Self-sustained tritium production is essential to the future of fusion. While an experimental machine such as ITER will draw upon the tritium presently available in the market (a couple dozen kilos), future fusion plants will have to breed their own tritium supply in a continuous manner.

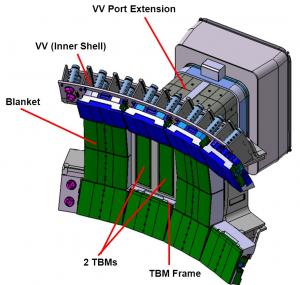

Tritium, which occurs only in trace quantities in nature, can be produced through the impact of fusion-generated neutrons on lithium nuclides present in the plasma-facing components. Based on this principle, six experimental Test Blanket Modules (

TBM) will be installed at the equatorial ports of the ITER vacuum vessel wall. Two of them will be procured by Europe; India, China, Japan and Korea will each contribute one. The Russian Federation and the Unites States will give support on specific technical items.

Over the years, as they are impacted by the neutron flux, the ITER TBMs will progressively become activated. "However different each TBM concept may be, we can reasonably anticipate the amount of radwaste that will be produced within the Tritium Breeding Systems (TBSs) and that we will have to manage," explains Magali Benchikhoune, the ITER Hot Cells & Radwaste Section leader and chair of the Test Blanket Program Working Group on TBS RadWaste Management (TBP-WG-RWM) that has been assigned to deal with this matter.

Following three and a half months of videoconference meetings, the international players of the TBP-WG-RWM met for two days—and for the first time in person—last week at ITER.

The group comprised the ITER Members' Test Blanket Module representatives; ITER Organization representatives for the TBM Program, radwaste management and safety; legal experts from all the contributing Members; and representatives from Agence Iter France (as the interface between ITER and the Host country, France).