9 rings, 70 plates, EUR 172 million

Two large contracts for the manufacture of ITER components were recently concluded by the European Domestic Agency (F4E).

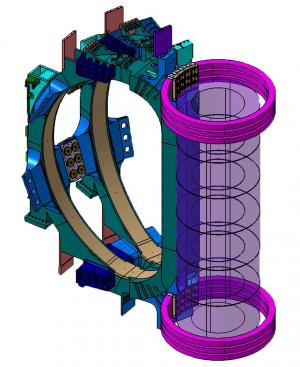

On 29 November, F4E signed a contract (EUR 12 million) for the supply of nine pre-compression rings for the ITER magnet system with EADS CASA Espacio in Spain. By holding tightly to the toroidal field coils at the top and bottom, these 5-metre-diameter fibreglass composite rings (in pink, at right) will reduce the fatigue on the magnet structures caused by electro-magnetic forces—consequently prolonging their operational life from ten to over twenty years.

The nine pre-compression rings will be the largest composite structures ever built for operation in a cryogenic environment.