The Project

- Building ITER

- Projects Underway

- Construction Archives

- Neutral Beam Test Facility

- Assembly Overview

- Tokamak Assembly

- Plant Assembly

- Commissioning

- Assembly Tooling

- Metrology

- Project Milestones

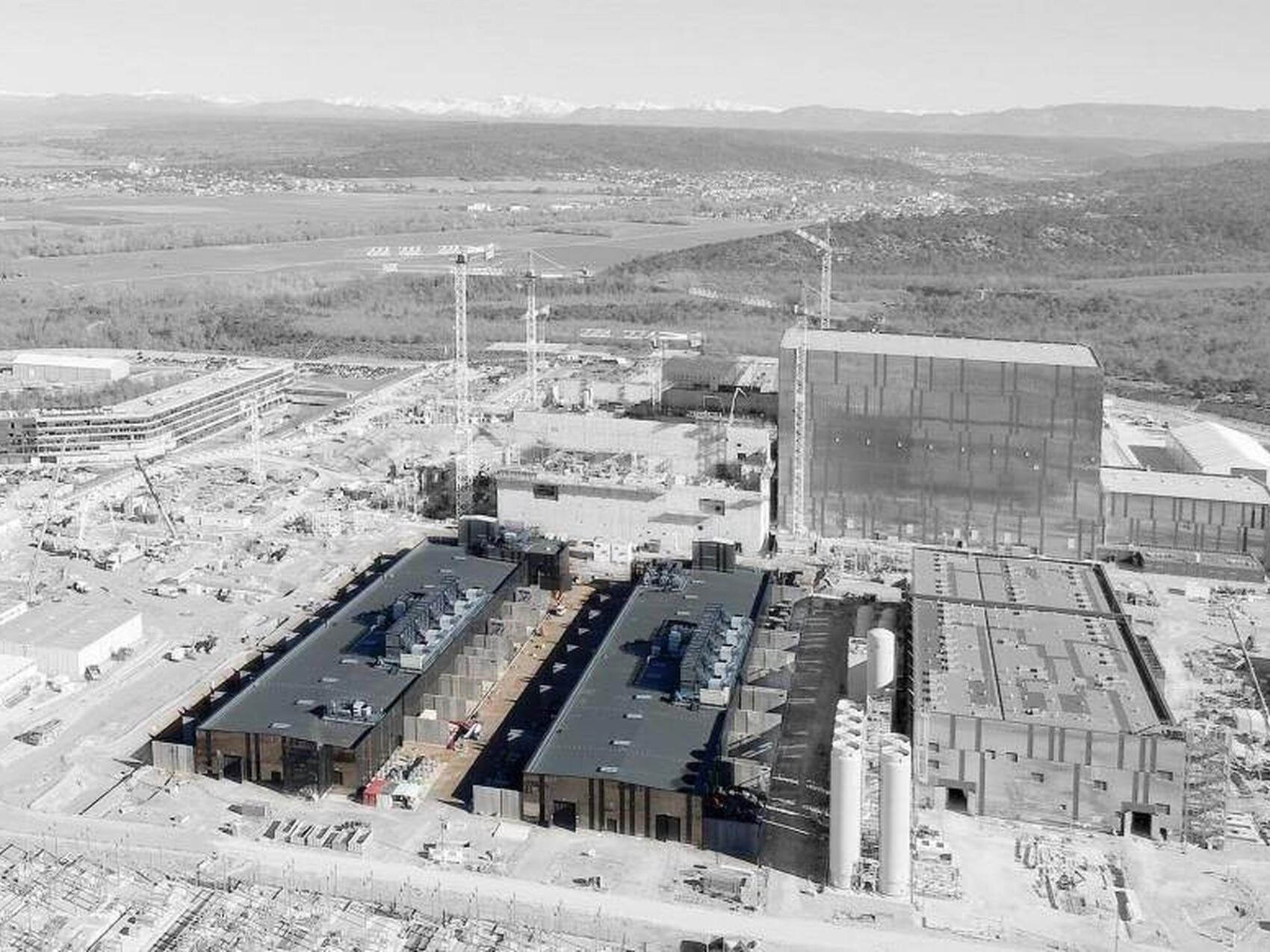

