Reviewing the progress of drain tank manufacturing

21 Dec 2012

-

Giovanni Dell'Orco, Section Leader for the Cooling Water System

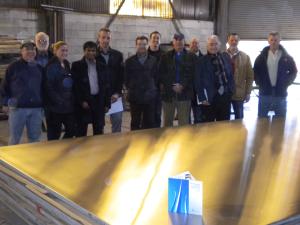

A perfectly polished ITER drain tank steel plate at Stainless Steel Services (USA) with a surface finish well below 1.6 micrometres. Alongside Giovanni Dell Orco, Thierry Jourdan and Babulal Gopalapillai from ITER are members of US-ITER, AREVA FS, Joseph Oats Corporation and Stainless Steel Services.

Five large-scale drain tanks are planned for ITER's tokamak cooling water system (TCWS)—two safety drain tanks; two normal drain tanks; and one drain tank for the neutral beam injection system. These drain tanks are the largest captive components of the TCWS, planned for installment in Tokamak Building level B2 in mid-2014. Fabrication of the drain tanks is underway as part of the US Domestic Agency (US-ITER) commitment to ITER.

Four of the tanks measure 10 m in height and have an internal diameter of 6.25 m (the neutral beam injection drain tank is about half the height, with the same internal diameter). The stainless steel plates used for the fabrication of these tanks are polished prior to manufacturing in order to achieve a minimum surface finish of 1.6 micrometres.

Polishing work on the stainless steel is currently underway in Philadelphia, Pennsylvania (USA) at Stainless Steel Services, a US Domestic Agency and AREVA FS subcontractor. During the second week of December, members of the ITER Organization Cooling Water Section and Quality Assurance Division visited the US-ITER subcontactors and their sub-tier suppliers in order to review the progress of drain tank fabrication work.