Construction of Cryostat Workshop to begin

There's already one facility on site for the fabrication of ITER components that are too large for transport and there's soon to be another. Ground breaking begins in May for a temporary workshop where the four main sections of the cryostat will be assembled from 54 smaller segments manufactured by India.

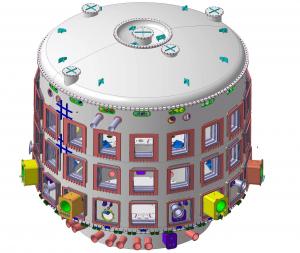

Like the largest poloidal field coils, the size and weight of the main cryostat segments makes travel along the ITER Itinerary impossible. The cryostat base section—1,250 tonnes—is the single largest load of ITER Tokamak assembly; the other three cryostat sections (lower cylinder, upper cylinder and top lid) weigh in the range of 600-800 tonnes each.

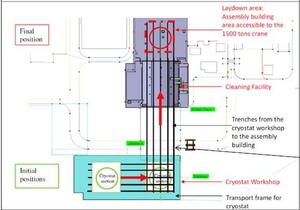

Within the on-site Cryostat Workshop, assembly activities will take place on two huge steel platforms built to support the weight of the components, jigs and fixtures.

"The 30 x 30 metre assembly platforms will also act as transporters," explains Bharat Doshi, Leader of the Cryostat Section. "The Cryostat Workshop will be linked by rail to the Assembly cleaning facility and building. Once completed, the cryostat sections can be moved on their assembly platforms by rails/rollers to the Assembly cleaning facility and from there transported to the Tokamak Pit by main bridge crane."

Planned along the fence on the northeast corner of the ITER platform, the football field-size (50 x 100 m) Cryostat Workshop will be approximately 100 metres from the Assembly Building. It will be equipped with equipment for machining, welding and testing, and a large "goliath" crane capable of travelling the facility's full length. "Assembling the four main sections, each 30 metres in diameter, will require several kilometres of joint welding in total," specifies Bharat.

As a high vacuum component, the cryostat is subject to strict quality requirements. Two types of testing will be carried out in the Workshop: an examination of each weld through non-destructive means (ultrasonics or radiography) and the vacuum leak testing of each joint (helium mass spectrometer leak detection). Dimensions and tolerance control will be achieved using sophisticated alignment and metrology equipment. Approximately 50 people are expected to manage the machining, alignment, welding and testing operations during assembly of the cryostat segments.

"The ITER cryostat will have the privilege of beginning and ending the assembly of the ITER Tokamak," says Bharat. "The base section of the cryostat will be the first large component installed in the Tokamak Pit and the top lid of the cryostat will be the last large component, set into place after the installation of the vacuum vessel, magnets, thermal shielding and central solenoid."

As soon as the Tokamak and Assembly buildings (and their heavy-lift crane) are available, the cryostat base must be ready ... and the lower cryostat cylinder soon after that. The Indian Domestic Agency is procuring two transporter platforms so that work can be carried out in the Cryostat Workshop on the two sections simultaneously. A gap of about two years will then follow before the upper cylinder and top lid can be assembled in the pit.

The contract for the design, fabrication and assembly of the cryostat was awarded in August 2012 by the Indian Domestic Agency to Larsen & Toubro Ltd—this contract also includes the set-up of the Cryostat Workshop, workshop assembly activities, and in-pit assembly (integration of cryostat main sections, welding, etc.). In the autumn, Larsen & Toubro awarded the construction of the Workshop to the French company SPIE Batignolles TPCI (part of the consortium that built the ITER Poloidal Field Coils Winding Facility).

Work on the steel-framed structure is scheduled to last 18 months.