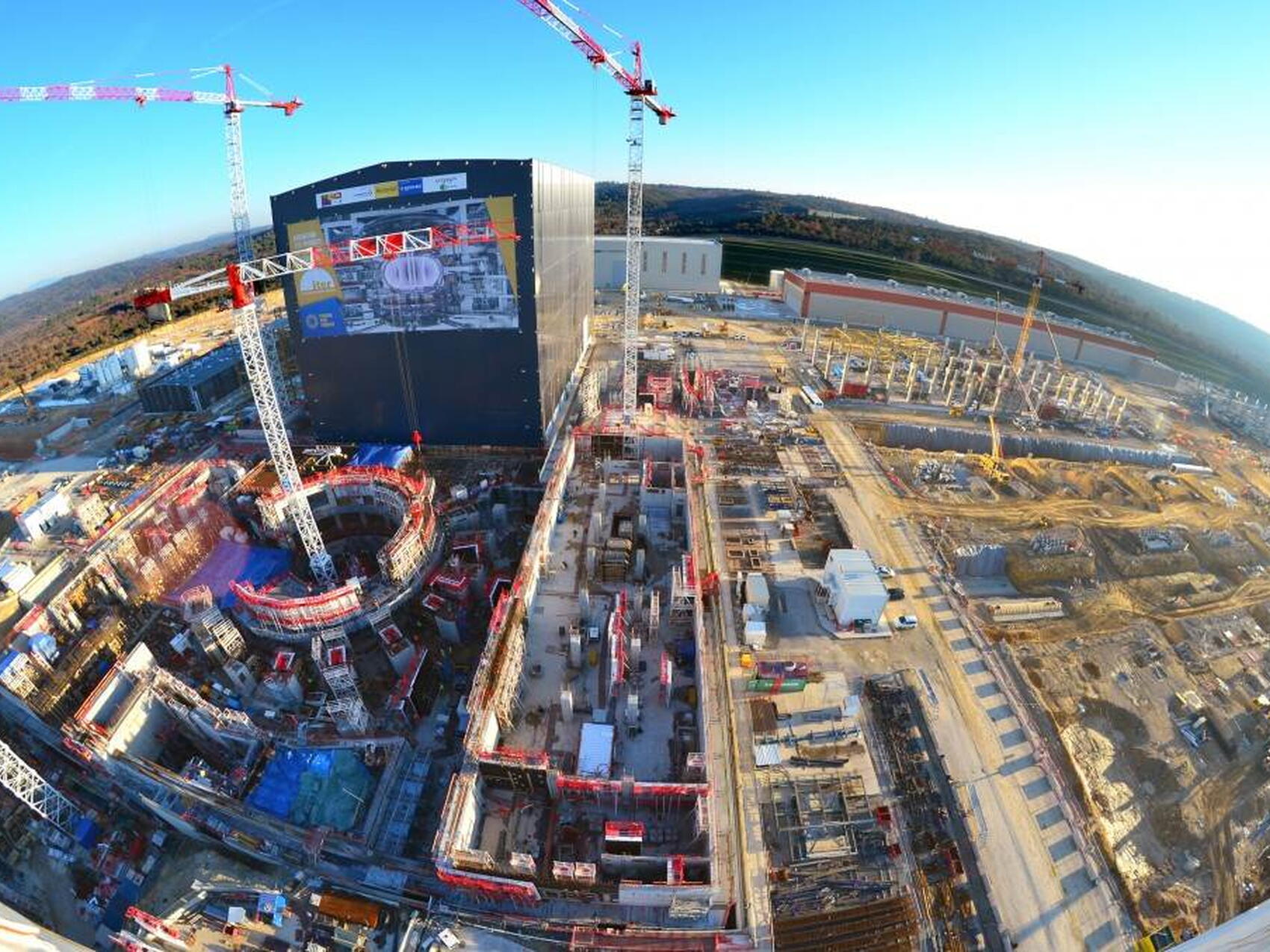

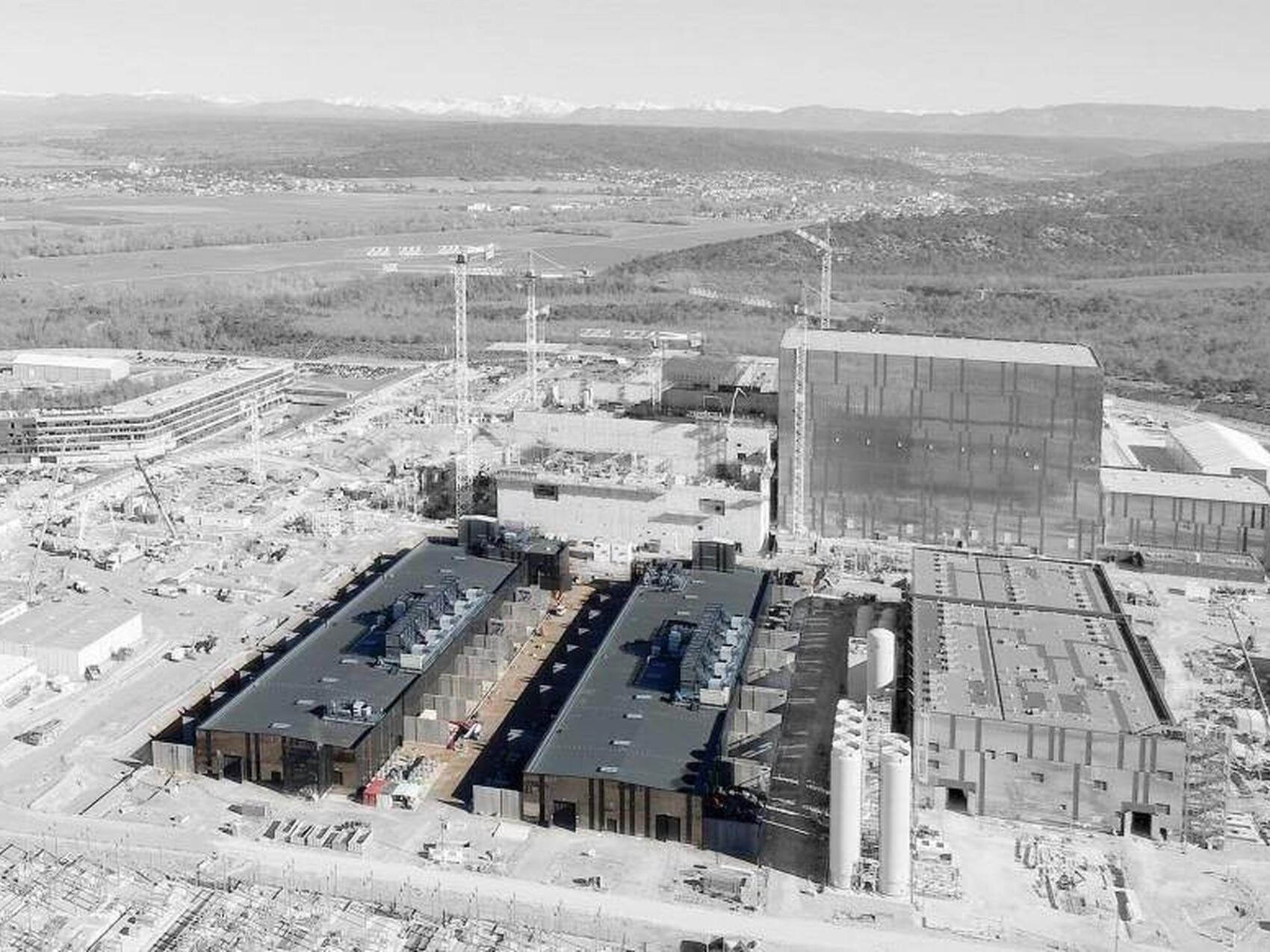

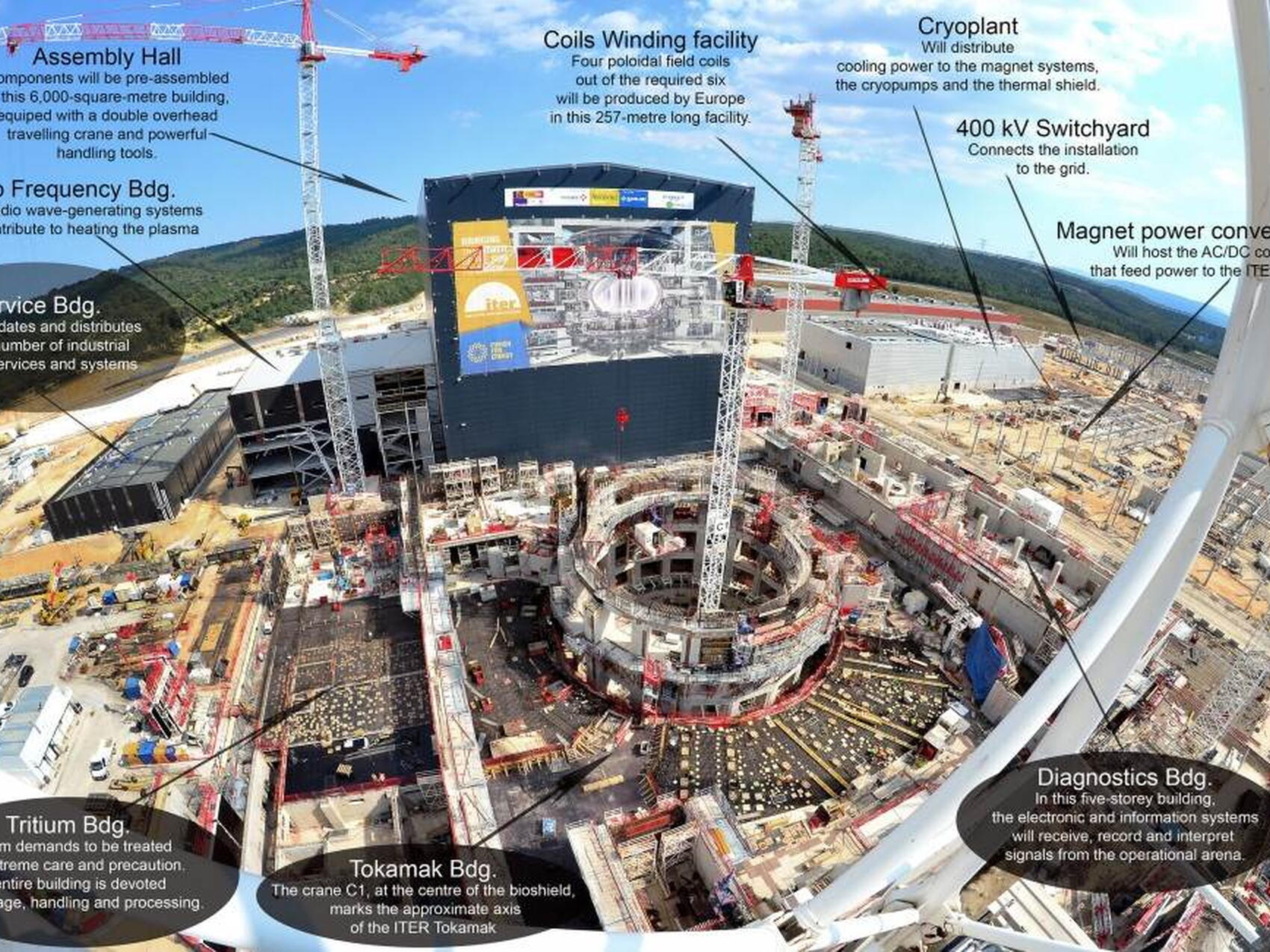

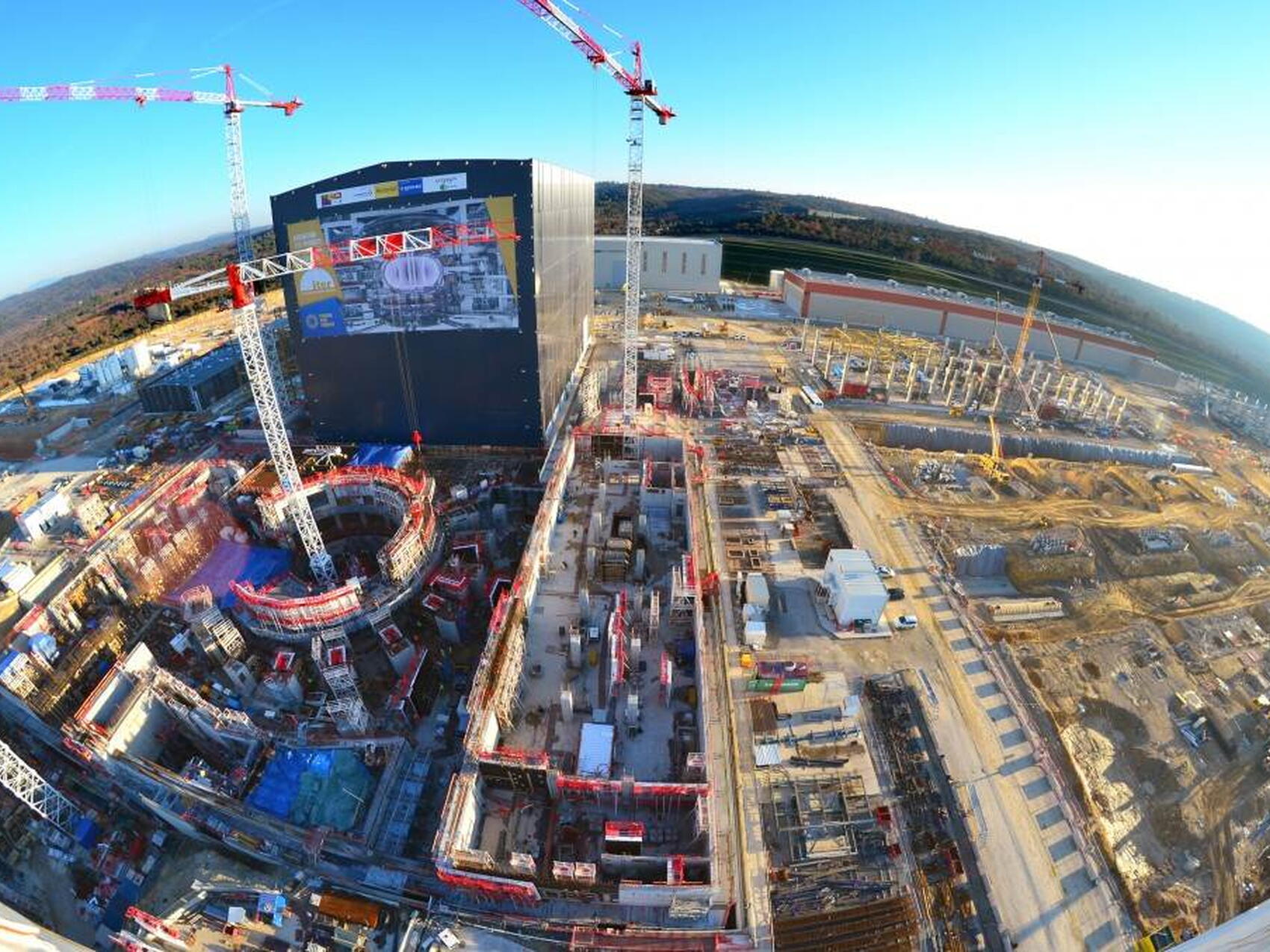

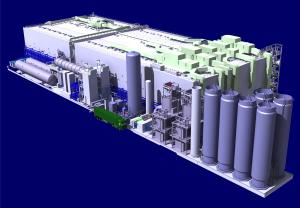

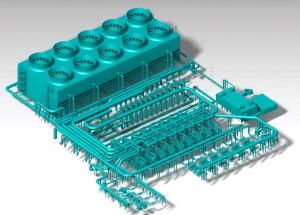

Magnet Power Conversion Buildings

The procurement responsibility for the electrical equipment in the twin Magnet Power Conversion buildings is shared by Korea, China and Russia. The twin buildings were transferred from the European Domestic Agency, Fusion for Energy, to the ITER Organization in April 2019.

Like a computer or a smartphone, ITER's 10,000 tonnes of superconducting magnets will be powered on direct current (DC). And—like flashlights and smartphones—they will need an "adapter" to convert the alternating current (AC) from ITER's electrical distribution network.

