"We are currently progressing with defining and planning the hundreds of construction work packages that will make up the complex assembly of the ITER tokamak," says Steve. "Each one must be reviewed for consistency with the assembly sequence that is being developed through detailed engineering studies before it can be included in the specifications of assembly contracts and finally executed in the field by a construction contractor."

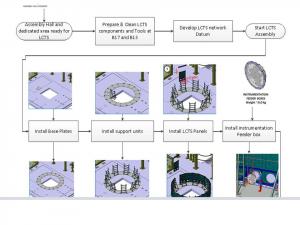

Major assembly framework contracts are being planned for the execution of works and for all the necessary support services; within these "umbrella" contracts detailed work packages will be issued based on the actual delivery dates of components and on construction progress. Even to prepare for the works, there are 10,000 tasks planned—engineering studies, mockups, trials, and the preparation of contracts, some of which need to be in place by mid-2015.

It is also necessary to elaborate a management plan for site works that defines roles and responsibilities, the management of work execution, cost control and other key factors such as logistics, materials, storage and expediting, with safety a prime consideration at all times.

Last May, the ITER Organization presented an overarching construction site management strategy to ITER's Management Advisory Committee (MAC) and since then has been moving forward to develop a detailed strategy and implementation plan.

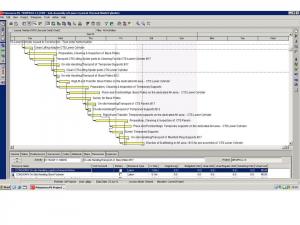

The Assembly & Operations Division is using industry-standard tools to manage planning—Primavera (for scheduling), Intergraph (for construction management) and most recently Cleopatra, dedicated cost estimating software that can handle high-level conceptual estimates based on limited information right down to accurate estimates based on detailed engineering designs.