Progress on magnet supports in China

11 Jun 2013

-

ITER China

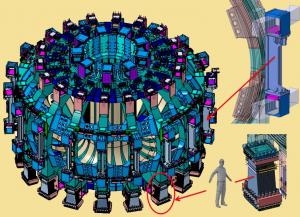

The gravity and poloidal field magnet supports, shown here, represent more than 350 tonnes of equipment.

The Chinese Domestic Agency is building the full set of magnet supports for ITER, representing more than 350 tonnes of equipment. The magnet supports will support the overall tokamak gravity load of 10,000 tonnes as well as withstand the unprecedented large electromagnetic loads experienced by the magnets.

The gravity support system, attached to the base of the cryostat with 18-fold symmetry (see image), needs to accommodate local thermal shrinkage during operation of -32 mm for the toroidal field coil structure cooled to 4 K while remaining rigid against all out-of-plane bending.

In May, representatives of the ITER Organization and the Chinese Domestic Agency were present to witness a step forward in the preparation of a gravity support mockup test frame, which is part of the qualification phase of the Magnet Supports Procurement Arrangement.

In May, representatives of the ITER Organization and the Chinese Domestic Agency were present to witness a step forward in the preparation of a gravity support mockup test frame, which is part of the qualification phase of the Magnet Supports Procurement Arrangement.

On 20 May 2013, representatives from the ITER Organization and the Chinese Domestic Agency witnessed the installation of the gravity support mockup multi-dimensional loading frame and preparation work for further qualification tests scheduled in September at SWIP, Chengdu.

The mockup aims to verify the reliability of design and simulate some sub-scale operation loads on the ITER gravity supports. To this aim, a true-size gravity support mockup and a multi-dimensional loading test frame system was designed by the Southwestern Institute of Physics (SWIP).

At the beginning of 2012, the loading frame system was fabricated by the Changchun Research Institute for Mechanical Science Co, Ltd. and pre-accepted by both the Chinese Domestic Agency and SWIP. It was delivered to SWIP in February for assembly.

In May 2103, the first set of Alloy 718 fasteners were released for the final gravity support mockup test installation; these had been manufactured by Guizhou Aerospace Xinli Casting & Forging Co., Ltd.

In May 2103, the first set of Alloy 718 fasteners were released for the final gravity support mockup test installation; these had been manufactured by Guizhou Aerospace Xinli Casting & Forging Co., Ltd.

Wuhan Heavy Machinery, the main machining and welding supplier of the Chinese Domestic Agency, is currently producing prototypes of poloidal coil supports in order to optimize and qualify final manufacturing processes in the prospect of beginning series manufacturing in 2014.