Architecture

CODAC is the control system that provides the interface "language" for 220 ITER plant instrumentation and control (I&C) systems, containing actuators, sensors and all instrumentation and control functions required to measure and control the plasma parameters. The CODAC team is a group of experts in various fields of automation of scientific installations.

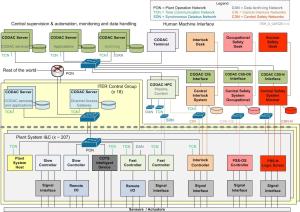

CODAC, being a central system, interfaces to more than 30 ITER plant systems. Machine protection (interlock) system and safety (personnel and nuclear) systems are explicitly decoupled from CODAC and act fully independently. The Control System Division is also responsible for the central interlock system and central safety systems.

Plant system controls are being procured together with the plant systems from the ITER Members, while the CODAC, central interlock and central safety systems are being implemented by the ITER Organization. This implies that the interface between the central system and the plant system I&Cs must be well defined and strictly adhered to. This also imposes a uniform standardized approach to design of the plant system controls in order to reduce overall project manufacturing and maintenance costs.

To reach these objectives, the ITER CODAC team publishes a handbook guiding all aspects of the plant system I&C lifecycle, the Plant Control Design Handbook (PCDH).

The CODAC Core System is a software suite for control system development. Plant system manufacturers shall use it as a template for new development, maintaining full compatibility with the CODAC control system. Induction training sessions are organized regularly to allow I&C engineers learn the Core System quickly and efficiently.

The Plant Control Design Handbook was issued in 2013 as a baseline version (v7) ready for application to ITER production systems. A minor update addressing some needs for clarification and some obsolescence issues was issued in September 2023. The CODAC Core System will be updated at least once a year throughout the construction phase of the ITER Project.

The CODAC team encourages all participating institutions as well as the larger scientific community to get involved early in testing and using the proposed standards and solutions in order to arrive at a robust production control system. Your feedback is important to us!