A centralized approach for cooling water piping

The ITER Organization and the US Domestic Agency have signed two agreements that will permit a more cost- and time-efficient procurement and integration process of the tokamak cooling water system (TCWS) piping as well as the completion of the final design of the largest TCWS components such as the pressure vessel, pumps and heat exchangers. The agreements, signed on 31 October, describe the transfer of responsibility from the US Domestic Agency to the ITER Organization for the execution of the design, procurement and pre-assembly of TCWS piping and the completion of the final design of the system.

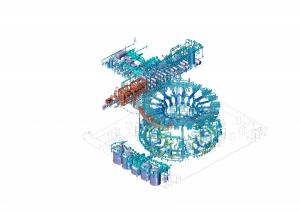

In 2009 the ITER Organization and US ITER signed the Procurement Arrangement for the TCWS. While the global responsibility for this procurement remains unchanged, the agreements signed last week allow TCWS piping to become part of one centralized procurement for all ITER piping equipment—some 60 km of pipes (1,700 tonnes), approximately 4,000 valves and 400 tonnes of pipe supports.

As for the largest TCWS components, they will still be manufactured under US Domestic Agency responsibility and delivered to the ITER site. However, their design will be finalized and their integration overseen by the ITER Organization. "We hope that by doing it this way the integration of these systems will be facilitated, given the stringent safety requirements and the complexity of the interfaces with many clients."

The next important steps are to agree on a project plan for the cooling water system centralized piping procurement and the TCWS final design, and to organize periodic meetings for the coordination of these activities.