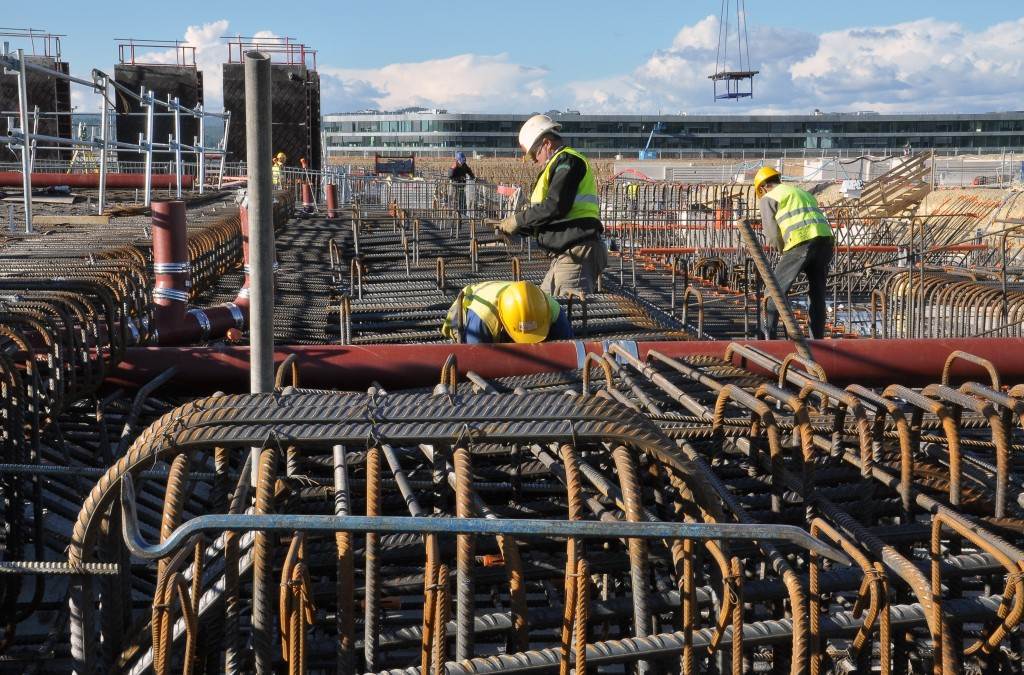

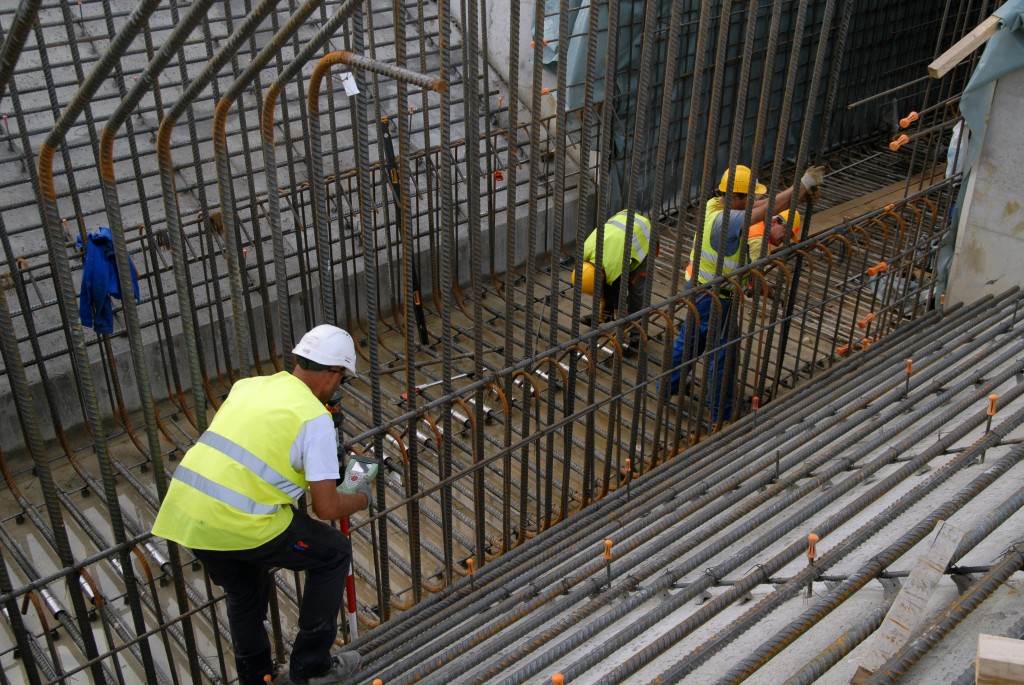

- Basemat: 1,400 tonnes of steel; 10,000 m³ of concrete

- Structure: 6,000 tonnes of steel

- Foundation thickness: 1.2‒2.2 metres

- Number of columns: 11 main (and 11 supporting) on each side

- Capacity of main cranes: 1,500 tonnes together

- Capacity of auxiliary cranes: 50 tonnes each

Photo Gallery