The Project

- Building ITER

- Projects Underway

- Construction Archives

- Neutral Beam Test Facility

- Assembly Overview

- Tokamak Assembly

- Plant Assembly

- Commissioning

- Assembly Tooling

- Metrology

- Project Milestones

Poloidal Field Coils Winding Facility

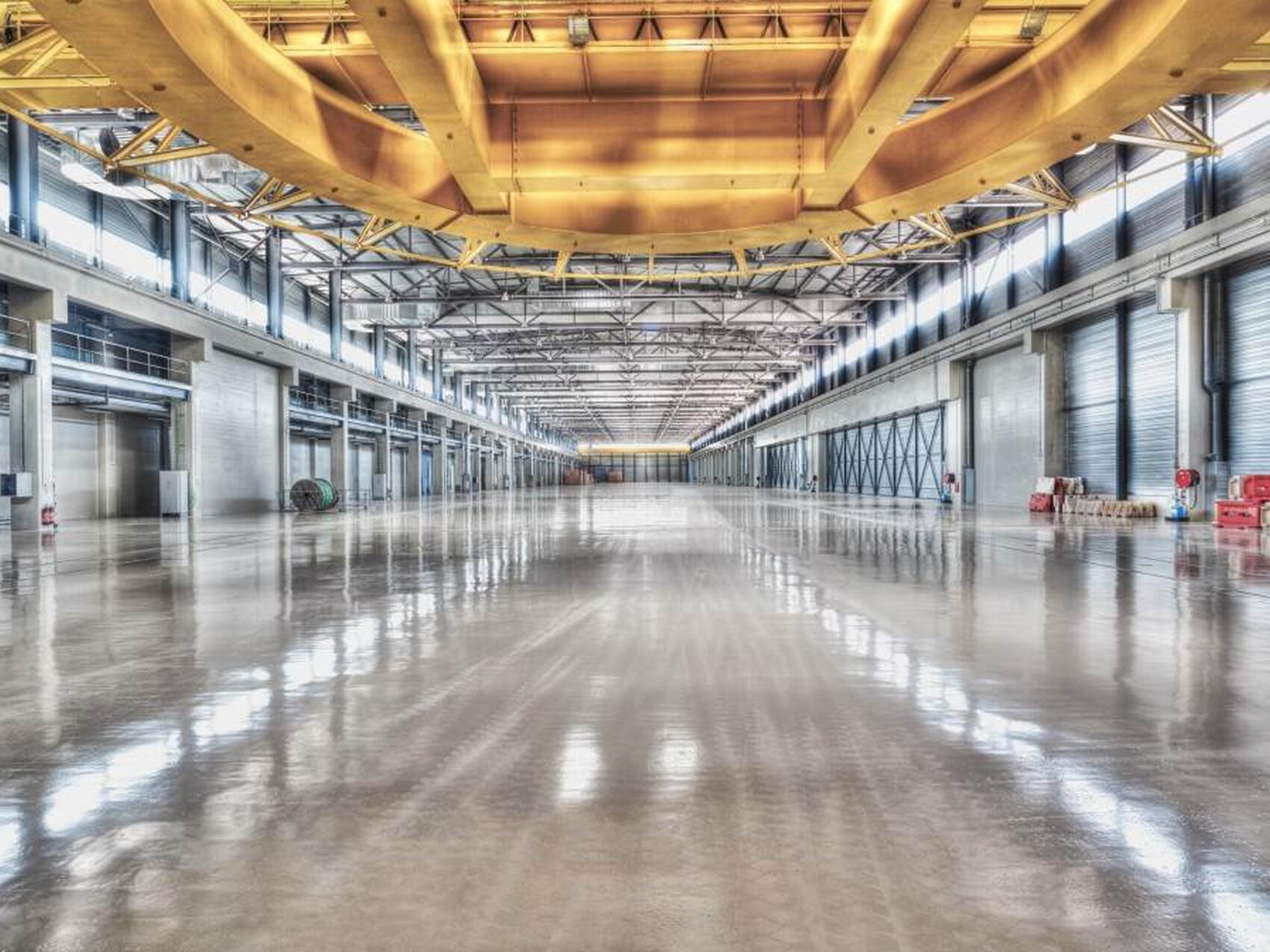

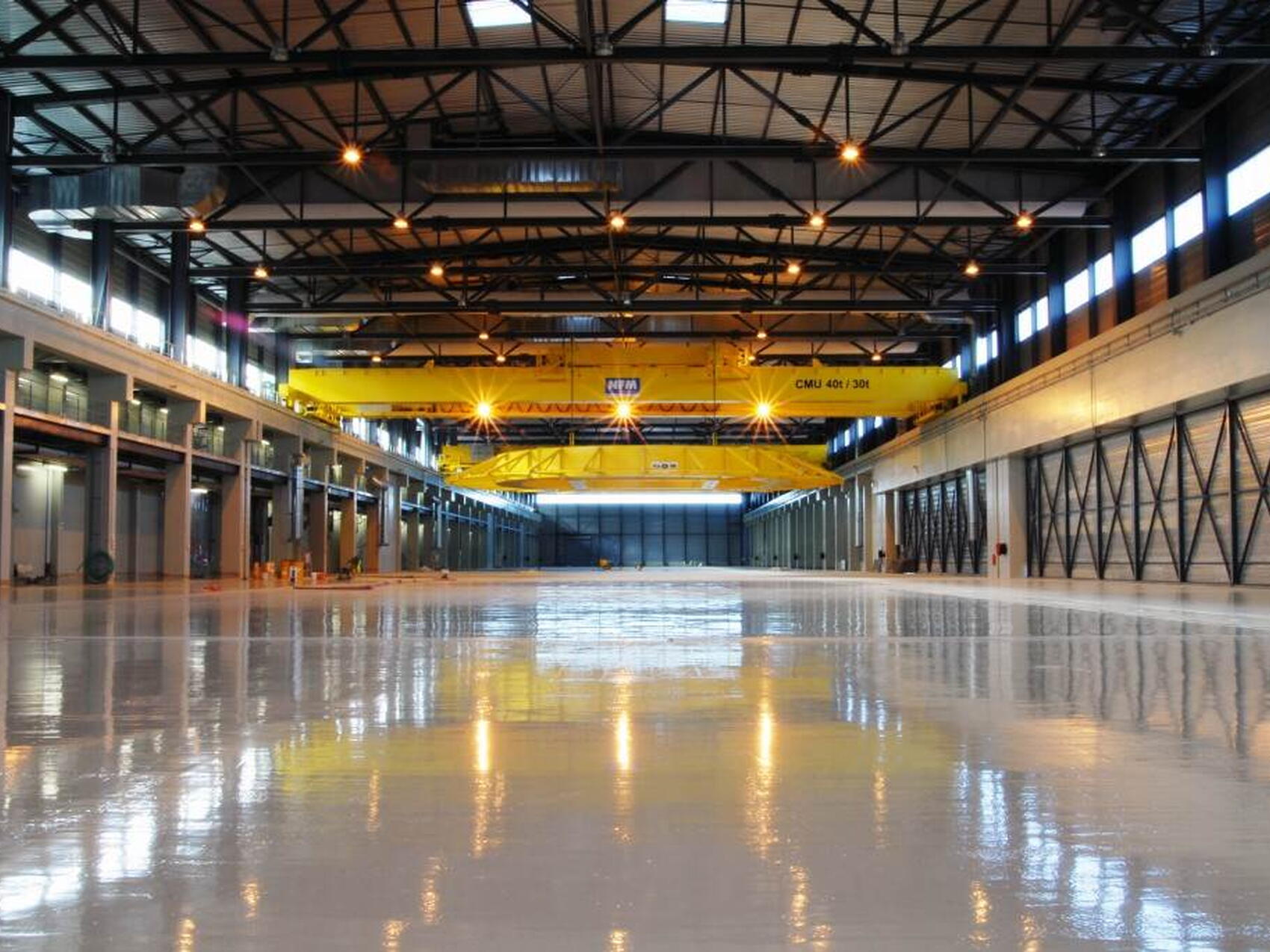

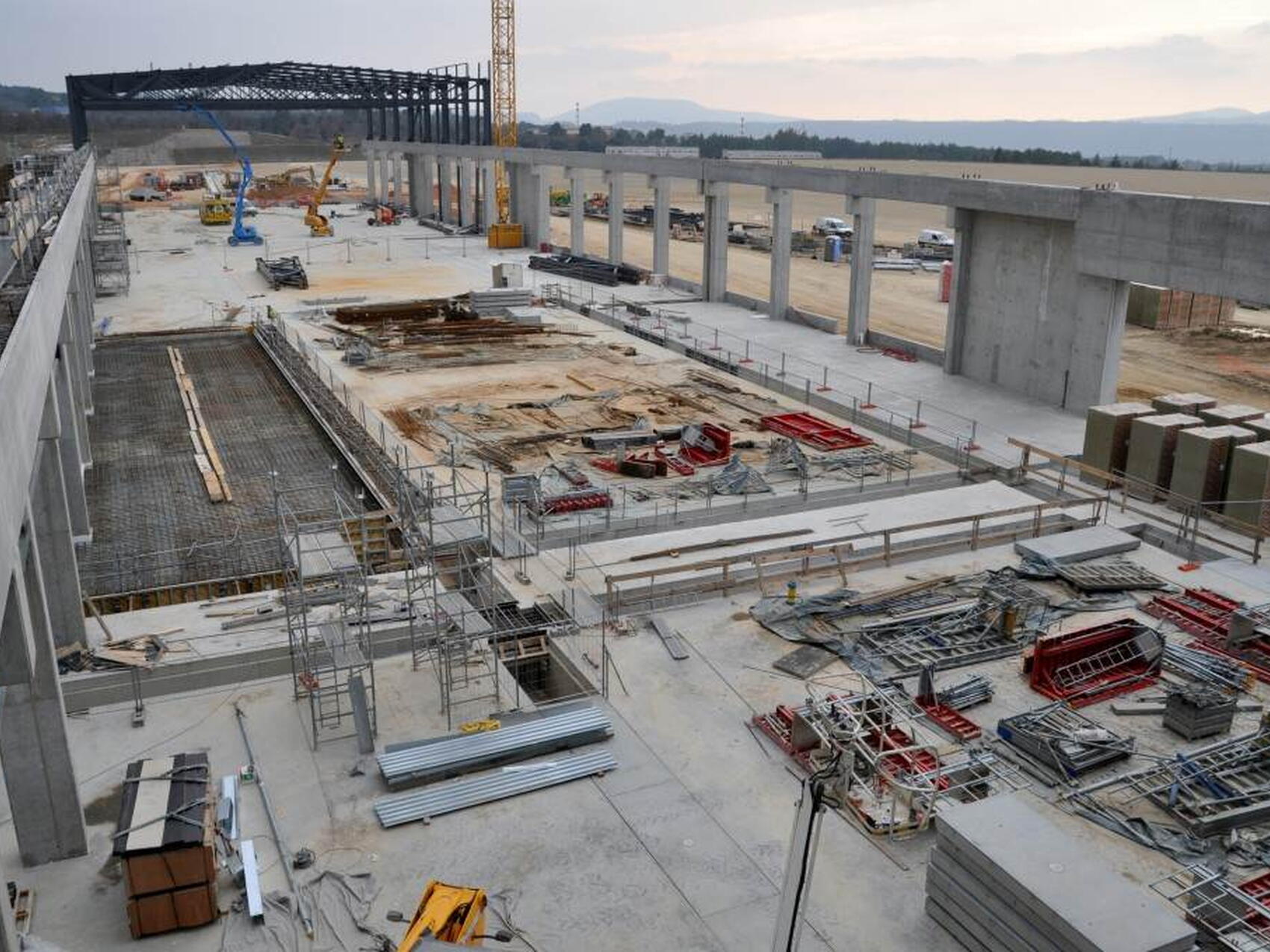

