The KSTAR fuelling system operates with four different gases for plasma creation, wall cleaning and diagnostics. For the experiment, one piezo-electric valve (for deuterium gas) was selected as an actuator. Various pre-configured patterns were used as reference inputs to the plasma control system for controlling the fuel injection. The plasma control system was implemented on a high performance computer using ATCA form factor, CODAC standard real-time operating system (MRG-R) and MARTe real-time framework originally developed at JET.

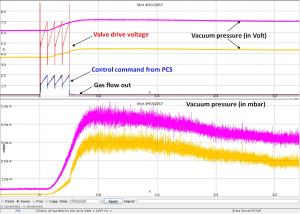

The density signal was simulated by programmable waveforms. A CODAC standard fast controller (fuel controller) was also implemented to control the embedded piezo-valve controller and to acquire diagnostics signals such as vacuum vessel pressure, gas flow, valve drive voltage, etc. at 10 kHz. The plasma control system communicated with the fuel controller over the standard CODAC real time network at 1 kHz.

As the measurements from the first test showed identical results as the KSTAR fuelling system, it was confirmed that the technologies adopted or being considered for ITER CODAC were applicable for the plant control at tokamak, that is, CODAC is heading in the right direction.