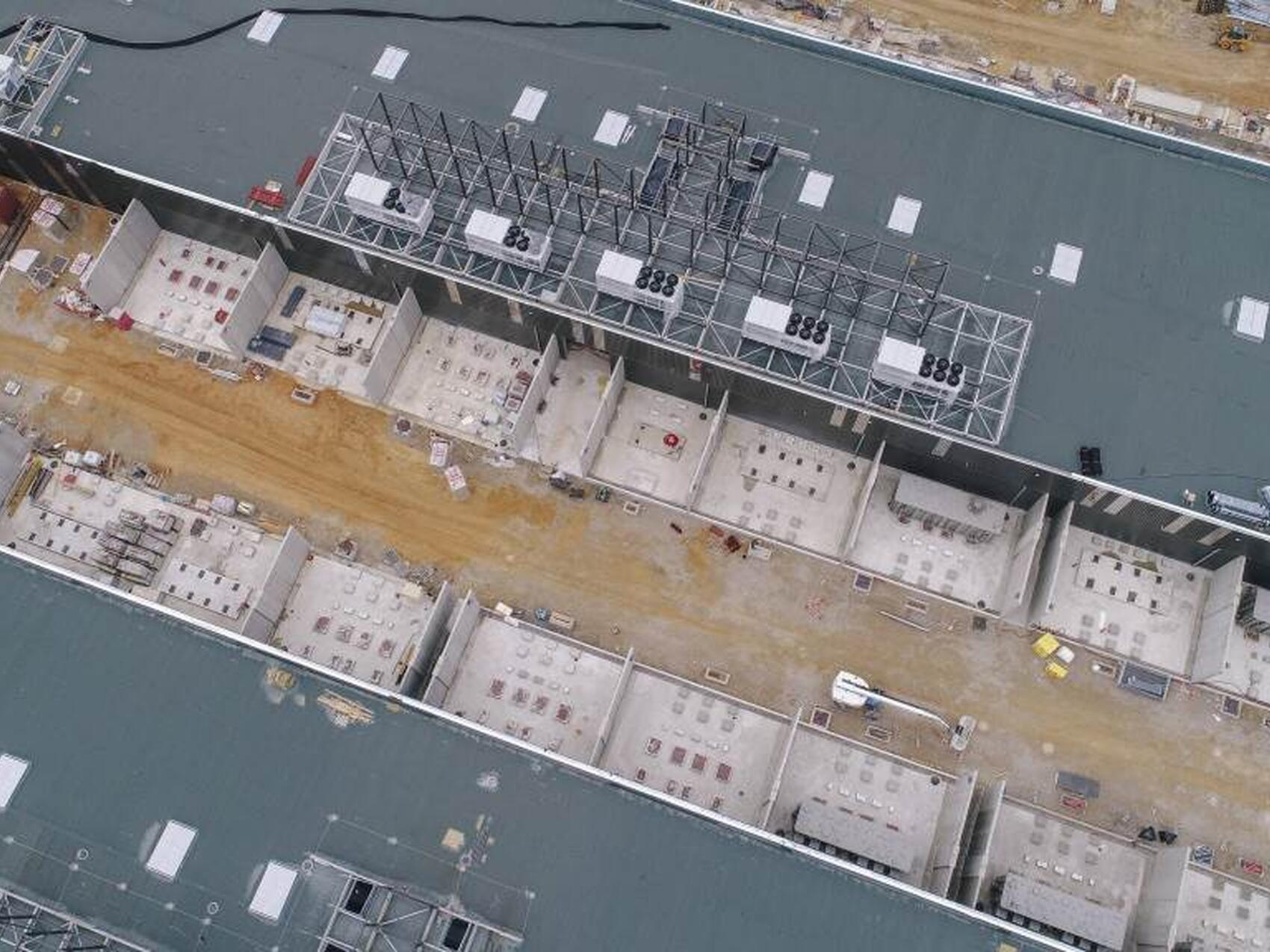

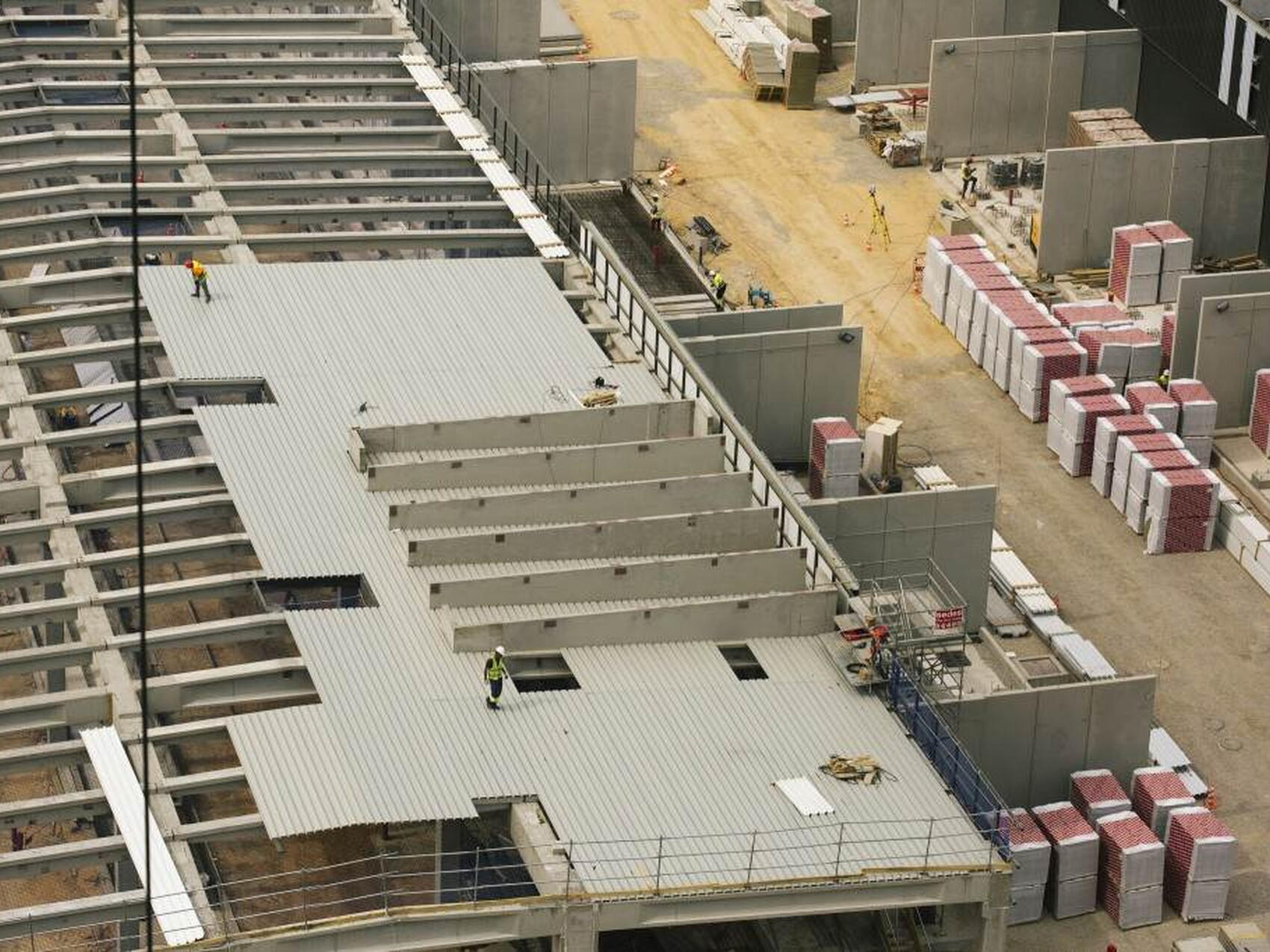

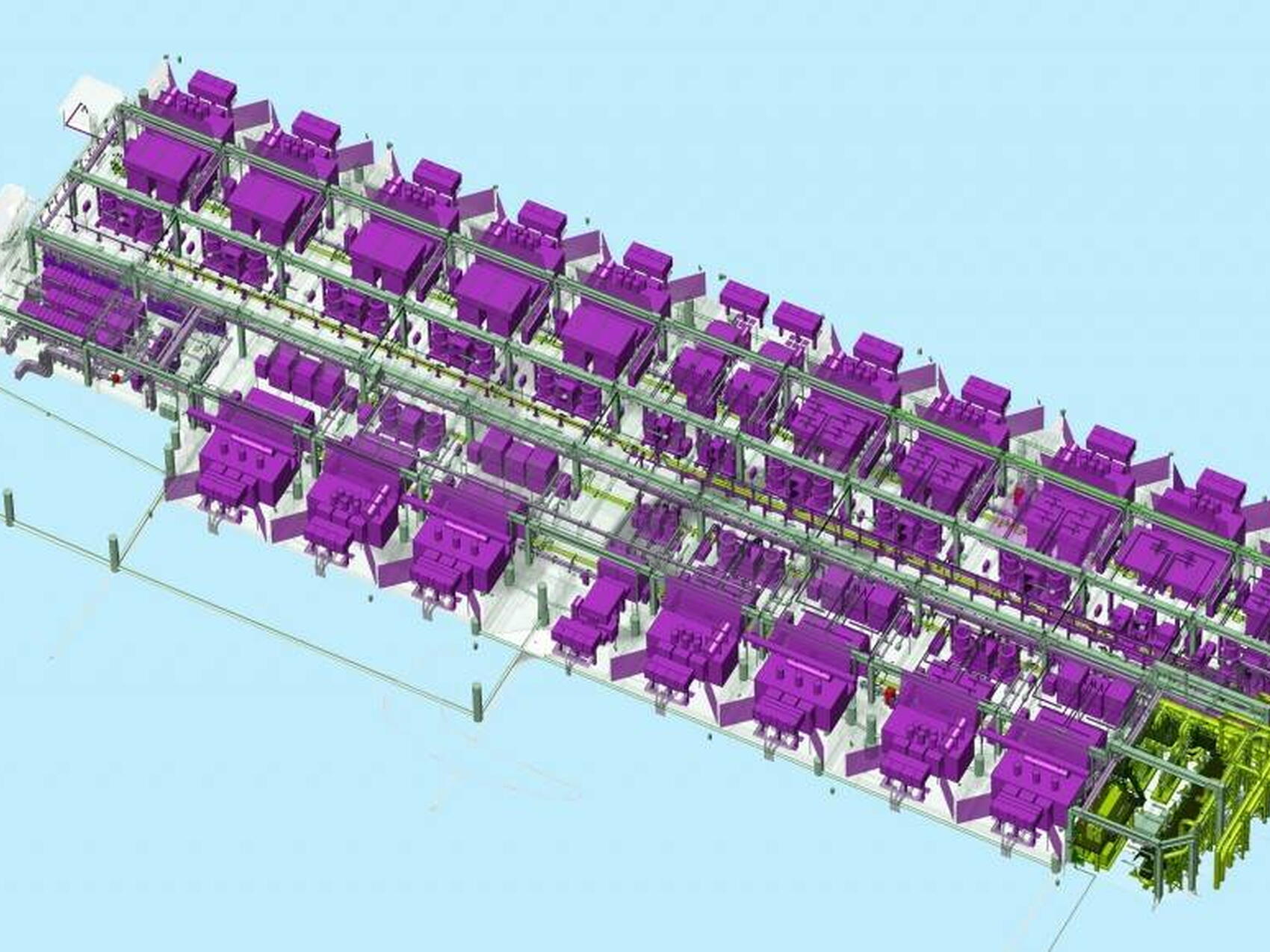

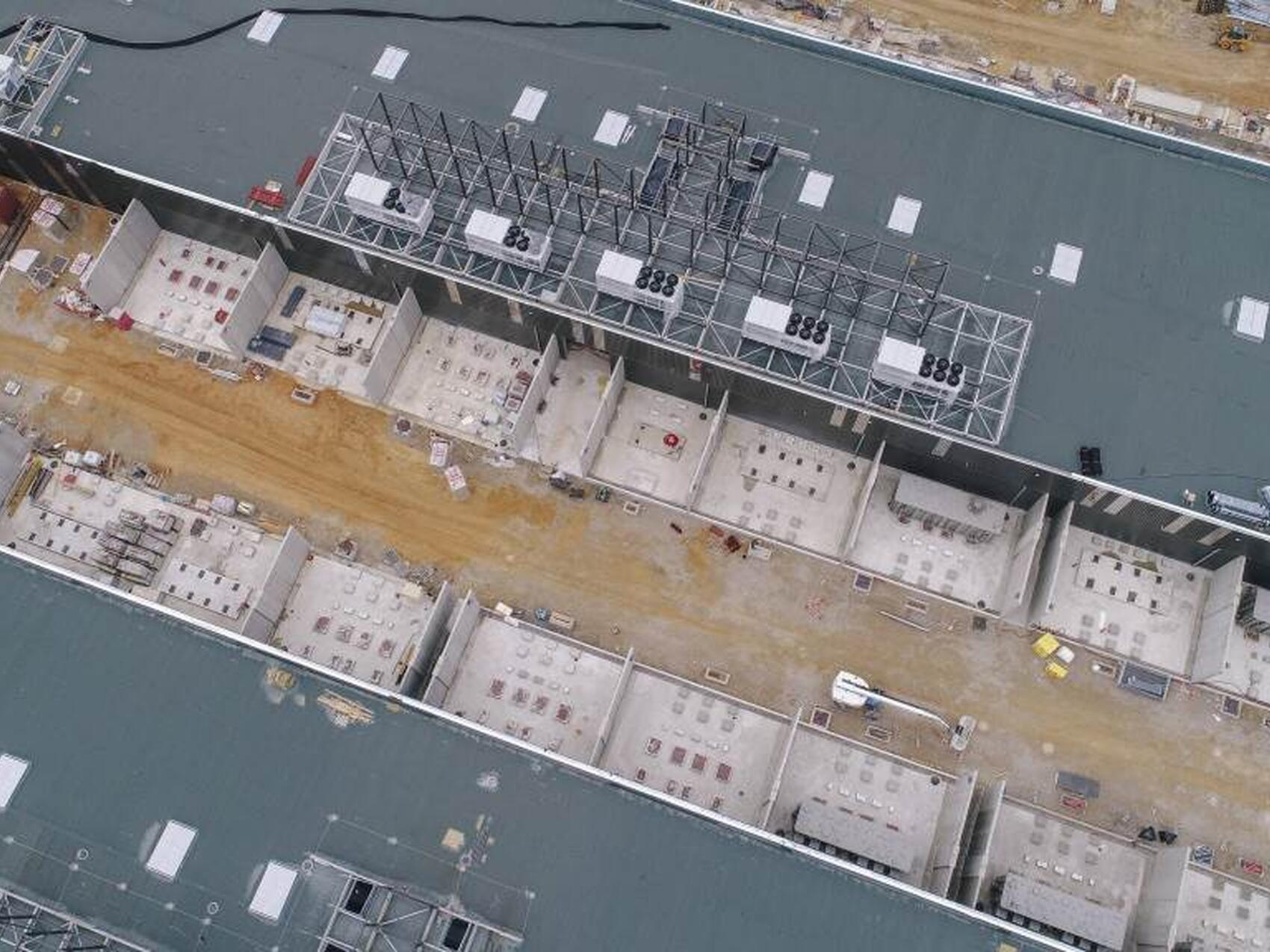

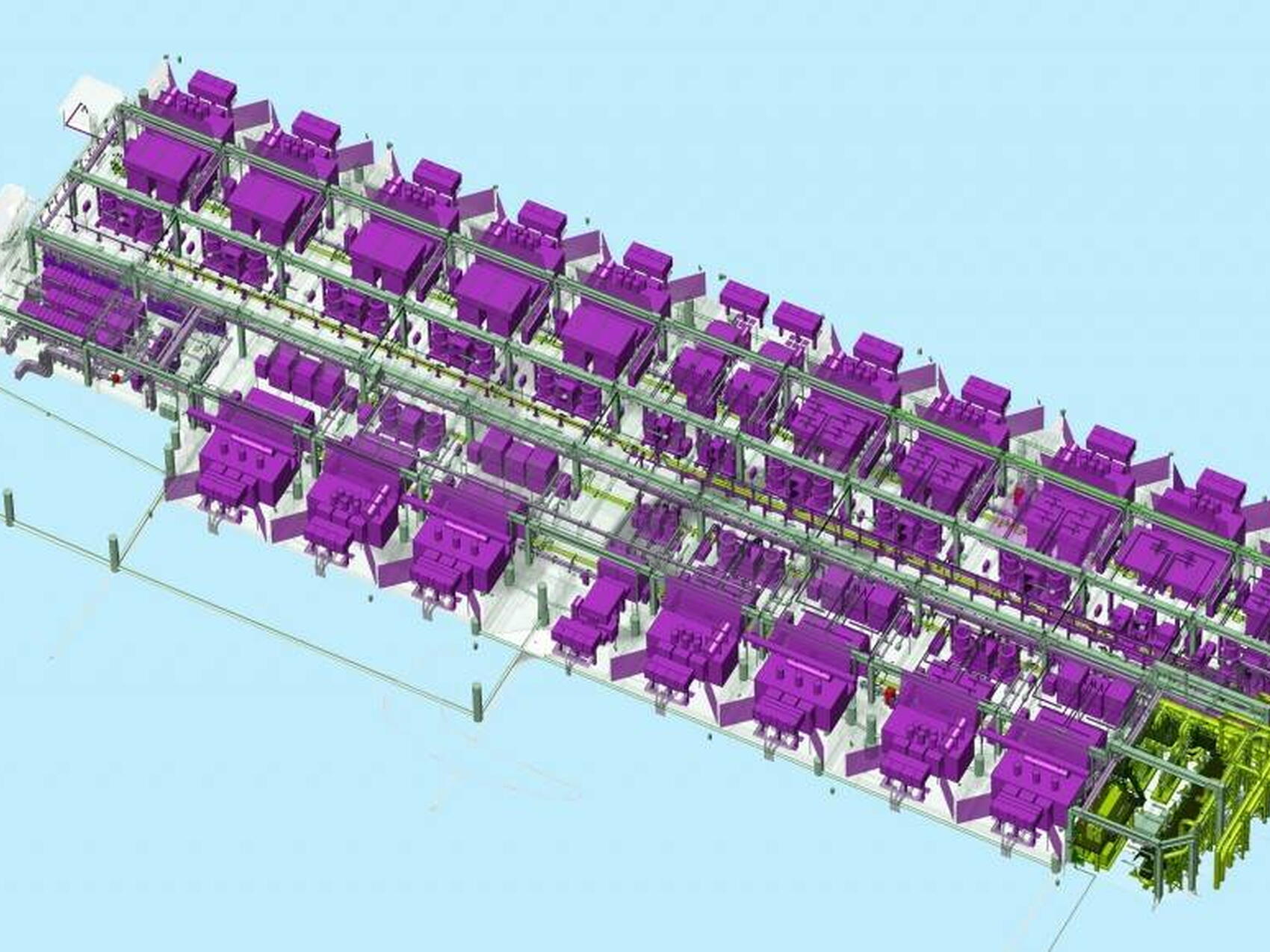

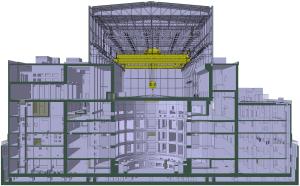

Two identical buildings on the platform—the Magnet Power Conversion buildings—play the role of adapter. One hundred and fifty metres in length, densely packed with equipment, the twin buildings are the "stepping stone" between the power arriving at the ITER switchyard at 400 kV, and the ITER magnets, which require power at DC voltages between 0.10 kV and 1.35 kV, depending on their size.