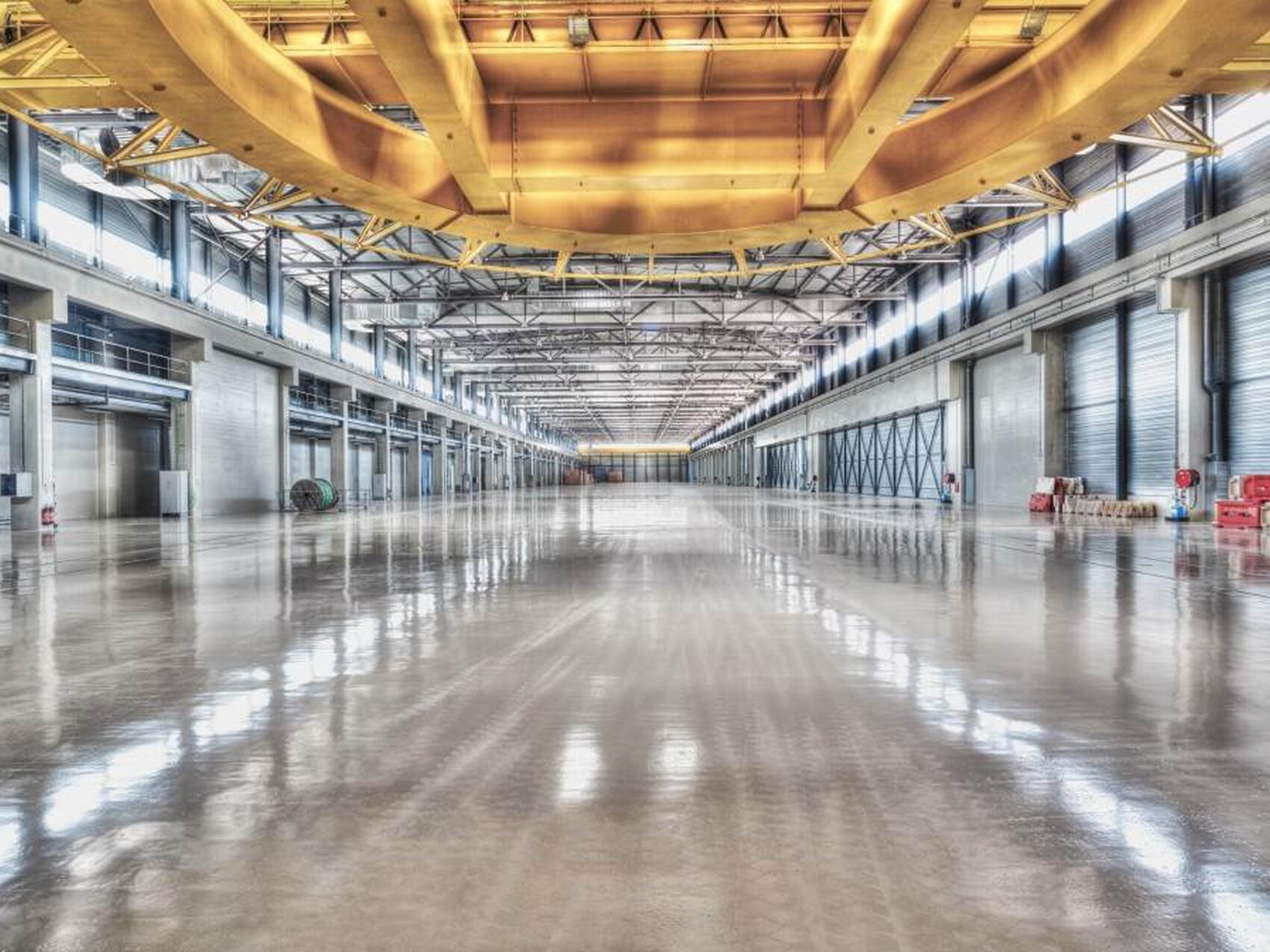

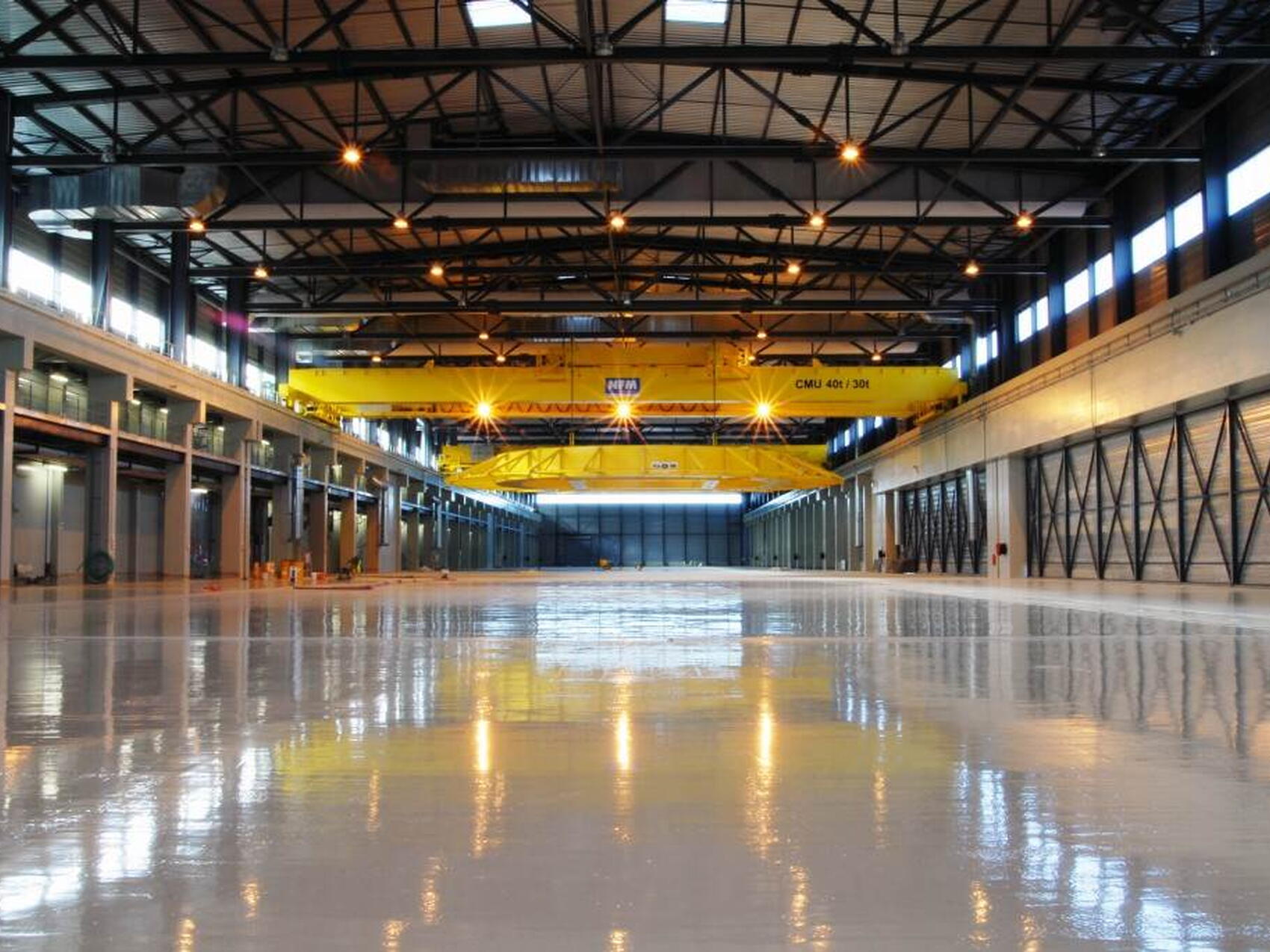

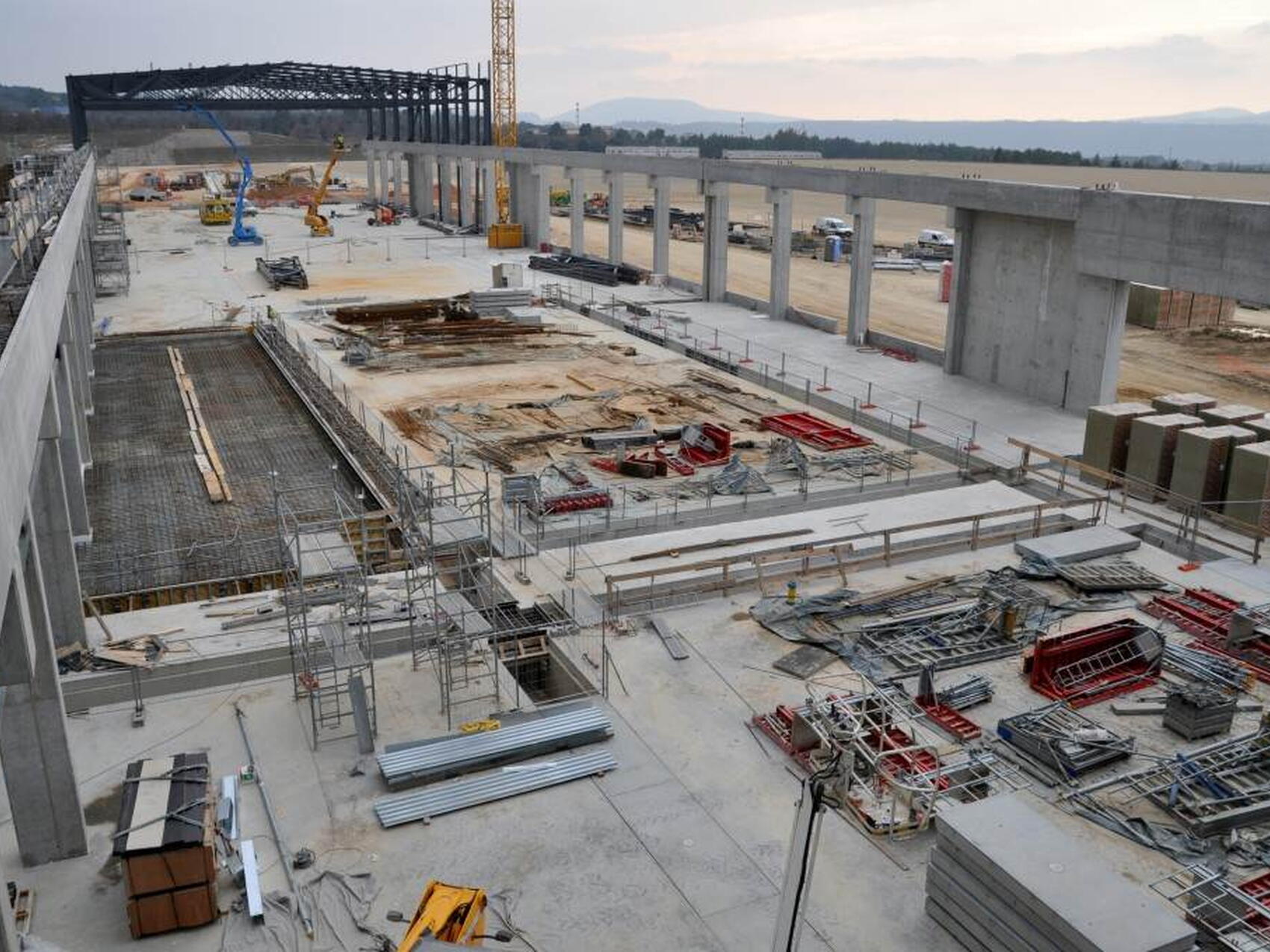

The first completed building on the ITER platform was the Poloidal Field Coils Winding Facility (2011). The European Domestic Agency built this facility for the winding and production of ITER's four largest poloidal field coils. Today, the building houses activities related to machine assembly.

