Europe will manufacture 60 divertor cassettes

As if that wasn't enough, the divertor structure will also have to withstand tremendous magnetic forces that will press and pull with a force on the order of one hundred tonnes.

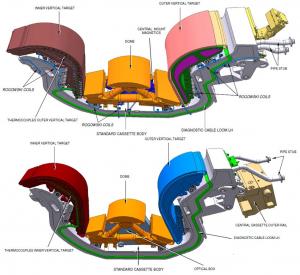

An essential component of the ITER machine, the divertor is also one of the most challenging to build, assemble and install.

Each nine-tonne cassette will be installed inside the vacuum vessel through remote handling operations. The highly complex and delicate installation sequences are being demonstrated and validated at the ITER Divertor Test Platform Facility in Tampere, Finland.

The Procurement Arrangement for the divertor cassette and assembly was signed on Tuesday, 19 April. It covers the manufacturing by Europe of 60 cassette bodies (54 cassettes plus 6 spares) and the integration of the components and diagnostics systems provided by other Domestic Agencies as part of different procurement packages.

Following the production of a full-scale prototype for assembly trials, series production should begin in 2015. The present schedule plans for the installation of all 54 cassettes beginning in 2021 during the second phase of ITER assembly; the divertor will only be needed when hydrogen-helium operation begins in 2022.