Inspecting drain tank manufacturing in the US

25 Jun 2013

-

R.A.

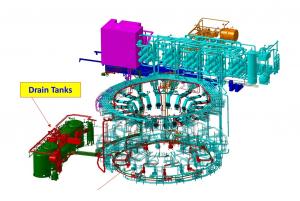

The largest drain tanks—nine and a half metres high and more than six metres in diameter—can hold over 227,000 litres (60,000 gallons) of water.

Across the river from Philadelphia, in the industrial suburb of Camden, New Jersey (US), manufacturing of the ITER drain tanks has begun at the Joseph Oat Corporation. Thick stainless steel plates are being welded and will soon be formed into cylinders—the largest nine and a half metres high and more than six metres in diameter, capable of holding over 227,000 litres of water.

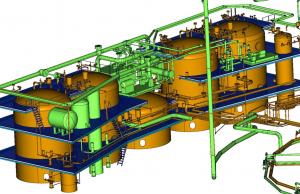

Procured by the US Domestic Agency, the drain tanks will be installed in the "basement" (level B2) of the Tokamak Building, ready to collect the water from the cooling circuits in case of leaks or accidental situations.

Because the ITER drain tanks fall into the category of "Safety Important Components" (SIC), the ITER Organization must ascertain that manufacturing processes and procedures meet the safety requirements established by French nuclear safety regulations and, specifically, the August 1984 Quality Order (Arrêté Qualité).

Installed in the "basement" of the Tokamak Building, the five drain tanks will collect the water from the cooling circuits in case of leaks or accidental situations.

"As nuclear operator, it is our responsibility to control that this set of regulations is applied throughout our whole chain of contractors and suppliers," explains Joëlle Elbez-Uzan, acting division head for Nuclear Safety, Licensing & Environmental Protection at ITER.

An important point at this stage in the manufacturing process is to make sure that the tanks' stainless steel is not exposed to pollution from carbon. Exposure to carbon could cause corrosion, which would put at risk the required leak-tightness of the tanks.

In Camden, Joëlle and Safety Control Section Leader Lina Rodriguez-Rodrigo noted with satisfaction that a specific "ITER zone," clearly separated from other production and using specific tooling, had been organized within the factory.

Joëlle and Lina's sojourn at Camden was short (two days) but fruitful. "The 1984 Quality Order is well implemented," says Joëlle. "US ITER has done a great job in propagating its requirements down the whole chain of contractors and they have a permanent representative in the factory we visited. For us, it is a very strong guarantee."

The Camden inspection was part of the annual audit program that ITER Safety, Quality & Security Department submits for approval to the ITER Director-General. One other inspection has already been performed this year on vacuum-vessel manufacturing in Korea; next on the agenda are the fast-discharge units, whose fabrication has begun at the Efremov Institute in Russia.