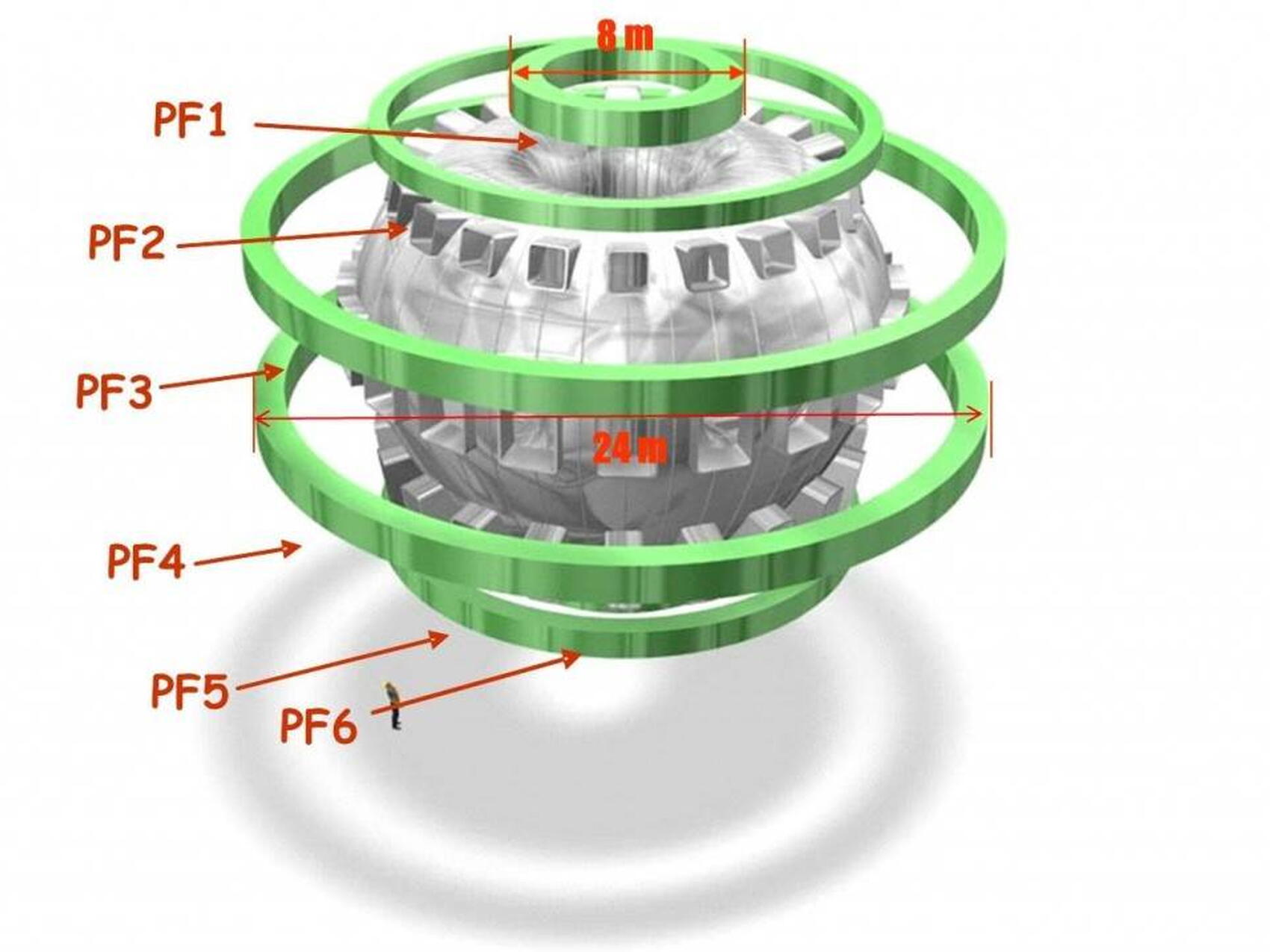

The large red-topped manufacturing facility located on the east side of the construction platform housed the assembly of ITER's four largest poloidal field coils, part of ITER's magnetic confinement system. Ranging in diameter from 8 to 24 metres, they were simply too large to be transported in their finished state.