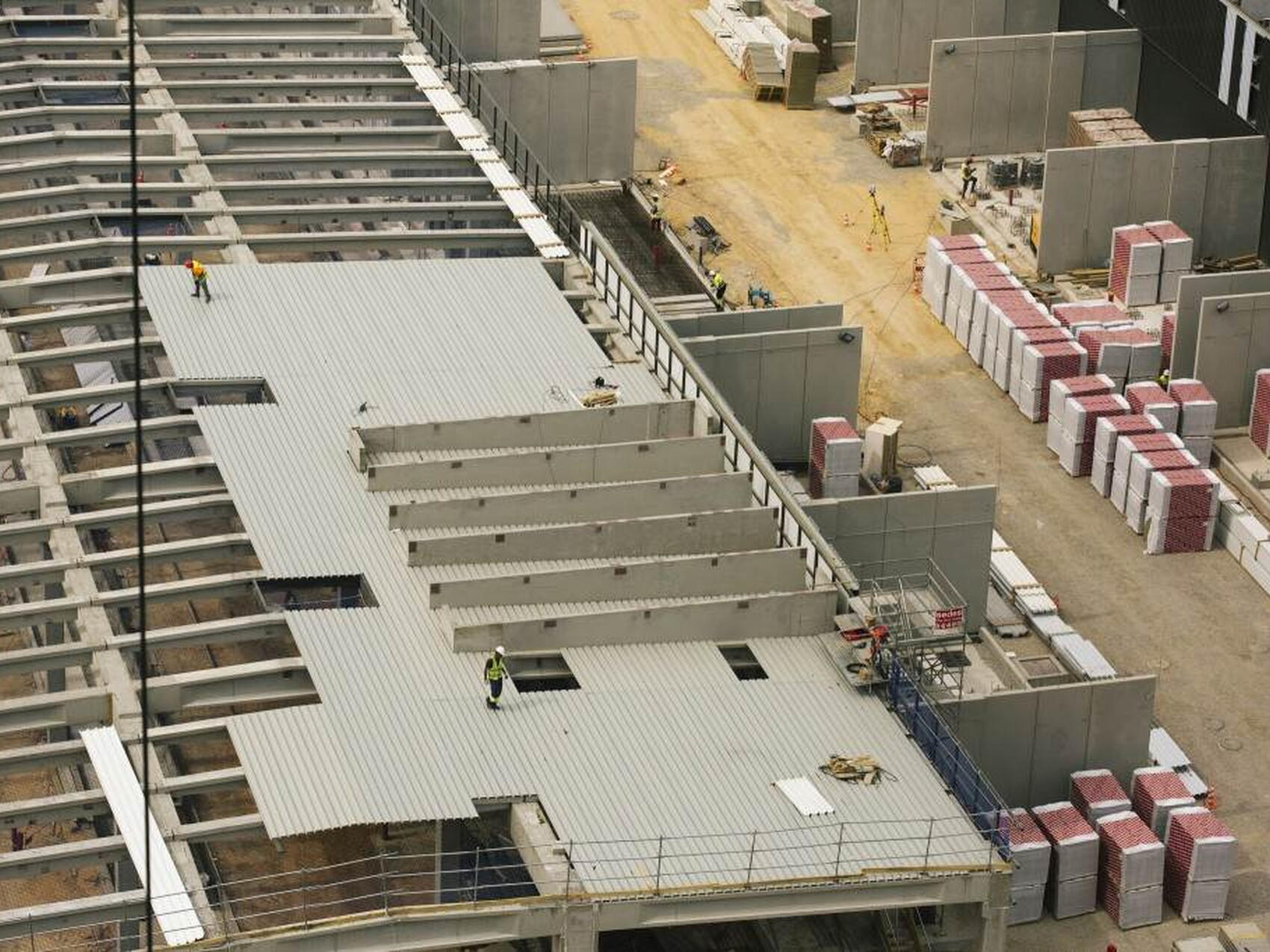

Before it reaches the superconducting magnets, the electrical power from the 400 kV switchyard is stepped down through a cascade of transformations. First, three very large pulsed power electrical transformers reduce the voltage to 66 kV and 22 kV before the electrical power is fed to the converter transformers outside the Magnet Power Conversion buildings. Forty-four AC/DC converter units—comprising a transformer, a converter and a busbar section—are needed for first-phase operations (Start of Research Operation, SRO).

The converter transformers are each dedicated to a specific magnet system (central solenoid, toroidal field coils, poloidal field coils, correction coils). Their role is to bring the voltage down to approximately 1 kV (the precise voltage is determined by the individual magnet system). Each one is paired with a large rectifier whose function is to convert the AC current to large DC current.

Once the current has been "rectified," it can be fed to the magnets. Given the intensity of the current, steel-jacketed aluminium bars called "busbars"—actively cooled through a constant flow of pressurized water—replace more traditional cables. No fewer than 5 km of bipolar busbars will travel through the Magnet Power Conversion buildings and across 50-metre-long elevated bridges to the Tokamak Complex. On the last leg of their journey, the busbars will almost fully occupy two levels of the Diagnostics Building.

Also housed in the Tokamak Complex are the fast discharge units and switches that offer an alternative path to the huge amount of energy stored in the ITER magnet system (up to 50 gigajoules) in the case of a "quench"—a rare but anticipated event that causes part of the magnet system to lose superconductivity.

Magnet Power Conversion Building facts:

- Construction: 2016-2019

- Total area: 9,400 m² indoor plus 5,700 m² outdoor

- Number of buildings: 2

- Building dimensions: 150 metres long, 30 metres wide

- Number of converter units: 44, in two batches (32 then 12)

- Start of integrated testing: 2023

Photo Gallery