Hot Cell

Equipment used in the ITER Tokamak is transferred by remote handling transfer cask, then cleaned in the Hot Cell in two steps—remotely and hands-on. The cleaning operation prepares for the maintenance of the equipment in support of the machine.

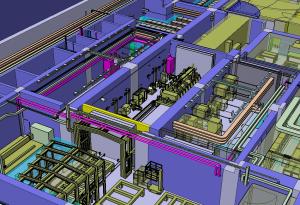

The ITER Hot Cell & Radwaste Facility supports the operation, maintenance, radwaste management and decommissioning of the ITER Tokamak. The facility consists of different buildings including the maintenance buildings (Hot Cell along with complementary buildings), radwaste buildings and the Personnel Access Control Building. Together, they provide a secure environment for the processing, repair or refurbishment, testing, and disposal of ITER components that have become contaminated or activated by neutron exposure.

Although no radioactive products are produced by the fusion reaction itself, energetic neutrons interacting with the walls of the vacuum vessel will "activate" inner components of the vacuum vessel over time. Also, these components and associated equipment can become contaminated by the dust produced during plasma operations.

Replacement and refurbishment operations within the Hot Cell & Radwaste Facility will be performed by remote handling systems capable of handling components up to the size of a school bus. The Hot Cell & Radwaste Facility will also house remote handling equipment for their decontamination, maintenance and testing. In addition, the Hot Cell & Radwaste Facility will perform treatment and packaging, and temporarily store tritiated and non-tritiated radwaste until final export to the French disposal facilities. It is also where test blanket modules that have been in the machine will be handled after their service, when part of the system is separated as radwaste and another part is returned to the Domestic Agencies for research purposes.

These operations will be housed in a safe, confined, and shielded area containing analytical systems for tritium, contamination and radiation measurement.