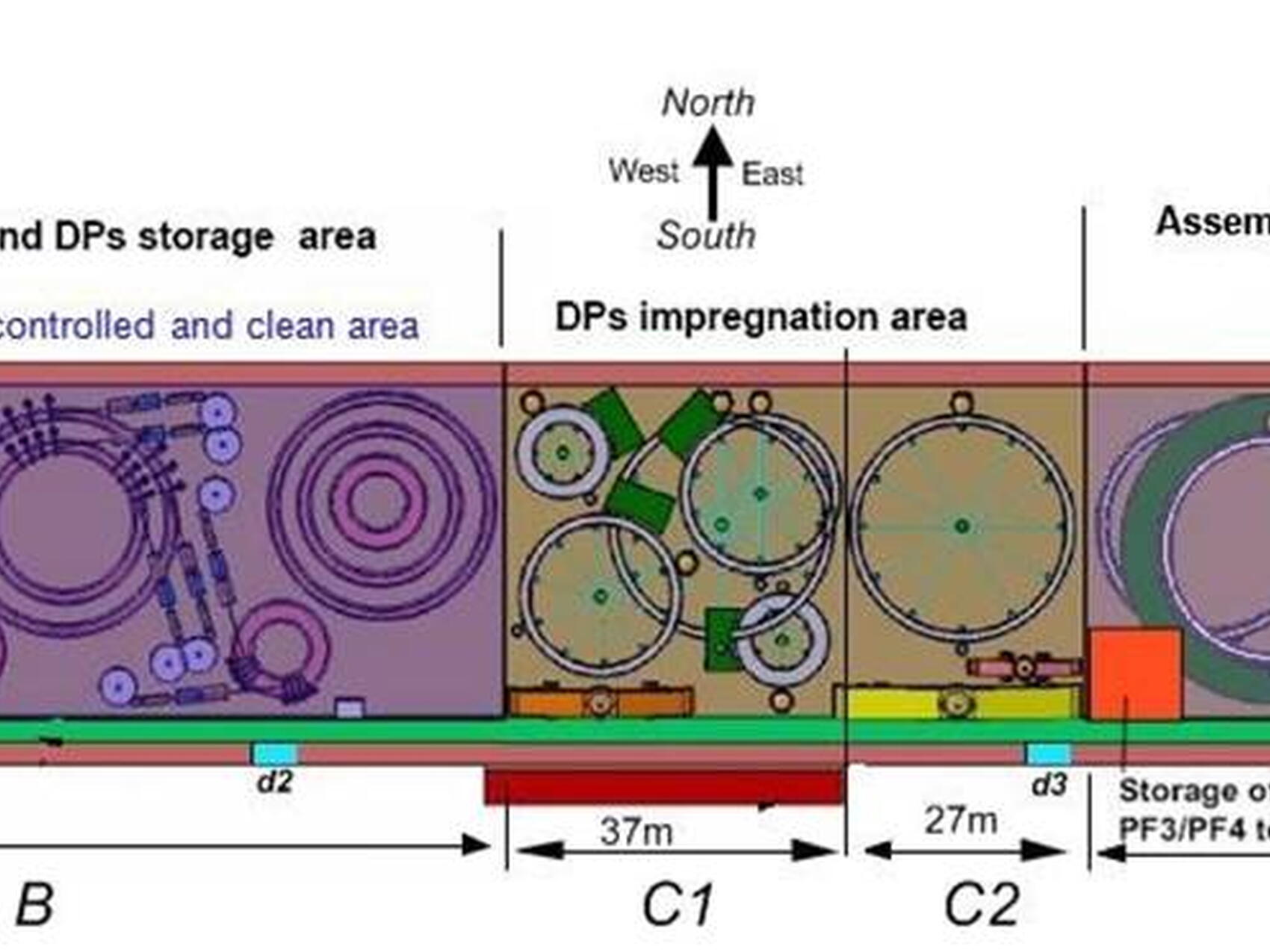

The Poloidal Field Coils Winding Facility accommodated docking stations for the unloading and temporary placement of the superconducting coils, production zones corresponding to the successive steps of the winding and assembly process, and offices. Two overhead travelling cranes worked from opposite ends of the building to manipulate and transport the heavy loads and a third heavy-lift gantry crane was installed for the final assembly stages.

Construction of this concrete and steel structure began in August 2010 and was completed in December 2011. The building's metal cladding—five layers of metal sheeting and insulation—was designed to isolate the shop floor, where cleanliness was a priority, from the dust of the platform. After qualification activities in 2016/2017, the teams began the series production of double pancakes, which are flat, spiralled coils that are stacked in layers to form the coil winding packs. The complete process, from winding to finished coil, required approximately two years per coil.

Production activities have ended and the facility has been reconverted for activities that support ITER machine assembly.

For more information on poloidal field coil manufacturing see this page.

Winding Facility facts:

- Construction: August 2010-December 2011

- Surface area: 12,000m²

- Dimensions: 257 metres long, 49 metres wide, 18 metres tall

- Floor slab: 40 cm thick, designed to withstand 42 tonnes/m²

- Lift capacity of bridge cranes: 25 tonnes, 100 tonnes

- Gantry crane lift capacity: 400 tonnes

- Beginning of qualification activities: 2016

- Coil fabrication: April 2017-March 2024

Photo Gallery